Although wire rope has been in use for over 100 years, it is a complex structure that is still not well understood. Wire ropes are made in diameters from less than 1/32 to more than 7 in and can have as many as 900 individual wires. The mining industry uses a lot of wire rope, not only for hoists for shafts and slopes, but also for elevators, cranes, draglines, and haulage cables. This report is limited to a discussion of the kinds of wire ropes used for hoists in coal mines and in metal-nonmetal mines.

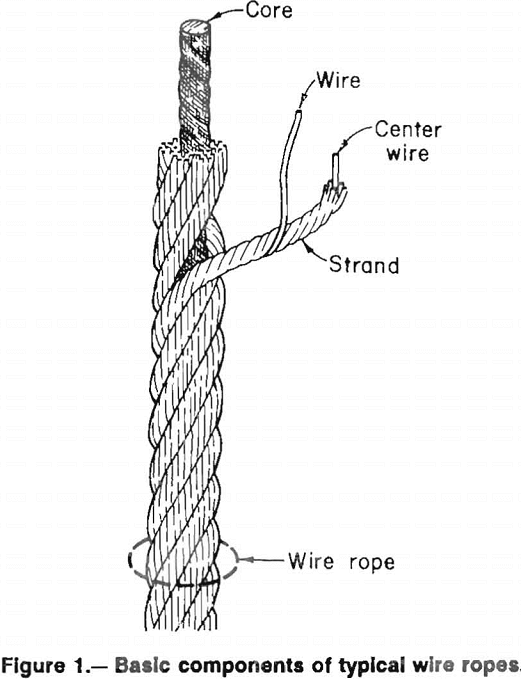

Wire rope consists of three basic components; while few in number, the components may vary in both complexity and configuration to produce ropes for a specific purpose or characteristic. The three basic components of a standard wire rope design are (1) wire that forms the strand, (2) multiwire strands laid helically around a core, and (3) the core (fig. 1).

Wire for rope is made in several materials and types, such as steel, iron, stainless steel, morel, and bronze. By far, the most widely used material is high-carbon steel. This is available in a variety of grades, each of which has properties related to the basic curve for steel rope wire. The most common grades used in mining are improved plow steel (IPS) and extra improved plow steel (EIPS). The wire type and grade are selected based upon the rope’s service requirements.

Strands are made up of two or more wires, laid in any one of many specific geometric arrangements, or in a combination of steel wires with some other materials, such as natural or synthetic fibers. It is conceivable that a

strand can be made up of any number of wires, or that a rope can have any number of strands.

The core is the foundation of a wire rope; it is made of materials that will provide proper support for the strands under normal bending and loading conditions. It is important to the strength of a rope that the original configuration of the components are maintained throughout the service cycle. Core materials include fibers (hard vegetable or synthetic) or steel. A steel core consists either of a strand or an independent wire rope. The three most commonly used cores are fiber core (FC), independent wire rope core (IWRC), and wire strand core (WSC).

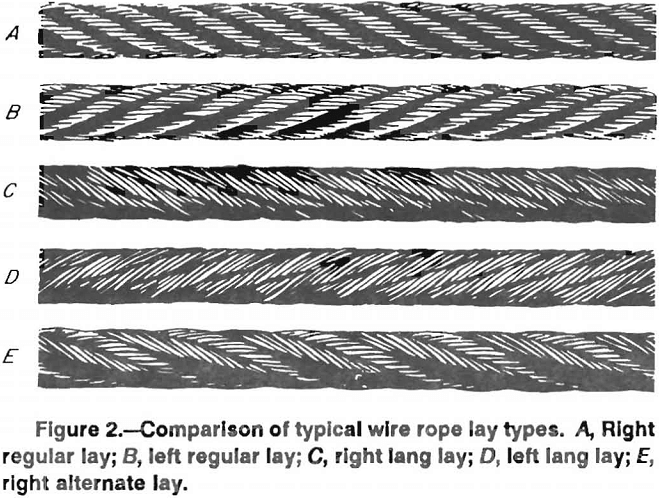

In a wire rope, the wires and strands are “laid” in a variety of patterns to obtain different rope characteristics. Typical lays are shown in figure 2. In figures 2A through 2C, strands are shown as normally laid into the rope to the right, in a fashion similar to the threading in a right-hand bolt. Conversely, the “left lay” rope strands in figures 2B and 2D are laid in the opposite direction.

In regular lay ropes (figs. 2A-B), the wires lay in the strand opposite the strand lay in the rope, causing the wires to appear to align parallel to the rope axis. In lang lay ropes (figs. C-D), the strand lay and the rope lay are in the same direction, causing the wires to appear to be at an angle to the rope axis. Alternate lay (fig. 2E) consists of alternating regular and lang lay strands. Compared with other types, the superiority of lang lay rope in certain applications derives from the fact that these ropes are more resistant to abrasion and have greater fatigue resistance.

