Coal Processing Methods

More coal processing is done in foreign coal-producing countries because of their requirements for a smokeless fuel, their need to make a satisfactory metallurgical coke from inferior quality coals, and their general lack of indigenous oil or gas from which to produce chemicals or other carbon-based products. High-Temperature Carbonization Conventional Coke Manufacture The demand for […]

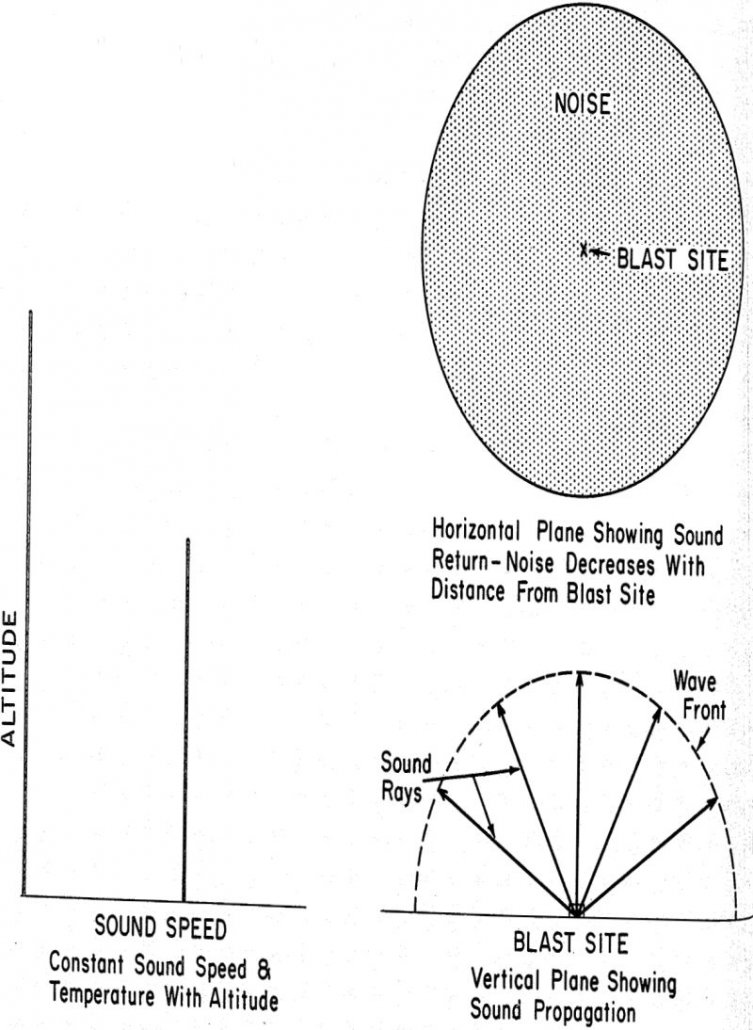

Reduce Blasting Noise

The public relations problems of users of explosives have greatly increased within the past few years. One reason is that explosives and blasting agents are being consumed in increasing quantities. The principal reason, however, is that more people have become physically affected by blasting. Mines, quarries, and construction sites that were formerly in relatively remote […]

