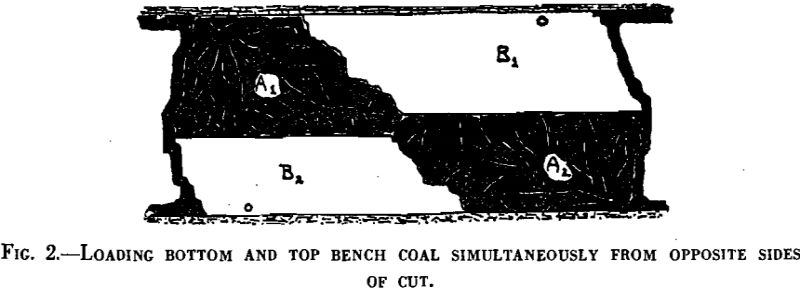

Mining Face Preparation

Anthracite Although the unmined anthracite will last for approximately 150 years, most of the thicker and cleaner coal beds have been almost entirely first-mined and pretty well robbed, leaving much of the present and future production to come from thin and dirtier beds. Herewith is a section of one of the dirty beds being mined […]

Sinter Reduction

First, the relation between straight lime basic sinter’s susceptibility to disintegration and basicity was examined under various boundary conditions. Some selected results are shown in Figure 2: for variable fuel rates disintegration is governed by various influence factors: first, there is the well-known maximum as a function of basicity. More surprising is an additional effect: […]

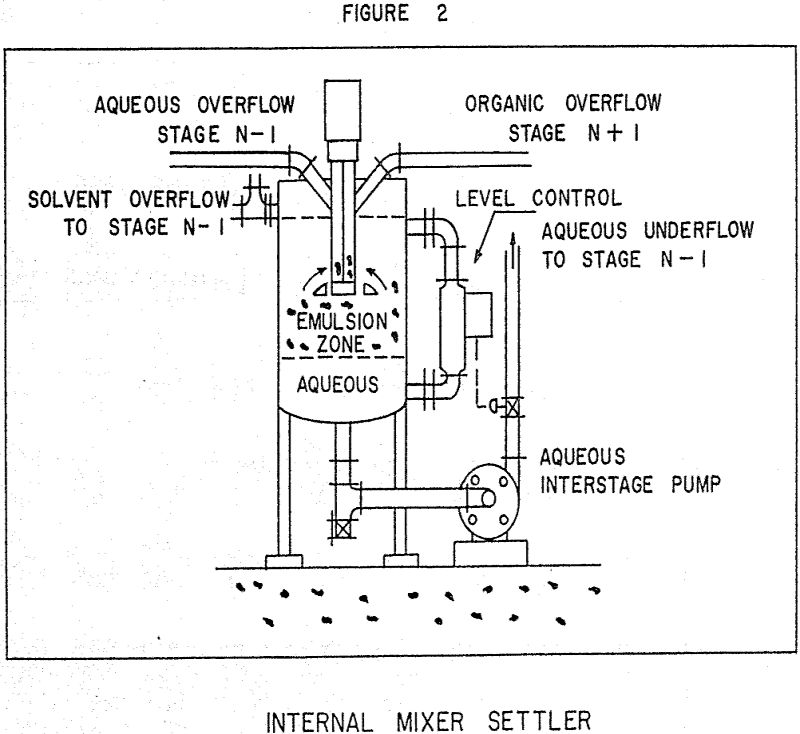

New Solvent Extraction Techniques for Uranium Purification

This paper reviews several new applications of solvent extraction developed in conjunction with a research project carried out under the AEC Raw Materials Division by the Dow Western Division laboratories during the last two years. Several methods for direct solvent leaching of ores have been investigated by AEC contractors. The method studied at this laboratory […]

How to Control Flotation Reagents

Reagent control in flotation is more an art than a science. Operators vary the amount of reagents used according to the metallurgy obtained. The amount of collector may be increased, for example, if tailings losses are high and decreased if concentrate grades are low. Often control decisions are based on only one assay, such as […]

Electric Furnace Melting of Copper

The final casting of refined copper has been restricted for generations by the following sequence of operations: Filling the reverberatory furnace, melting, skimming, blowing or flapping, and poling. The hoped-for 24 hr cycle, producing 300 tons or more, has been taken up largely with the necessary but time-consuming tasks of cleaning the bath, sulphur elimination, […]