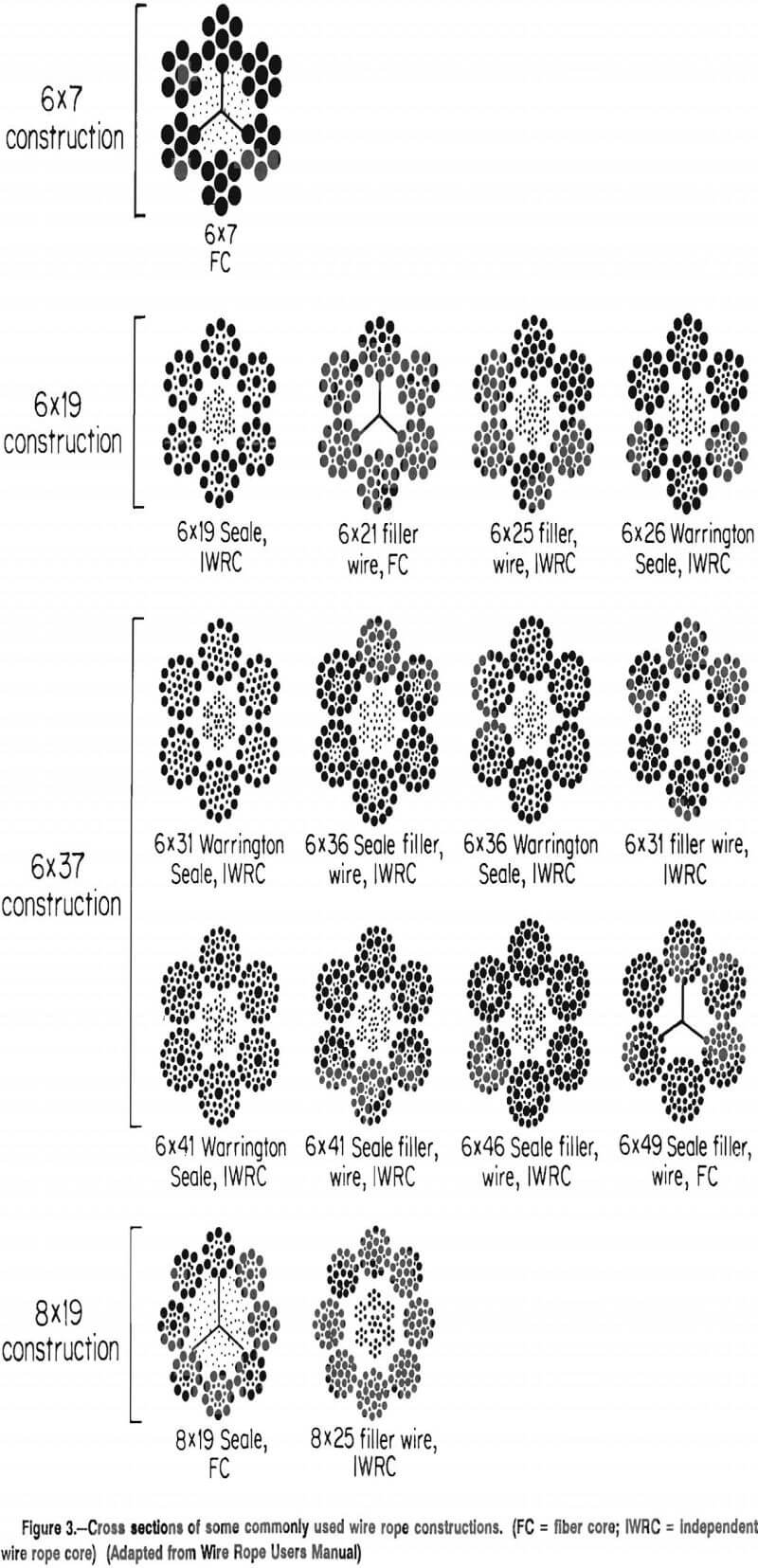

A variety of wire configurations, called the construction, are also used to achieve the best combination of wear and flexibility for the particular application. The wire rope cross sections, illustrated in figure 3, show the classification

of some commonly used constructions. The rope constructions listed in this report are arranged under their respective classification groups.

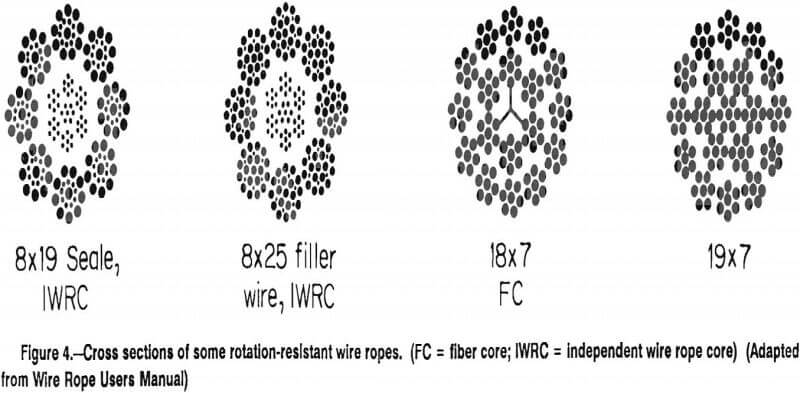

Rotation-resistant rope is a specialized wire rope category; in this category, the selection of the right rope requires more than ordinary care. Because wires and strands are laid in a helical shape, there is a tendency for a rope to try to unwind under tension. When rotation is restrained, as by the shaft guides, a torque force is developed. In a rotation-resistant rope construction, the outside strands are laid in one direction (left or right) and the inside strands are laid in the opposite direction. This construction creates counteracting torques and helps prevent the rope from rotating in either direction when a load is applied. Some typical rotation-resistant wire rope cross sections are shown in figure 4.

Mine Safety and Health Administration Data Bank

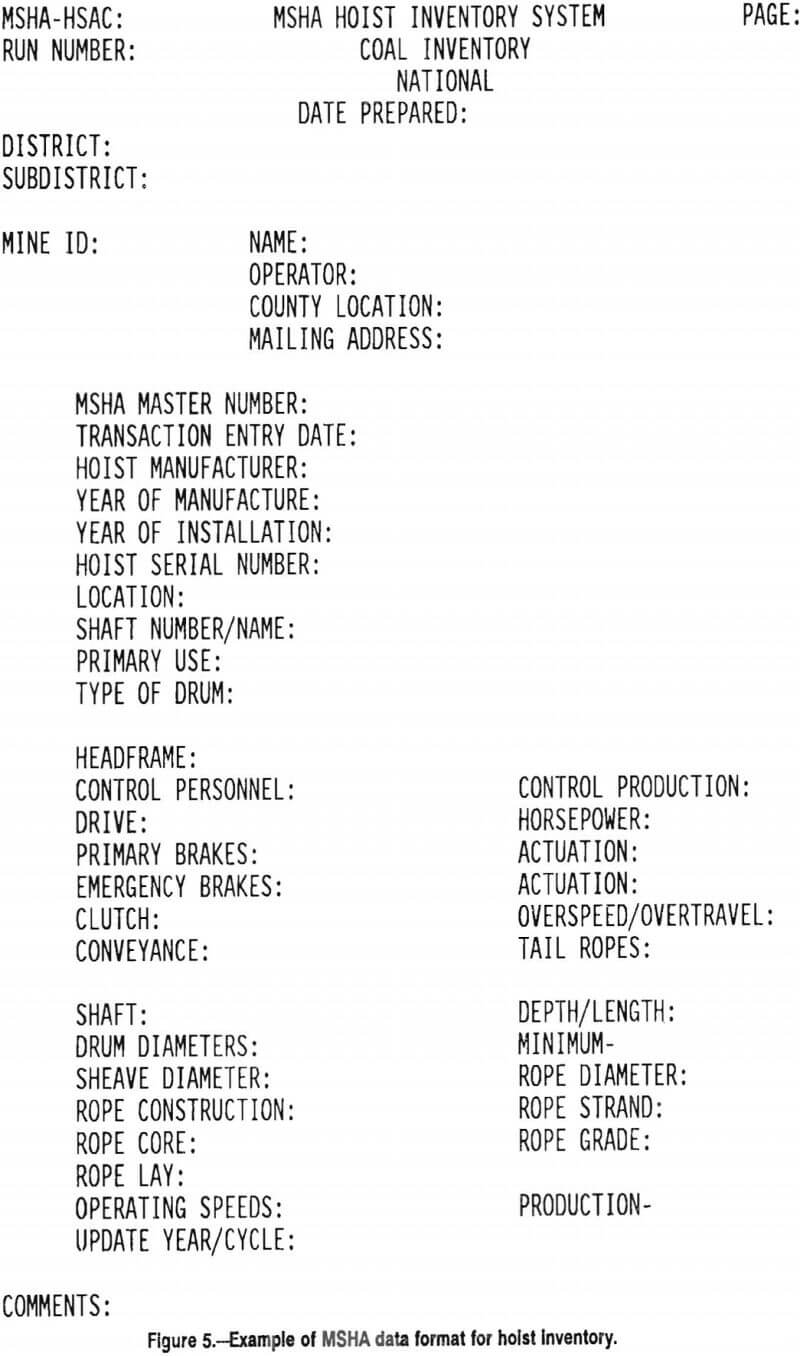

MSHA maintains a data bank that contains a comprehensive amount of detail on about 80% of the hoist and elevator systems used in mines in the United States. For this report, only hoist data are considered. The format of data collected by MSHA for hoist systems is shown in figure 5.

