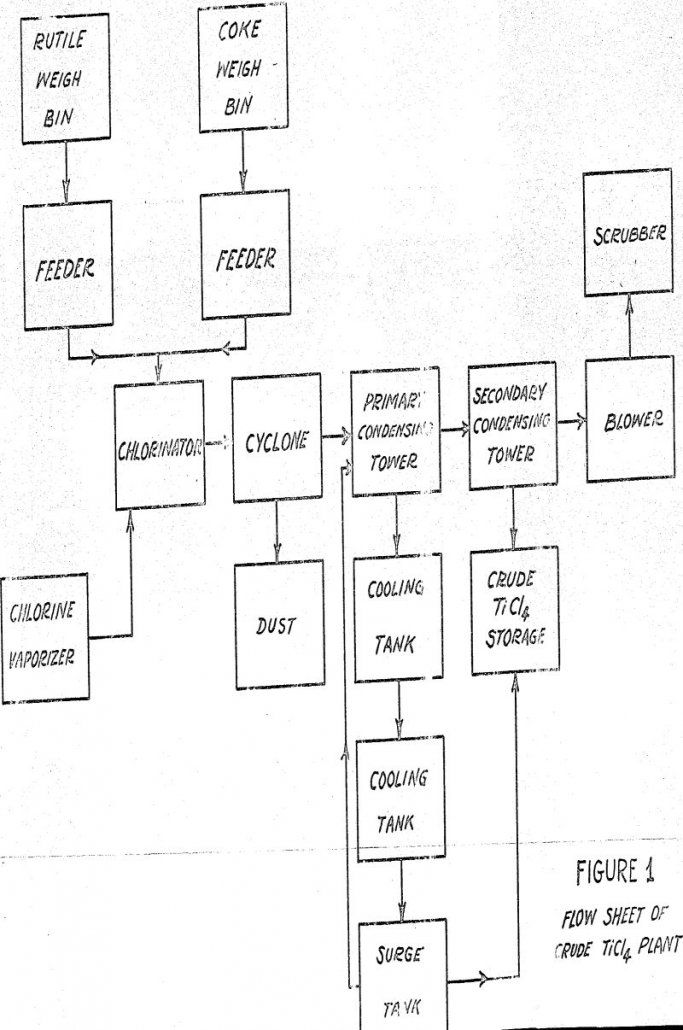

Fluidized Bed Chlorination of Rutile

Starting with rutile, containing more than 95% TiO2 and of the proper particle size, the commercial production of titanium tetrachloride via fluidized bed chlorination is relatively very simple and economical. As compared to shaft chlorination, it operates at a much higher capacity for given sizing of equipment, and appears more foolproof, requiring less attention. At […]

