As a dealer of a top Brand of manufacturers of ovens and furnaces, well known in the mining industry for the design and production of custom-built equipment. Knowledge of this industry has enabled us to design an improved assay furnace. Technologically advanced, this furnace has several unique features which facilitate its use and assure results of the highest quality.

Our BEST SELLING assay furnaces:

- 1-year-warranty

- 24 crucibles (30 gram crucibles)

- Overall dimensions

40” W x 40” D x 76” H - Working space

14½” W x 22” D x 7½” H

ASSAY FURNACE FEATURES

Made of heavy gauge sheet metal, is specially formed to provide superior structural strength. The control panel is slightly recessed, providing protection for the electronic controls. All electric and electronic controls are grouped at the base of the furnace. These easy-to-read controls include:

- PB-6 electronic analogue temperature control, calibrated at our plant;

- PB-6 electronic over-temperature safety control, calibrated at our plant;

- one ammeter (1 phase) or three ammeters (3 phase);

- pilot lights and switches;

- security compactors.

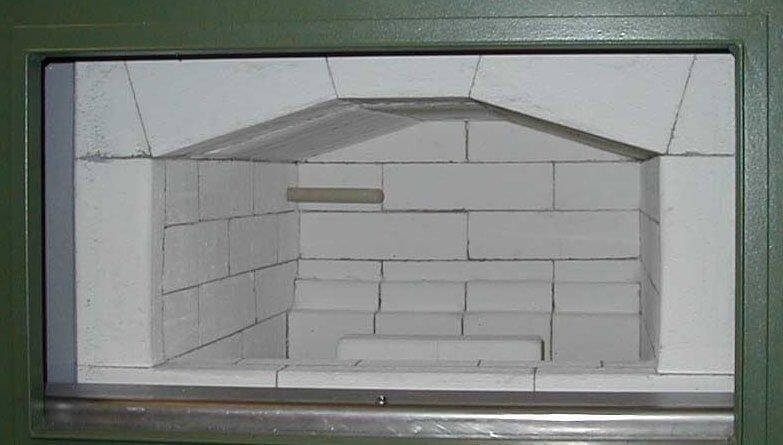

HIGH QUALITY REFRACTORY BRICKS

- Refractory brick ensure excellent insulating properties, resulting in reduced heat-up time, increased temperature uniformity and lower production costs.

- The materials used in the construction of the treating chamber offer excellent protection against corrosive emanations that may result from the process.

- The guillotine-type door is counter weighed and opens from top to bottom. The operator of the furnace may open the doors slightly with minimum heat loss and minimum amount of fresh air filtering into the chamber.

- The door is easily opened by a short rotation lever, which can be installed on either side of the furnace.

A wide door vent made of stainless steel is contrived into the furnace door. Its location permits an ideal view of the inside of the chamber, especially the top of the cupels.

At the proper moment, opening of the vent enables fresh air to come in contact with the top of each cupel, providing excellent oxidation. The high quality results of this procedure are attributable to a thorough study of the fresh air circulation and ventilation in the chamber.