The data compiled by MSHA on hoist systems are divided into two categories: (1) coal mine hoist systems and (2) metal-nonmetal mine hoist systems.

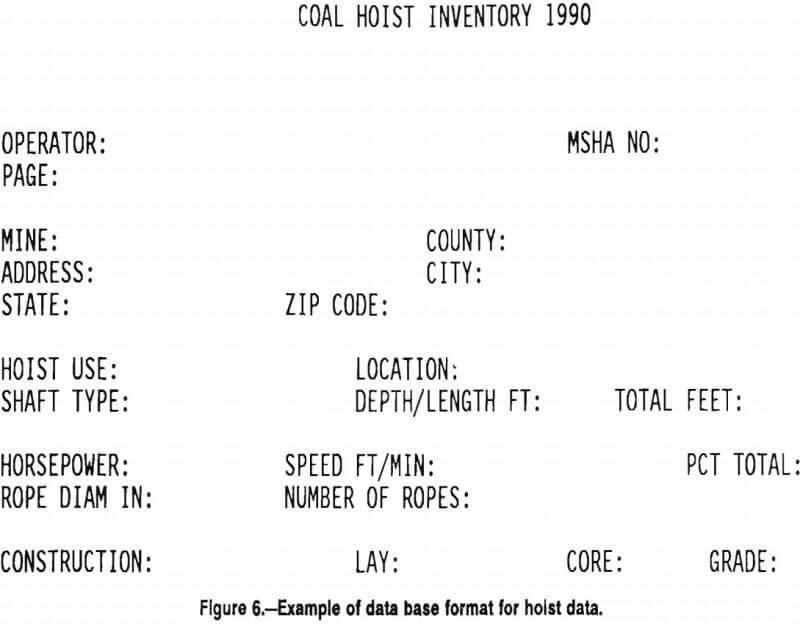

As can be seen, the data consist of a large volume of information related to use, electrical equipment, mechanical systems, and ropes. From this information, specific data were extracted that included the rope diameter, construction type, and lay type. The easiest and most efficient method to extract these data was to use a DMS. The DMS was used to establish the format illustrated in figure 6.

Data Base Management System

A data base is an organized collection of related information or data. Data base management is a very powerful tool that provides the capability to manipulate and quickly organize a large mass of data for a specific purpose. The most important feature, however, is the capability to quickly select and rearrange the data in any order or format desired.

Many DMS’s exist that incorporate important features. These features may include—

- Editing.—Correcting and updating file information.

- Searching— Finding specific information quickly.

- Indexing.–Rearranging specific data in a specific format.

- Storing—Saving edited and indexed files for recall.

- Creating documents—Making finished reports.

Other features are available, depending on the system that fits the user’s requirements. One disadvantage of using a DMS with the MSHA data is that wire rope sizes are nominal and are expressed in inches and fractions. For manipulation by computer, these sizes must be converted to decimals, which incorrectly implies great precision of diameter measurements.

