Sulfide Ore Treatment Gold – Silver – Copper – Cobalt – Zinc Recovery

A procedure was developed for recovering gold, silver, cobalt, copper, and zinc from a massive sulfide ore by a hydro-metallurgical process. The procedure consists of (1) oxygen pressure leaching; (2) iron, arsenic, and copper removal from the leach solution by precipitation; (3) selective extraction of cobalt and zinc from solution; (4) electro-deposition of the cobalt […]

Assaying

Assaying for ruthenium, rhodium, palladium, silver, osmium, iridium, platinum, gold is performed by fire assay. This ancient form of quantitative chemical analysis by which metals are separated and determined in ores and metallurgical products with the aid of heat and dry reagents. At present, this technique is used principally to preconcentrate the noble metals from […]

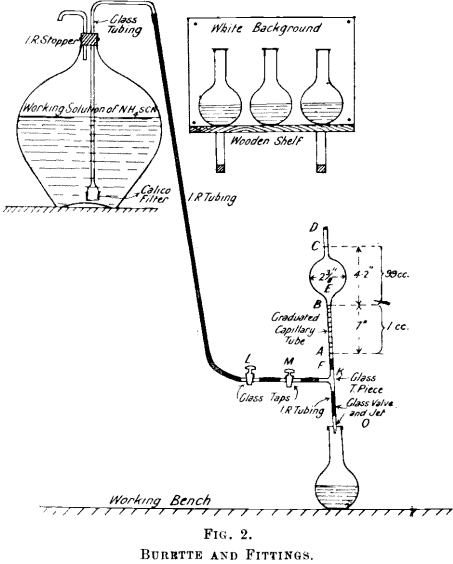

Silver Fineness Determination

This excellent volumetric method commends itself as a means of estimating the fineness of silver—firstly, owing to the large number of possible impurities which do not affect its accuracy (these impurities include Cu—up to 70%— Au, Pb, Zn, Bi, Cd, Fe, Mn, Sb, and As) ; secondly, the method combines accuracy with speed. The above […]

De-Silverizing Bullion

The de-silverizing of base bullion is carried out in accordance with the principles of the well-known Parkes process. The base bullion produced by the blast furnace department carries (apart from silver values) impurities, the chief of which are copper, antimony, and arsenic. In order to more clearly indicate the grade of the base bullion, the […]

Mechanical Roasting in Silver-Lead Smelting

What Colonel Dwight says regarding the treatment of oxidized ores holds true also of the silver-lead smelting operations in Utah. The ore sought for was such as would, with appropriate fluxes, yield slag, and “lead bullion,” as the lead reduced from the ore and carrying its gold and silver, was called. No matte, and probably […]

Effect of Manganese on Silver Leaching

In Mexico and elsewhere there are large bodies of valuable silver ore containing manganese which present great, and hitherto insuperable, obstacles to a satisfactory extraction by cyanide. The proportion of the silver that is soluble in cyanide varies greatly and may be as low as 5% only. The mere presence of manganese in the ore […]

