Hydraulic Dredge Design

Let us assume that it is desired to design a hydraulic dredge capable of raising average hydraulic material 15 feet above the pump through 4000 feet of pipe line and at the same time be suitable for general all round work involving also short lines and low heads. It is generally accepted that a 20 […]

Scows

The most common conveyance for the transportation of dredgings (pumpings excepted) is the bottom-dump mud scow. It is in effect a hopper barge, without means of self propulsion, consisting simply of a hull rectangular in plan and cross section, containing a number of independent hoppers called pockets, and with both ends raked or rounded (in […]

Zinc Concentrate Roasting & Cadmium

Cadmium is not the principal recoverable constituent in any ore, but it does occur at a ratio of about 1:200 with zinc. If lead and zinc are considered major products, then the major metal byproduct of the zinc industry was the more than 3 million pounds of cadmium produced in the United States in 1978 […]

Autogenous Grinding & Semi Autogenous Grinding Circuits

Size reduction is the most expensive operation in most mills. Crushing and grinding usually require the greatest portion of capital costs and often make up 60-70 percent of total mill operating costs as shown in Figure 1. Selection of the proper crushing and grinding method must, therefore, be done with great care to be sure […]

Grinding Circuit Simulation

These programs and the simulation algorithms are discussed below. Note that in some Grinding Circuit Simulations, a residence time distribution model is used. In the MRRC simulation package, however, only the two extremes of well mixed and plug flow through the mill are considered. This approach reduces the amount of input information and computation required […]

Pyrometallurgy Chrome Recovery Plant Design

Chrome Recovery Plant Design: The purpose of the design phase of this project was to prepare the preliminary design of a pilot plant capable of: treating an average of at least one hundred pounds per hour of metallic scrap, and recovering a minimum of 65 percent of the contained chromium and other valuable metals (for example […]

Zinc Regrind

The flotation section starts with a bulk concentrate float for lead and copper using four rows of eleven cells each as roughers and scavengers. The froth taken off the roughers is then pumped to a two stage cleaner circuit. Scavenger froth and cleaner tails are returned back to the head of the rougher circuit. Froth […]

Recover Chromium from Scrap Metal

Although world chromium resources are ample for the foreseeable future, political and economic events have raised doubts about the uninterrupted availability and reliability of chromium supply. Chromium is used extensively in the metallurgical industry and has no technically viable substitute for such critical applications as nickel-base superalloys required for aircraft gas turbine engines. The United […]

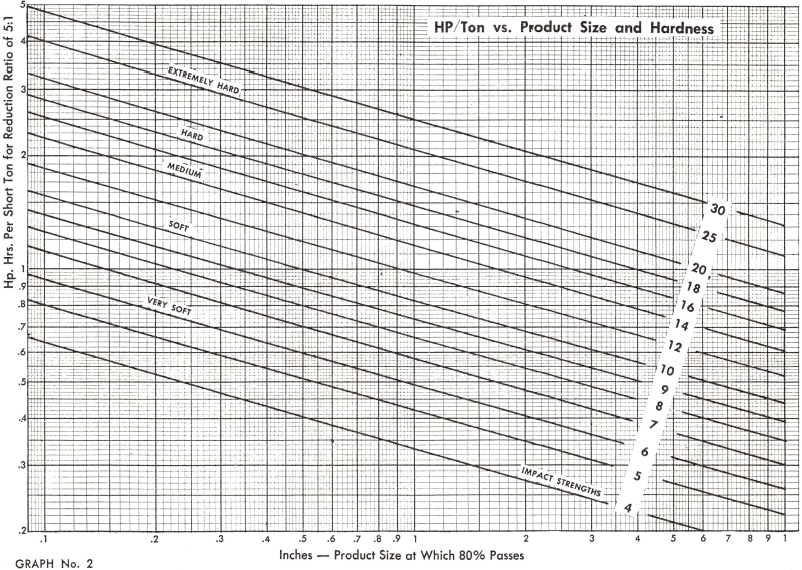

How to Size a Cone Crusher Motor

In the cone crusher capacity table, a maximum motor size recommendation is given for any eccentric throw. Only in rare circumstances is this maximum horsepower required; in many installations a motor of only half the rating of the maximum is required. If there is any doubt regarding the proper motor size, a sample of the […]

Cone Crusher Maintenance

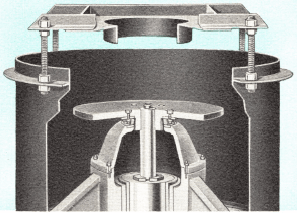

WOBBLE PLATE FEEDER A wobble plate feeder is furnished as standard equipment with Fine crushing chambers and as optional equipment with Coarse and Intermediate crushing chambers. It consists of a distributing plate to which a wobbling motion is imparted by the gyrating motion of the main shaft. The feeder is equipped with an enclosing hopper […]