Results

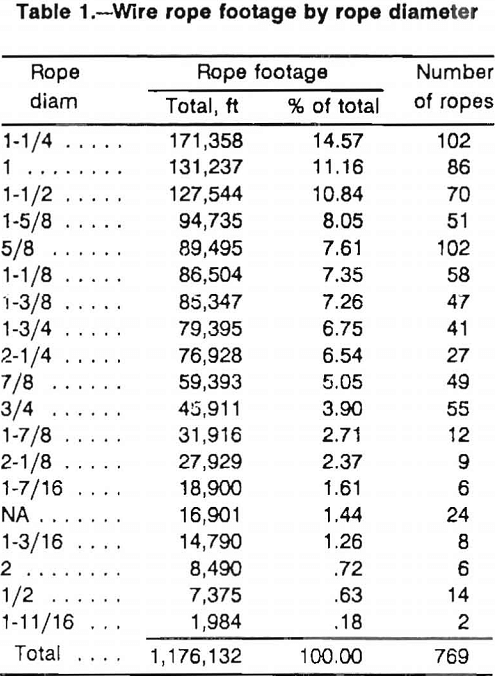

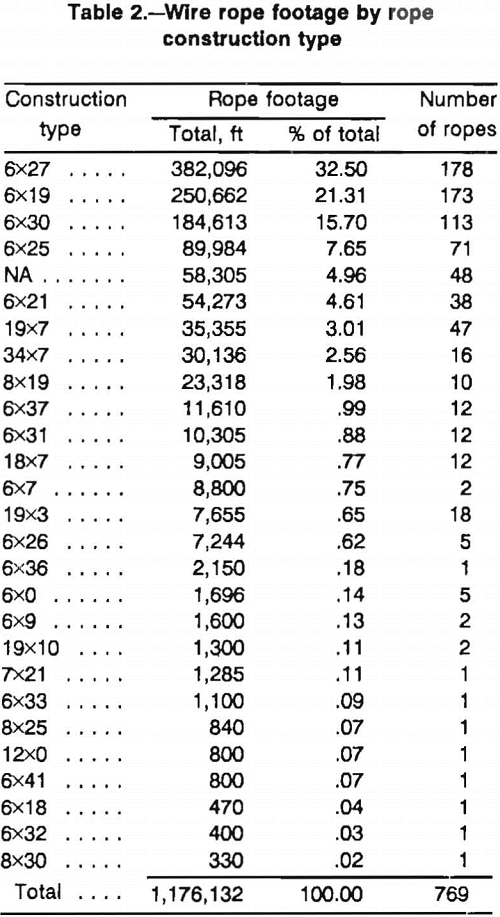

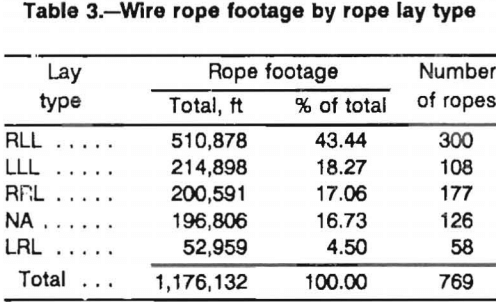

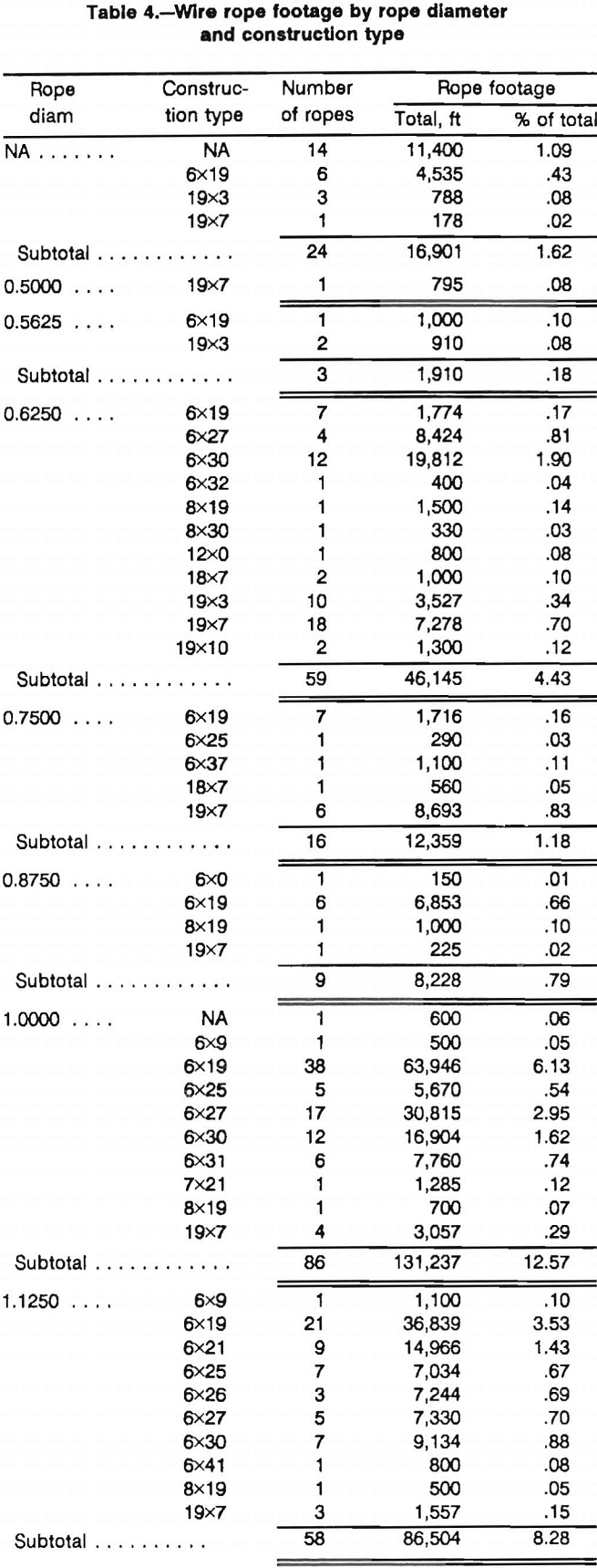

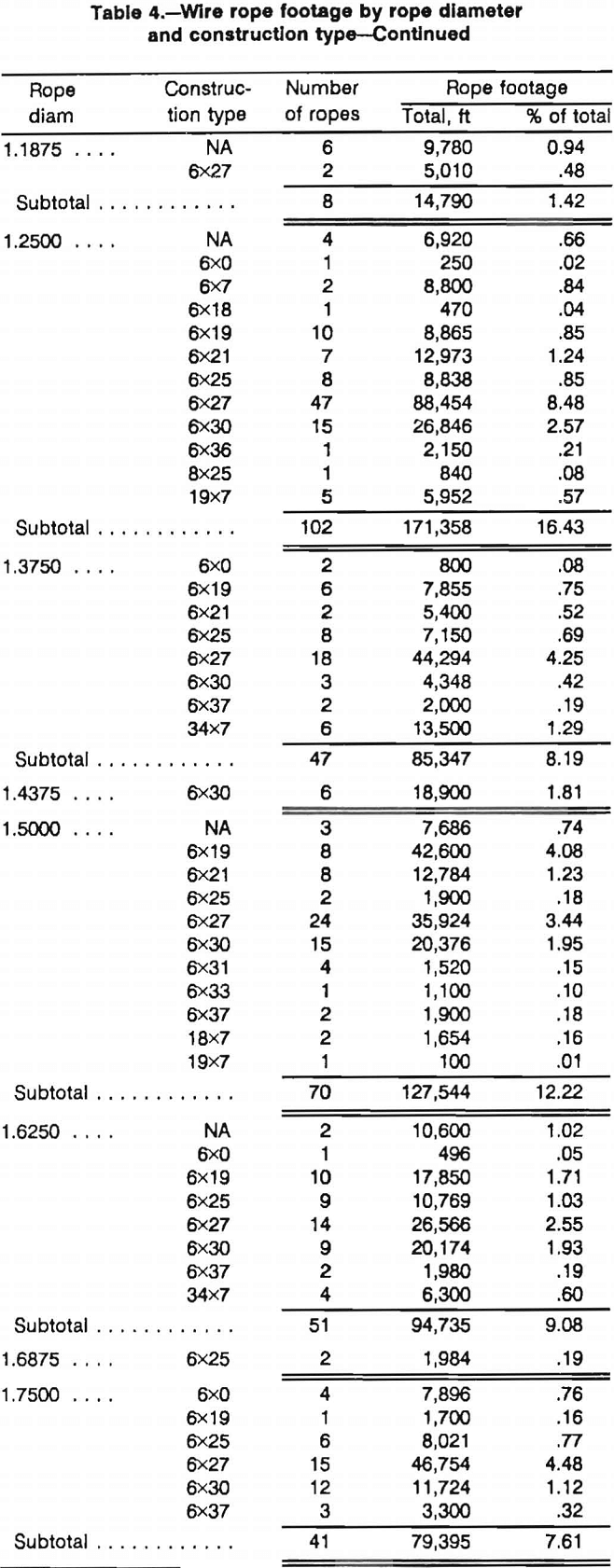

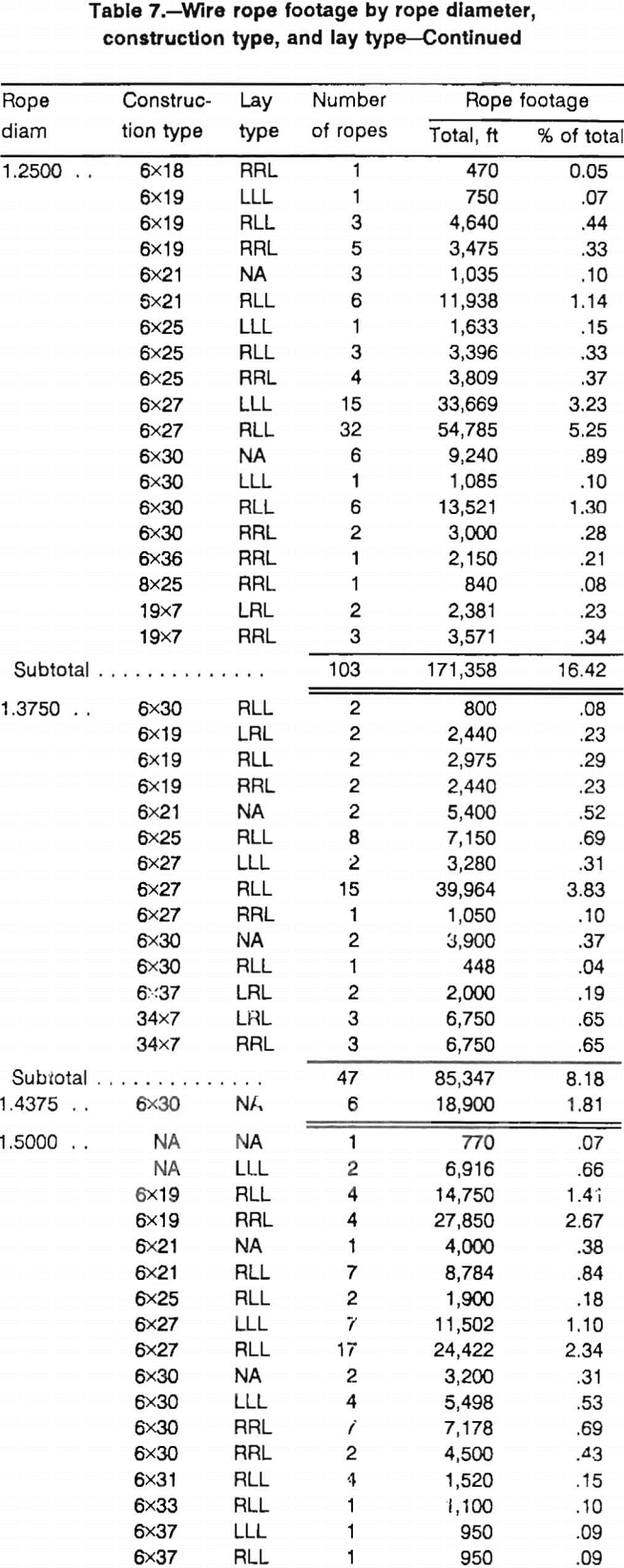

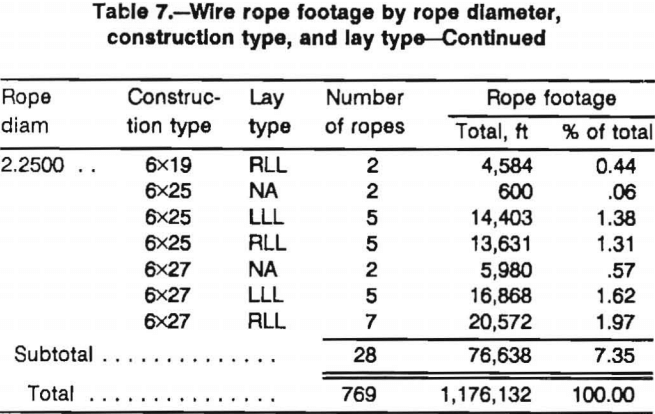

The information contained in the tables of this report represents specific data that were extracted from the large data base provided by MSHA. Of particular interest is the distribution of hoist ropes throughout U.S. mines. Using the MSHA data detailed in figure 6, the hoist rope inventory was sorted initially by three rope characteristics considered separately: (1) rope diameter (table 1), (2) construction type (table 2), and (3) lay type (table 3). This was an attempt to determine whether or not there is a dominant wire rope used in U.S. mines for hoisting. The criterion used for sorting the data was total rope footage.

By utilizing a DMS to construct the tables in this report, the task of identifying the most popular ropes was greatly simplified. Wire rope with a diameter of 1¼ in has the largest percentage of use at 14.57%, as indicated in table 1, by individual characteristic. A 6×27 wire rope construction is most prevalent at 32.50%, as indicated in table 2. Right lang lay (RLL) is the most common lay type at 43.44%, as indicated in table 3. Many of the left lang lay ropes, which comprise 18.27% of the total, are paired with right lang lay ropes on friction hoists for torque balance.