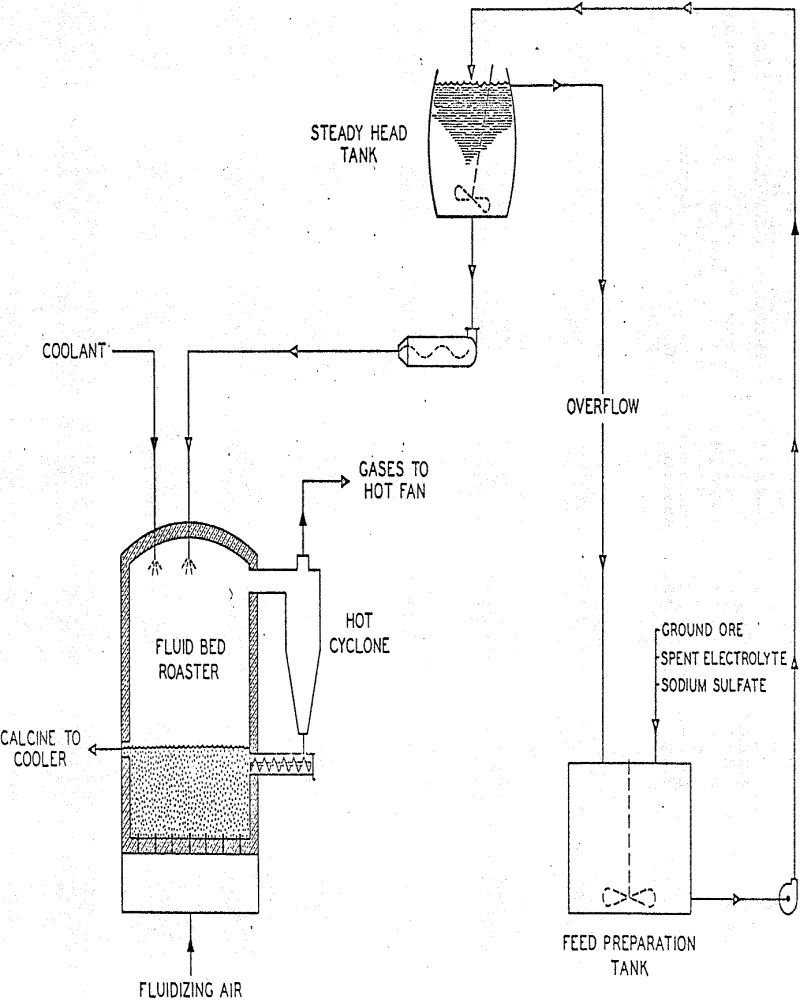

Complex Sulfide Sulfation Process Ores Pilot Plant

The design, operation, and performance of an integrated pilot plant for recovering zinc and copper from a complex sulfide ore are described. Metallurgical processing comprised selective sulfate roasting in a fluid bed, leaching in a weak sulfuring acid solution, recovering copper by cementation with scrap iron, air oxidation to remove soluble iron, more-or-less conventional purification […]

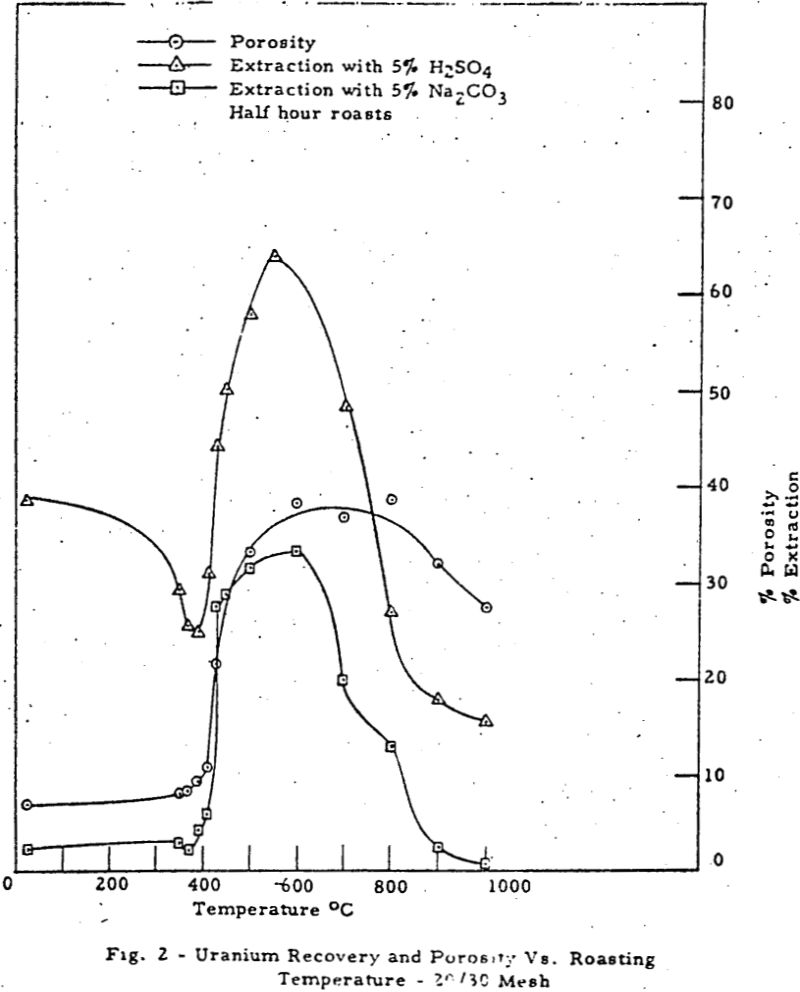

Factors Affecting Ore Leaching

This work defines and systematizes the physical factors of the problem of leaching and demonstrates for the first tine the utility of macropore volume, micropore volume., specific surface, pore size distribution and permeability as parameters of leaching based on a study of the recovery of uranium from the Top Black member of Chattanooga Shale. A […]

