Blast Optimization and Ore Fragmentation Modeling

Blasting plays a key role in all facets of operations. Obviously, drilling and blasting costs are determined by blast design, but the downstream costs that are closely related to blasting results are often treated as separate functions: loading, hauling, cleanup, and crushing and grinding are all heavily influenced. Diggability and bucket fill factor are a […]

Mine Ventilation Recirculation Systems

In many deep mines, the design of a ventilation system to satisfy the airflow requirements might be difficult to implement and expensive to maintain. The problem may even be more serious when the mine workings are dispersed and located a considerable distance from the surface connections. This problem can be alleviated by including a controlled […]

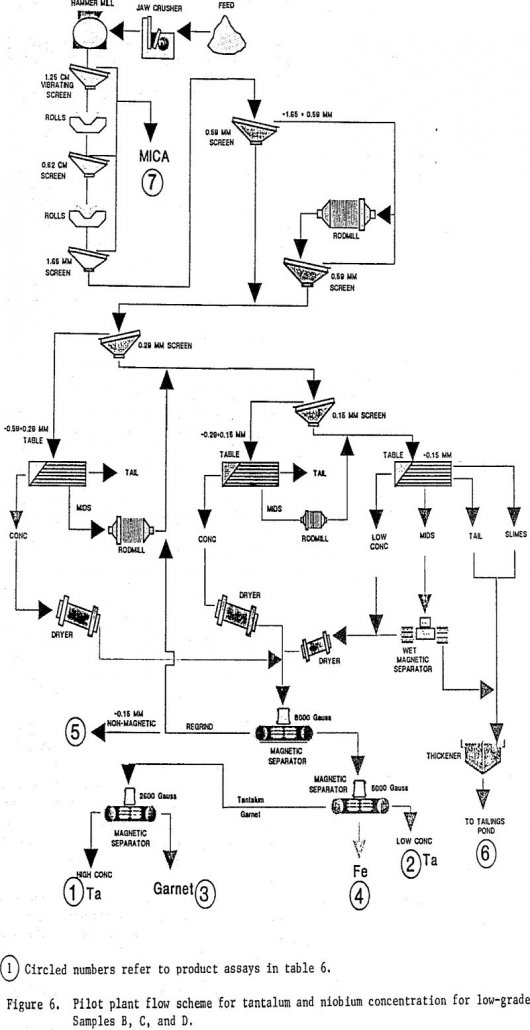

Extract Tantalum & Niobium from Pegmatites

The Bureau of Mines’ Intermountain Field Operations Center, Denver, CO; and the Bureau’s Salt Lake City Research Center, Salt Lake City, UT, jointly studied domestic sources of tantalum and niobium as part of the Bureau’s program to reduce national dependency on imported minerals and metals that have key uses in industry and defense. Presently the […]

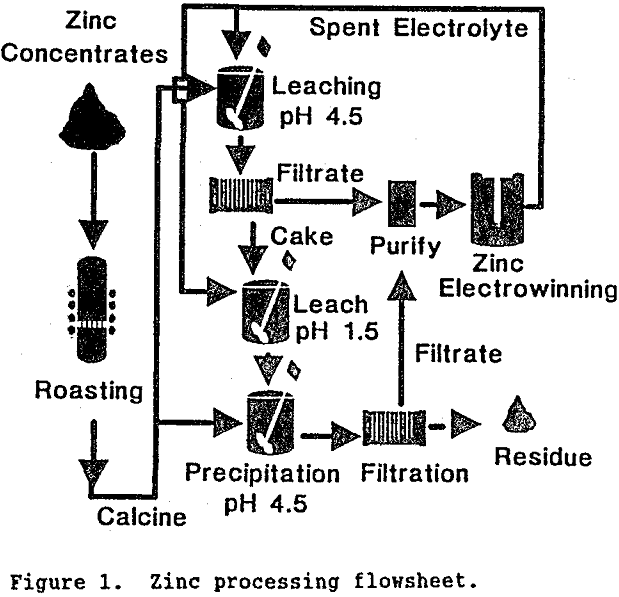

Germanium Extraction from Zinc Hydrometallurgy

Germanium is an important strategic metal used in fiber optics, infrared detectors, and semiconductor devices including transistors, diodes, and rectifiers. Substitution for germanium cannot be made without substantial loss in performance in most cases. Germanium is generally not concentrated naturally, although trace amounts are found in many minerals. Germanium is produced almost exclusively from waste […]

