As the electrolytic plant of this company operates at a current density of approximately 35 to 40 amperes per square foot when running up to capacity, the arsenic and antimony content of the anodes delivered to the plant is of considerable importance as bearing on the purity of the refined cathodes turned out.

Owing to the rather high relative percentage of antimony, it has always been the custom to determine antimony as well as arsenic in all forms of copper. Thus, anodes have been analyzed in which the antimony was about equal to the arsenic, although the average shows about 2 parts of arsenic to 1 of antimony. In the refined copper the relative proportions of the two impurities vary considerably, but probably in the average are about equal. In this latter case, the percentage of the two is so small that ordinarily no attempt is made to separate them, the report of analysis showing percentage of As and Sb combined.

Although rapid and exceedingly accurate determinations of arsenic may be made by means of various distillation schemes, the determination of antimony, either by itself or together with arsenic, has always been more or less cumbersome and has required a considerable amount of time. By the methods, details of which follow, the determination of arsenic and antimony, either separated as in the case of anodes or together in case of refined copper, is accomplished in 24 hr. from the time the sample is received by the chemist.

As to the accuracy of the results obtained, it can be quite positively stated that in this respect these methods are very satisfactory, much more so than any heretofore employed in our work, and when the rapidity of determination is considered, the results are very accurate.

Arsenic and Antimony in Converter Copper

Treat 10 g. of the sample in a No. 5 beaker with 30 cc. of sulphuric acid, 20 cc. of nitric acid, and about 50 cc. of water. When solution is complete, heat to boiling to drive off all red fumes, add water to fill beaker about two-thirds and electrolyze about 2.5 hr. at 4 amperes.

The copper is deposited on a large platinum gauze cylinder cathode having the following dimensions : height, 3 in.; diameter, 3 in. The gauze is made of wire 0.0085 in. in diameter and has 36 meshes to the inch. To strengthen the cathode, supporting rings of platinum wire 0.005 in. in diameter are provided at top and bottom. The precipitation is continued until the solution contains about 0.25 g. of copper. It then has a faint blue color. A little experience teaches the proper point at which to remove from the battery. The cathode is rinsed with a little water from the jet when removed from the solution.

The acids are now neutralized with ammonium hydroxide and the solution made acid with hydrochloric acid with 2 or 3 cc. of the acid in excess. Pass a rapid stream of hydrogen sulphide about 30 min. and allow the precipitated sulphides of copper, arsenic, antimony, etc., to settle about 30 min. Filter through a 12.5-cm. paper (C. S. & S. No. 597) in a 3-in. smooth funnel. Discard filtrate. Wash precipitate once on paper with water and then wash sulphides into No. 3 beaker with very smallest possible amount of water. Instead of No. 3 Griffin shaped beaker it is much better to use a No. 5 tall, usual form beaker, as the subsequent evaporation may be carried out much faster without loss by spattering. The beaker containing the sulphides is placed under the funnel and the small amount of sulphides still adhering to the filter is dissolved with 25 or 30 cc. of hot aqua regia poured carefully around the edges of the paper. It is usually well to pour about 10 cc. of this aqua regia into the original No. 5 beaker and transfer from there to the paper, as sometimes a film of antimony forms on the bottom of this beaker. In order to prevent too great action of the aqua regia on the filter paper it may be diluted about one-quarter with water. The whole must, however, be very hot to attack sulphides on paper. Wash No. 5 beaker and paper with a small amount of water. At this point it is of great importance to keep the solution as low as possible, consistent with good work, as any unnecessary solution means extra time to evaporate.

Cover the beaker containing the sulphides and aqua regia, boil about 25 or 30 min. to thoroughly break up the sulphides, remove the cover after washing with a small amount of water from a fine jet and rinse down the sides of the beaker with the fine jet. This should add very little to the bulk of the solution in the beaker. Continue evaporation to complete dryness at a temperature just high enough not to cause loss by spattering. The residue should smell “ sweet.”

Add about 4 or 5 g. of stick potassium hydroxide and 30 cc. of water and boil vigorously for 10 or 15 min. All arsenic and antimony will go into solution. Add 25 cc. of strong sodium sulphide solution (1 lb. of fresh mono-crystals to 2 liters of water) and again boil vigorously 5 or 10 min. Allow to cool, decant the clear liquid through an 11-cm. paper (C. S. & S. No. 597) into a No. 2 beaker, again add 25 cc. of the strong sodium sulphide solution to the black sulphides left in the beaker, stir well and transfer to filter paper, washing well with a jet of dilute sodium sulphide (1 lb. to 8 liters of water) from wash bottle. If the operator be sufficiently careful to keep the sulphides well wet on the paper, the above washing may be more conveniently accomplished with a jet of hot water. However, if the copper sulphide be allowed to dry, washing with water is liable to carry through some copper. A convenient bulk for the filtrate is from 150 to 175 cc. Add 5 cc. of good hydrogen peroxide and heat until the strong yellow color of the solution fades. Unless too much organic matter has been taken up by the action of too concentrated aqua regia on the filter paper, the solution should become nearly colorless. Cool and electrolyze over night at from 0.10 to 0.15 ampere. Antimony alone is precipitated.

