Sulfide Ore Treatment Gold – Silver – Copper – Cobalt – Zinc Recovery

A procedure was developed for recovering gold, silver, cobalt, copper, and zinc from a massive sulfide ore by a hydro-metallurgical process. The procedure consists of (1) oxygen pressure leaching; (2) iron, arsenic, and copper removal from the leach solution by precipitation; (3) selective extraction of cobalt and zinc from solution; (4) electro-deposition of the cobalt […]

Refining Gold: Remove Zinc by Distillation

It seems desirable to remove zinc more completely than can be done by acid-treatment, and also to obtain it in a form at once available for precipitation again. I feel safe in saying that from 40 to 50 per cent, of the zinc originally used for precipitation could be thus recovered. Philip Argall says, in […]

Refining Zinc Precipitates: Cyanide Leaching of Gold & Silver Extraction

Attempts to discover, for the cyanide process, a better precipitant than zinc have been unsuccessful. Hydrogen sulphide, sulphurous acid, ferrous sulphate, etc., precipitate gold and silver from cyanide solutions either not all or incompletely. Aluminum has been tried, but it costs too much, and cannot be used in solutions containing lime. Charcoal has been used […]

How to Process Copper Lead Zinc Ore with Gold and Silver by Flotation

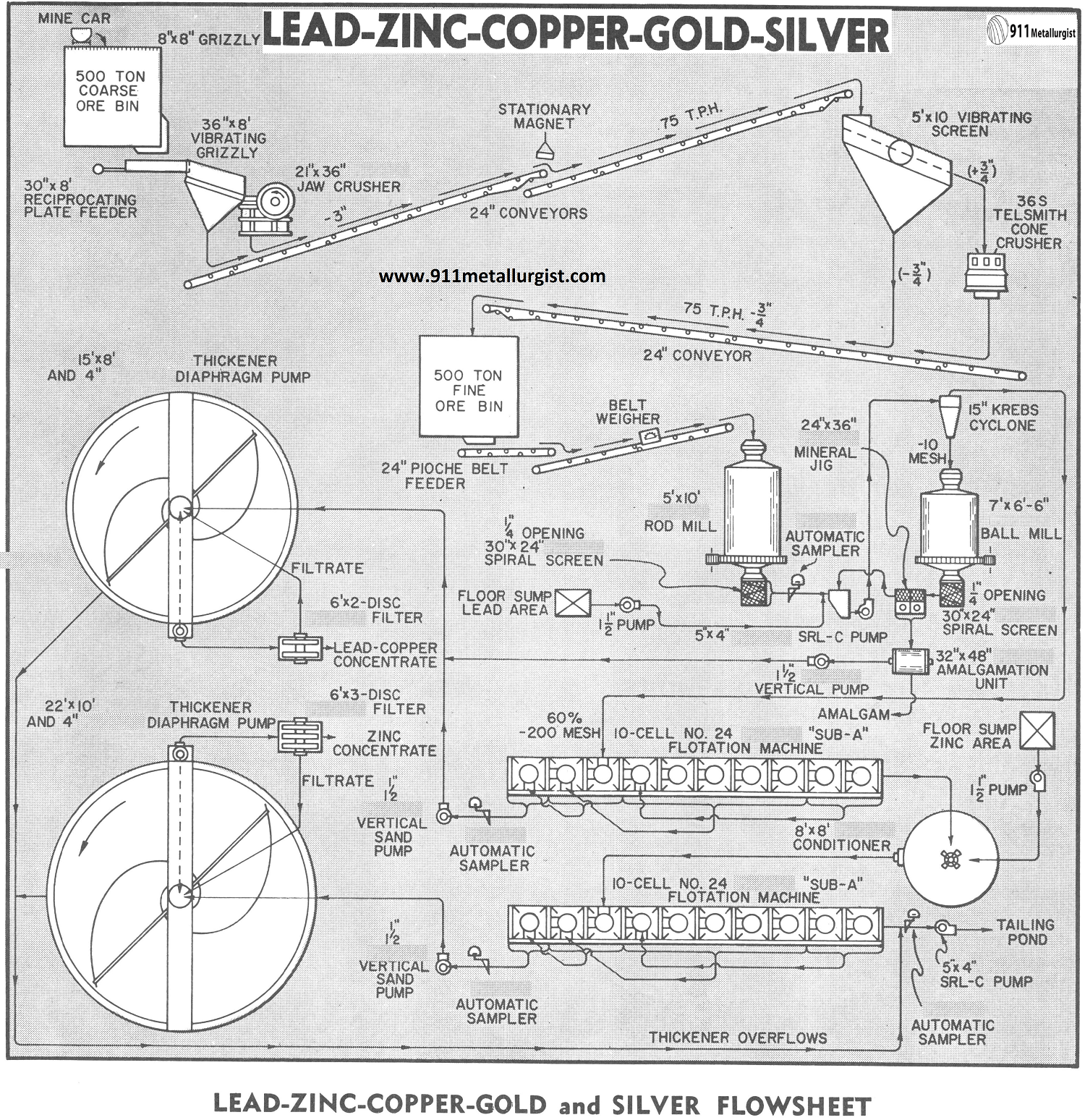

The flowsheet in this study was designed to treat 500 tons per day of a complex base metal ore containing gold and silver values. The presence of free gold offers opportunity to recover these values in the grinding circuit so that the gold could be amalgamated, and marketed directly to the mint. The ore as […]