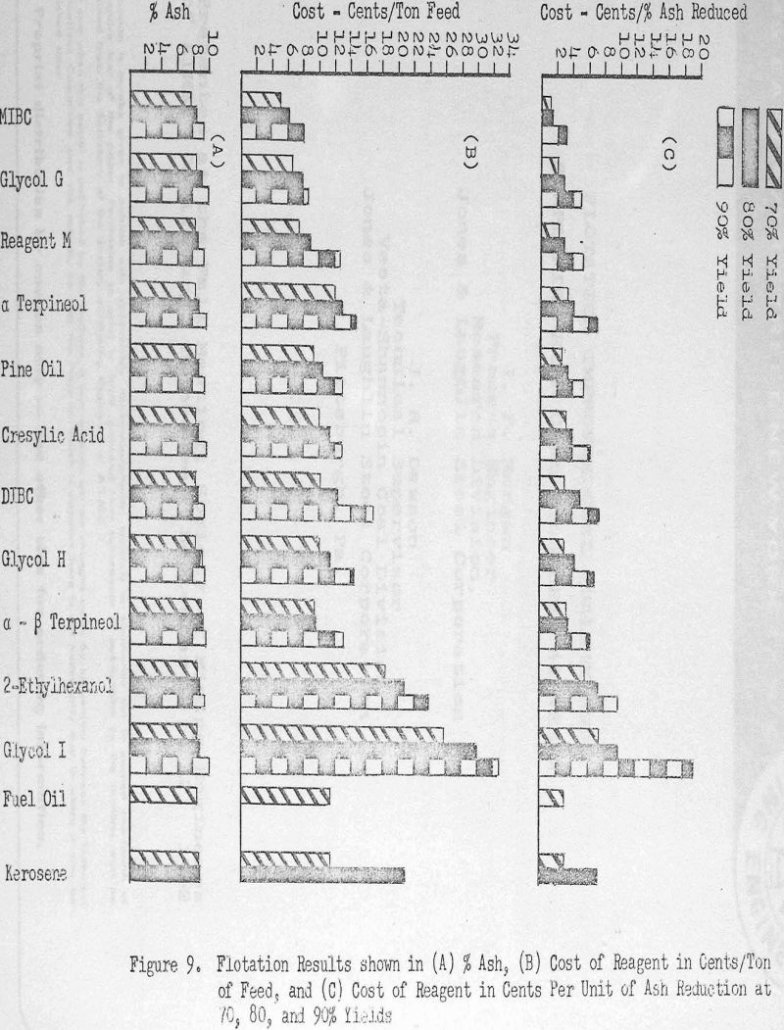

Coal Flotation Frothers – Yield Selectivity VS Cost

This paper presents the results of a study in which commercially available forms of various reagents were used as flotation frothers. Flotation procedures which would conform in general to those employed in a large number of commercial coal flotation plants were utilized. The reagents employed have been grouped into the following chemical classes; aliphatic alcohols […]

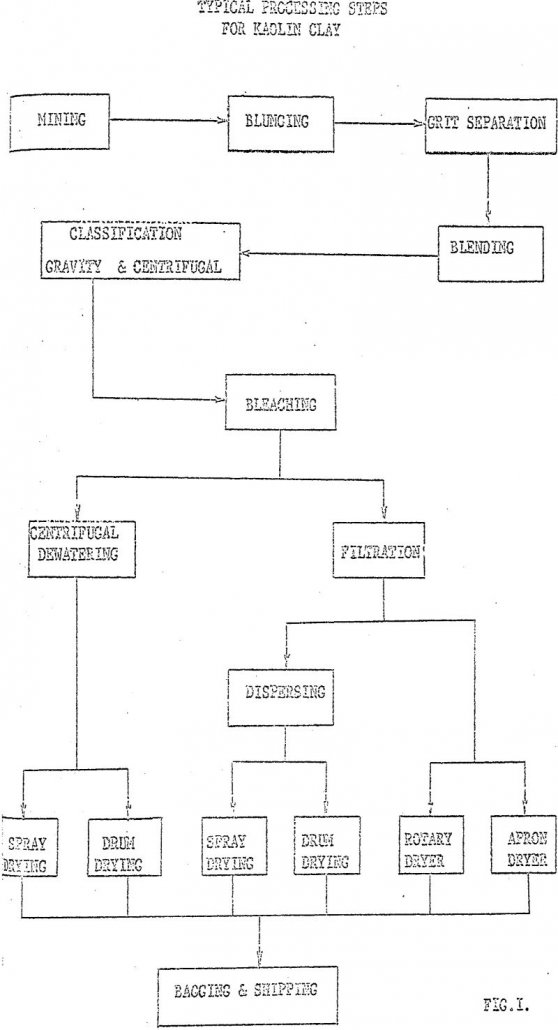

Dewatering and Processing Kaolin Clays

The dewatering steps discussed will include gravity settling, centrifugal dewatering, vacuum filtration, and thermal drying. Of these dewatering steps particular attention will be given to vacuum filtration and the variables affecting filtration of these kaolin clays. Kaolin consists essentially of the mineral kaolinite, which is a hydrated aluminum silicate (Al2O3·2SiO2). Commercial deposits of kaolin occur […]

