Table of Contents

This report will be given in two sections. The first section outlines techniques and equipment to form almond shaped fluorspar briquettes by means of briquet presses, and the second section outlines techniques of the balling disc.

Briquet Presses

Fluorspar has been briquetted for a number of years and the so called “peach pit” briquet is known to many steelmen. Present production is estimated at over 100,000 tons annually. Slide 1 shows an assortment of various sizes and shapes of briquettes. It is possible to form fluorspar into almost any configuration of briquet. For safety on the melting floor, pillow type briquets are preferred. Ease of mechanical handling and durability of the product are facilitated by an almond shape. The dimensions of the almond can vary from 1-in. to 1-½-in. in length, from 13/16-in. to 1-in. in width and from ½-in. to 1-in. in thickness.

A wide variety of pillow shapes are available. Briquet presses can be supplied that permit changing from one size briquet to another. Since steelmen prefer different briquet shapes, the product can be changed simply by changing the briquet dies thus allowing one machine to supply several mills. Briquetting of fluorspar is accomplished at room temperature with the use of a binder or at elevated temperature without the use of a binder.

A number of substances other than fluorspar have fluxing properties in steel making applications. Considerable work was done during World War II in order to find a fluorspar substitute. When spar became available after the war much of this work died out. Interest in these materials is being revised as good grade metallurgical fluorspar is becoming increasingly difficult to obtain.

Disc Process

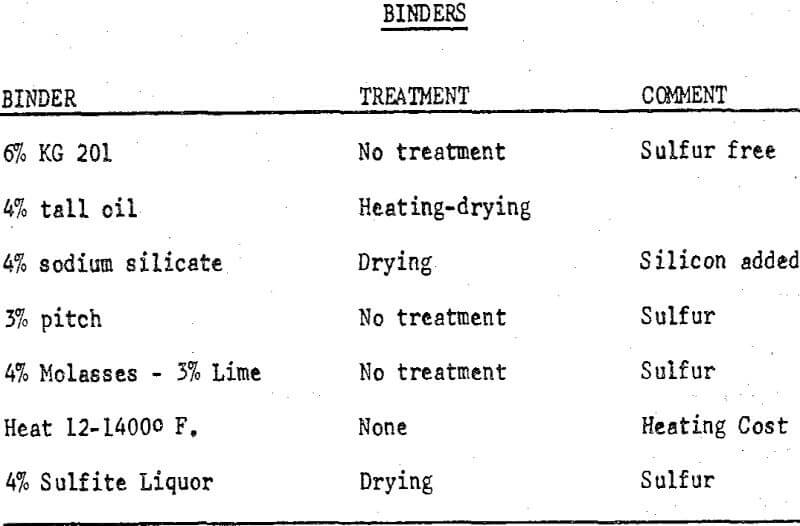

This report traces the development of the fluorspar (calcium fluoride) pelletizing process now in use at the Fluorspar Division of Minerva Oil Company, Cave-in-Rock, Illinois, Starting with a fluorspar flotation concentrate of 70 to 75 per cent minus 325-mesh size, a hard, high-purity pellet is produced. The process is somewhat unique, and there was little prior record of pelletizing techniques to guide in the development of the process. Sodium silicate is used as the balling agent, and induration is at a temperature of about 600° F. The fluorspar pellets are particularly adapted to use in the basic oxygen furnace.

A major factor in developing a process for pelletizing was the decomposition of fluorspar, with resulting evolution of fluorine, at temperatures starting about 1600° F. below the point where bonding would occur by incipient fusion. A further consideration was that the small tonnage to be pelletized would not justify the large expenditure required for high-temperature operation, as in iron ore pelletizing. For these reasons, it was necessary that the pellets be cured at a relatively low temperature with the balling agent functioning as the binder. Sodium silicate (41° Be water glass) was found to meet all the desired specifications, and it was relatively inexpensive.

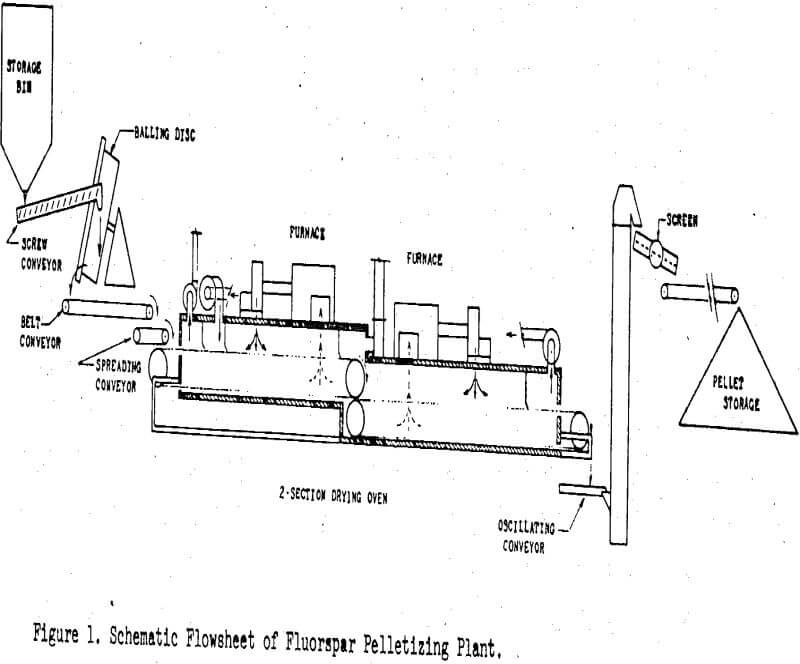

Production Plant

The feed is a flotation concentrate practically free of all sulphides or elements harmful to steel production. The optimum particle size of the feed is between 70 and 75 per cent minus 325-mesh, with 20 per cent of the fine particles in the minus 10-micron range. Optimum size of the flotation concentrate is maintained by wet grinding in a ball mill, operating in closed circuit with a cyclone classifier.

The pelletizing pan or disc is 8-ft in diameter by 2-ft deep, with a 9-in. reroll lip welded on the periphery of the pan. The pan is designed to operate at a slope variation from 45° minimum to 65° maximum from the horizontal, and at speeds from 10 rpm to 30 rpm. The size of the pellets is varied by a combination of slope and speed adjustments. With a 55° slope the size of the pellets can be maintained at 3/8-in. to 5/8-in. by changing only the speed of the pan.

The results have been satisfactory, although alterations to the drying and curing oven are planned. The present oven grate is in two 30-ft sections, and in dropping from the first section to the second section some breakage of the partly dried pellets occurs.