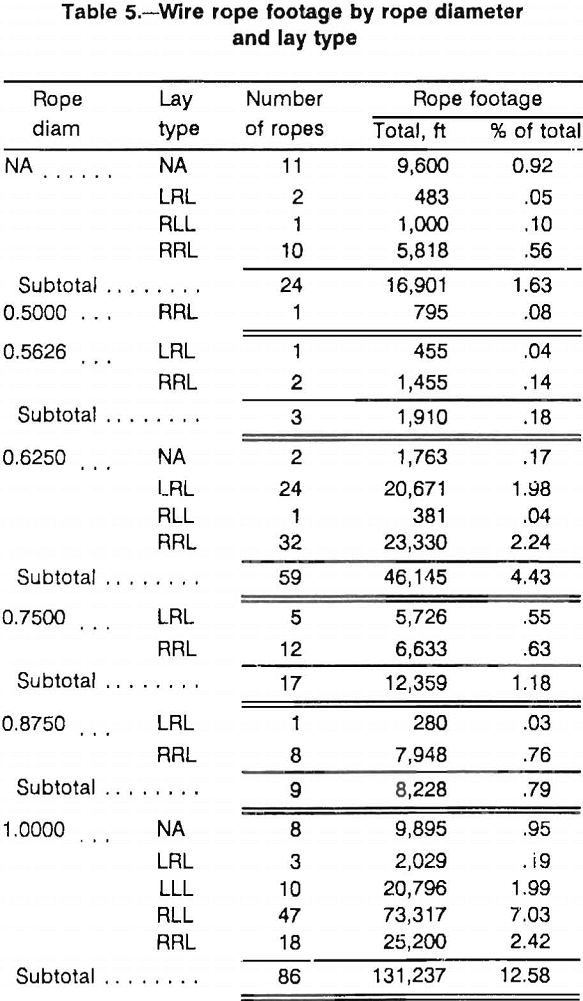

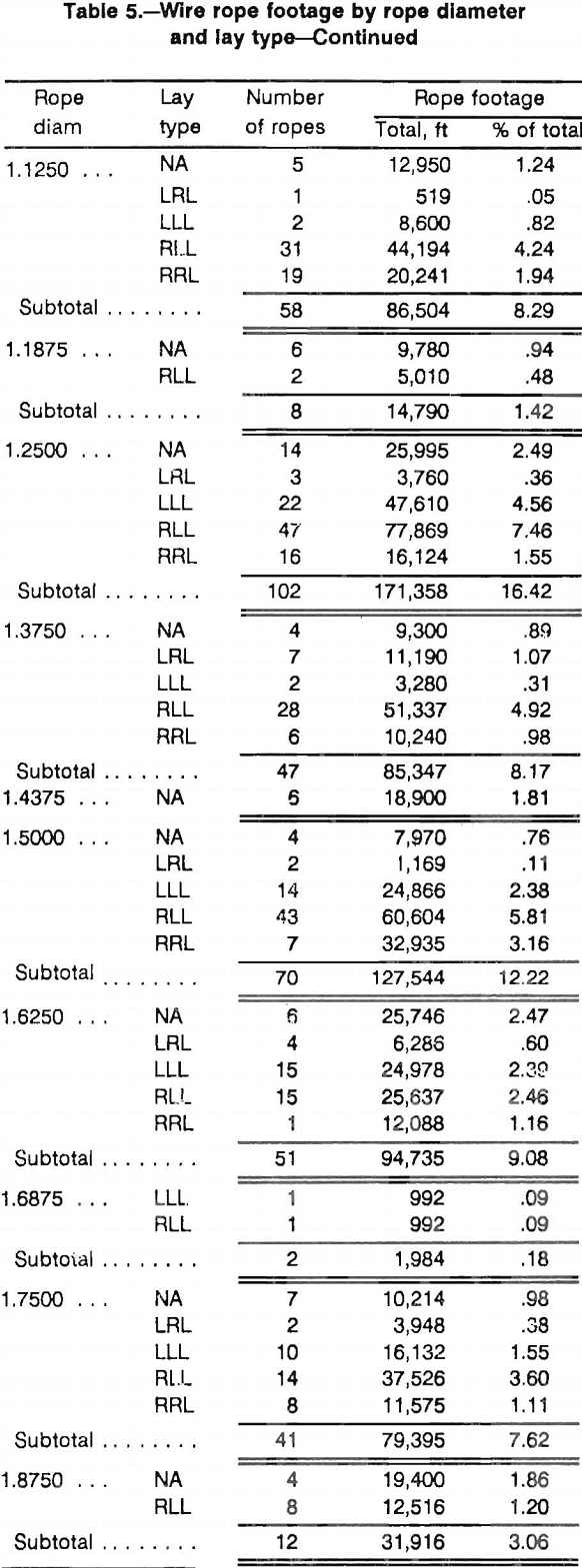

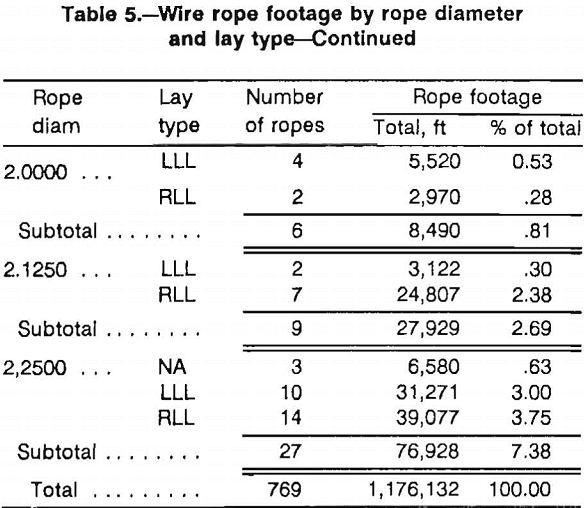

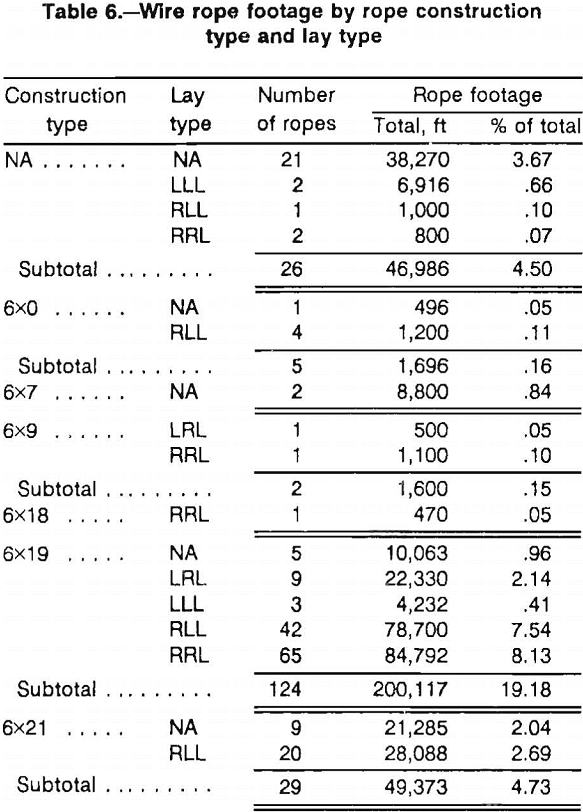

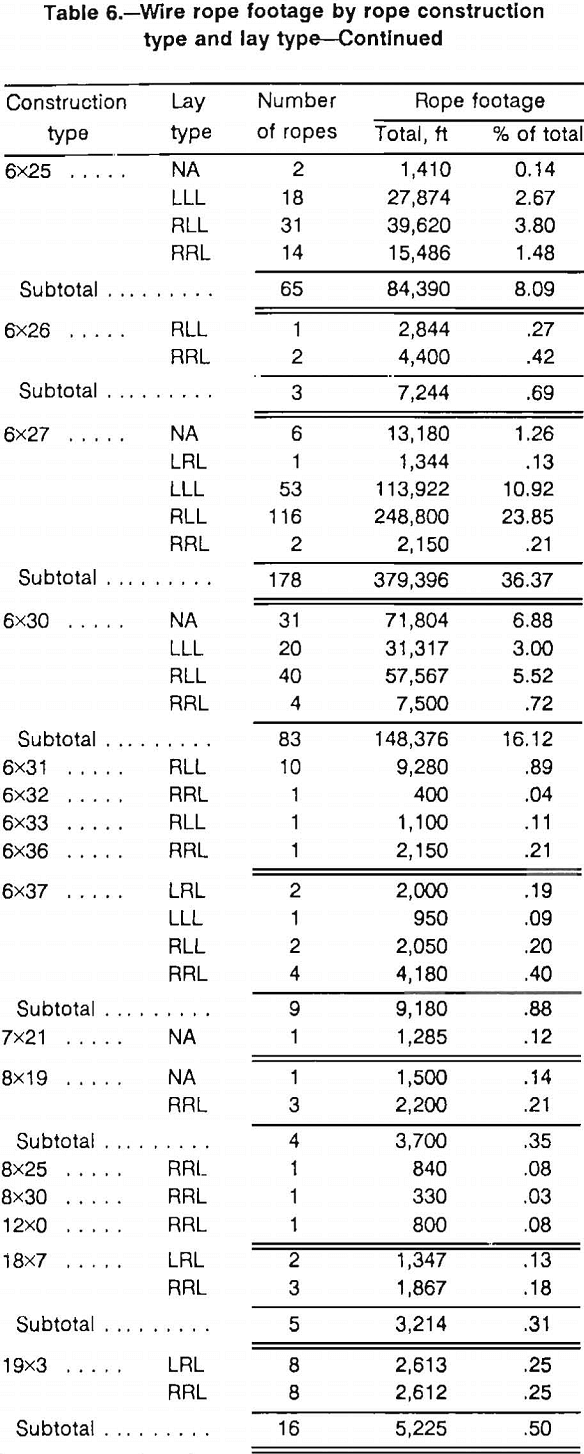

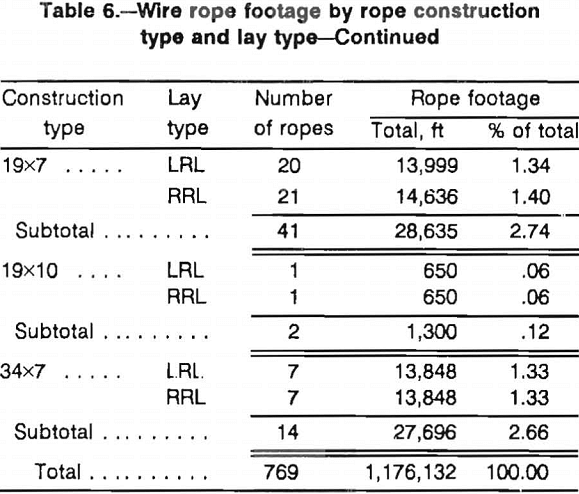

The first step aided significantly in determining the most prevalent ropes by individual characteristic. The next step was to sort the hoist rope inventory by rope characteristics considered in pairs. The relationships of rope diameter to construction type, rope diameter to lay type, and construction type to lay type are shown in tables 4, 5, and 6, respectively. The information contained in these tables confirms the information in tables 1 through 3. However, the total footage of each rope is drastically reduced when rope characteristics are paired. As shown in table 4, 1-¼ in, 6×27 rope is only 8.48% of the total footage. As indicated in table 5, 1-¼ in, right lang lay rope is 7.46% of the total footage. As shown in table 6, 6×27, right lang lay is 23.85% of the total footage. The second step using a DMS confirmed the information assembled during the first step and illustrated how dominance of a hoist rope is reduced when characteristics are paired.