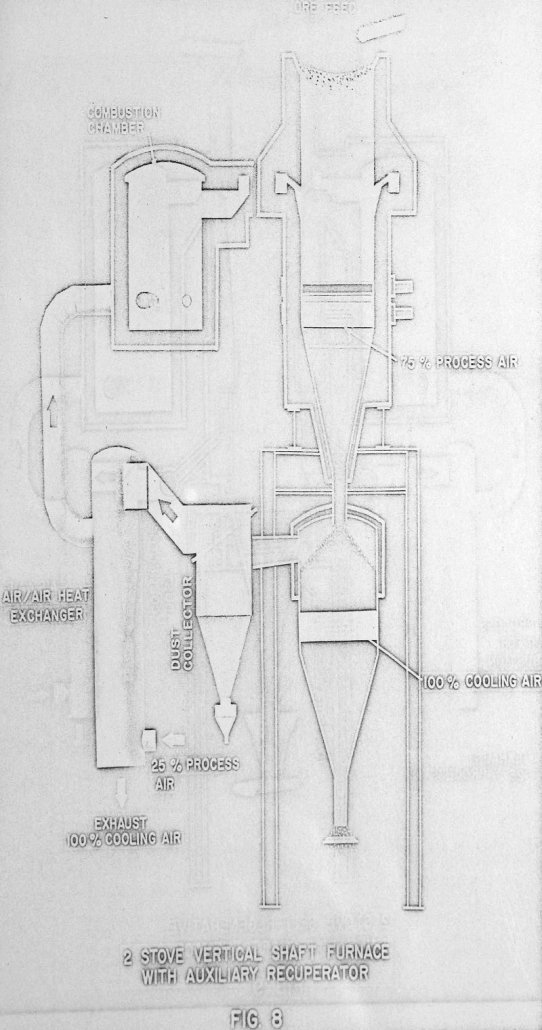

Vertical Shaft Furnace Design

Vertical shaft furnace design and operation have their roots deep in antiquity. There is substantial evidence to indicate that iron was reduced from its oxides to serve mankind’s needs long before recorded civilization actually prior to 3500 B.C. For at least 5500 years man has been matching wits with Nature to find better methods of […]

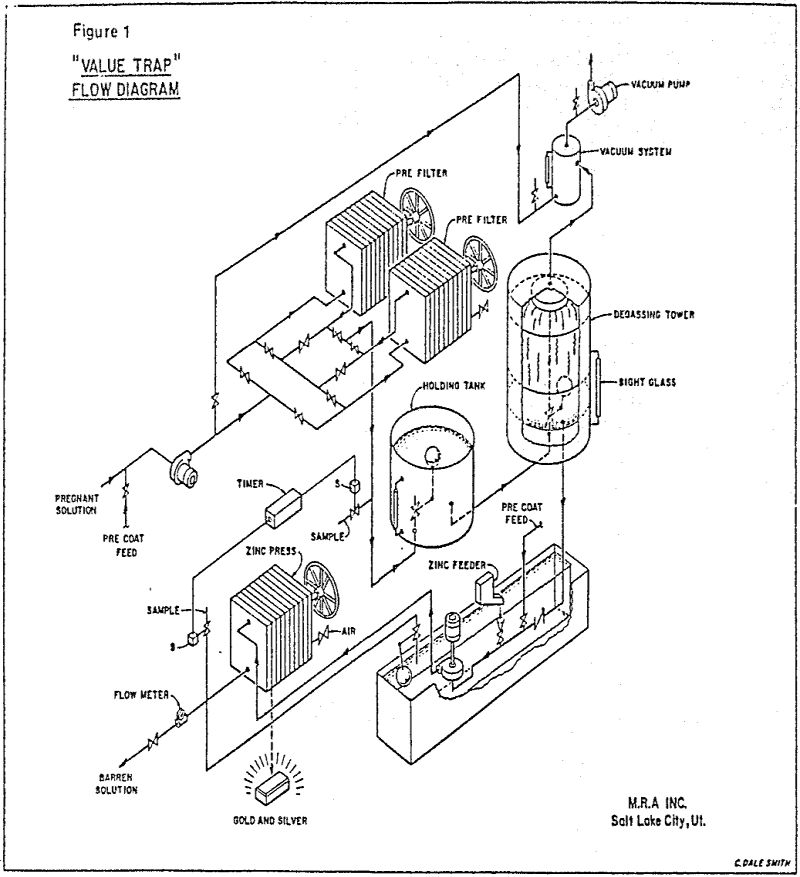

Design Merrill-Crowe Plant

The removal of metal values from cyanide solutions, fortunately, can be done in several ways. The oldest practiced method is, cementation with zinc, or Merrill-Crowe. Clarifying Filters Today the clarifying filtration is done with every kind of filter imaginable. Most of these filters are precoated with diatomaceous earth, DE, to produce extremely clear solutions. The […]