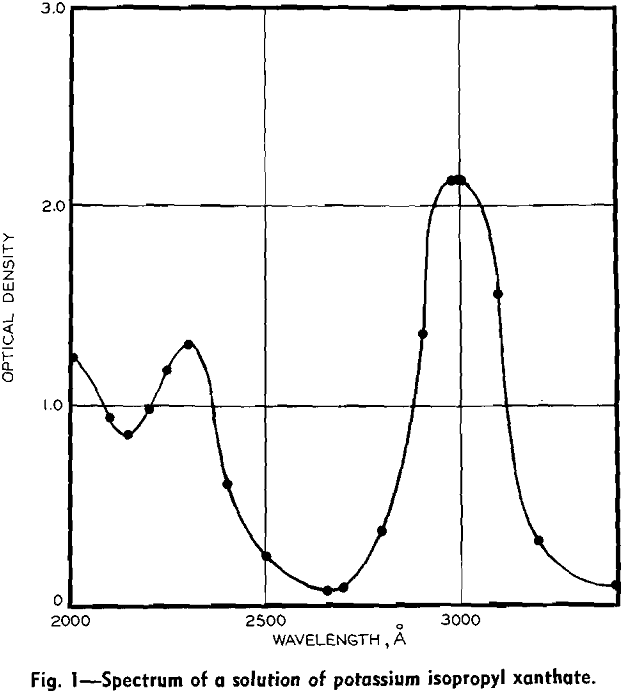

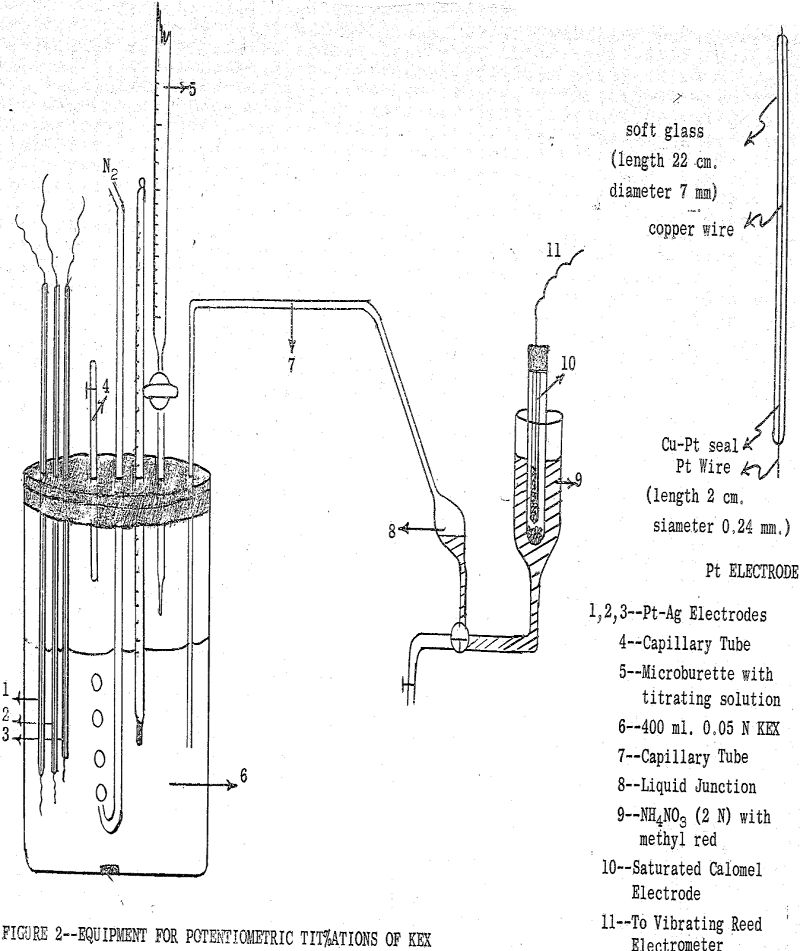

Metal Ethyl Xanthates Solubility

The flotation system is usually distinguished from other physical chemical systems by the importance of interactions at the solid-liquid and solid-gas interfaces. In recent years, numerous quantitative studies have been made of the distribution of common collectors between the solid and aqueous solution phase. Although in flotation the main emphasis is placed on the adsorption […]

