The response of feldspar flotation to tallow diamine dioleate collector in the presence of sulfuric acid is studied using, batch flotation experiments. Application of this non- hydrofluoric acid (non-HF) reagent system in the flotation of mineralogically and chemically different feldspar ores is compared with that of the conventional hydrofluoric acid system. The dependence of flotation recovery and concentrate grade on feed particle size distribution, conditioning time, pulp density, and pH, combined variation of collector and acid addition rates, sodium hydroxide concentration in the collector solution, and initial pulp pH prior to conditioning is studied. The results have been discussed in relation to applicability of the non-HF system to plant trials, and the nature of the collector adsorption in the selective flotation of feldspar.

Reagents and Test Samples

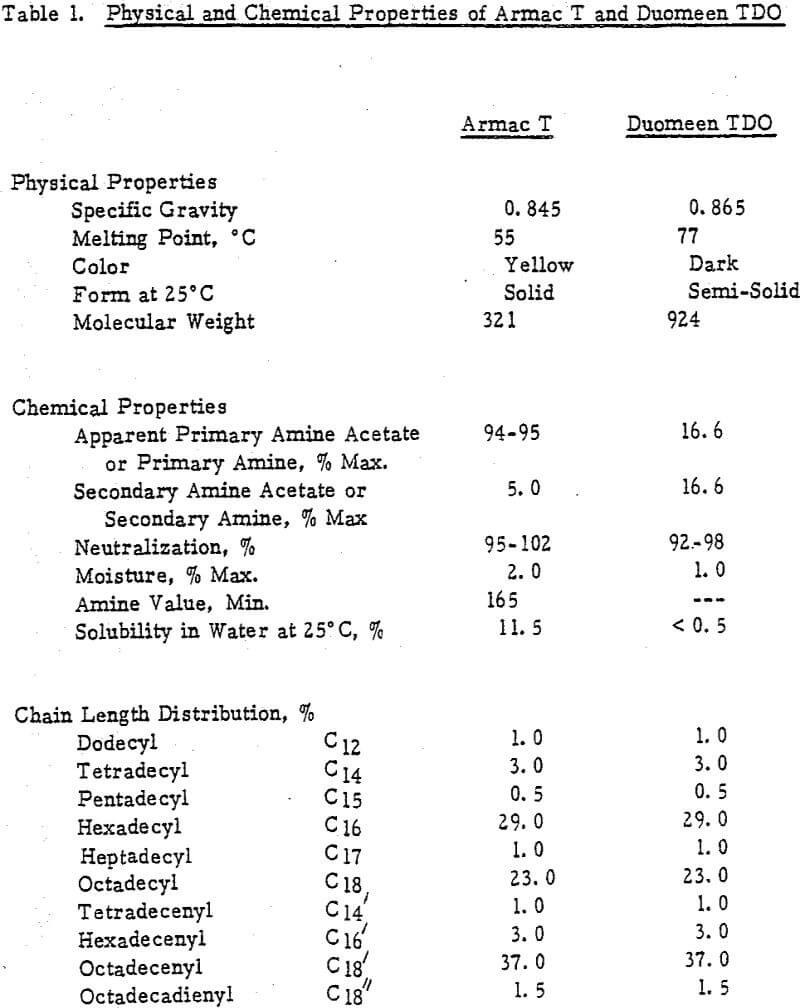

In the experimental investigations the following reagents were used: industrial grade collectors- Duomeen TDO and Armac T, and acids hydrofluoric and sulfuric. Both Duomeen TDO and Armac T are manufactured by Armak, Industrial Chemicals Division. Armac T is a typicallly used collector in the presence of hydrofluoric acid in the conventional flotation of feldspar.

Since Duomeen TDO is not soluble in water, it is dissolved by heating water to approximately 50° C, adding sodium hydroxide to raise pH of water to 10.0-11.0 and then adding Duomeen TDO to makeup 2.5 or 5% solution, followed by thorough agitation. Approximate proportion of sodium hydroxide to solubilize the reagent is 2-4% by weight of Duomeen TDO. In most of the experiments, an alcohol type frother, such as Aerofroth-65 was used. Occasionally, a polypropylene glycol type frother, H-26, was used interchangeably. The H-26 frother is marketed by Hunt Chemicals, Marion, North Carolina.

