Melting Points of High Fusion Temperature Metals

In this paper, it is proposed to outline a method for the determination of melting points of those metals and alloys having high fusion temperatures. The application of the method as used to determine the melting points of alloys of tungsten and molybdenum will be given. It will be seen from these results that tungsten […]

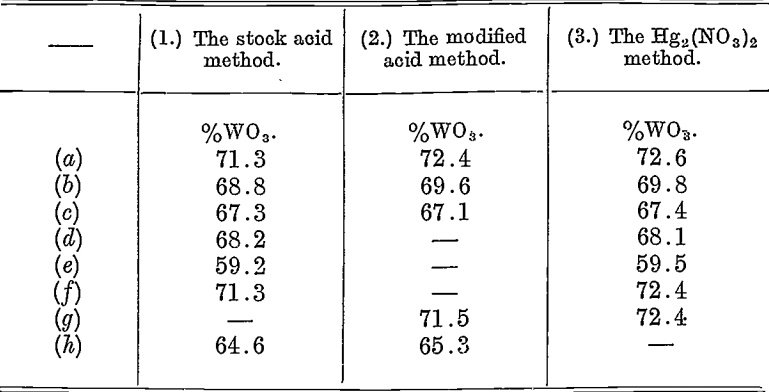

Assaying Tungsten Determination

In dealing with wolfram ores and concentrates, we identified 3 three determination methods for the estimation and Assaying Tungsten that are discussed below are well known, but these results of their trials and comparison under technical conditions may be interesting. Tungsten Assaying Method 1 The routine procedure for the assay of rich wolfram ores or concentrates […]

Tungsten Metallurgy

Nearly all alloy steels containing tungsten are made in the electric furnace where tungsten is introduced to the steel’s metallurgy in the form of ferro-tungsten. Ferro-tungsten, melts between 3500 and 3700 degrees F., while tungsten powder melts between 6000 and 6200 degrees F. Neither will actually melt in a steel-making furnace, but the ferro-alloy because […]

Extracting Tungsten from Wolframite Gold Ore

The present great demand for tungsten due to world conditions has resulted in an increase of tungsten ore dressing problems for our metallurgists. The flowsheet study shown here was recently developed for treatment of a very complex tungsten-gold ore. The flowsheet study previously shown for tungsten was devised for a simple tungsten ore free of […]

Extraction of Tungsten from Scheelite Ore

High price and ready market for acceptable tungsten concentrates present a very attractive incentive for the mining and processing of tungsten ores. Since all tungsten ores are very friable and slime easily, concentration must take place as soon as the mineral has been liberated by either crushing or grinding methods. Regardless of the care taken […]

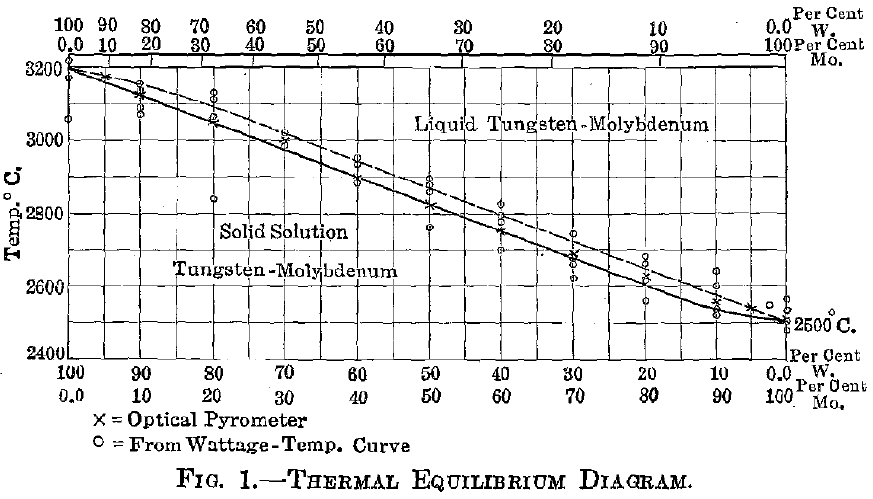

Tungsten Molybdenum System

A complete list of the elements includes 18 that melt above 1,700° C. There does not exist one complete thermal equilibrium diagram for any pair of these 18 elements. Several of these elements have been combined, in relatively small proportions, with metals of lower melting point: e.g. tungsten, molybdenum, and vanadium, in steels, or with […]

