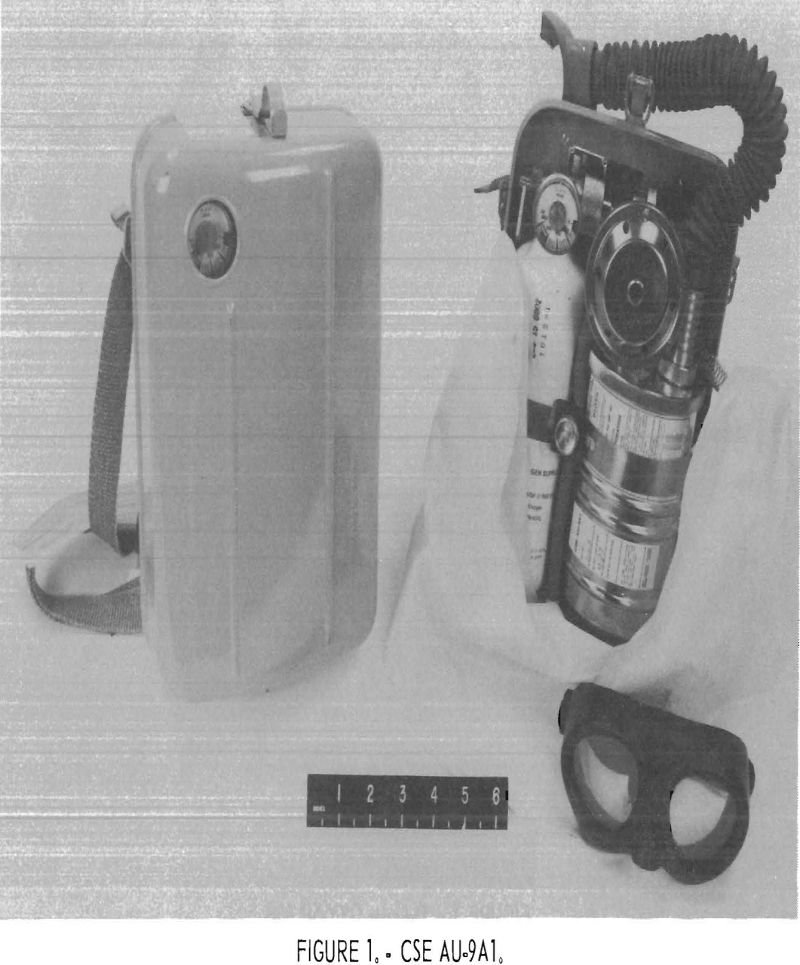

Oxygen Self Rescuers

Coal mine operators in the United States were required to make available to each underground coal miner a self-contained self-rescuer (SCSR). The regulations (30 CFR 75.1714) require that each person in an underground coal mine wear, carry, or have immediate access to a self-rescuer that provides an oxygen source. The oxygen self-rescuer will replace the […]