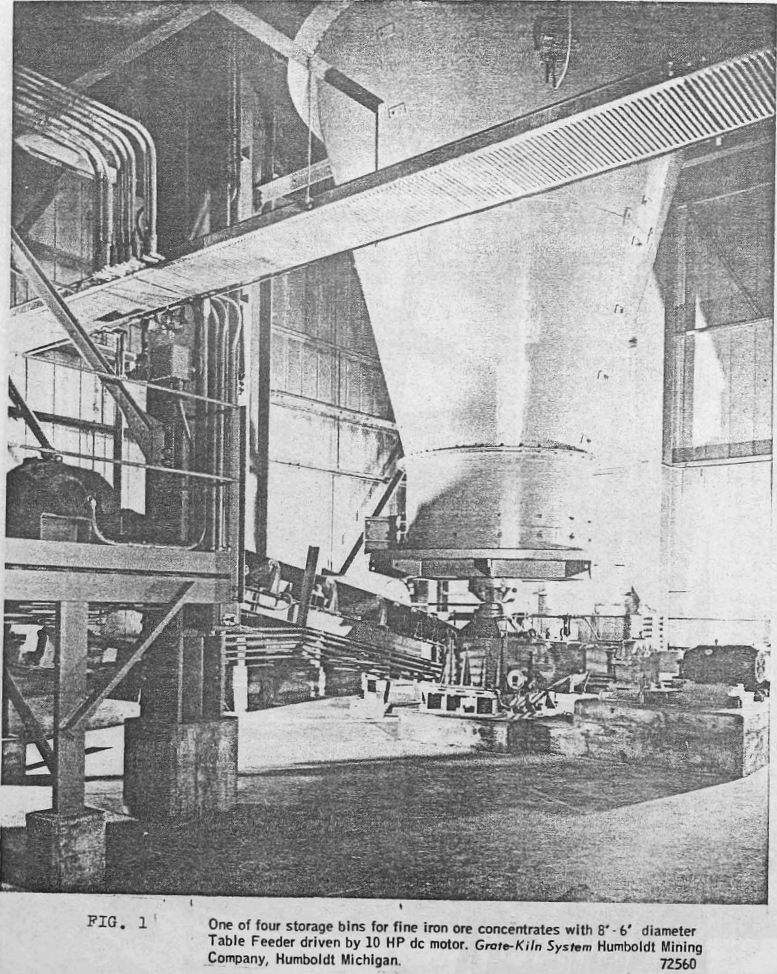

Grate-Kiln System Operation

The Humboldt and its Grate-Kiln System Operation on crude ore is a mixture of cherty specular hematite and magnetite, with minor amounts of martite and sericite. Mineralization varies from coarse to extremely fine grained. The overburden varies from zero to 50 ft. The ore body is approximately 1300 ft. long and varies in thickness from […]

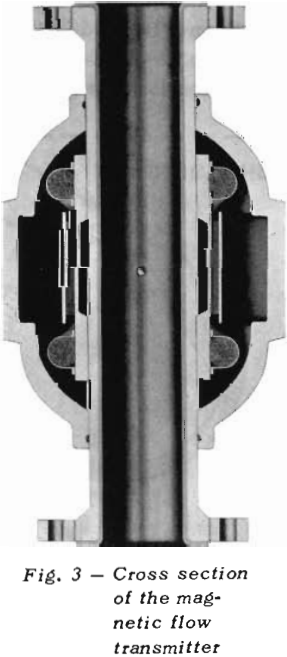

Slurry Mass Flow Measurement

Advances in instrumentation now make it possible to measure accurately flow of such diificult-to-measure liquids as mining slurries. A mass flowmeter, which introduces no restrictions in the line, will measure the mass flow of slurry equal to the volume flow times the mass/unit volume. In the mass flowmeter system a volume flow measurement is electrically […]

