Anemometer to Measure Air Flow Self Aspirating Cell

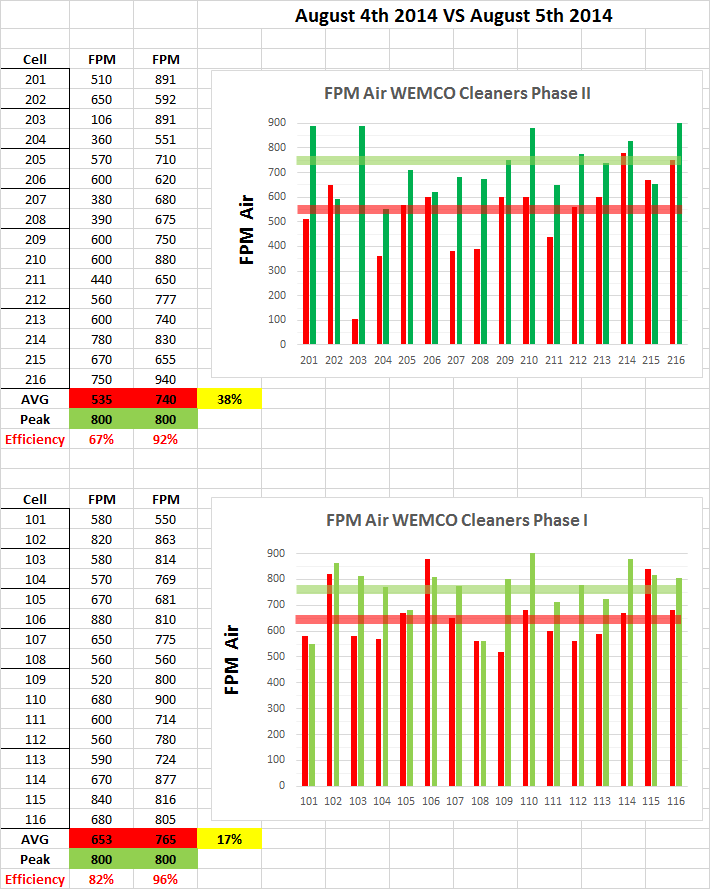

I once used an Anemometer to Measure Flotation Cell Air Flow on Self Aspirating WEMCO machines. Overtime, operations & maintenance got lazy and never took care of cleaning the airflow supply pipe into the cell. It was clear flows were partially to completely blocked. I improvised the method and now found one the US Bureau […]

Selective Flocculation and Flotation

The Bureau of Mines undertook a research program to insure an adequate supply of iron raw materials for future iron and steel making needs. A sample was obtained of oxidized taconite from the western Mesabi Range in Minnesota, and the metallurgical response of the taconite to beneficiation by a process that included selective flocculation-desliming-cationic flotation […]

Mill Liner Handler

Rod Mill Grinding

A detailed experimental study of breakage kinetics in a batch rod mill indicates that while the system is inherently nonlinear, the feed disappearance kinetics for the finer sizes and the coarser sizes at high holdups is well represented by first-order behavior. The set of breakage distribution functions was found to be normalizable and independent of […]

Recycling Chrome Refractory Waste

Chromite ore in combination with various quantities of magnesia is used in basic refractories. Refractories of this type are used as linings in steelmaking and copper smelting furnaces, rotary cement calciners, and glassmaking tanks. However, most of the consumption is by the copper and steel industry. Approximately 20 percent of the chromite consumed in the […]

Ni-Hard Grinding Balls

Through a cooperative agreement, the Carondolet Foundry Co. of St. Louis, Mo., supplied 1,000 pounds of 2-inch Ni-hard balls for comparison with balls of other composition. Ni-hard balls are said to contain 2.5 to 6 percent nickel and 0.5 to 1.5 percent chromium. They have a Brinell hardness of 548. The company also furnished a […]

Grinding with Pebbles VS Steel Balls

Operators in the metallics industry, sometimes forget that pebble mills are an important factor in fine grinding. However, pebble mills are not extinct, as is shown by reference to a recent paper on ore milling, wherein it was shown that five of the 44 so-called “ball” mills mentioned actually were pebble mills. If the nonmetallics […]

Why use Different Size Balls in a Mill

Several years ago, Davis assumed that the rate of wear of the different sizes of balls in a ball mill was directly proportional to the weight of each ball, and he evolved a formula for calculating a balanced charge. Operators have used this formula when purchasing balls for a new mill or when reloading an […]

Ball Mill Diameter vs Length Compared Efficiency

Operators may rightly ask how much reliance should be placed on laboratory ball milling when they are using mills so much larger. This question was foremost in the earliest work at Rolla; in fact, in the beginning more attention was given to plant tests than to laboratory tests. The operators had calculated their results in […]

Grinding Efficiency of Ball Chips VS new Balls Compared

Battered Reject Balls and New Spherical Balls Compared: Operators are sometimes at a loss to know when a mill should be dumped to discard the worn and battered balls. Similarly, the present authors found an unknown variable when they compared the laboratory work of a new grinding medium with the plant performance of media, some […]