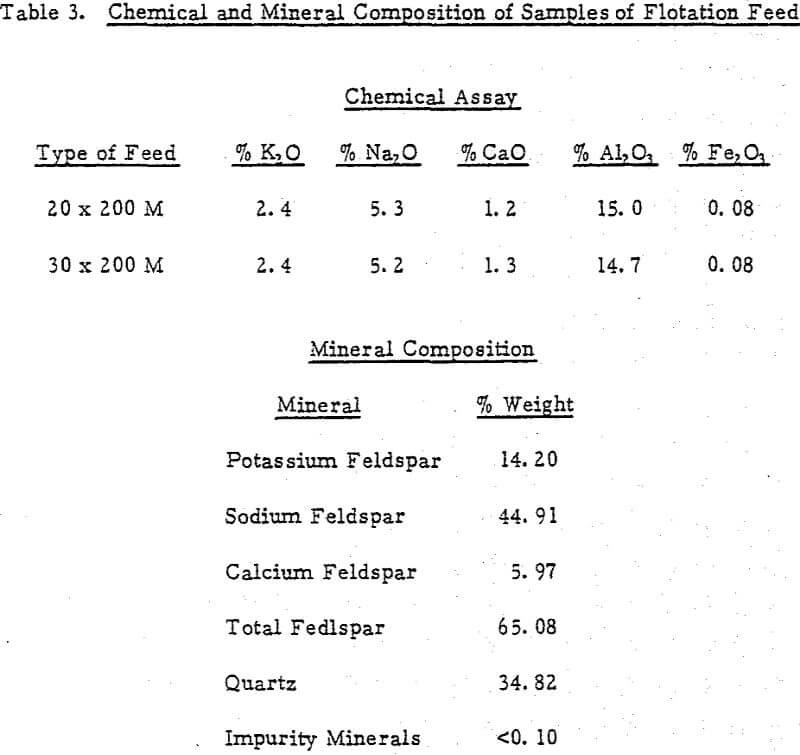

The bulk sample was collected from the Lawson United Feldspar and Minerals Company mill at Spruce Pine, North Carolina. This bulk sample was collected before the pulp entered feldspar conditioner circuit . In other words, from this material, mica and iron minerals were already floated, and the remaining pulp was ready for conditioning and flotation of feldspar. The bulk sample was washed thoroughly in tap water to remove traces of collector and acid coating on the particles and stored wet until it was used for experimentation.

Experimental

All the reagents were introduced to the conditioner as 2. 5% solutions prepared by using Asheville city water. The following steps were involved in the flotation procedure.

Conditioning of each sample was carried out in a 1000 ml beaker using a 4- bladed, 6.25 cm wide impeller at 700 rpm for desired length of time (normally 5 minutes). The pulp density, unless otherwise mentioned, was adjusted to 50% solids, the reagents collector and acid, added to the pulp, and conditioned. The order of addition of reagents to the conditioning pulp was not found to be critical as long as there was not too much time lag involved between the addition of the two reagents.

Flotation of feldspar was conducted in a 500 g Denver laboratory flotation machine at 1200 rpm, 20-25% solids. Flotation pH was not adjusted and flotation was carried out until there were no more particles in the froth. Normally, flotation time was 1.5 to 2 minutes.

