In 1955, before planning an accelerated stripping program, Chino Mines Div. began an engineering study to improve data for estimating truck haulage costs for any future haulage layout. The study aimed to develop: 1) significant unit costs, 2) a method of estimating travel time from which truck needs and future stripping rate could be determined, and 3) yardsticks of performance to measure haulage efficiencies.

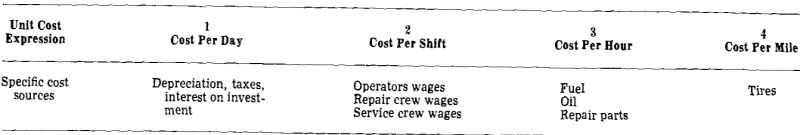

For yardstick purposes, the unit cost expression in this table is considered constant for a given level of efficiency as explained by the following analysis:

- Daily costs, or fixed annual costs, are costs of depreciation, taxes, interest on investment. These are fixed for a given fleet.

- Shift costs, or costs per operating day, are those resulting from the standard shift assignment of crews for operating, repairing, and servicing the truck fleet.

- Hourly operating costs include costs that result from operating the fleet. They are affected by operating delays and to some extent by duration of haul.

- Mileage costs for equal road surface conditions do not vary, since tire wear depends on ground contacts and is therefore a constant cost per mile.

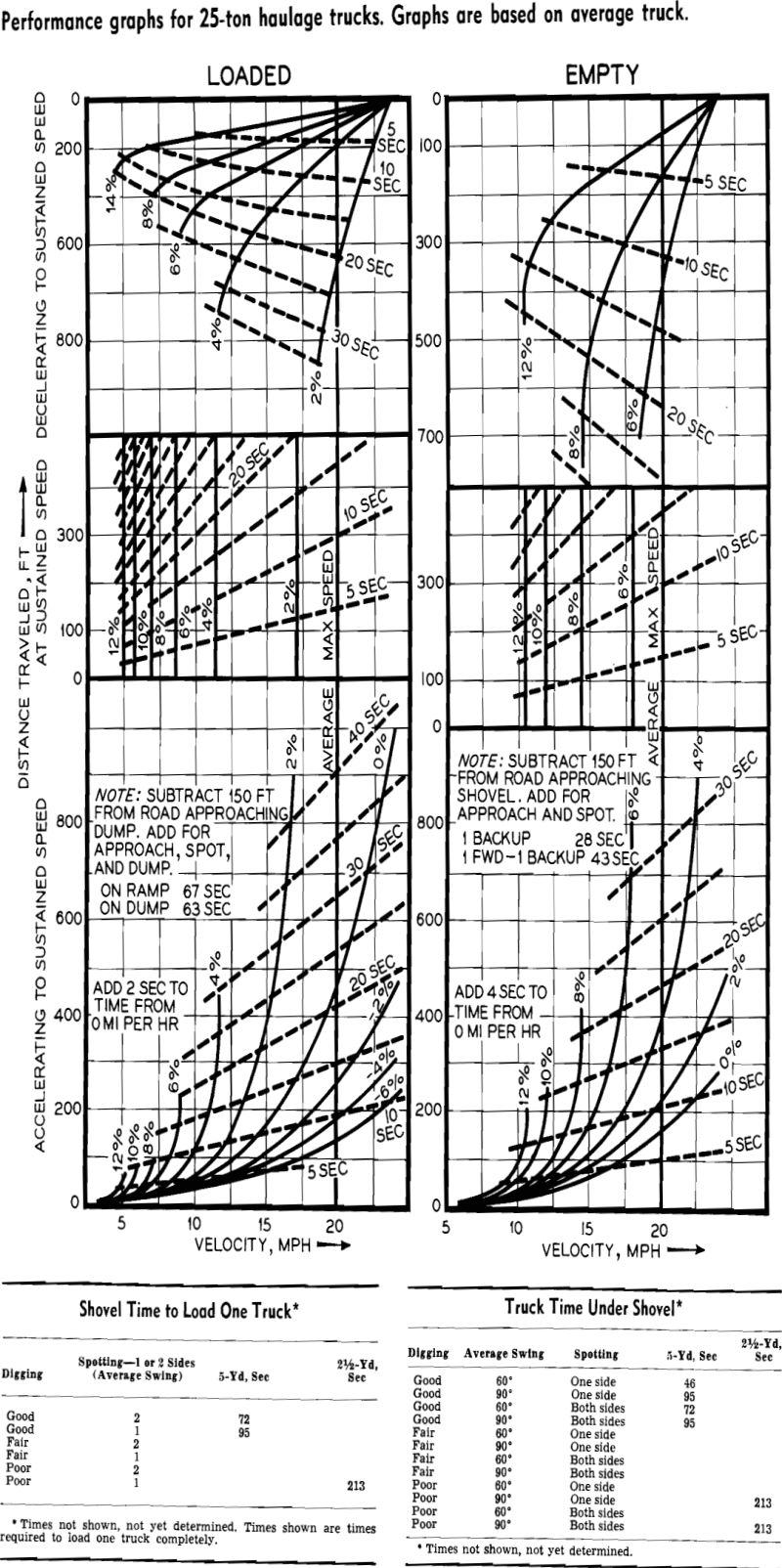

(Instructions numbered to correspond with the parts of the estimating sheet)

- Determine the expected loading and hauling conditions.

- Determine the total truck cycle time by determining the time for each travel element of the trip.

- Determine the time that the truck is under the shovel from the accompanying table, “Truck Time Under Shovel.”

- The number of trucks required for a given operation is determined by dividing the shovel time to load one truck into the total truck-trip time.

- The expected tonnage per shift is determined for two conditions:

a. When there is a fraction more trucks than needed to cover the shovel based on total available shovel operating time, time required to load one truck, and tonnage per truck-trip.

b. When there is a fraction of a truck less than needed to completely cover the shovel based on total truck-operating time, time per truck-trip, tonnage hauled per truck-trip, and the number of trucks in operation.

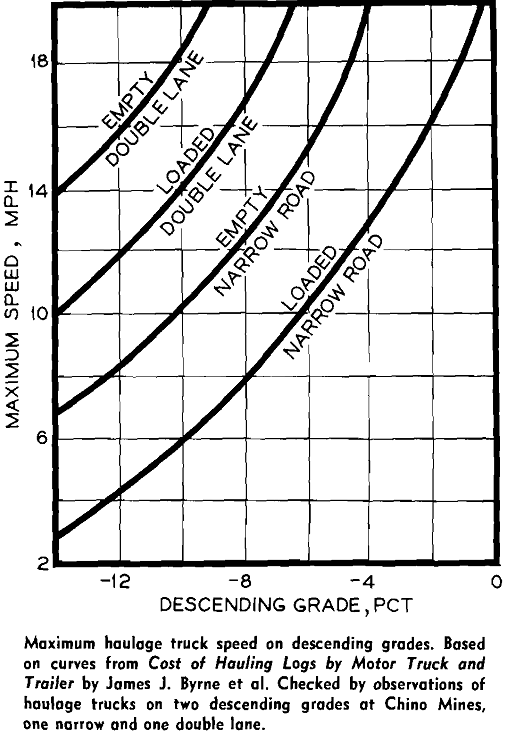

The trip time for a haulage layout must be known before the number of trucks required and the resultant truck haulage costs can be estimated. Total trip time is the time required for the sum of the following separate operations: loading, travel loaded, spotting and dumping, travel empty, spotting at the shovel, and delay time. Time study is used for determining the time required for loading, spotting, and dumping, spotting at the shovel, and delays.

Related: Best Lightweight hand carts