Lead Zinc Sulfide Separation by Sequential Flotation

In the majority of the zinc operations, sphalerite (ZnS) is associated with galena and often sulfides of iron and copper. It is therefore essential to arrange the flowsheet not only for recovery of the valuable minerals, but also to selectively separate them into products acceptable to the smelters for ultimate conversion into metal. The flowsheet outlined […]

How to Process Low-Grade Lead Zinc Ore by Flotation

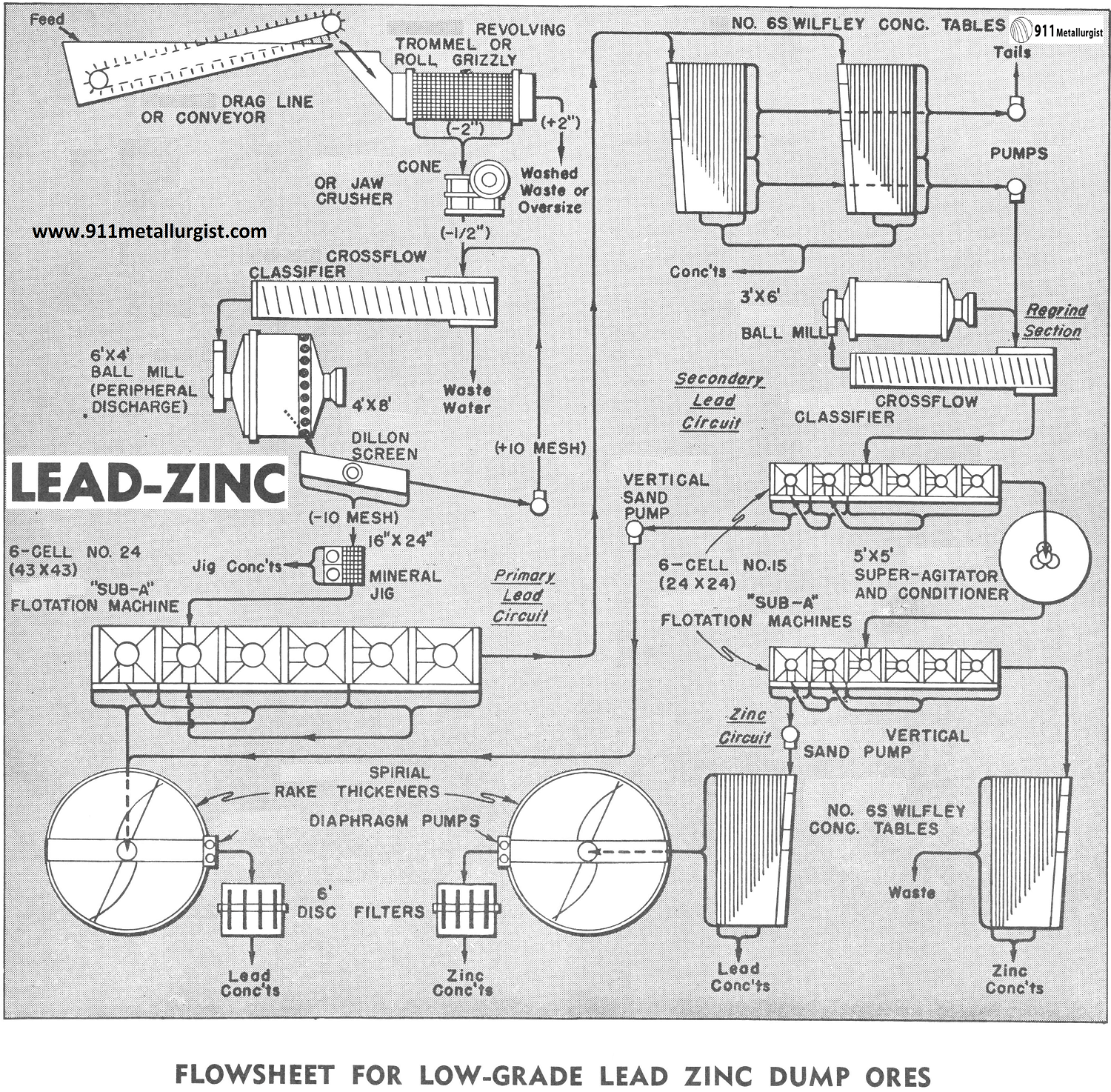

The flowsheet above was designed to treat economically approximately 200 tons in 24 hours of a low-grade dump ore containing lead and zinc values as well as some silver in both sulphide and oxide form. Due to varying specific gravities of the values, gravity concentration in addition to flotation was indicated. As is common in many […]

