Mineral Jigs for Concentration of Lead Ores

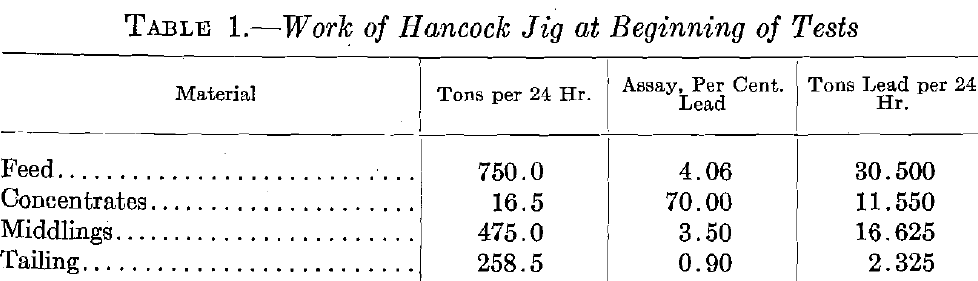

The following notes are taken from results obtained on a standard 25-ft. Hancock jig tested during regular operation. The object of the tests was to determine the conditions for most effective work, and the nature of products that could be made. The material treated was sized between 9-mm. and 2-mm. round- hole screens, and was […]

Ball Mill Crushing

Until the advent of the porphyry coppers and the introduction of flotation which soon followed, crushing and grinding for many years proceeded along somewhat stereotyped lines, without important alteration in type of machinery. For the finer crushing and grinding, stamps, rolls, and various patterns of Huntington and Chilean mills were in general use. Ball mills […]

Cyanide Processing Equipment and Plant Options

The Jig, placed between the ball mill and classifier, is one of the most valuable and affordable improvements in cyanidation in recent years and was developed by the metallurgical engineering and Mining Equipment Companies. This Mineral Jig has the marked advantage of removing a large portion of the metallic values without excessive dilution, and water […]

Gravity Recovery or Flotation ahead of Gold Cyanidation

Process Flowsheet NO. CY-3 is shown one of the outstanding improvements made in cyanidation whereby the coarse metallic minerals are removed from the grinding circuit by means of the Mineral Jig. The hutch product from this jig is amalgamated with a Amalgamator or Clean-Up Pan and thus the coarse mineral values, such as metallic gold, are […]

Counter Current Decantation Cyanide Gold Leaching

The Process Flowsheet CCD CY-1 shows (below) the continuous counter-current decantation system, in which all the ore is first reduced to a very fine state in the grinding mill-classifier circuit, in a cyanide solution. The slime overflow of the classifier, usually 70%—200 mesh, or finer, is sent to the first thickener, known as the primary thickener. […]

Gold Cyanidation Circuits

The principle of dissolving gold and silver values in solutions of potassium or sodium cyanide is old and has been thoroughly carried out in practice for many years. There have been only a few changes in the chemical procedure and also few changes in the type of equipment used. The gold and silver are dissolved […]

Peripheral Discharge Ball Mills -Theory and Practice

These notes are based on observations made while on a recent trip through the West, for the purpose of studying the practical operation of the ball-mill. The writer takes this opportunity to express his thanks for courtesies extended at the many plants visited as well as for the valuable data received. While there are several […]

Basic Principles & Variables Affecting Froth Flotation

The basic factors, principles and variables affecting froth flotation are enumerated in condensed form below: Ore. (a) Mineralogical character. (b) Fineness of grinding. (c) Method of grinding. Agents. (a) Principal flotation agent. (“Oil”) α Character. β Quantity. (b) Minor agent. α Character. β Quantity. Water. (a) Quantity with respect to solids, i.e. pulp thickness. (b) […]

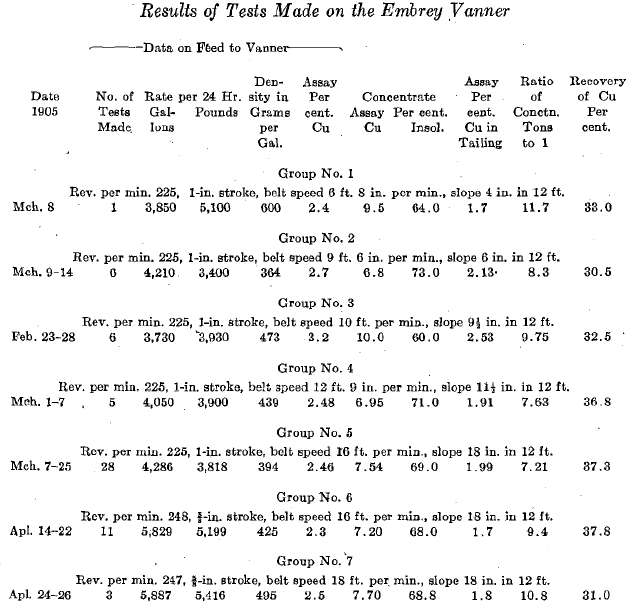

Round Concentrating Tables

The principal object of this paper is to present data on the development of the revolving convex round table as a concentrator for the through 0.07-mm slimes from the ores of the Butte district, although some brief notes on the earliest recorded use of this type of concentrating table in the ore-dressing plants of the […]

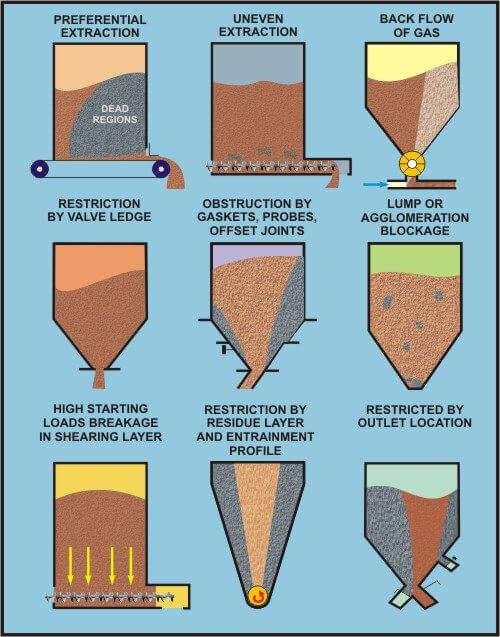

Bulk Storage Hopper Flow & Feeder

The performance of Bulk storage hoppers and silos is sensitive to the nature of their contents so consideration must first be given to the physical properties with respect to the operational requirements of the system. See the I.Mech.E publication: – ‘Guide to the specification of bulk solids for storage and handling applications’. by Lyn Bates […]