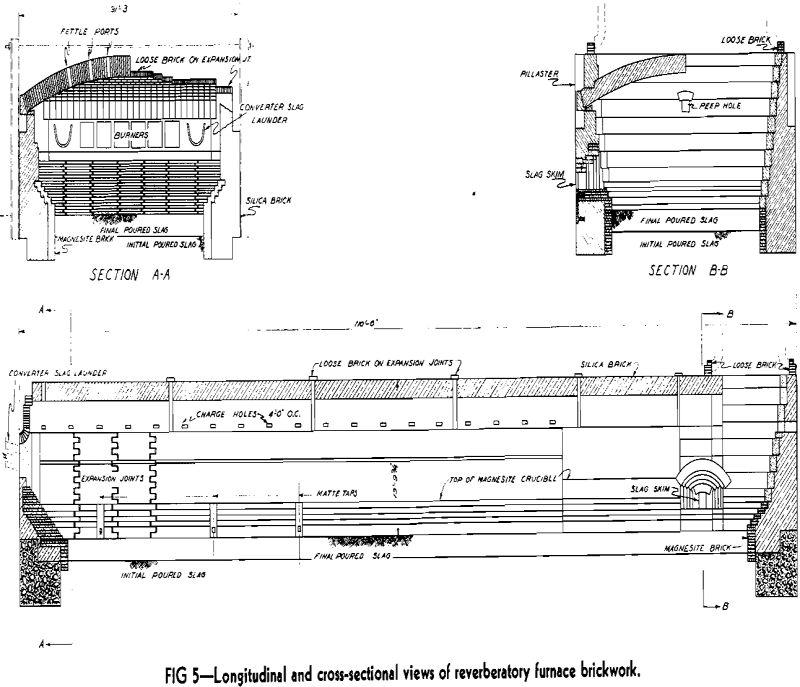

Morenci Smelter Arizona

Copper smelters of various kinds have operated in the Morenci district since 1872, but all have been abandoned with the exception of the present Morenci Smelter of Phelps Dodge Corporation, which was completed in 1942. During the five-year period starting in 1937, the Morenci ore body was prepared for open pit mining, pilot mill test […]

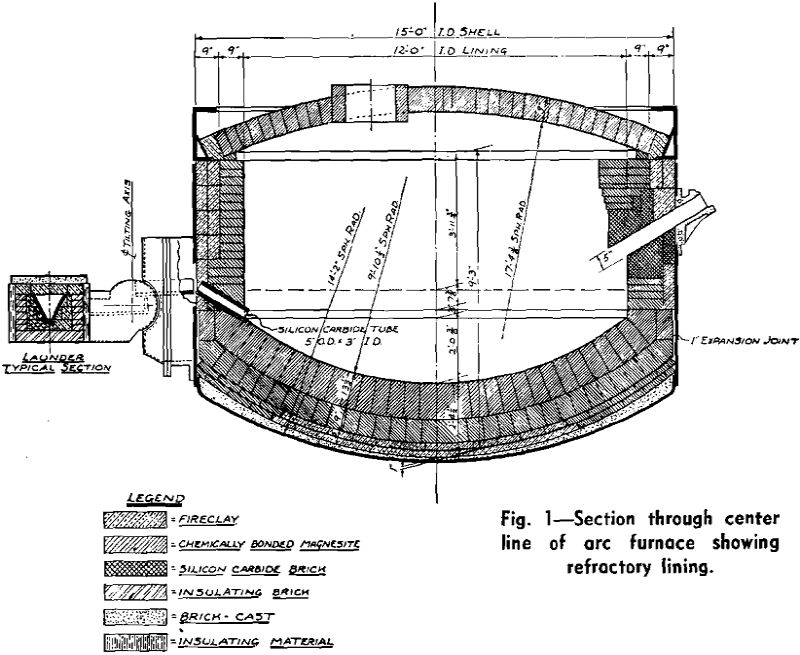

Arc Melting of Titanium Metal

Because of the reactivity of titanium metal with all known refractories and the common atmospheric gases, melting of the metal presents numerous problems. It is necessary to provide an inert atmosphere in the furnace as well as a crucible material that will not react with the molten metal, if a ductile ingot is to be […]