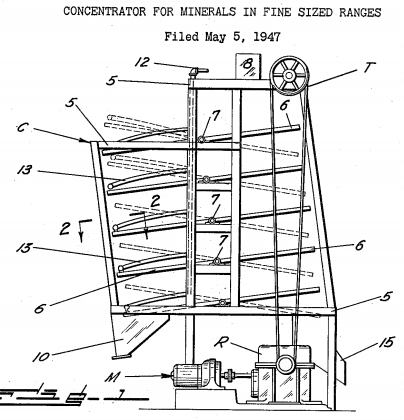

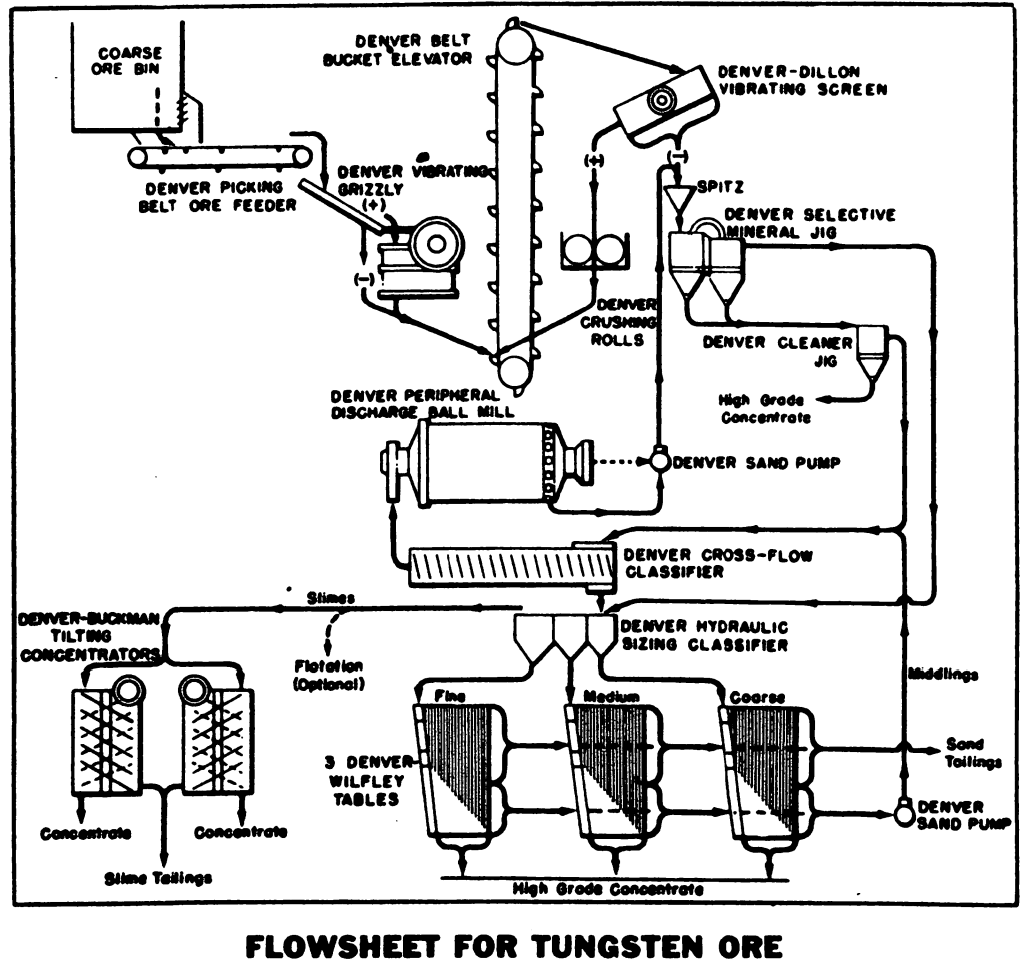

Tungsten Extraction Process

The Beneficiation flowsheet shown with this study is particularly adapted to the concentration of tungsten ore in small tonnages. Tungsten minerals are generally in the friable class and therefore concentrating processes are hindered by the excess amount of fines produced in the crushing and grinding steps. Special consideration must be given to the stage reduction […]

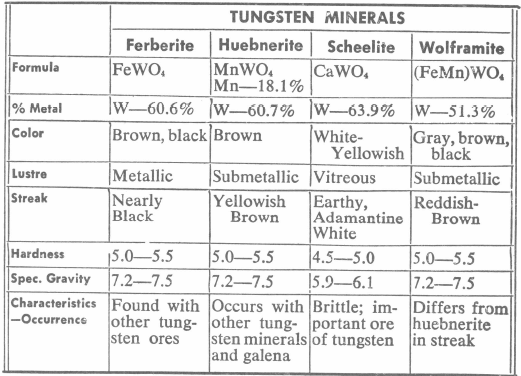

Froth Flotation of Tungsten Ore

Scheelite (CaWO4) and Wolframite ((Fe,Mn)WO4) are the principal minerals of tungsten, but other important minerals include ferberite (FeWO4) and huebnerite (MnWO4) will also respond to froth flotation. The high specific gravity of these minerals makes many of these ores amenable to gravity concentration methods, however, the fine dissemination of mineral in gangue for some ores […]