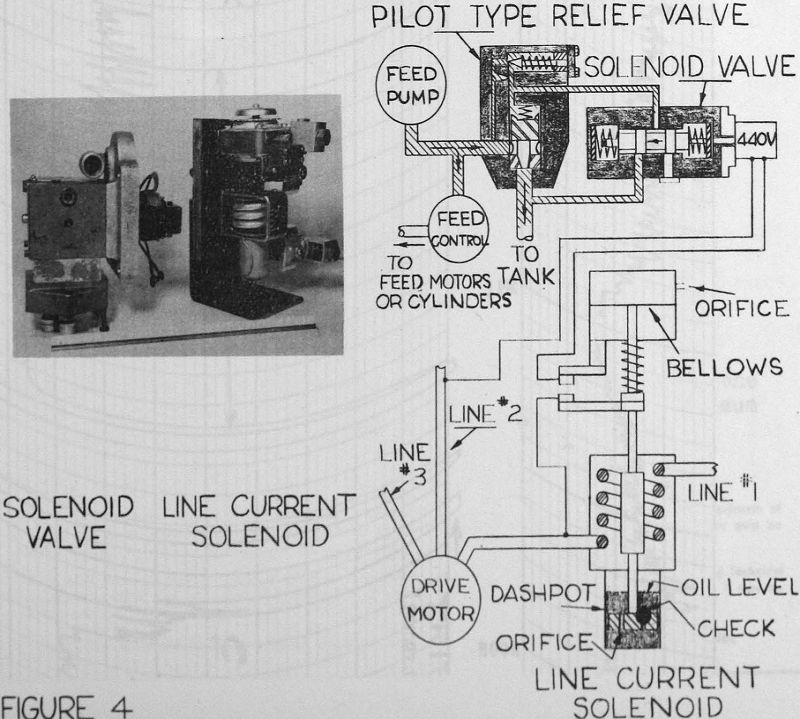

Maintenance and Operation of Mining Machinery

Modern high capacity underground mining machinery is a complex of mechanical, electrical and hydraulic components which have greatly increased capability over similar components of mining machinery of ten and even five years ago. Looking into the future I feel certain in stating that there will be changes equally great in the coming five and ten […]

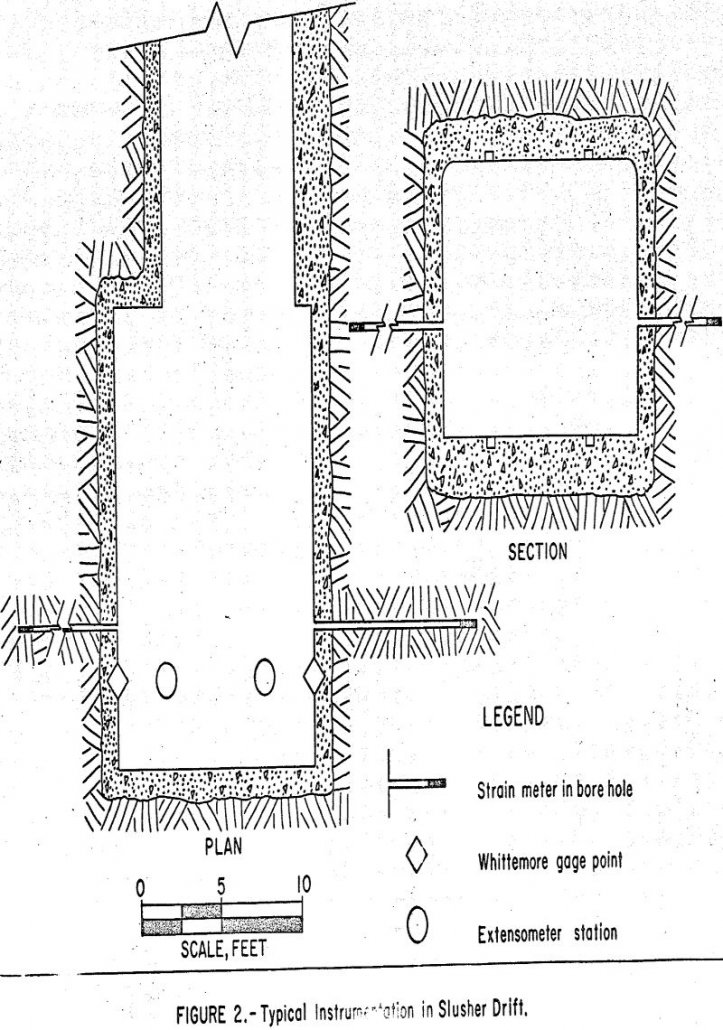

Influence of Block Caving upon Adjacent Mine Openings

The stress distribution around single and multiple underground openings has been determined both from theory and from photoelastic laboratory model studies. These determinations require certain simplifying assumptions: The rock is elastic homogeneous, and isotropic; the opening or openings are in an infinite medium, are subjected to plane stress or strain, and are not affected by […]