Results and Discussion

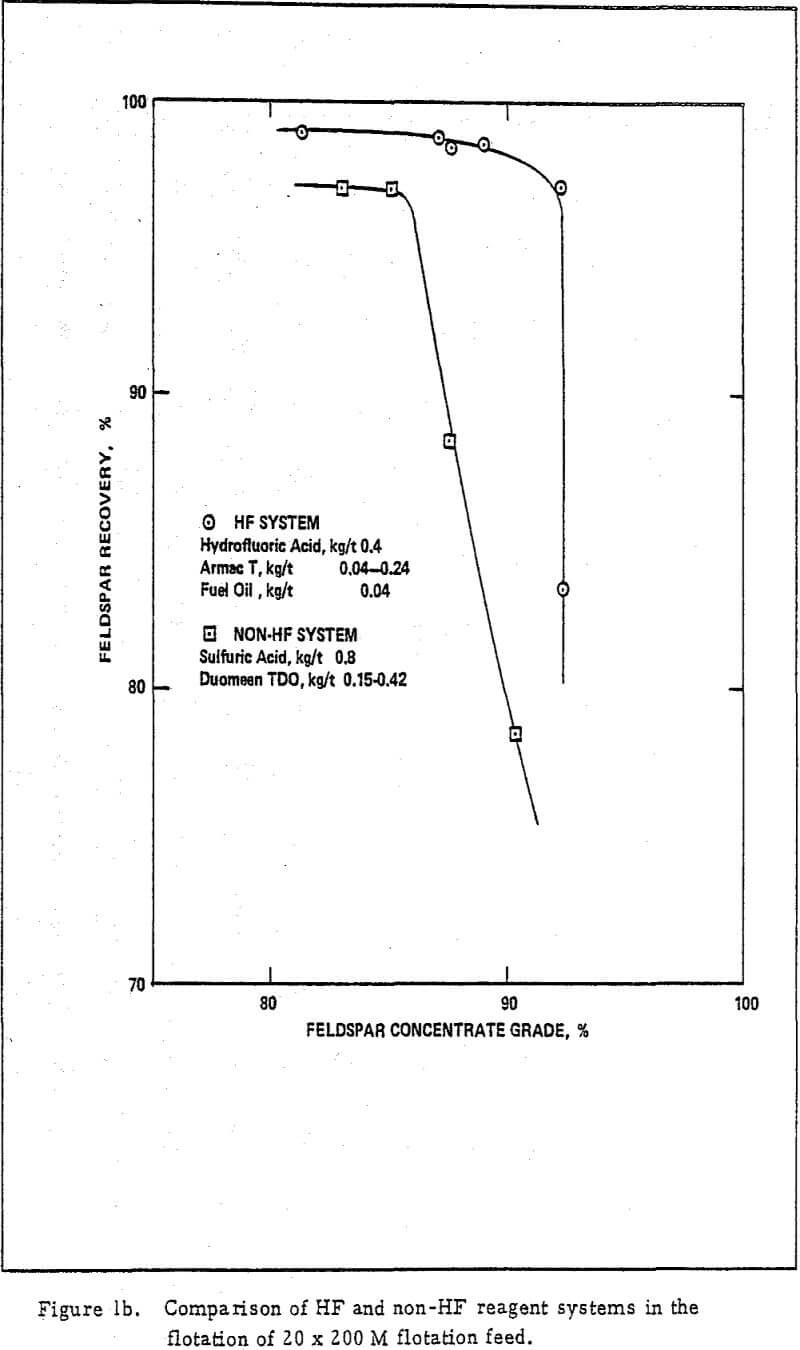

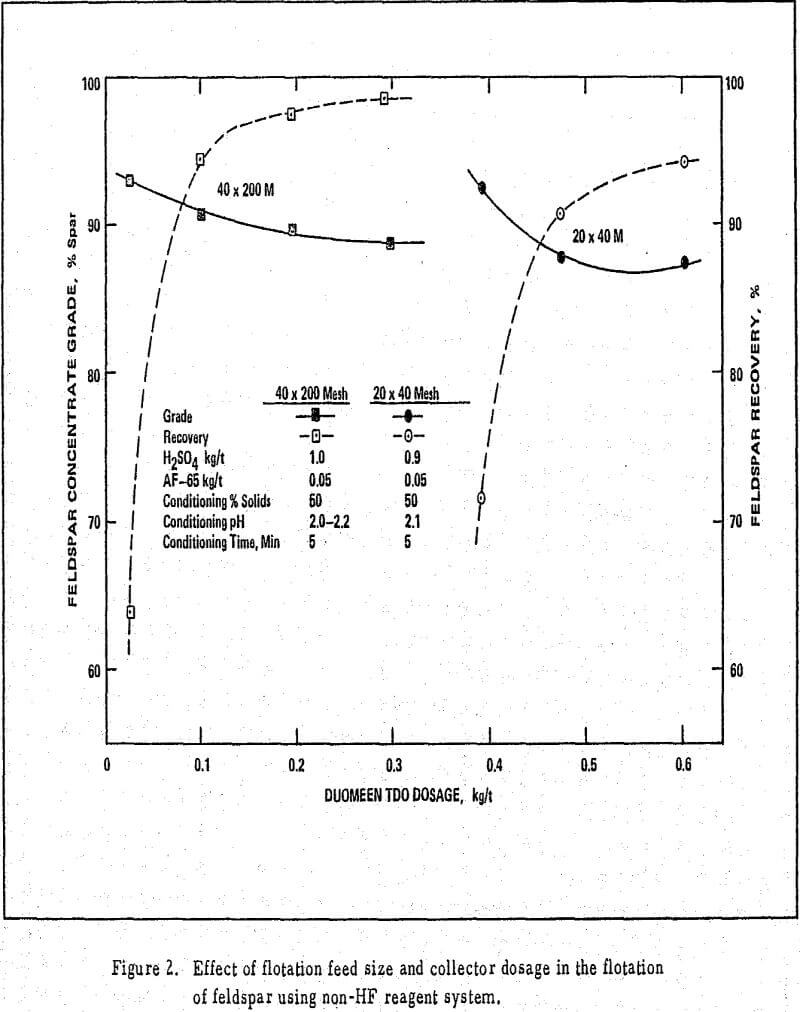

The feldspar rougher concentrate grade, quartz tailing grade and recovery of feldspar were excellent in the non-HF tests. In general, tests on other ores indicated that recoveries obtained from the non-HF system were 2-3% lower than that obtained from the HF- system. The fact that recoveries of feldspar in the non-HF system were lower, was attributed to inability of the non-HF system to float coarse feldspar particles. A part of the problem may be attributed to non-liberation of feldspar, and to non-flotation of middling particles that contain only a small proportion of feldspar. In fact, this was one of the reasons that forced us to examine the non-HF system thoroughly and understand its limitations.

