Leach Pad Construction: After the site of this Silver Heap Leaching pad was prepared, a pad base consisting of about 15 inches of mill slimes or a fine bentonitic clay from an old nearby tailings pond was laid down. The pad was constructed slightly larger than the dimensions of the heap to go on it; i.e., about 5 feet all around. Subsequent experiments have shown that this base is most effective if it is spread while slightly damp, 2 or 3 inches at a time and rolled or compacted between each application. A multi-stage build-up is the recommended procedure to insure an impermeable base. The final stage of pad construction is the addition of a layer of several inches of ore crushed to minus 1-inch and spread evenly over the day base at about a 9 percent slope. Some operators favor the use of welded plastic sheeting of about 10 mil thickness, laid on a clay base and covered with gravel and/or fine sand. The most recent pad base now being installed will employ a reinforced plastic on a clay base and a clay and crushed ore cover. In any case, it is essential that an absolutely impervious barrier be emplaced and maintained so as to completely contain the leach solutions from the heap.

No solution leakage problems have been encountered due to pad base failure. The integrity of all pads and pond linings has been maintained completely.

Loading the Heap

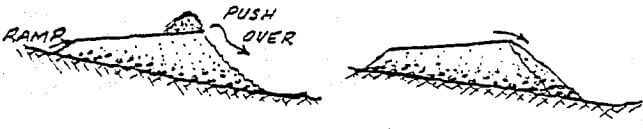

After the pad is constructed, the ore is placed on the pad with a 1½ yard loader in 5 foot lifts. Loading the heap should be done so that the coarse is at the bottom of the pile and the finer material is at the top. This allows for better solution distribution and decreases the possibility of vertical channels of solution flow through the heap. To do this a ramp is started up to the final level of the lift. Ore is dumped on the edge of the ramp and pushed over. This lets the larger rock roll to the bottom and the finer rock stays at the top.

A leveling lift will have to be put down first, then all subsequent lifts will be an even thickness throughout.

After each lift is loaded, the ore is ripped to loosen the areas compacted by machinery. After each lift is leached, the ore is ripped before loading the next lift.

About 800 tons of ore could be loaded in one day, taking 6 working days per lift.

The cyanide solution works best if there is an ample supply of oxygen in the solution. Using rainbird plastic sprinklers, the solution is broken down into a spray, allowing oxygen from the atmosphere to be dissolved into the solution.

Frequently, it has been found that the amount of dissolved oxygen is depleted after it has percolated 10 feet into the heap. Beyond this point the cyanide solution will not dissolve the silver or gold effectively. For this reason no lift should be more than 10 feet thick. Also, shallower lifts usually work better for finer material.

Pregnant Solution Ponds

Pregnant solution moving under the ore heap, along the pad, flows through a small decantation pond. This small pond is used to let some of the solids settle out before entering the main pregnant solution storage pond. Solution is decanted off the top of this small pond through a stand pipe into the main pond. When the solution is very slimey (for example, after heavy rains or a new batch of clayey ore is added to the heap), a mixture of water and lime is added into the decant pipe. This helps to settle some of the slimes and also helps maintain pH control.

The main pregnant solution pond was constructed with a capacity of 400,000 gallons just below the ore heap and the small decantation pond. The bases or liners in these ponds were prepared in the same way as the pad. The pond is designed to hold all solution from the leaching system (72,000 gallons), plus the added volume of water from a 100-year rain over the leach area. A second large dam with a impervious lined pond has been constructed below the main pond to collect and control all cyanide solutions and run-off that could overflow from the primary leach area. This second pond provides additional insurance against accidental overflows in the system.

The values contained in the main pond vary from the time cyanide is first added to the new batch ore until 6 to 8 weeks later, when a new lift of ore is needed for leaching.

Solution from the first days of leaching will have the highest values, ranging from 0.8 to 1.0+ ounces of silver per ton of solution. After 10 to 14 days, values usually drop to about 0.3 to 0.4 ounces of silver per ton of solution. The heap becomes “passive”. At this time the heap may be allowed to drain and to aerate. It is then ripped to a depth of 4 or 5 feet with a single scorpion ripper behind a D-8 CAT. Spacing of the ripper pattern is about 6 feet. The pregnant solution then assays 0.6 to 0.8 ounces per ton coming OFF the heap.

After 6 to 8 weeks, depending upon the amount of fines in the heap, values in the solution drop to about 0.3 ounces per ton. The average value in the pregnant solution pond during this 6 to 8 week period is about 0.5 ounces per ton. The plan is always to leach the heap until an economic cut-off point has been reached. Then after ripping again, another 5 foot lift is added and leaching continued in the same manner. While the upper lift is undergoing its initial leach phase, the remaining values in the lower lift(s) are slowly being worked on, if oxygen and free cyanide (in solution) are available.