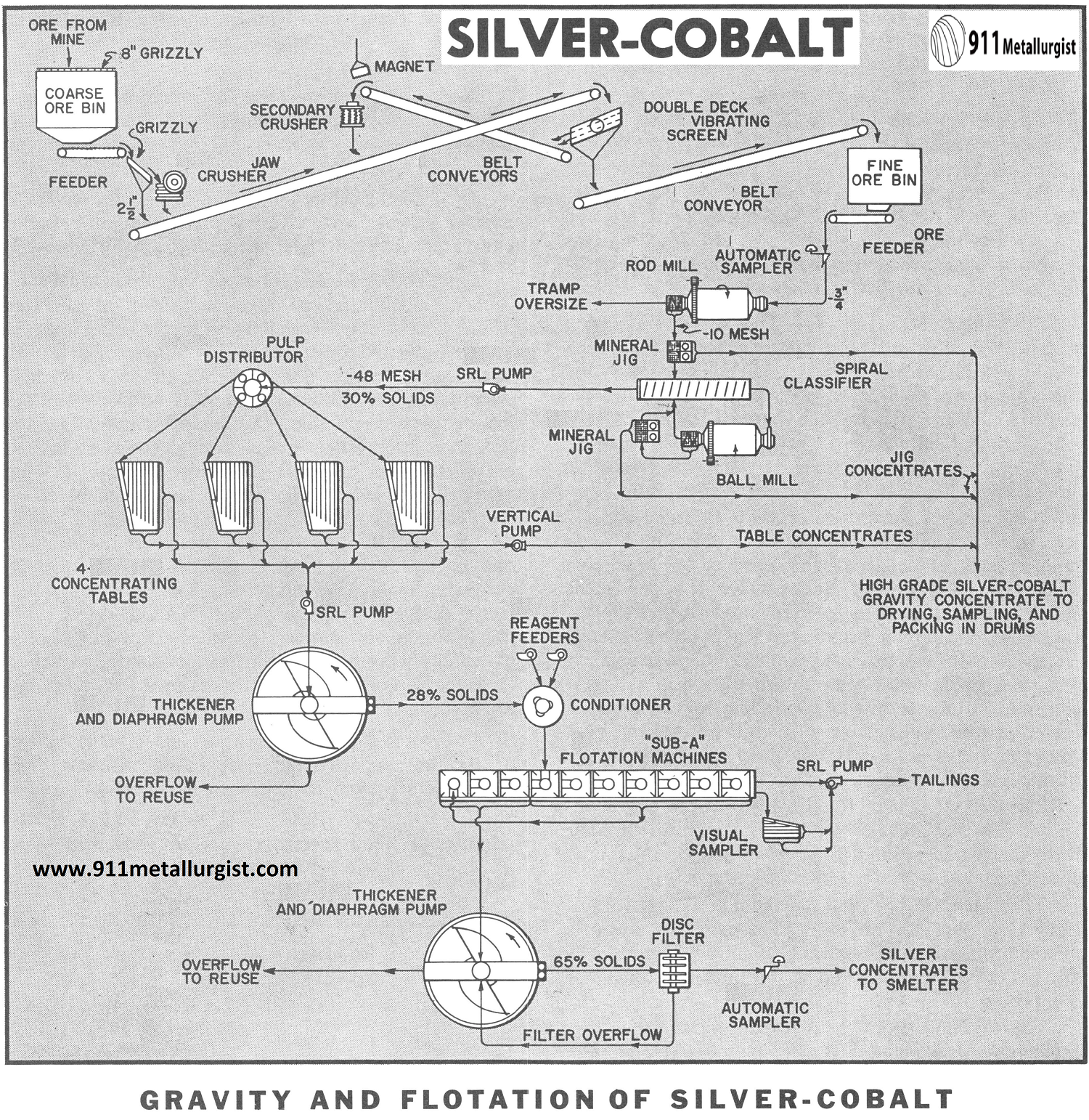

Silver & Cobalt Processing by Gravity and Flotation

The treatment of complex silver cobalt ores occurring with antimony and arsenic require special metallurgical processing to produce concentrates most advantageous for smelting. Gravity concentration is used to initially recover a high percentage of the native silver and cobalt. The concentrate is marketed and payment received for these constituents. Flotation treatment of the gravity tailing […]