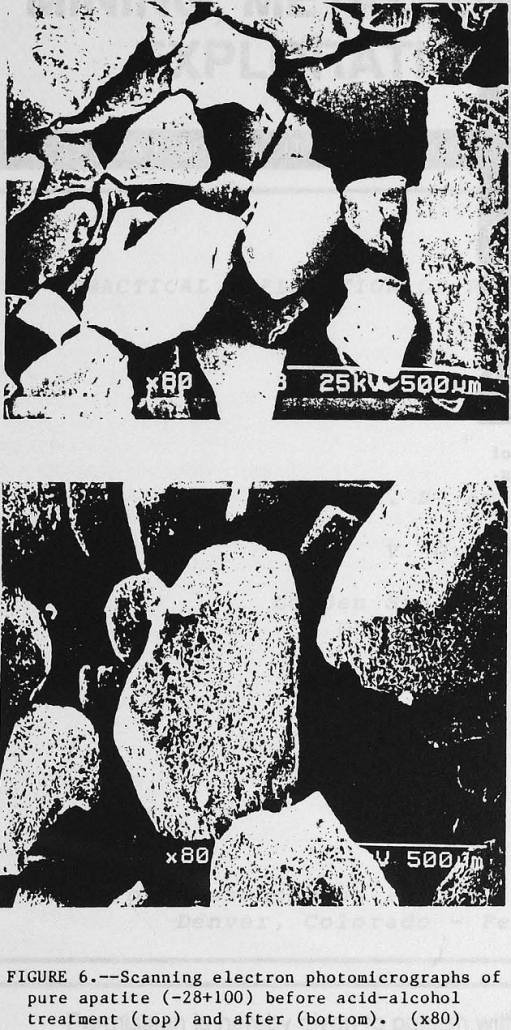

Apatite Leaching using H2SO4 & Methanol

Current practice for the production of wet-process phosphoric acid (H3PO4) involves leaching beneficiated phosphate rock with aqueous H2SO4. Typical processing involves mining the ore, also called matrix, using a dragline, then forming a water-based slurry to facilitate pumping the ore to a beneficiation plant. Phosphate values contained in the minus 150-mesh fraction of the ore […]

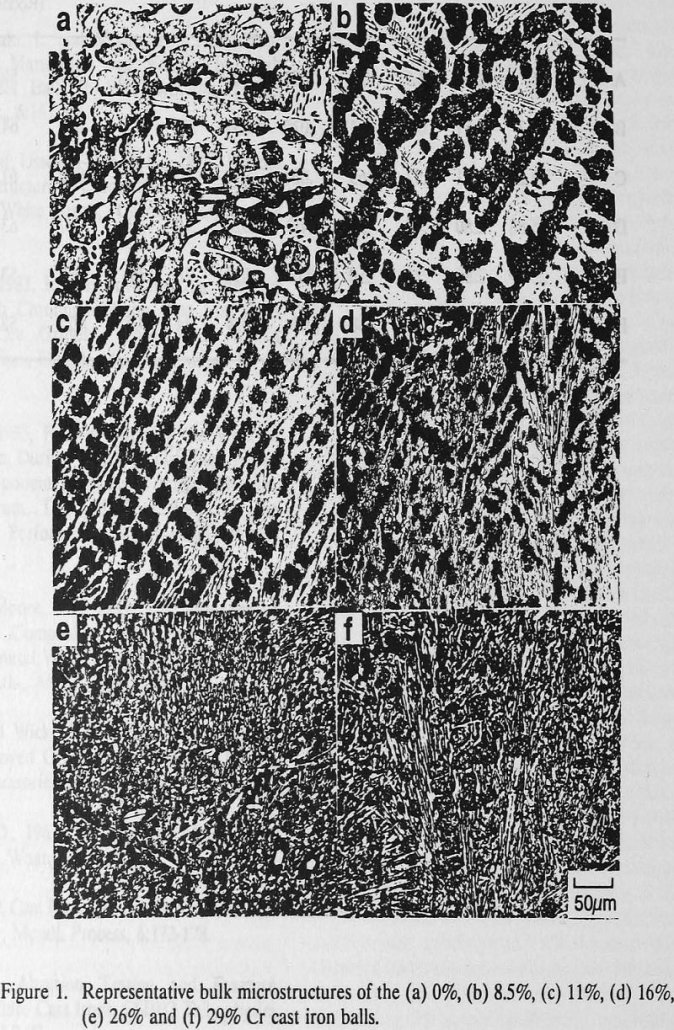

Effect of Chromium on Wet Grinding Performance

Because of higher efficiency, wet grinding is more widely used than dry grinding, but leads to an increased consumption of grinding media due to corrosion in some ores. In dry grinding, the wear rate of high chromium cast irons is frequently ten times lower than cast or forged steel with a cost ratio of 2-3 […]