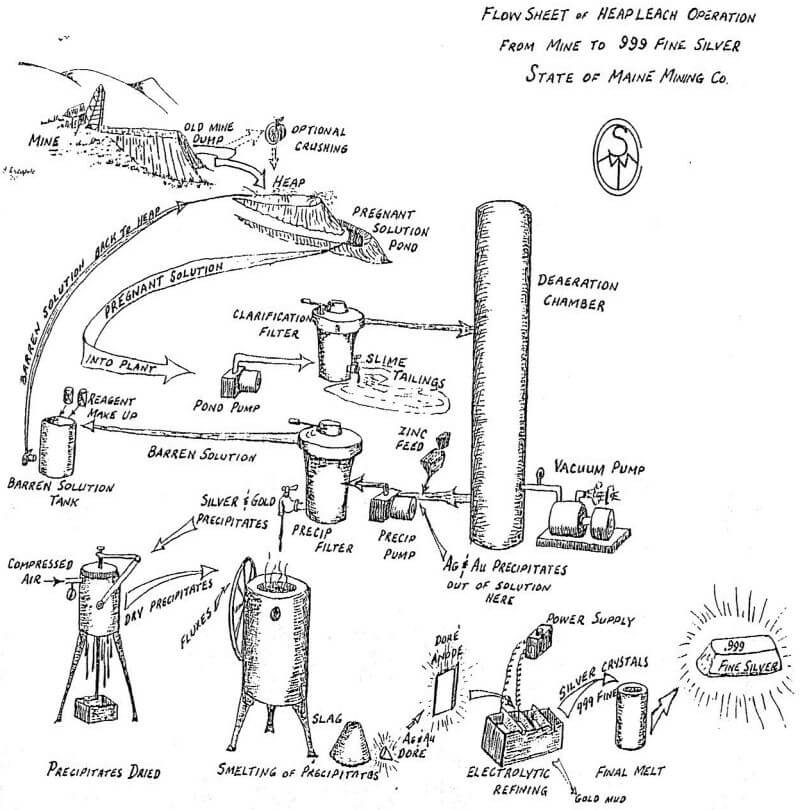

Plant Operation

Solution from the pregnant storage pond is pumped into a clarifier filter where any remaining slimes are removed from the solution.

After clarification, the solution is run through a vacuum chamber to remove the dissolved oxygen (deaeration).

As the solution leaves the vacuum chamber, zinc dust is introduced and precipitation of the silver and gold takes place almost immediately. At this point the cyanide strength should not be excessive because some of the precipitated precious metal values may redissolve before they can be removed from the circuit in the precipitation filter. The solution with the suspended solids then passes through another filter to remove the silver and gold precipitate. The barren preg solution flows out of the precipitate filter and into a barren solution storage tank. Here samples are taken to determine the amounts of silver and gold remaining in solution.

Cyanide and caustic are added to bring solution back up to the desired pH strength and free cyanide.

Solution from this tank is then pumped back through the sprays and onto the heap.

Titrating for cyanide concentration is done with standard silver nitrate reagent on the pregnant solution coining OFF the heap. This is to determine how much free cyanide is left in solution after leaching. If the solution does not show any cyanide, then all of the available silver and gold may not be taken into solution. When the solution shows that some cyanide is present (usually a few hundredths of a pound per ton), then the available silver and gold is being taken into solution. But, as mentioned before, an excess of cyanide may redissolve silver and gold from the precipitation filter. For this reason, fresh cyanide is added only after precipitation before the barren preg goes back onto the heap.

Typical Operating Data

Leach 4000 to 5000 tons per lift

Heap size: 180 by 100 feet, 5 feet high 300 tons of solution in 24 hours (50 gpm)

Fresh water make-up 50 tons (worst conditions: dry, hoc, windy day and night)

Values in preg solution, ounces of silver per ton of solution:

First 16 hours – 0.8 to 1.0

10 to 14 days – 0.3 to 0.4

After ripping – 0.6 to 0.8

At shut down -0.3

Average 6 to 8 weeks – 0.5

Pump out decant pond about every two years due to slime build-up.

The pH of the barren preg solution ON to the heap is maintained at 10 or slightly better in order to stabilize the cyanide. The free cyanide in the ON solution is dependent upon the determination of how much is coming OFF. Pregnant solutions coming OFF the heap should show between 0.01 and 0.05 pounds of free cyanide per ton of solution. If less, increase the strength of ON solution in an appropriate amount.

The integrated heap leaching and Merrill-Crowe precipitation circuit required a minimum of operating labor; e.g., one full time worker and one part-time helper per 8 hours, 3 shifts per day, seven days a week.

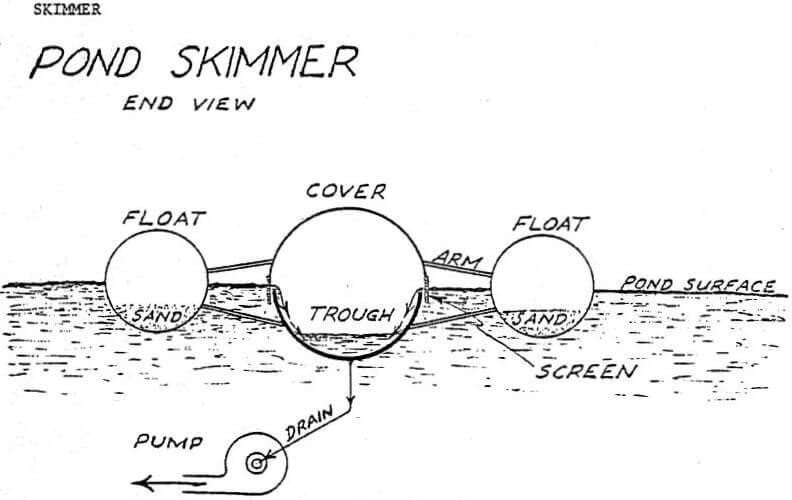

The trough is 8 to 20 feet long, with closed ends, supported by two outrigger floats, one on each side. The floats are attached to the trough and to the cover with several outrigger arms spaced on each side. The precise levelling and adjustment of trough lip below the pond surface is made by adding sand as a ballast to the two floats.

This skimmer pulls the top 1/8 inch of solution off the surface; therefore, maximum aeration and since it is screened and covered, there are no birds, bugs, or debris in the recovered solution.

Further, there is a minimum of silt or suspended solids trapped and taken off in the out-flow.

When pumping from strong preg storage ponds to the precipitation unit, care should be exercised to avoid any air entrapment by vortices, cavitation, or stirring in of extra air. Any extra air puts an unnecessary load on the deaeration unit.