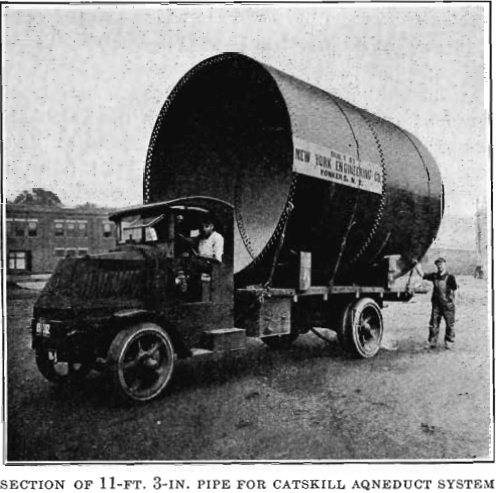

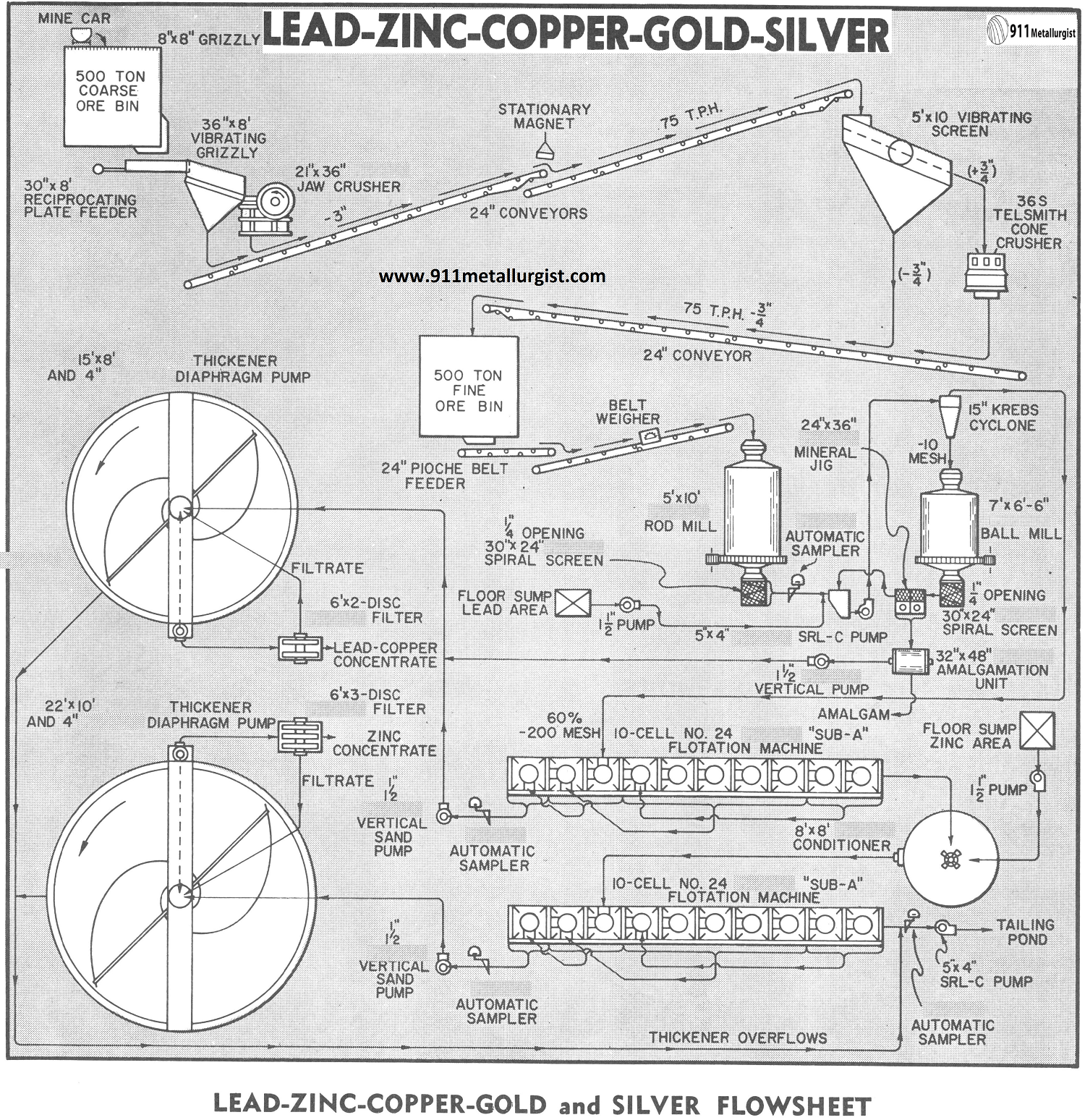

How to Process Copper Lead Zinc Ore with Gold and Silver by Flotation

The flowsheet in this study was designed to treat 500 tons per day of a complex base metal ore containing gold and silver values. The presence of free gold offers opportunity to recover these values in the grinding circuit so that the gold could be amalgamated, and marketed directly to the mint. The ore as […]