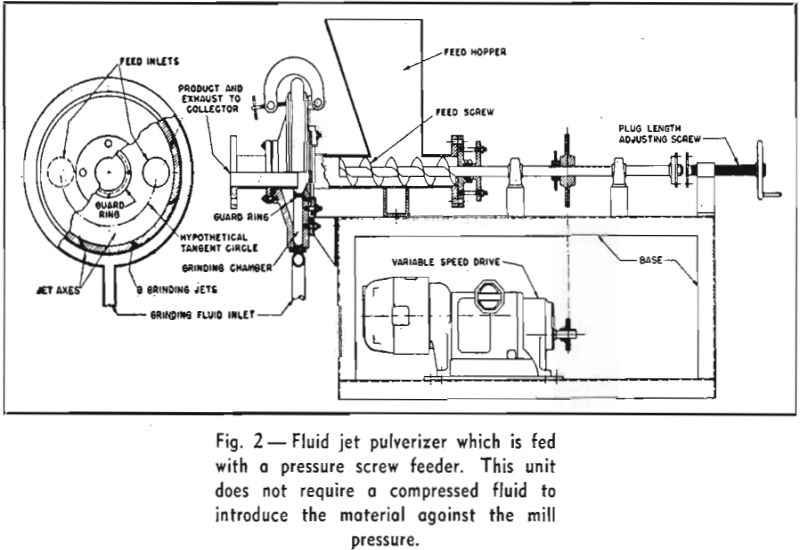

Ultra-Fine Grinding and Classification

Fluid jet mills-employing a compressible fluid to grind materials to the sub-sieve range, was developed in the early 1930’s, and the subsequent acceptance of these units was the result of their ability to pulverize solids that, because of physical properties, could not be processed by other attrition methods, such as ball, pebble, and hammer mills. […]

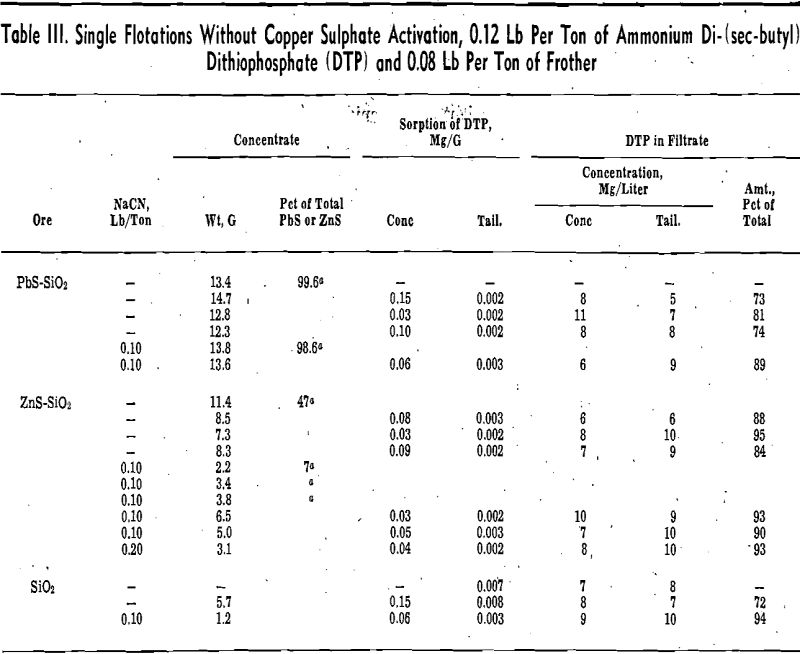

Dithiophosphate in Selective Flotation of Lead and Zinc

Dithiophosphate collectors are commonly used in the flotation of sulphide minerals. Studies of the interaction of a typical dithiophosphate collector with galena surfaces have been previously reported from these laboratories. These fundamental studies were carried out by employing phosphorus labeled radioactive dithiophosphate. Radioactivity determinations then could be used to measure readily and accurately the small […]