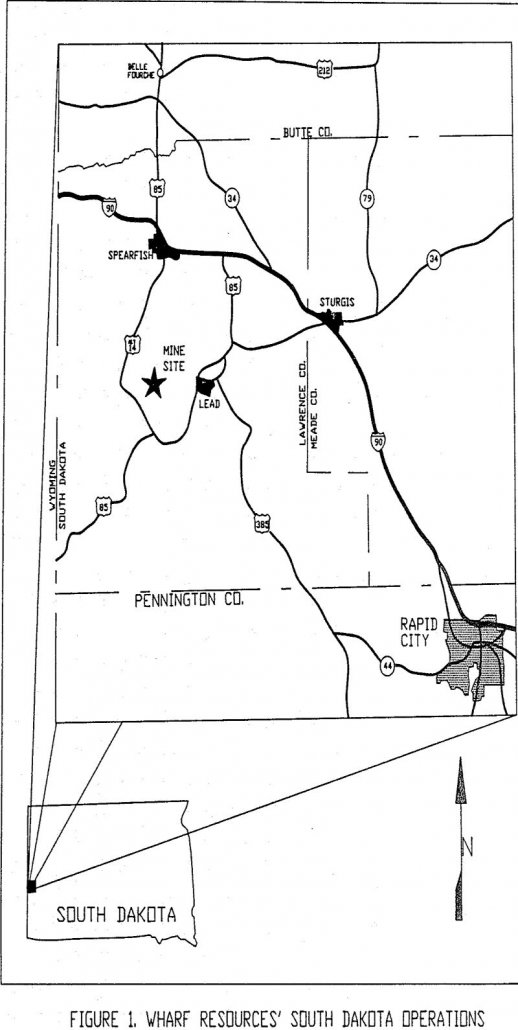

Heap-Leaching Pad Volume Calculations

The estimating of volumes is a routine practice in an open pit-heap leaching operation. Until recently, the conventional cross-section manual method has been used at Wharf Resources’ South Dakota operation for the estimate of material mined from the pits, crushed ore delivered to the heaps, unload spent ore, ore and topsoil stockpiles, waste dumps and […]