How to Process Oxidized Lead-Zinc Ore by Flotation

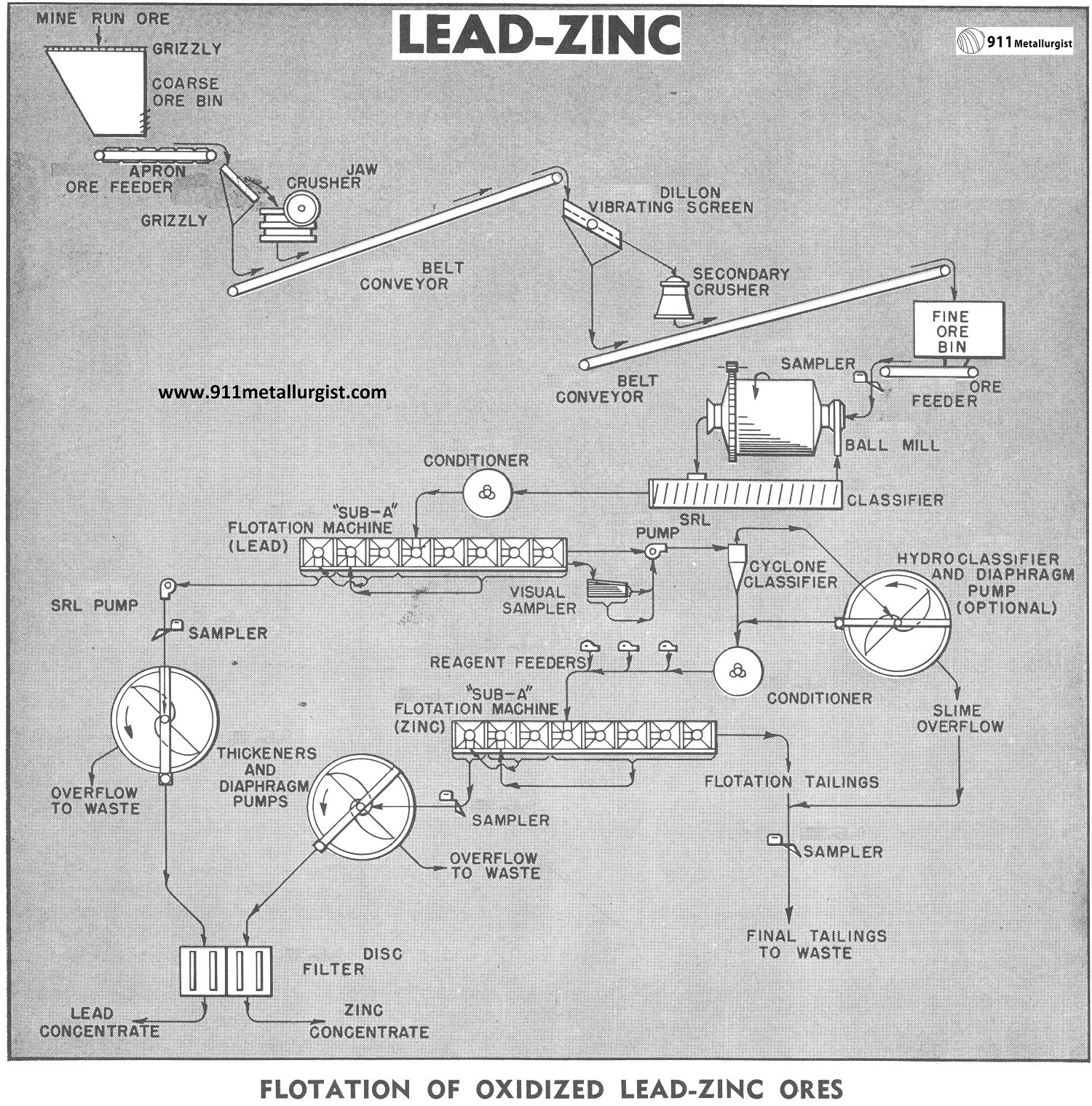

The problem of treating oxidized lead-zinc ores for the production of high-grade lead zinc concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals. The ore for treatment is a lead-zinc carbonate ore in a mixed siliceous-lime carbonate gangue. The association of […]