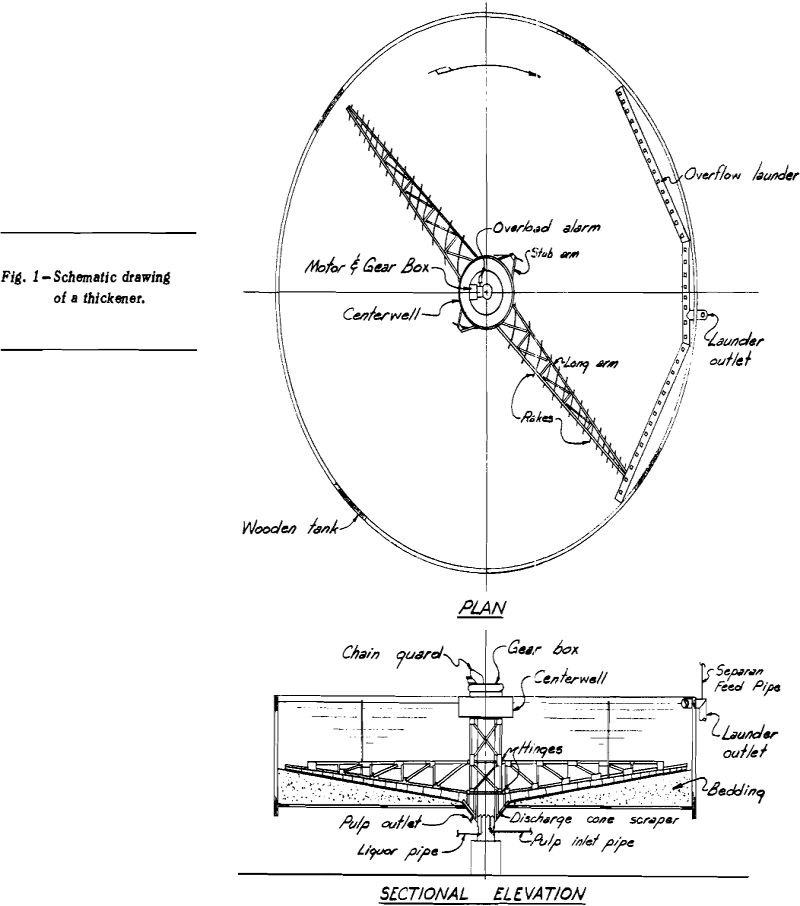

How to Handle Coarse Ore in a CCD Thickener Circuit

The use of a series of thickeners for washing of the slime fraction of a leached ore is not uncommon in the uranium industry; however, few ore processing mills have used a thickener circuit for washing leached total ore. The common practice is to wash the sand fraction in classifiers and the slime fraction only […]

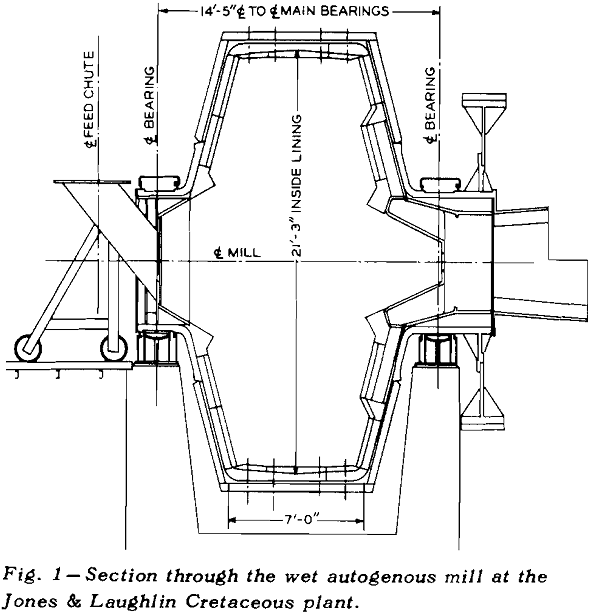

Grinding Iron Ore in a Wet Autogenous Mill

The Cretaceous plant at the Hill Annex mine of the Jones & Laughlin Steel Corp. was designed with a wet autogenous mill for grinding low grade iron ore so that it could be concentrated by spirals and flotation cells. The plant, on the west end of the Minnesota’s Mesabi Range, went into operation in June […]