In the morning remove the cathode, carefully washing the adhering solution which contains arsenic into a clean No. 4 beaker with a jet of water, wash in water and two changes of alcohol, dry carefully over an alcohol flame, and weigh for antimony. When the current is interrupted, the antimony coated cathode should be removed, washed, and dried with as much dispatch as possible, as the antimony is quite soluble in the sodium sulphide solution. The cathode employed for this deposition is an ordinary split, foil cylinder, one that has been roughened by long use.

Transfer the solution from the No. 2 beaker to the No. 4 beaker containing washings from the cathode. Make distinctly acid, using dilute sulphuric acid (1 part of H2SO4 to 4 parts of water). Pass a strong stream of hydrogen sulphide about 10 min. Allow to settle 20 or 25 min., and filter through 11-cm. paper. The arsenic is retained on the paper, finely divided sulphur, only, passing through. It is best to decant the partly clear liquid, only, through the paper. Transfer the heavy arsenic sulphide and sulphur with any accompanying solution directly to a No. 2 beaker. This is done with a jet of water. Now decant any excess water from the No. 2 beaker through paper and place this No. 2 beaker, which contains the arsenic sulphide, under the funnel. Dissolve the small amount of arsenic sulphide on the paper through into the beaker with dilute ammonium hydroxide (1 part concentrated NH4OH to 4 parts of water. It is best to wash down the sides of the No. 4 beaker in which the sulphides were precipitated with 10 or 15 cc. of this dilute ammonium hydroxide in order to recover any arsenic that may have adhered to the beaker. Then pour this washing from the No. 4 beaker around the edges of the filter paper, thus carrying any arsenic on the paper down into the bulk of the arsenic in the No. 2 beaker. Wash the No. 4 beaker and the paper with a small amount of water from the jet.

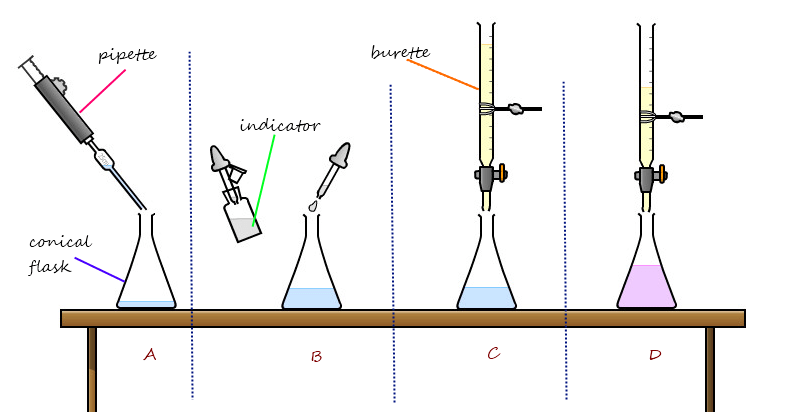

Make the contents of the No. 2 beaker acid with sulphuric acid and add 7 or 8 cc. in excess. Evaporate to sulphuric fumes at a temperature just high enough not to cause loss by spattering and then place on very high heat from 1 to 1.5 hr. Cool, wash the rim and the sides of the beaker down thoroughly with water, add water to half fill the beaker, neutralize the acid with ammonium hydroxide, make slightly but distinctly acid with hydrochloric acid, and filter through an 11-cm. paper into a No. 4 beaker, washing thoroughly with hot water. Add water to about half fill the beaker, neutralize the acid with sodium bicarbonate and add 3 or 4 g. excess. Cool to the temperature of the room, add starch solution, and titrate with standard iodine solution.

Titrating solutions

Starch Solution.—Make a thick emulsion of starch in 30 cc. of water by hard boiling and dilute to 200 cc. Cool, and use as desired. This solution should be made fresh each day.

Iodine Solution.—Dissolve 10.21 g. of iodine in 8 or 10 cc. of water with 17 g. of potassium iodide and dilute to 2 liters. Each cubic centimeter of iodine solution is equal to about 0.0015 g. of arsenic.

To standardize the iodine solution, dissolve 50 mg. of arsenic tri-oxide in about 30 cc. of water and 1 g. of potassium hydroxide, make acid with hydrochloric acid, alkaline with sodium bicarbonate, add 3 or 4 g. excess of the sodium bicarbonate, and titrate with the iodine solution after adding starch indicator.

In employing the above method for determining arsenic in converter copper, the arsenic should, in order to work most satisfactorily, be not lower than 0.04 or 0.05 per cent. When the arsenic is present in lower amounts it is well to use a charge of 20 g., in which case the original solution should be made in a correspondingly larger amount of the sulphuric nitric acid mixture, that is, from 90 to 100 cc. This mixture is made up in the proportion of 200 cc. of nitric to 300 cc. of sulphuric acid.

Arsenic and Antimony in Refined Copper

The lack of a short, satisfactory method for this determination has long been a source of much lost time and of delay to the management of this company. By the following scheme, results which are exceedingly reliable may be turned out in a very short time as compared to methods heretofore employed.