Galena – Sphalerite Flotation & Separation Method

The problem of treating oxidized lead-zinc ores for the production of high-grade lead zinc flotation concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals. The ore for treatment is a lead-zinc carbonate ore in a mixed siliceous-lime carbonate gangue. The association of […]

Silver Lead Zinc Ore Processing Method using Flotation

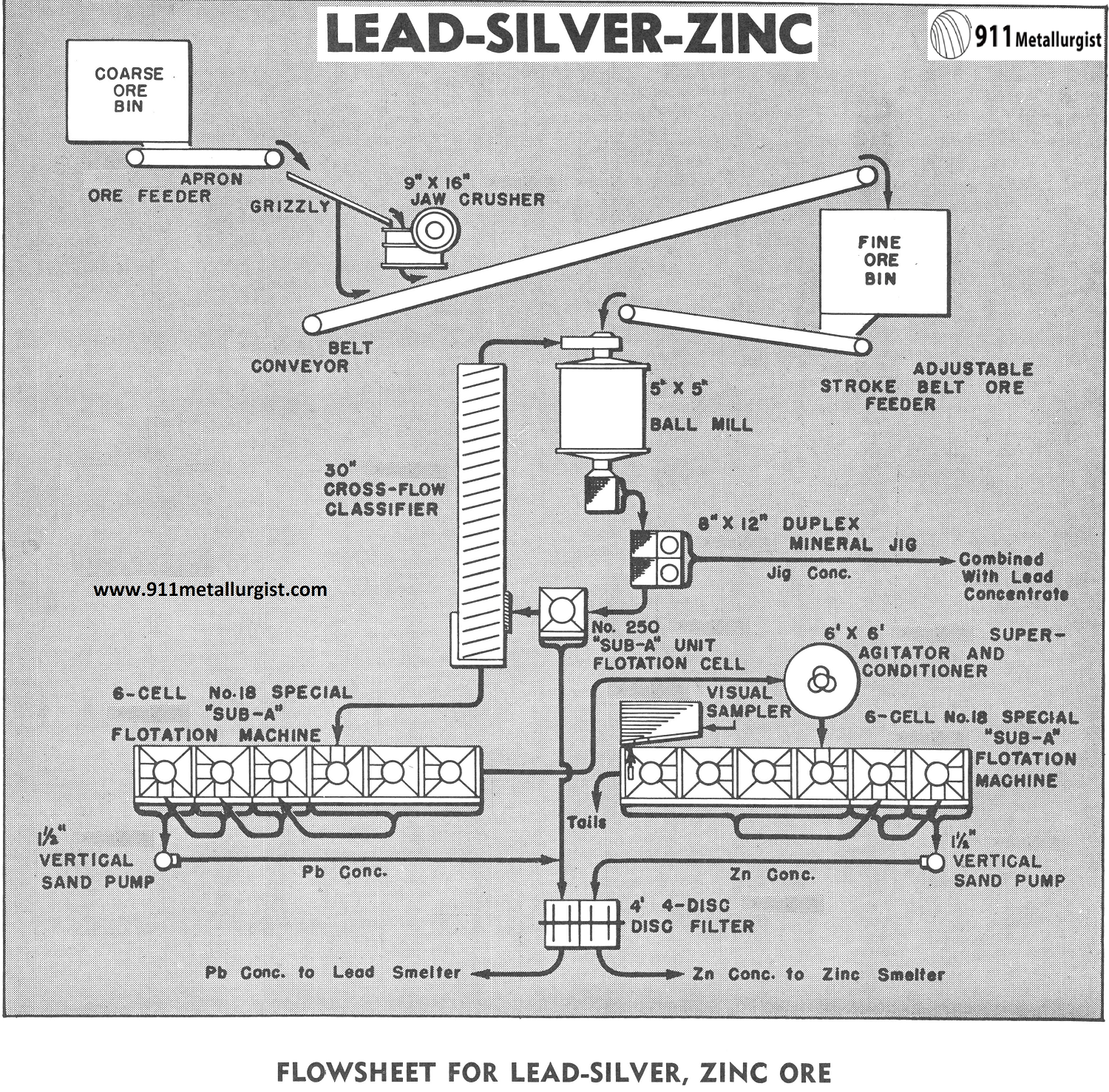

Sulphide ore of lead and zinc containing considerable silver was submitted for testing with the purpose of determining a flowsheet for the production of separate lead and zinc concentrates for marketing at their respective smelters. It is necessary to recover as much silver as possible in the lead concentrate as a higher return for this […]

Chalcopyrite (Cu) Sphalerite (Zn) Separation by Flotation

The Problem with separating Copper from Zinc by flotation The treatment of heavy sulphide ores of copper containing zinc and pyrite is often extremely difficult particularly if soluble copper and sulphates are present. This is usually the case in ore deposits near the surface or in tropical countries where the annual rainfall is quite high. The […]