Clay Dewatering – Settling – Thickening

The Florida phosphate industry currently produces more than 80% of the total U.S. supply of phosphate rock. The production of this critical mineral is accompanied by the generation of large quantities of dilute phosphatic clays. The disposal of these phosphatic clays has been a problem to the Florida phosphate Industry since the introduction of large-scale […]

Using Wetlands for Treatment of Mine Water

Acid mine drainage is one of the most persistent industrial pollution problems in the United States. Over 5,000 miles of our country’s streams and rivers still fail to meet water quality standards due to acid mine water that originates primarily in abandoned mined lands (Kim et al., 1982). Less than 10 percent of this total […]

Calculate the Size of a Ball or Rod Mill and its Motor

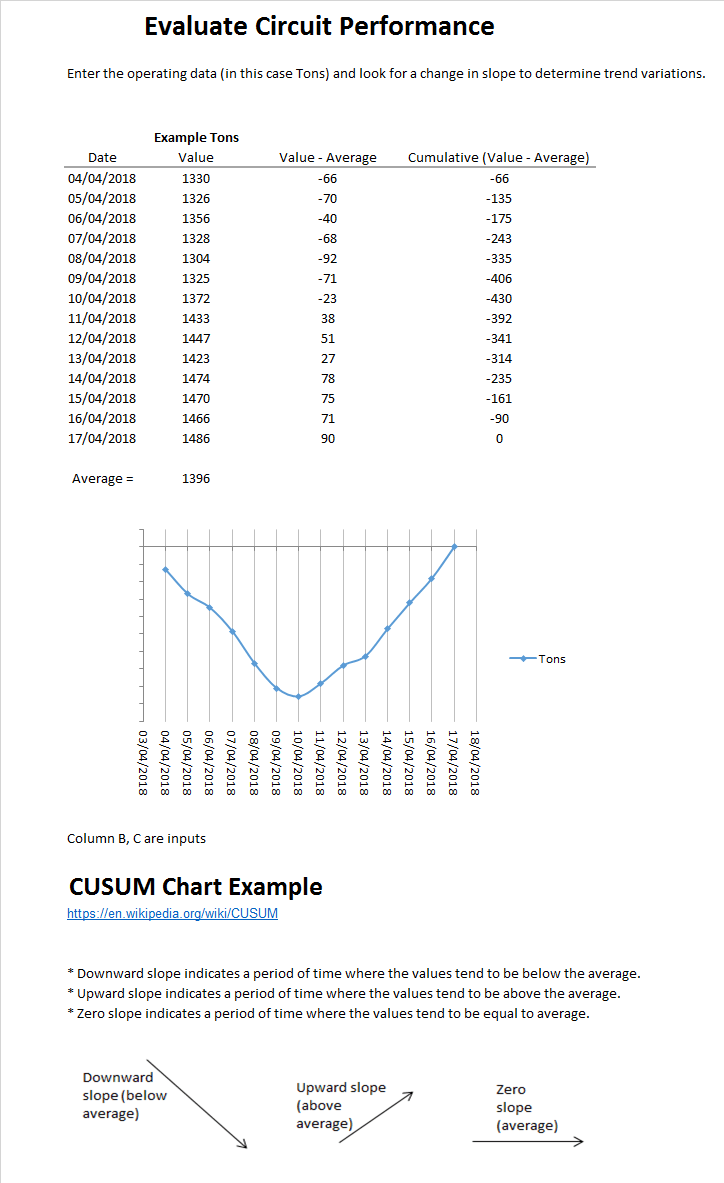

Evaluate Mineral Processing Plant Performance in Excel

Evaluate plant performance using CUSIM chart example

Mill Operator Training Program

Few people would dispute the necessity of transmitting literally thousands of pieces of information about the new plant to the operator. In fact, there is really only one way to actually do it We have found that writing a series of custom plant operating manuals, specifically designed for an education level of the average high […]

Acid Activated Clay

Acid-activated clays are produced almost exclusively from southern or nonswelling bentonites by treatment with various mineral acids. When used for their ability to decolorize or “bleach” color pigments from vegetable and petroleum oils, they are called bleaching clays or bleaching earths. Although sometimes confused with fuller’s earths, which are also sometimes called bleaching clays (Table […]

Atmospheric Elution Process

Acid-washed carbon is loaded into the top of the column from a feed vessel and allowed to rill into the feed hopper. The carbon flow from the feed vessel is automatically choked and will only feed as carbon is withdrawn from the base of the column. There is sufficient surge capacity in the feed hopper […]

Solvent Extraction & Electrowinning Operating Costs

It is fairly easy to separate the capital cost for SX from that for EW. For this reason one might choose to categorize the operating costs in the same way. However, because of the way SX-EW plants are designed and operated and the manner in which costs are allocated this can be a difficult task. […]

Gold Recovery from Molybdenum Concentrate by Cyanidation

Here we describe a cyanide leaching-carbon adsorption plant designed to recover the gold from the molybdenum concentrate. Process Design: The molybdenum concentrate assays typically, 45 percent molybdenum, less than 1 percent copper (chalcopyrite) and 3.5-5.0 percent iron (chalcopyrite-pyrite). Gold and silver average 8 and 40 ppm respectively which at an average molybdenum concentrate production of 10 […]

Recover Ultrafine Chalcopyrite by Flotation

Froth flotation is used almost universally in the beneficiation of base metal sulfide ores. Although flotation is very efficient for particles between 150 and 10 µm in size, this efficiency drops off rapidly, as the particle sizes drop below 10 µm. Significant quantities of these ultrafine sulfide values are lost in the beneficiation of copper […]