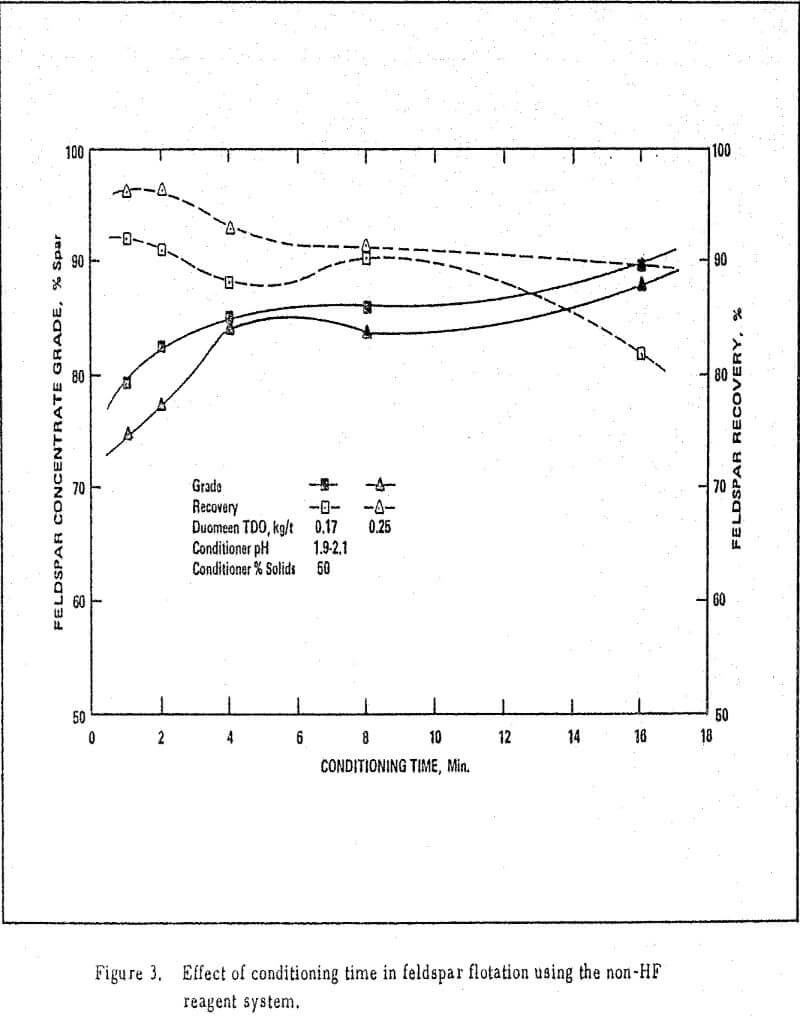

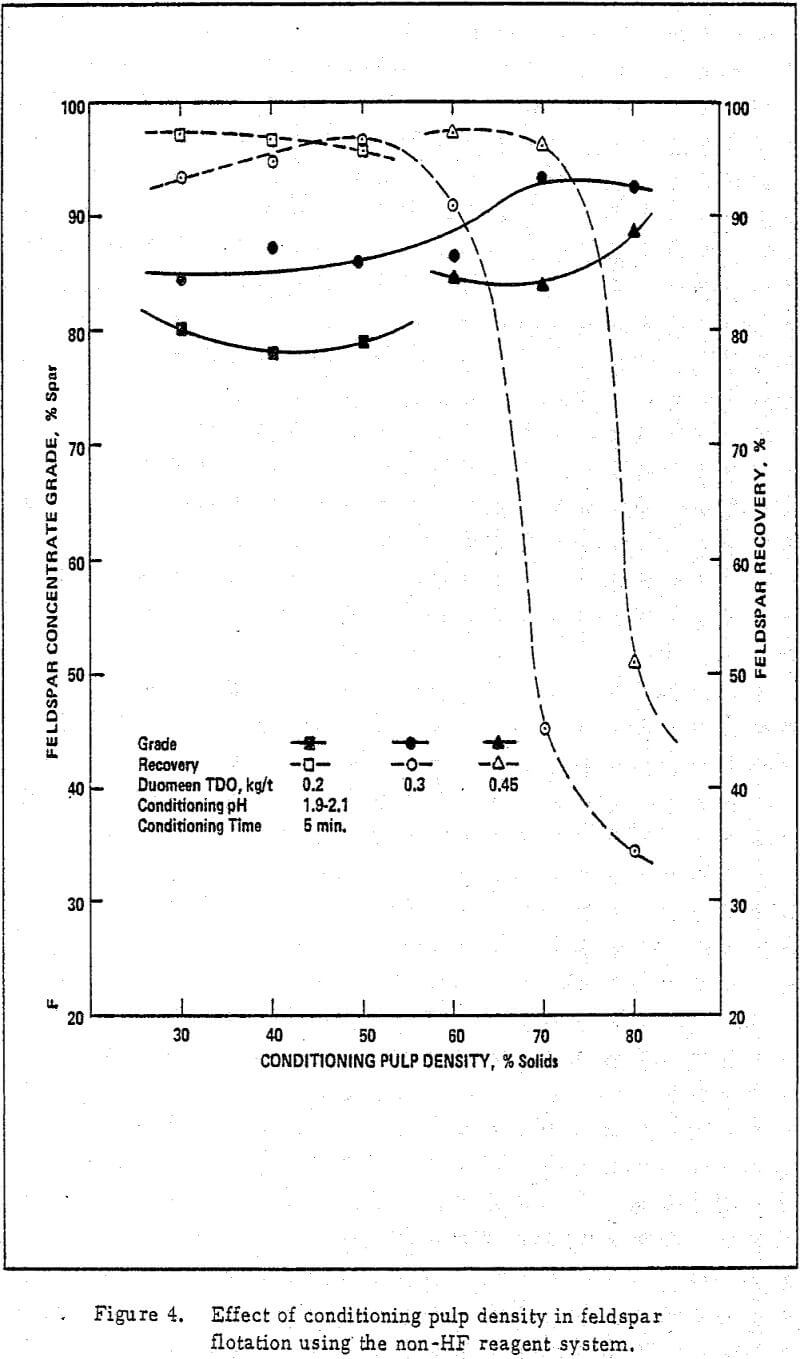

In the following tests on the effect of process parameters, when using the non-HF reagent system, only rougher flotation was conducted to maintain uniformity of results. If the cleaner flotation were to be carried out, feldspar concentrate grade could be improved by 5-9 percentage points at the cost of 1-2 percentage points recovery, due mainly to dropping off of entrapped quartz particles. Also, it should be noted that the following tests have been primarily concerned with the study of effect of conditioning parameters on feldspar recovery.