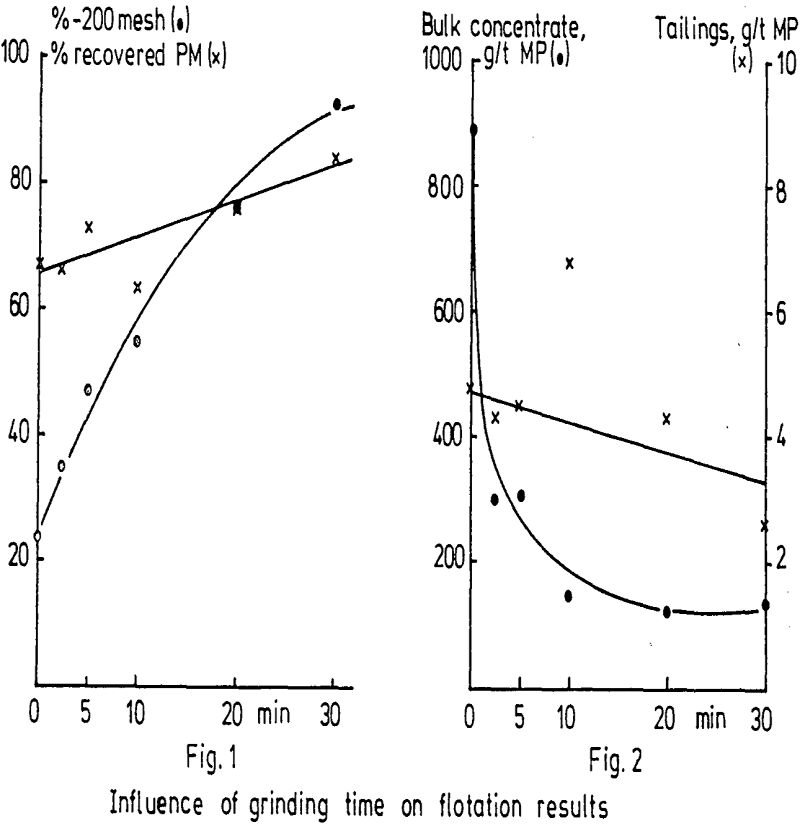

Reprocessing Gold Tailings by Gravity Methods

Tailings originating from the gravity concentration of a gold ore containing about 14 g/t Au have been treated by various beneficiation methods. These tailings have been screened on the 147 and 74 micron sieves and the two coarsest fractions have been separated on shaking tables with unsatisfactory results, but the concentrates have been examined in […]

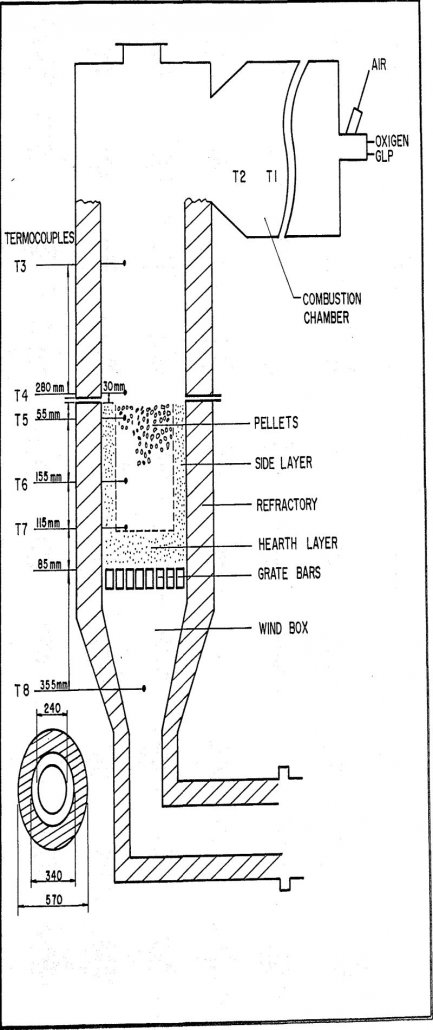

High MgO Blast Furnace Pellets

The pellets were produced in the pilot plant, and followed the steps bellow: – Definition of pellet chemistry – Model for high MgO blast furnace – Pellet production run Pellet chemistry was defined based on the fact that high MgO levels have the capacity to attain improved softening and melting characteristics. Therefore the chemical properties […]

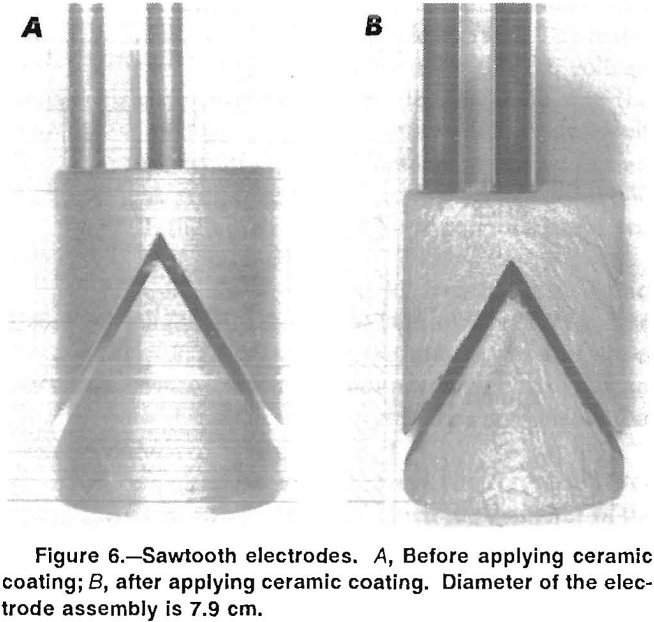

How to Make Lead Metal by Molten Salt Electrolysis

Molten-salt electrolysis of lead chloride is an integral unit operation in a ferric chloride leaching process that was developed by the U.S. Bureau of Mines for treating galena concentrates as an alternative to smelting. Prior to the Bureau’s work, several other investigators had studied molten-salt electrolysis of lead chloride. As part of the Bureau’s research […]