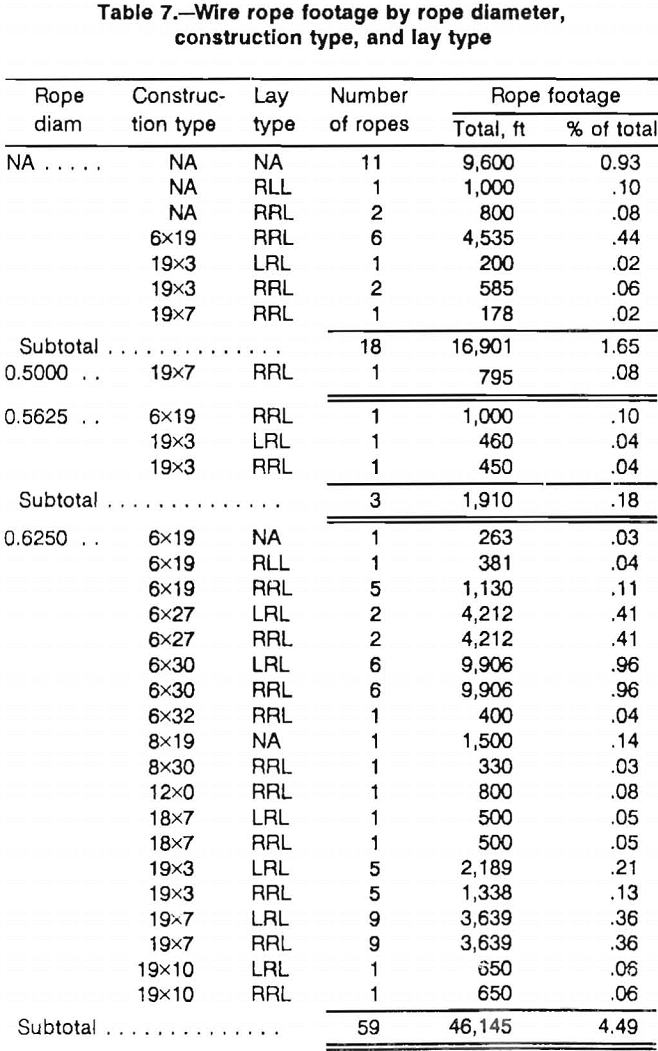

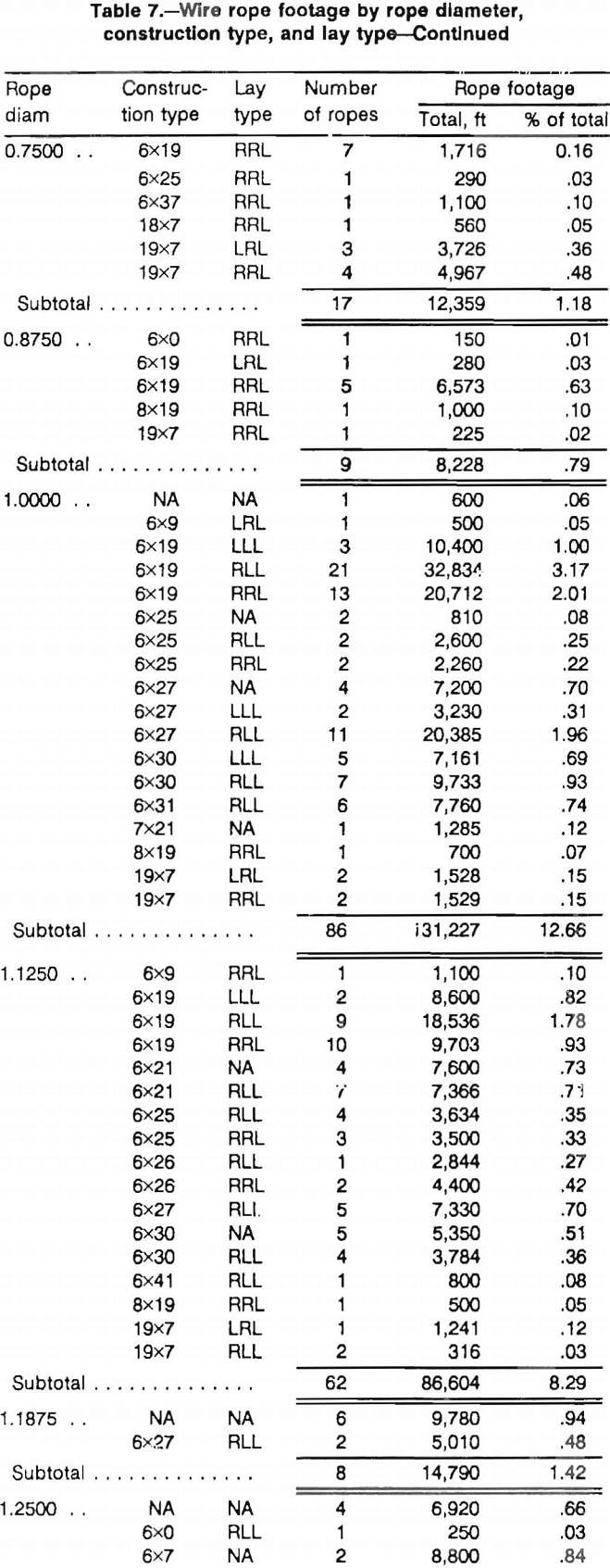

Finally, all three characteristics were considered together. The data are displayed in table 7. Again, a DMS simplifies this task. The earlier data were verified. But, once again, the total footage is reduced. Ropes with the combination of 1-¼ in, 6×27, right lang lay characteristics represent 5.25% of the total rope footage for hoisting in use in U.S. mines.