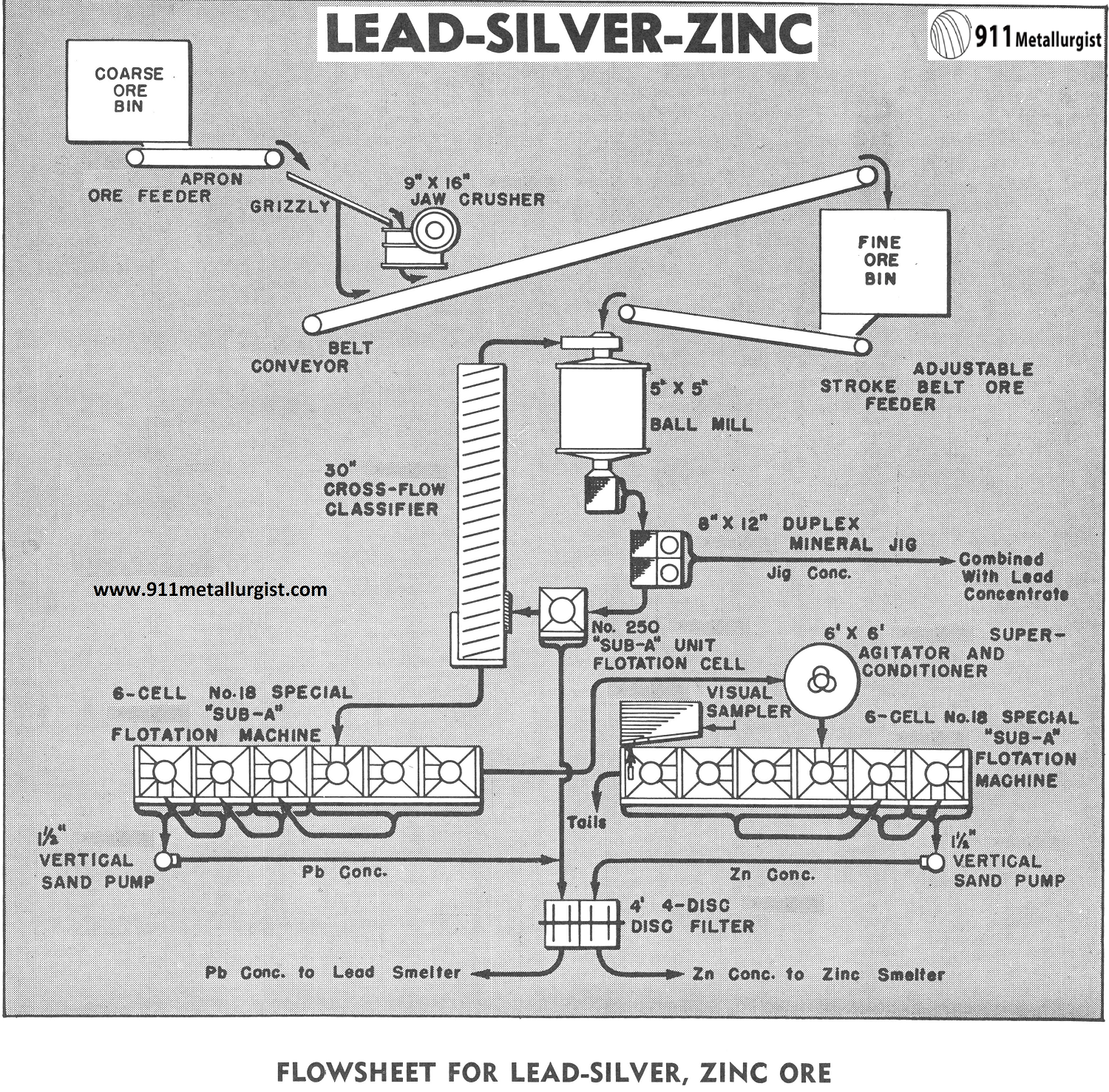

Silver Lead Zinc Ore Processing Method using Flotation

Sulphide ore of lead and zinc containing considerable silver was submitted for testing with the purpose of determining a flowsheet for the production of separate lead and zinc concentrates for marketing at their respective smelters. It is necessary to recover as much silver as possible in the lead concentrate as a higher return for this […]

Gold and Silver Leaching by Cyanidation

Introduction to Gold and Silver Leaching The cyanide leaching process is the most important method ever developed for extracting gold from its ores. The early development of the process is attributed to a Scotchman, John Stewart Mac Arthur, in collaboration with the Forrest brothers. The method was introduced into South Africa in 1890. From there it spread […]