Magnetic Filtration of Kaolin Clay

The kaolin development brings together for the first time four concepts that make practical large scale use of high extraction magnetic filtration (HEMF). These include retention time, extreme gradients, high intensity fields, and efficient design of large high field magnets. Each of these elements was known and available but never refined and optimized in magnetic […]

Handling Sticky Flotation Concentrates

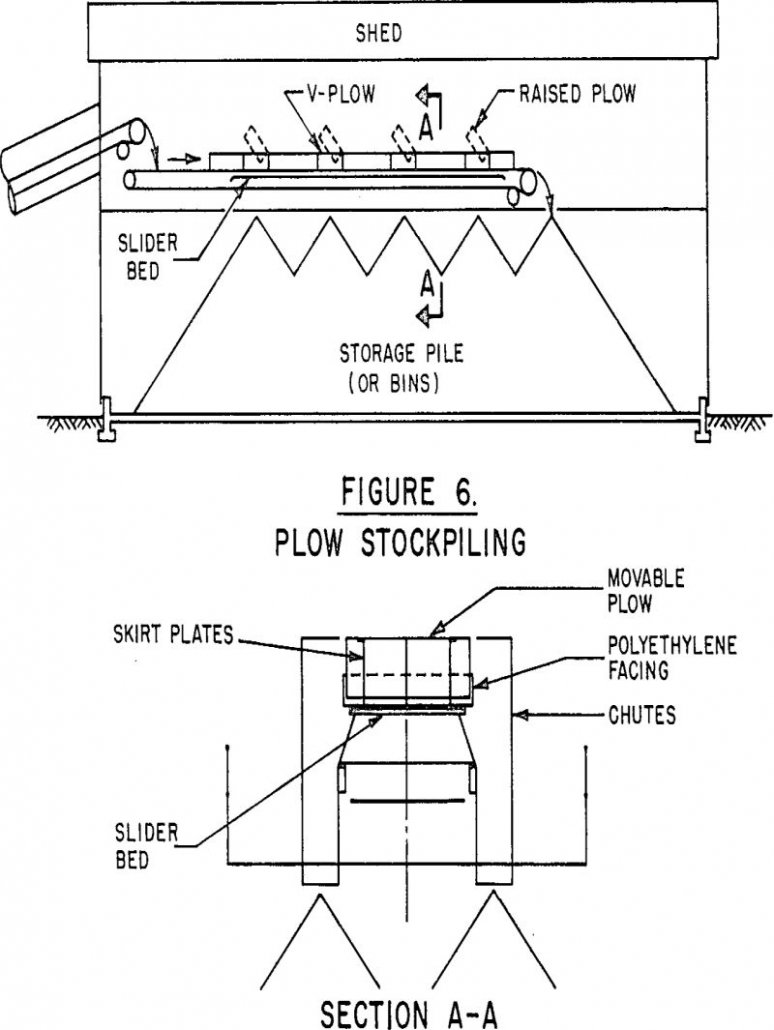

The passage of an ore pulp through the froth flotation process results in the production, after dewatering, of a finely divided concentrate. This intermediate product must be handled to the subsequent process facilities via belt or other types of conveyors, hoppers, bins, chutes and feeders, and the like. Flotation concentrate has some difficult handling properties […]

Effect Grinding Media on Selective Flotation of Copper Lead Zinc

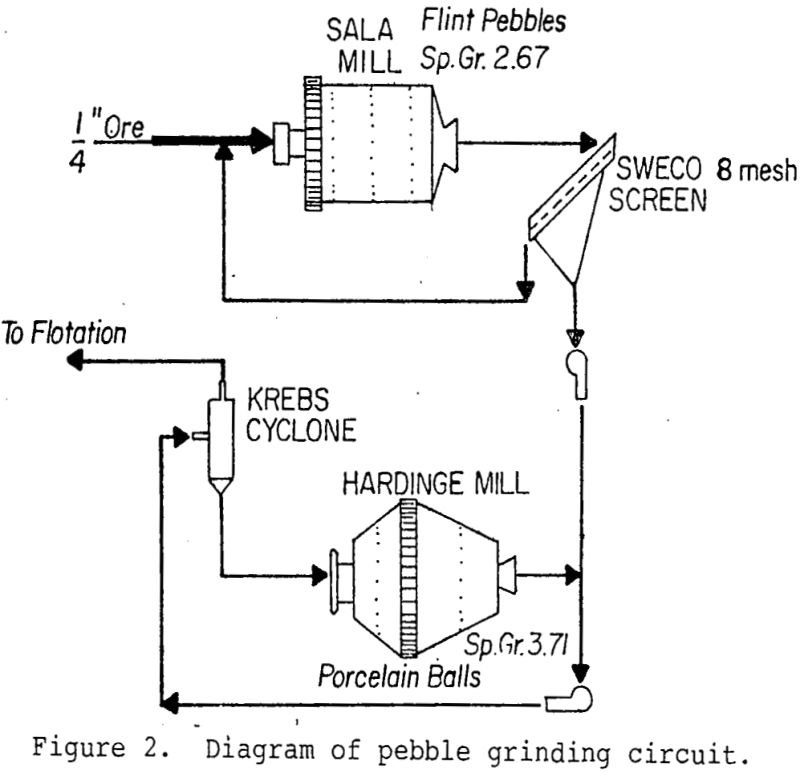

The normal practice for processing complex sulphide ore has been to grind with steel balls and/or rods in steel mills before flotation. Little thought had been given to the effect of grinding media on flotation selectivity of copper – lead zinc ore. Ore Sample The mill feed for the pilot-plant investigation was from a copper-zinc […]

How Rotary & Spray Drying of Copper Concentrate Compares

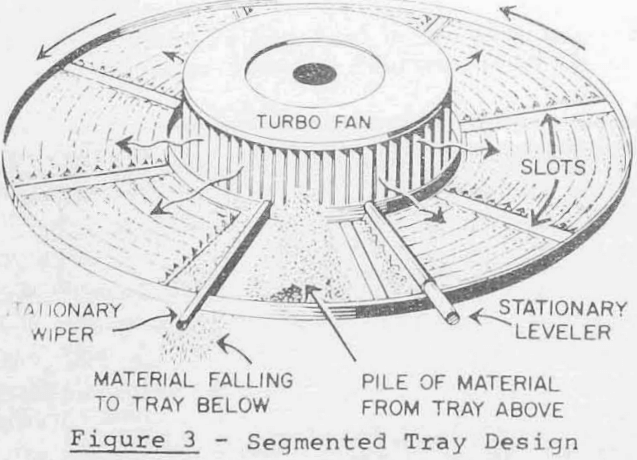

The rotary drying system consists of a final concentrate thickener to dewater the slurry to about 60%-70% solids; a vacuum filter (disc or drum) with the necessary vacuum pumps to dewater the thickened material further to about 14%-20% moisture on a dry basis; a collecting belt underneath the filter to receive the filter cake; a […]

Drying & Calcining Ammonium Diuranate

‘Yellow cake’, so named because of its inherently bright yellow color, is a finely divided precipitate that can be formed after the leaching step when refining uranium ores. Feed solids enhancement then occurs to at least 50% by weight using filters or centrifuges. This is followed normally by drying and then calcining with the conversion […]