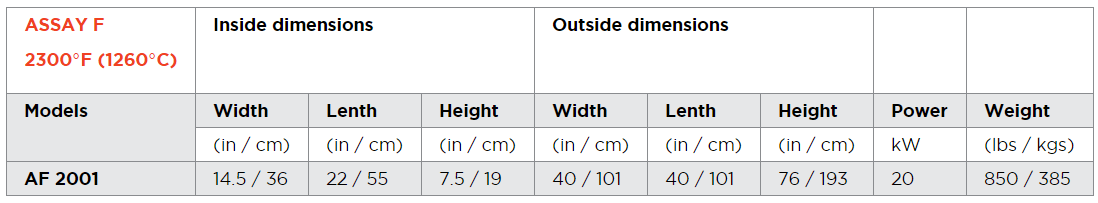

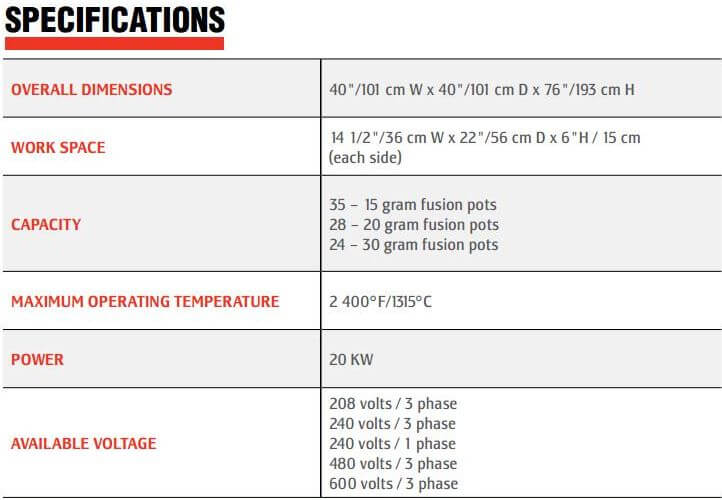

ASSAY FURNACE DIMENSIONS

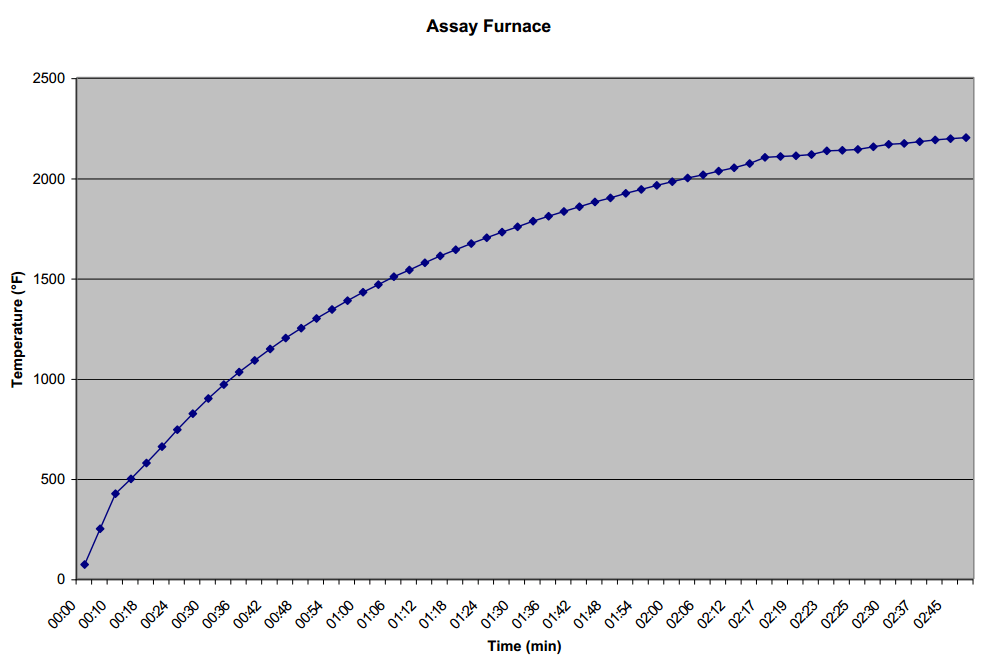

ASSAY FURNACE HEAT CURVE PROFILE

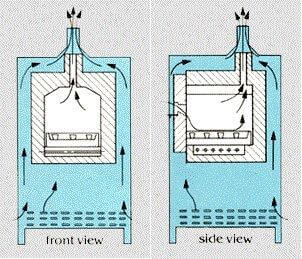

Furnace’s Heat Treating Chamber is completely independent from the furnace casing, ensuring better ventilation of the electrical connections for increased reliability.

This characteristic, coupled with superior insulation, enables the furnace casing to remain cool, keeping the room where the furnace is installed at a comfortable temperature year-round.

A drawer is installed beneath the door, allowing the operator to clean the hearth plate without soiling the lab floor. Process residue is swept towards the front of the plate and falls into the drawer, which can be quickly emptied.

An access door on each side of the furnace permits easy replacement of elements and thermocouples. This operation may be executed without displacing the furnace’s insulation.

A Silicon Carbide Hearth Plate is solidly held in place by a support contrived in the refractory brick. Resistant to wear and corrosion, this plate allows uniform distribution of heat.

Removable slides facilitate installation of the hearth plate, avoiding accidental damage to the elements.

A Venturi-type chimney, extending from the vault of the heating chamber, enables complete evacuation of gases and fumes resulting from the process. It also permits a continuous exchange of air inside the furnace casing. A 6-inch diameter connecting pipe is installed at our plant. The furnace may be rapidly connected to ducting of a conventional chimney, this at little cost.

Six Silicon Carbide Elements are located beneath the hearth plate. The number, configuration and location of the elements, as designed to ensure superior heat-up time and temperature uniformity. A low-watt density maximizes element life.

Furnaces operating on a 3-phase electrical specifications leave our plant fully balanced for even amperage draw on all three lines, optimizing usage of your electrical capacity.

Our furnaces are built to offer maximum reliability and efficiency. Nonetheless, no furnace can forever endure rigorous and sometimes abusive operating practices. For this reason, all our furnaces are built so as to permit easy and rapid repairs at relatively little expense.

We supply parts for all brands of furnaces, ovens and kilns. We also custom build furnaces.