The Boy Mechanic Collection: Volume 1, 2 and 3 – 1000s of Things For Boys To Do

Metallurgy Tutorials, Exercises and Examples

Introduction Industrial Furnaces Material and heat balance in converting Material and heat balance in roasting of chalcopyrite ore Material balance in Coke making Material balance in cupola Material balance in mineral processing Material balance in roasting Materials Balance in Iron making Matte smelting Materials balance Measurement of Quantities Mineral Beneficiation Production of Gaseous fuel Pyrometallurgical […]

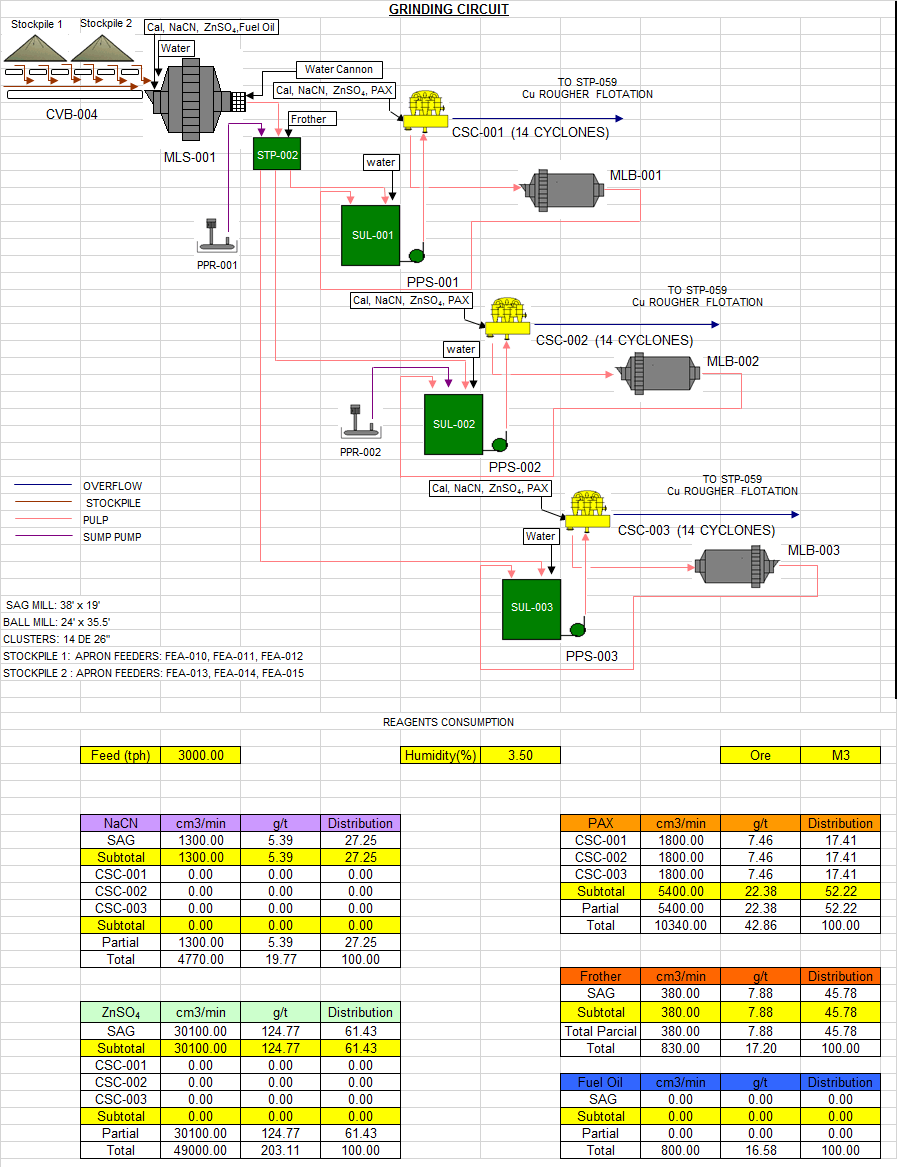

Antamina Process Flowsheets

Hardinge Conical Ball Mill

The Hardinge Ball Mill consists of three sections. After the usual type of trunnion bearing the mill consists of a short conical section showing a sharp drop from feed entrance to maximum mill radius. A cylindrical section of varying length then follows and toward the discharge end connects with a comparatively long and conical section […]

Rock Crushing Rule of Thumb

Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher. Between these capacities, you have a choice. Source: Chris Ottergren For a hard rock mine application below […]

Mineral Processing / Metallurgy Rules of Thumb

Here is a list of General Rules of Thumb often used in Mineral Processing and Metallurgy: A concentrator (mill) requires up to 3 tons of water for each ton of ore processed. It is therefore important to operate with the maximum practical pulp density and minimum practical upward or horizontal movement. The basic philosophy requires movement over the […]

Grinding Rule of Thumb

Here is a list of Rules of Thumb often used in Grinding Circuits: Fine ore bins (or stockpiles) that provide feed to the grinding circuit should have a capacity equal to 30 hours of processing. Source: Northern Miner Press Grinding is a low-efficiency, power-intensive process and typically can account for up to 40% of the direct operating […]

Froth Flotation Rule of Thumb

Here is a list of Rules of Thumb often used in Froth Flotation: Clean metallic gold particles (free gold) finer than 200 microns (65 mesh) float readily with appropriate reagents. Gravity separation is desirable for larger particles. Source: Mining Chemicals Handbook (Cyanamid). When designing the flotation circuit for a proposed mill, the scale-up factor for flotation retention times […]

Zen Metallurgy

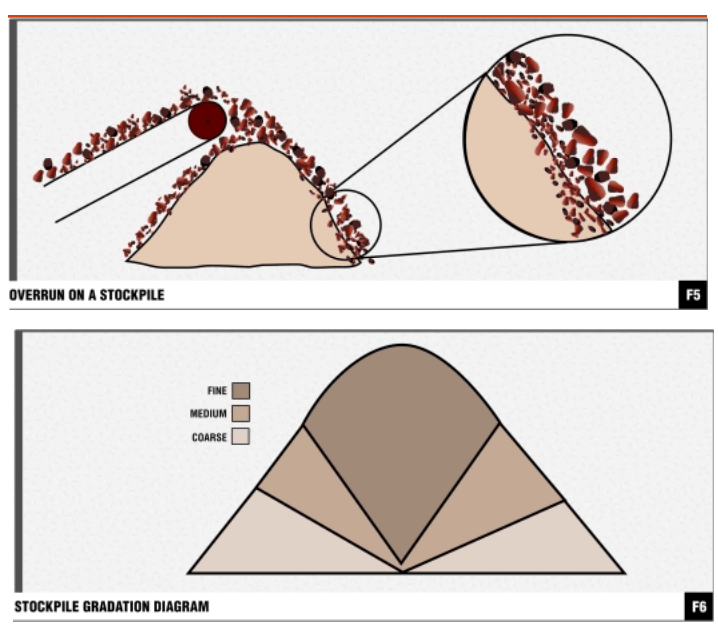

Stockpile Segregation

The video below graphically explains the common problem of Coarse Ore Stockpile Segregation. This topic relates to SAG Mill tonnage and the bad habit of putting bulldozers “dozers” on ore stockpiles. Stockpile-Segregation”>