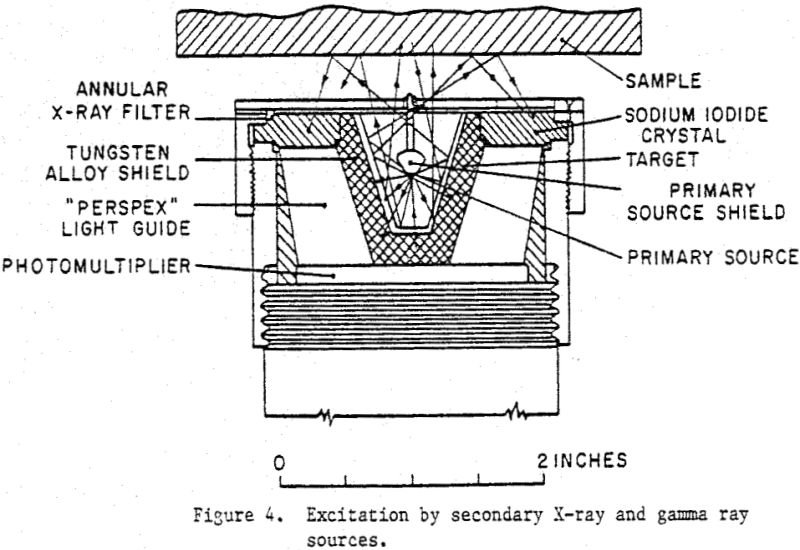

On Stream Analysis

An on-stream analyser cannot be considered in isolation from the mineral process where it is to be ultimately installed. Depending upon the requirements of the process, an on-stream analyser can be designed in several ways. If a feasibility study done on the process shows that several elements in a multi-channel stream are to be analysed […]

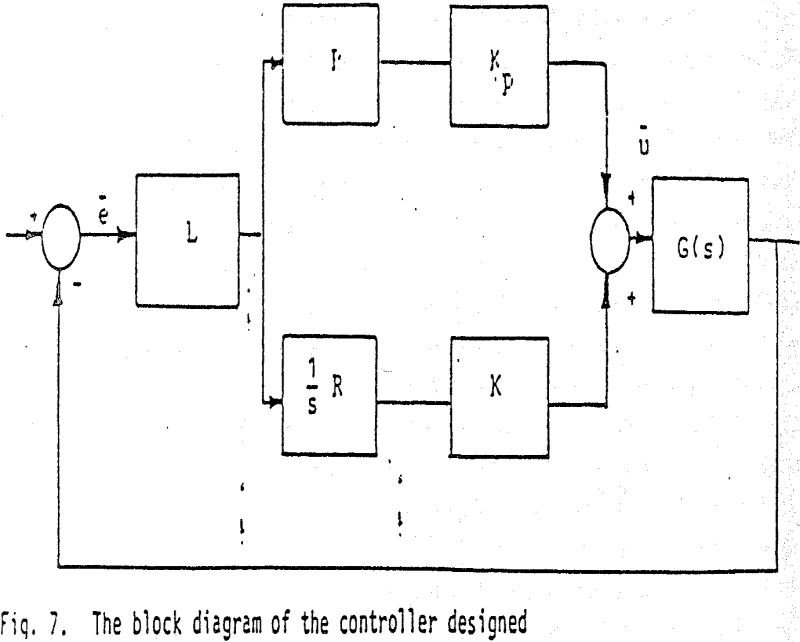

Design of a Grinding Circuit Control System

In this case, the primary grinding stage in a concentrator comprises a rod mill in open circuit and a semi-autogeneous mill in closed, circuit with a hydrocyclone classifier. All the measurements have computer interfaces and all the control circuits have been implemented by the process control computer. The crushed ore feed to the rod mill […]