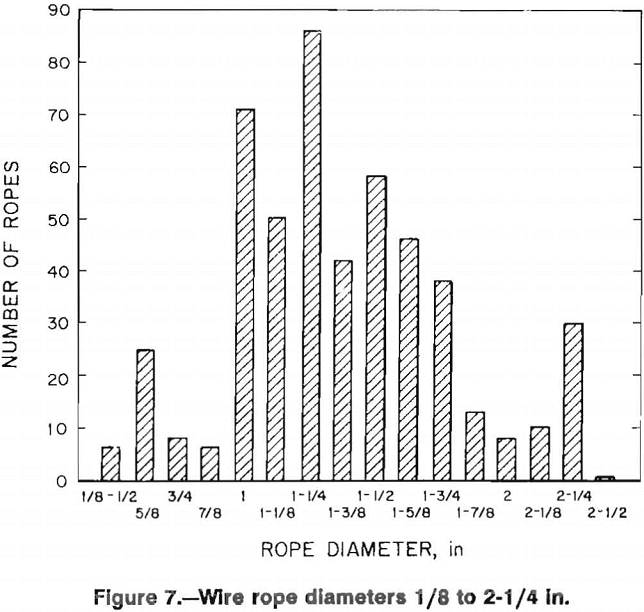

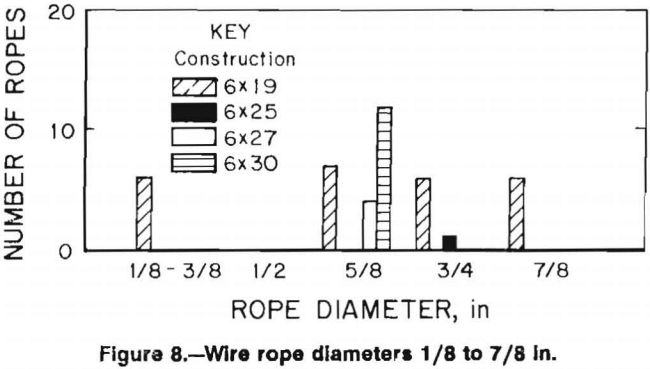

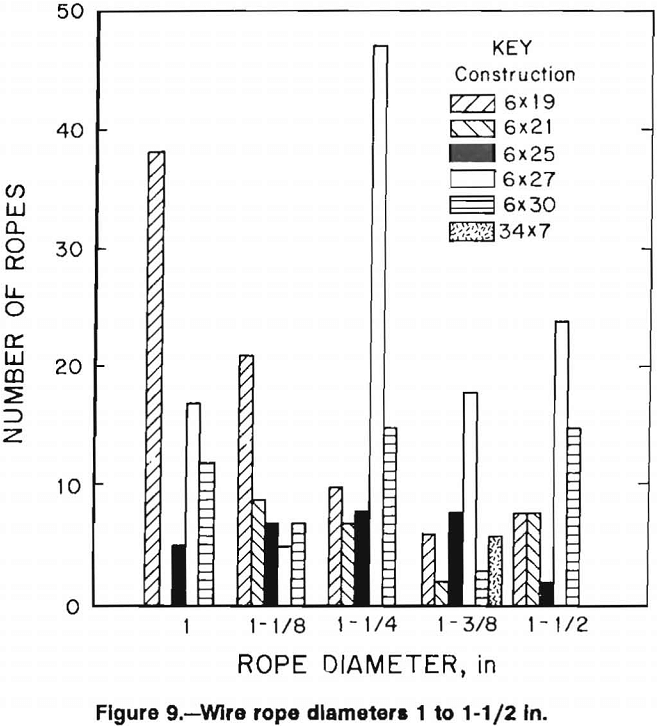

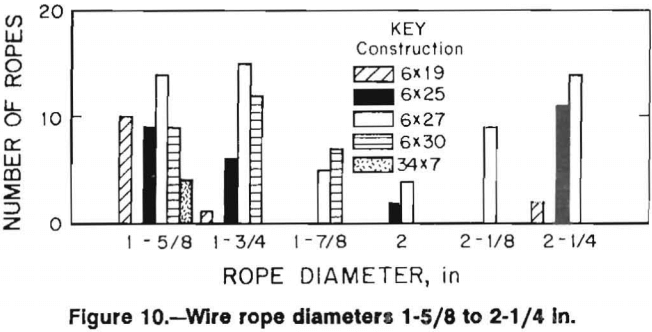

The total number of ropes at each rope diameter contained in the MSHA data is illustrated in figure 7. From this figure, many of the ropes have diameters between 1 and 1-¾ in. Furthermore, it is graphically displayed in figures 8, 9, and 10 how each rope diameter is divided into its prevalent construction types. The graphs only display ropes with the combination of diameter and construction totaling at least 1% of the total footage or has a diameter that is a multiple of 1/8 in. About 80% of the MSHA hoist inventory for rope footage is incorporated in figures 7 through 10.

A more detailed listing of data is provided in the appendix, which is arranged by rope diameter, construction type, and lay type for individual mine information reported by MSHA.

Conclusions

The data analyzed in this report deal only with data presented in the MSHA data base. The small percentage (5.25), representing the largest footage of ropes and containing the three characteristics of 1-¼ in diam, 6×27 construction, and right lang lay, reflects the data base. Information pertaining to ropes for specific mine applications should be made after careful evaluation of rope properties produced by the manufacturers. No attempt is made in this report to generalize rope properties.

A DMS is a powerful computer tool for extracting, organizing, and correlating large amounts of information. A DMS is useful for analyzing specific data contained in a large volume of data. Information from other sources can be combined for additional analyses.

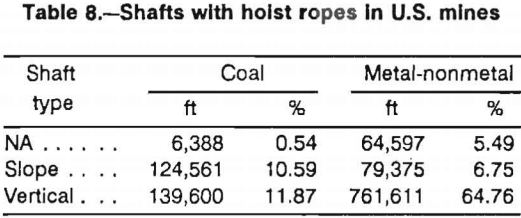

The total rope footages contained in the MSHA data base do not necessarily represent the total rope footage used at a mine. For hoisting ropes, mines are categorized as having slope or vertical shafts. The slope shaft rope footage accurately accounts for rope footage. The footage reported for vertical shafts may not be totally accurate. Vertical mine shaft footage is measured from the surface to the loading level. This footage does not include the rope used from the head sheave to the drum and dead wraps. However, increasing the amount of wire rope to account for the hoisting system would not alter the prevalence of wire rope usage. The percentage of mines in the United States that are vertical and slope is illustrated in table 8.

Summary

Analyzing wire rope data by individual characteristics could lead to the erroneous conclusion that one type of wire rope used in U.S. mines for hoisting is dominant. However, when characteristics are combined, the information yields a different conclusion. Although one set of characteristics is greater than all other combinations, the use of wire rope varies widely, with no dominant combination. As indicated, a 1-¼ in, 6×27, right lang lay rope combination is greatest, but only represents 5.25% of the total footage.

A DMS is most useful in handling large amounts of data and extracting and organizing the information. This report is concerned only with the rope parameters of diameter, construction type, and lay type. However, by using a DMS with the data base information supplied by MSHA, it is possible to correlate mine data by factors such as the State and county of the mine location, the depth of the mine, and the type of mine. Examples of other information obtainable with a DMS using the MSHA data are (1) all mines that are greater than 1,000 ft in Colorado, (2) vertical shaft mines and slope mines, (3) mine operators from any State or county, and (4) MSHA number and page number so that the original files can be searched. Other useful information can be generated with a DMS by performing mathematical calculations, such as determining sheave diameter to rope diameter (SD/RD) or drum diameter to rope diameter (DD/RD) ratios. Also, all of the data on the MSHA report plus any calculated data can be stored in a file. No attempt is made in this report to correlate the MSHA data with data from other sources, such as diameter versus breading strength or shaft depth versus life expectancy. No correlation is made to relate the type of rope to safety factors. Each manufacturer produces different properties in their ropes. Specific manufacturers should be consulted to determine fitness for service of their particular rope.