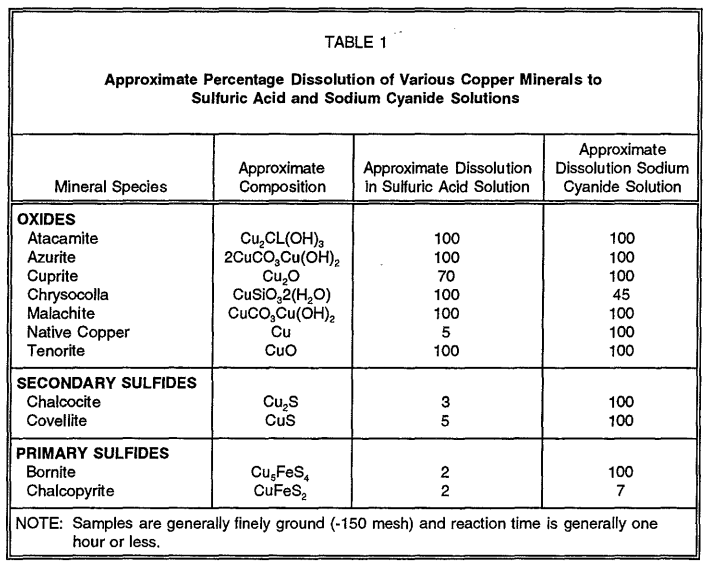

Acid Solubility of Copper Mineral Species

Process Air & Plant Air

Process air is supplied to the process by two 150 HP, 1200 nm3/hr, 250 kPa compressors. Each compressor is a totally self-contained package. Each compressor is an electric motor driven, single stage screw compressor complete with accessories piped, wired and baseplate mounted. Under normal operating conditions only one of the two compressors will be used. […]

Mining Camp Fresh Water System

Introduction to an EXAMPLE Fresh Water System Water is pumped from the fresh water well to the camp tank which provides pressure and storage capacity for the camp. The camp distribution system is located between the well and the camp tank, such that the pipe between the camp and the tank may have flow in […]

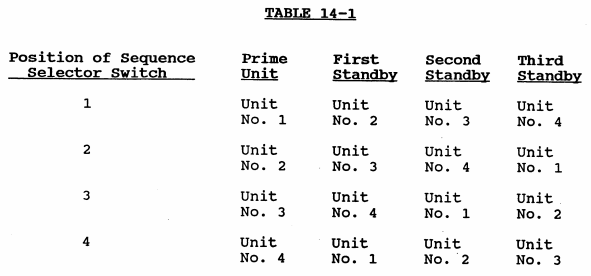

Diesel Power Generation for Mining Operations

On our EXAMPLE mining operation, the power generation and distribution system consists of four components: Diesel electric generation Diesel fuel system Heat recovery system Power distribution system The system is intended to operate automatically with local control panels in the generating/electrical room, with some remote monitoring in the main control room. Detailed Process and […]