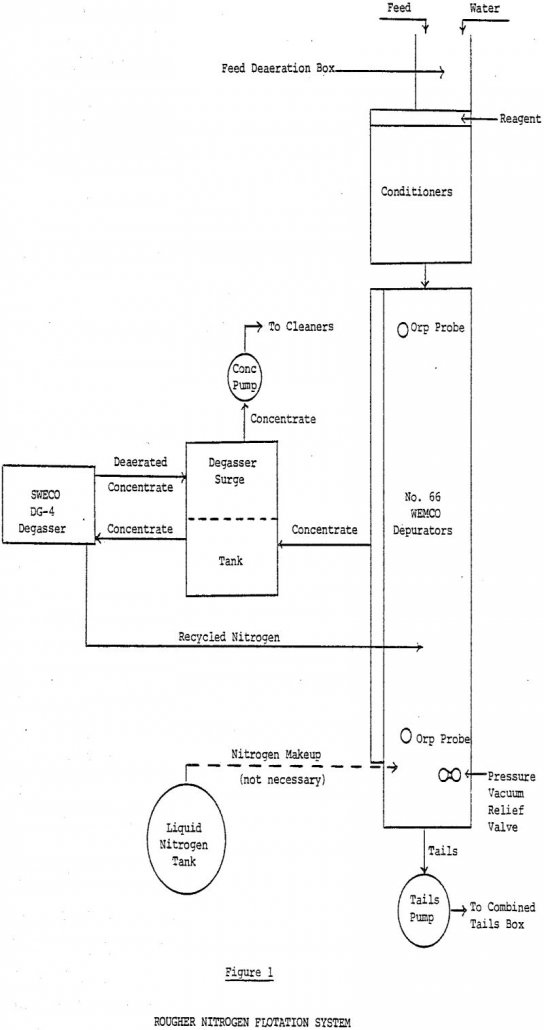

Nitrogen Gas Molybdenum Flotation from Copper Concentrate

Mill feed averages 0.7% Cu, primarily as chalcopyrite, and 0.024% Mo. The copper concentrator produces 1050 mt/day of bulk Cu-Mo concentrate averaging 27% Cu and 0.6% Mo. Molybdenum plant feed is thickened to 62% solids and stored in two 150 cubic meter tanks. Two identical flotation circuits are fed from a constant head tank through […]

How to Recover Potash from Carnallite

The Bureau of Mines conducted research on techniques for recovering potash values from high-insoluble-slimes-bearing domestic carnallite ores. In the first phase of the study, two techniques were devised: (1) a method where the insoluble slimes were depressed during potash flotation and (2) a method where insoluble slimes were removed by flotation prior to potash flotation. […]

Electro-depositing PGM Platinum Group Metal Coatings

The Bureau of Mines has evaluated the substitution of platinum-group metal coatings for bulk platinum-group metal objects as a means of reducing the consumption of the platinum-group metals. The Bureau has conducted several studies of the electro-deposition of the platinum-group metals from molten alkali metal cyanide baths during the last two decades. The major incentive […]

Effect Particle Size on Leaching of Sulphide Minerals

Commercial leaching of sulphide ores by microorganisms is used in numerous oxidation situations as a scavenger process for treating low grade ores and very dilute metal waste streams at comparatively low capital and operating costs compared with conventional hydrometallurgical processes. Studies using synthetic mixtures to give pre-determined surface areas have also revealed that the size […]

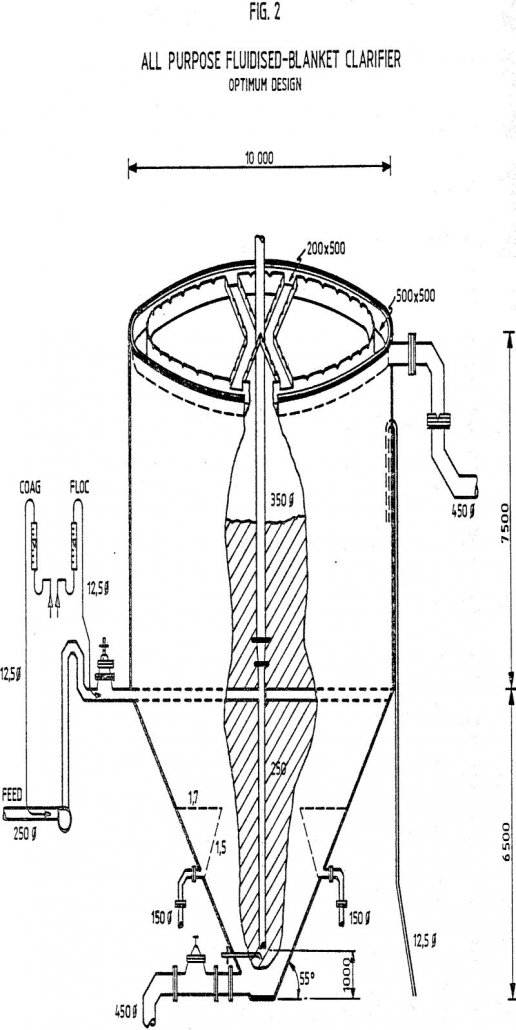

Gold & Uranium Pregnant Solution Clarification

Before precipitation of gold can be commenced the relatively high suspended solids content (on average 350 mg/L) of the gold bearing rotary filtrate has to be reduced below 5 mg/L. On most gold mines to which AAC provides technical services a final polishing step to achieve the required clarity takes place in Stellar pre-coat candle […]