Dissolve 25 g. of the sample and 50 mg. of pure iron in a No. 6 beaker with from 85 to 90 cc. of nitric acid and about 75 cc. of water. When the more violent action ceases, heat gently until the copper is completely dissolved and then boil until all red fumes are expelled. Dilute to about 600 or 700 cc. with very hot water and make ammoniacal. The ammonium hydroxide should be added, with constant stirring, until all copper hydroxide is redissolved. The beaker should be well filled at this point, if necessary by the addition of hot water. Stir thoroughly to collect the ferric hydroxide. Boiling is not allowable, as the copper in ammoniacal solution is too liable to be oxidized. Allow to settle 10 or 15 min., this depending on the time at the disposal of the operator.

Filter through a 12.5-cm. paper, preferably No. 86 Dreverhoff, as this is a very fast paper, admirably adapted for filtering off ferric hydroxide. In this filtration there is a tendency for copper hydroxide to form as the solution becomes cold or is washed with too cold water. A little concentrated ammonia will redissolve this hydroxide at any time it may appear. In the event of any of the ferric hydroxide adhering to the sides of the beaker, it may be conveniently washed down with a jet of dilute hydrochloric acid, 1 part of acid to 1 of water, or weaker. This acid washing is made ammoniacal and poured on paper with the main precipitate. The main part of the blue color should now be washed out. If necessary, a little hot ammoniacal solution, 1 part of ammonium hydroxide to 1 part of water, poured around the edge of the paper, will greatly hasten this operation.

This ferric hydroxide precipitate, which contains all of the arsenic as ferric arsenate and all the antimony, probably as an ammonium antimoniate occluded by the voluminous iron precipitate, is dissolved through paper with 3 cc. of nitric acid and 5 cc. of sulphuric acid which has been diluted to nearly 50 cc. with water and heated to boiling. Wash well with hot water. It is well to reserve a little of the hot acid solution to pour around the edges of the paper after washing with water. If any yellow color should show in the paper, wash again with hot water.

All of the copper that has been held by the ferric hydroxide must now be removed by electrolytic deposition on a small platinum gauze cathode having the following dimensions: height, 2.25 in.; diameter, 1.5 in. This cathode, as employed in our laboratory, is constructed of 52 mesh gauze and has supporting rings of heavy wire at top and bottom. The gauze is made of wire 0.0040 in. in diameter.

The solution, containing the iron, arsenic, antimony, and a small amount of copper, is heated quite or almost to boiling and a current of 0.5 ampere is passed for 2 hr. After about 1.5 hr., the sides of the beaker are washed down with a jet of water. This is to redissolve and remove any copper that may have spattered up from the main solution. At the end of 2 hr., the beaker is removed as quickly as possible, in order to avoid any re-solution of copper. It is unnecessary to wash the anode and cathode, as the small amount of solution adhering thereto will have absolutely no effect on the result, while attempting to save this solution may ruin the determination by copper being dissolved from the cathode.

Now heat the solution, from which all the copper has been removed, to boiling to be sure of complete oxidation, render ammoniacal, boil to aid in settling of precipitate, and when well settled filter through a firm 11-cm. paper. Wash once or twice with hot water to remove nitrates. In washing iron precipitate both in this and in the original filtration, it is well to disturb the precipitate on paper as little as possible.

Dissolve the precipitate through paper with a jet of dilute hydrochloric acid, washing alternately with hot water and dilute acid until no yellow color shows in the paper when it is washed with acid. The dilute acid should be made up of about 1 part of concentrated acid to 4 parts of water. Add ammonia carefully and finally drop by drop until the solution is but very slightly acid. For best results in this neutralization and subsequent reduction the solution should be near boiling temperature.

The reduction may be effected by ammonium bisulphite or, as suggested in Lunge’s Technical Methods of Analysis, Vol. II., Part I., sodium hypophosphite may be used. In either case no more than is necessary to effect reduction of the iron should be employed. When ammonium bisulphite is used long boiling is necessary to remove excess sulphur dioxide, hence the necessity of extreme caution to avoid any excess of the bisulphite. However, if the hypophosphite be used no boiling is required and the solution may be transferred at once to the hydrogen sulphide supply. In either case, cool and pass hydrogen sulphide 15 or 20 min. Weigh sulphides the following morning. The sulphides are weighed on an asbestos pad in a platinum Gooch crucible. The pad is prepared of moderate thickness of the very best quality of asbestos. It is washed with alcohol, dried at 105° C., and after cooling in a dessicator for 15 min. the crucible containing the pad is carefully weighed. The sulphides of arsenic and antimony are filtered on to this pad and are very thoroughly washed with water to remove all ferrous and ammonium salts. Wash well with alcohol to remove all water and then with carbon disulphide. After washing with carbon disulphide, using about 20 cc., follow with a thorough washing with alcohol. Dry 1 hr. at 105° C., cool 15 min. in dessicator, and weigh again.

The weight of the sulphides multiplied by 2.4 will give the result directly in percentage of arsenic and antimony, providing 25 g. was taken for assay. This factor has been arrived at after a great deal of experimenting.