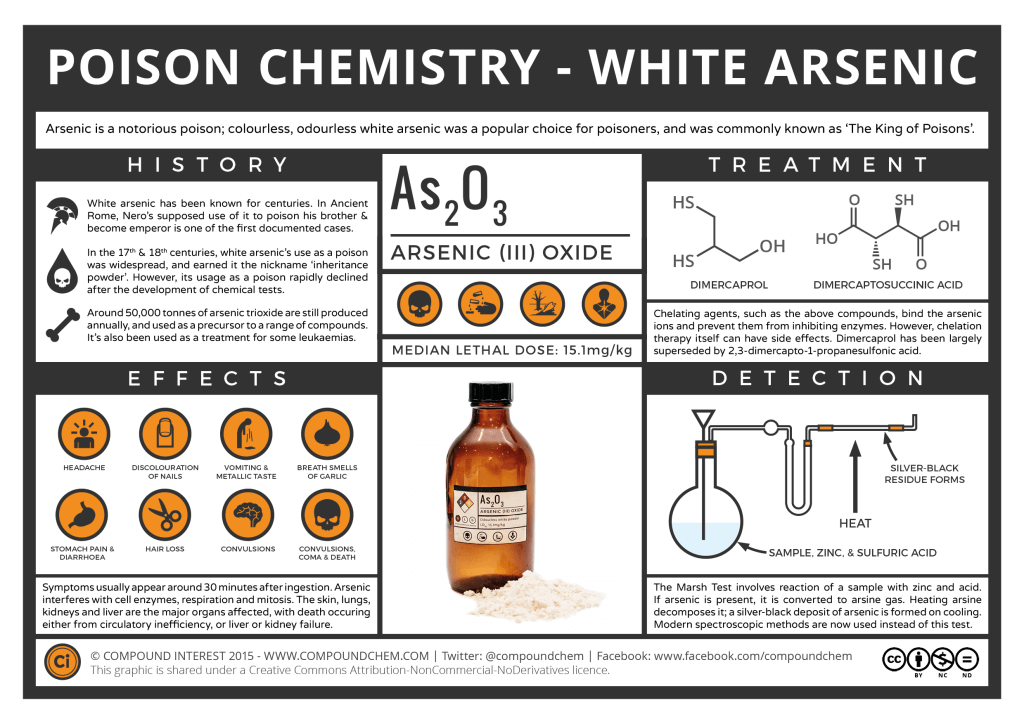

White Arsenic

https://www.compoundchem.com/category/poison-chemistry/

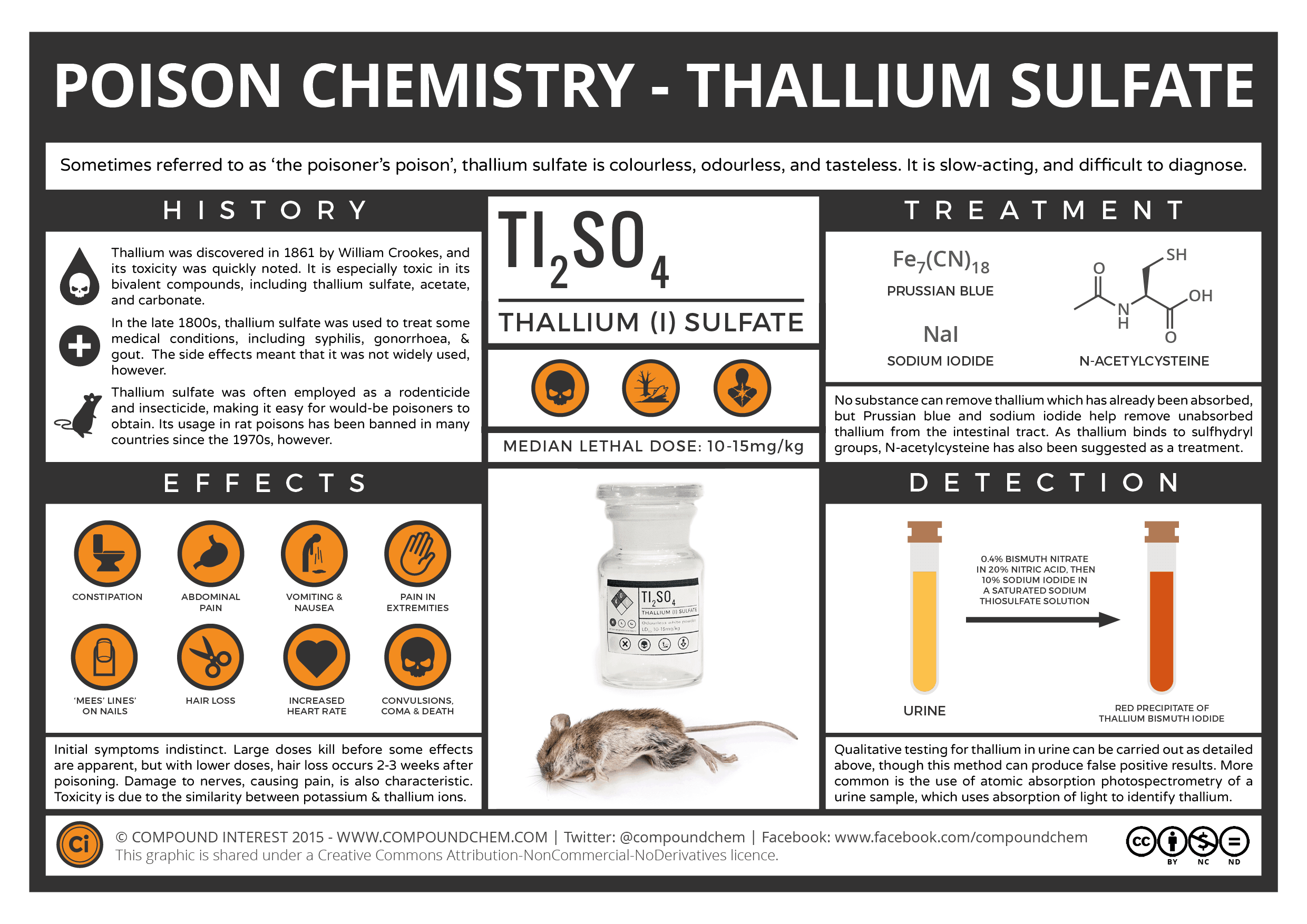

Thallium Sulfate

https://www.compoundchem.com/category/poison-chemistry/

Plant Tailings & Reclaim Process Water Startup & Shutdown Procedure

EXAMPLE Operation and Preparation for Start up Ensure the mill is prepared to start up at the design throughput and range of solids content. Walk the tailings line to check for damage to the pipe or overhead wires. Open the sluice gate at the tailings spillage diversion. Ensure the tailings box is free of obstruction. Ensure […]

Plant Tailings & Reclaim Water System Operating Procedure

EXAMPLE Tailings System Tailings from the processing plant are collected in a common tails box and flow by gravity to the tailings pond. The tailings flow at a rate of 51.6 cubic meters per hour and 34% solids. The tailings line consists of five separate sections and each individual section is designed to suit its local topography. […]

XRF for Better Plant Metallurgy Control

An un-monitored (un-assayed) tailing from a vibrating screen was exiting the system. Operators would eyeball the Zinc content from a handcut while true assays were only provided late the next day as part of the metallurgical material balance. Here I show 4 videos of the new step by step solution we implemented. It used a pizza […]

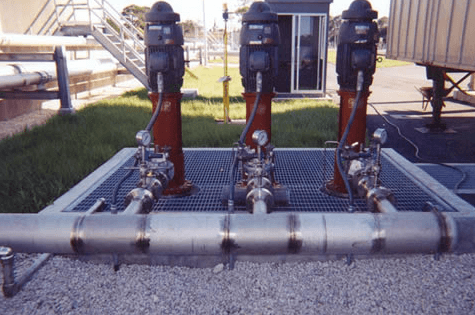

Preparing Flotation Reagents

The following flotation reagent mixing system is typical for the flotation reagent mixing systems: A-208, Xanthate and Sodium Silicate. The reagent mix tanks, for the above mentioned reagents, are located on the basement floor. Feed chutes from the main operating floor carry dry or wet reagents to each mix tank. Either reclaim or fresh water is […]