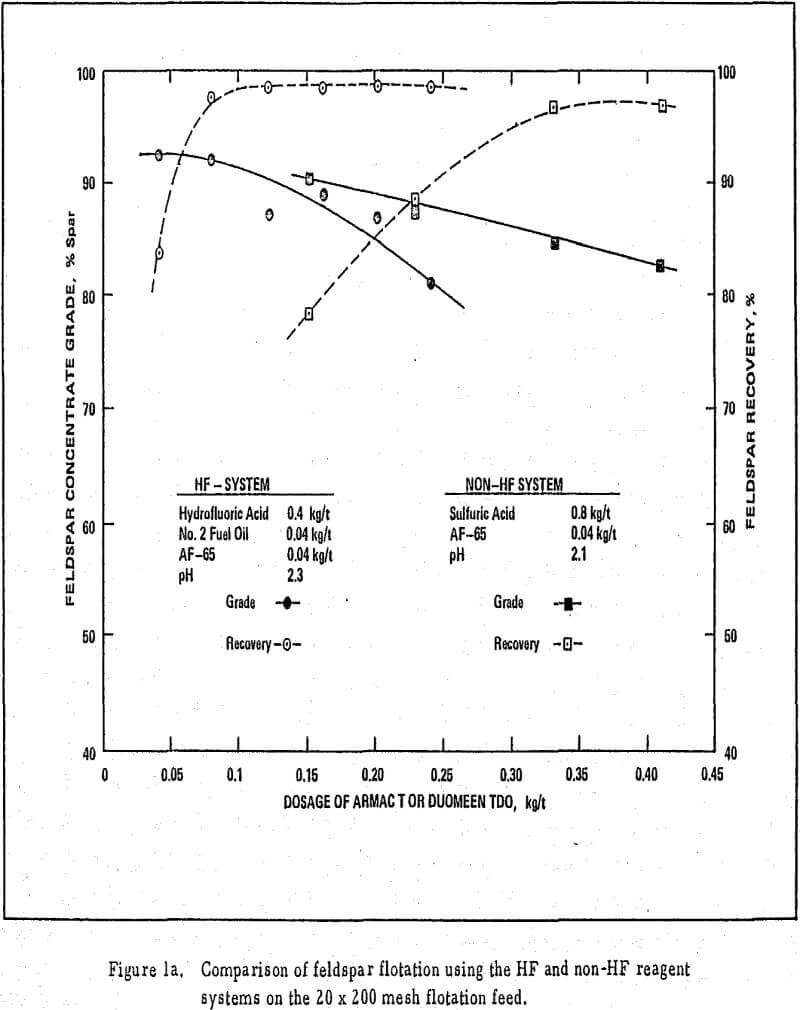

Batch flotation experiments were conducted on 20×200 mesh feed using both the non-HF and HF reagent systems in which the collector addition rate was varied over a wide range by keeping conditioning pH (acid addition rate) at a constant level. Another noticeable feature was the requirement of a large dosage of Duomeen TDO and a limited range of collector addition rate over which concentrate grade and recovery of feldspar were acceptable. It appears that floatability of feldspar from quartz and particle size are interdependent.

In a series of batch flotation experiments, the effect of conditioning pH was investigated by keeping Duomeen TDO addition rate constant. Three levels of Duomeen TDO addition rates were included in the study. In the lower pH levels, up to approximately pH = 2.0, the influence of conditioning pH was almost negligible. Beyond the pH = 2 level, selectivity towards feldspar was reduced. As a result, the feldspar concentrate grades decreased and recoveries increased.

In a series of experiments, the effect of combined variation of Duomeen TDO and sulfuric acid dosage in conditioning was studied. Addition rate of both the reagents was varied in steps of either 12. 5% or 25% from the normal range. It was not until the reagents addition rate changed to approximately ±25% over the normal range that the grade of feldspar concentrate started changing.

Pilot plant experience with the non-HF system has indicated that long residence times in highly acidic circuits prior to conditioning with non-HF reagents system was adversely affecting feldspar recovery, and Duomeen TDO consumption was increased. In order to investigate the effect of initial pulp pH, a series of flotation tests was conducted by preconditioning the pulp for one minute at a constant pH, and then adding Duomeen TDO and sulfuric acid, and conditioned for another five minutes at 50% solids, 2.0-2. 2 pH. Flotation of this pulp was conducted in the usual manner. Results of these tests demonstrate that preconditioning the pulp below pH 3 and above pH 7 adversely affected feldspar recovery. In the range of pre-conditioning pH 3-7, recovery of feldspar and concentrate grades were practically unaffected.