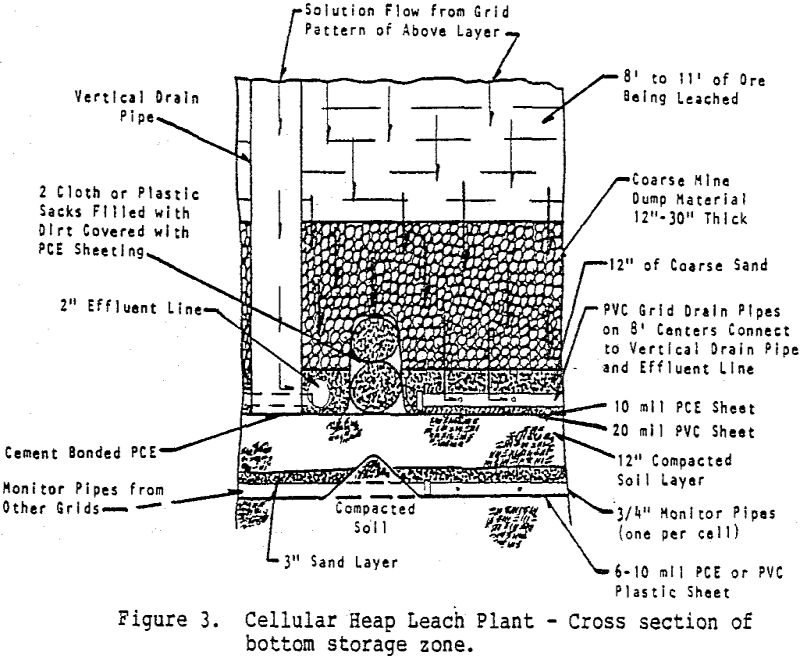

Cellular Heap Leaching & Cyanide Regeneration

In conventional gold and silver heap leaching systems, crushed or uncrushed ores are generally placed in a large rectangular pile on a pad surface and sprinkled with weak cyanide leach solutions. The solutions leach the ore particles in their downward migration through, the heap. Effluent solutions are usually stored, sent to a metal recovery system […]

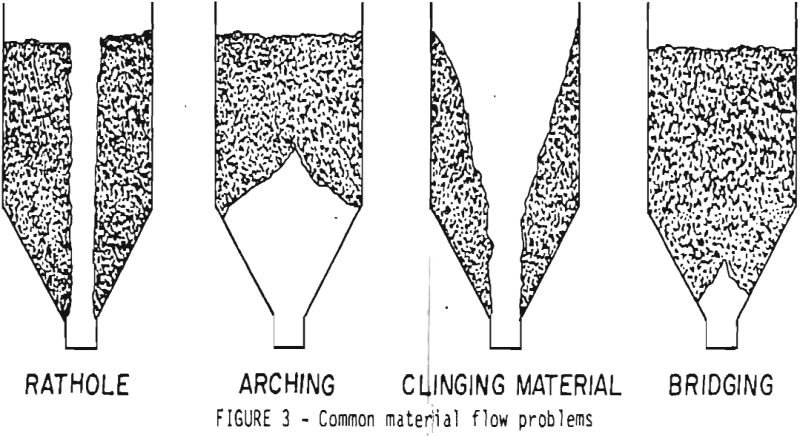

How to Keep Bins Flowing – Safety & Material Handling

Over the past several years, a number of deaths have occurred in the minerals industry as a result of workers entering bins or silos to correct flow stoppages or to conduct maintenance. In almost all of the fatalities, the direct cause of the accident could be attributed to a failure on the part of the […]