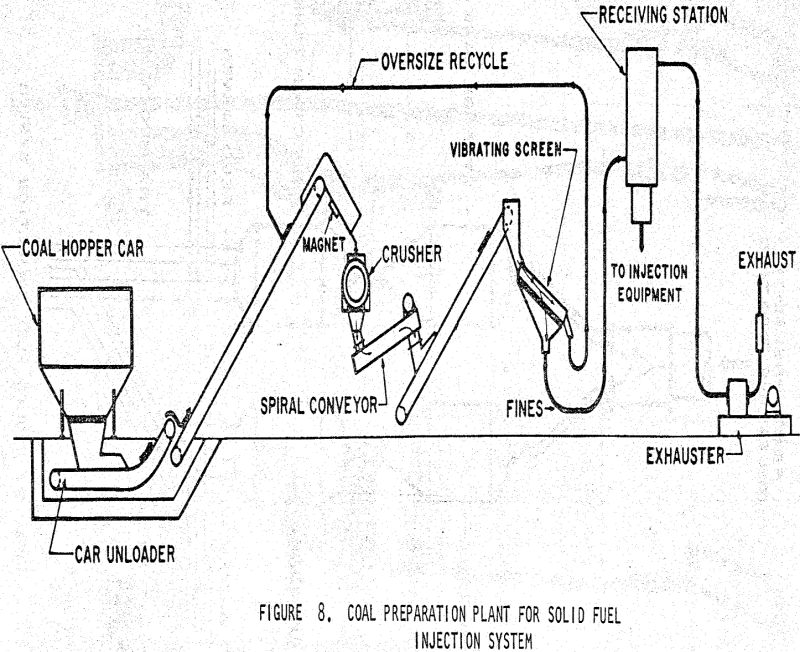

Coal and the Blast Furnace

During this period of evolution, man struggled with the only fuel he knew – charcoal. Some 5600 years passed before any attempt was made to use coal as a fuel for the blast furnace. Blast Furnace Practice No one factor can be pointed to as the prime cause of reduced coke rates and increasing production. […]

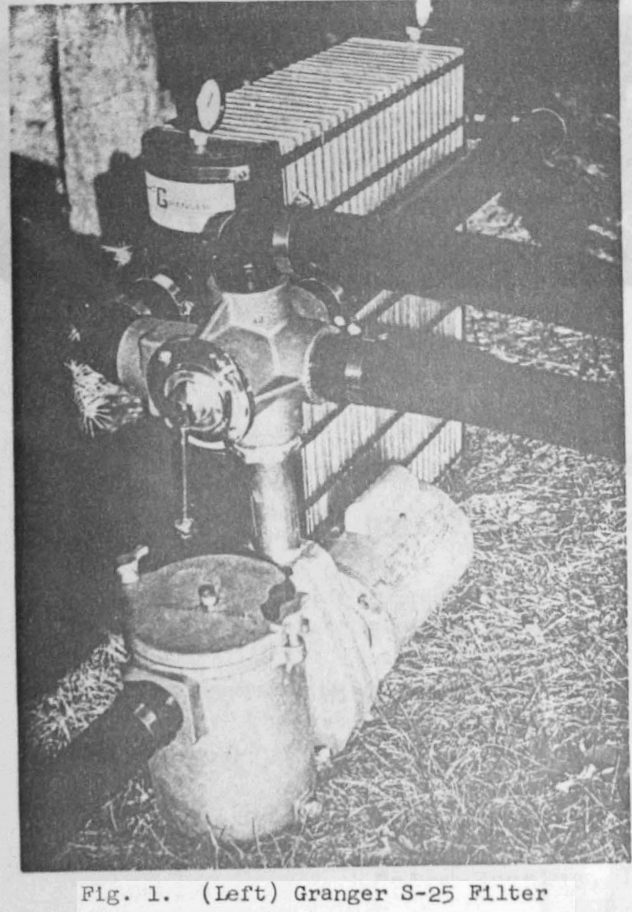

Clarified Solutions by Reversible Cake Filtration

In order to filter small amounts of fine slimy solids the reversible cake filtration process was developed. The filterable solids concentration in feeds can range from less than 1 ppm up to about 5%. The relative advantages of this process are usually the greatest in the range of.0.05% to 1.0% filterable solids. Filterable solids that […]

Bucket Wheel for Open Cast Mining

In deep strip mines the job of moving overburden may be so much bigger and more costly than the removal of coal or ore that the operation is often called dirt mining. Constant improvement in stripping machines and techniques of using them is needed to offset rising costs and to increase production in mines that […]

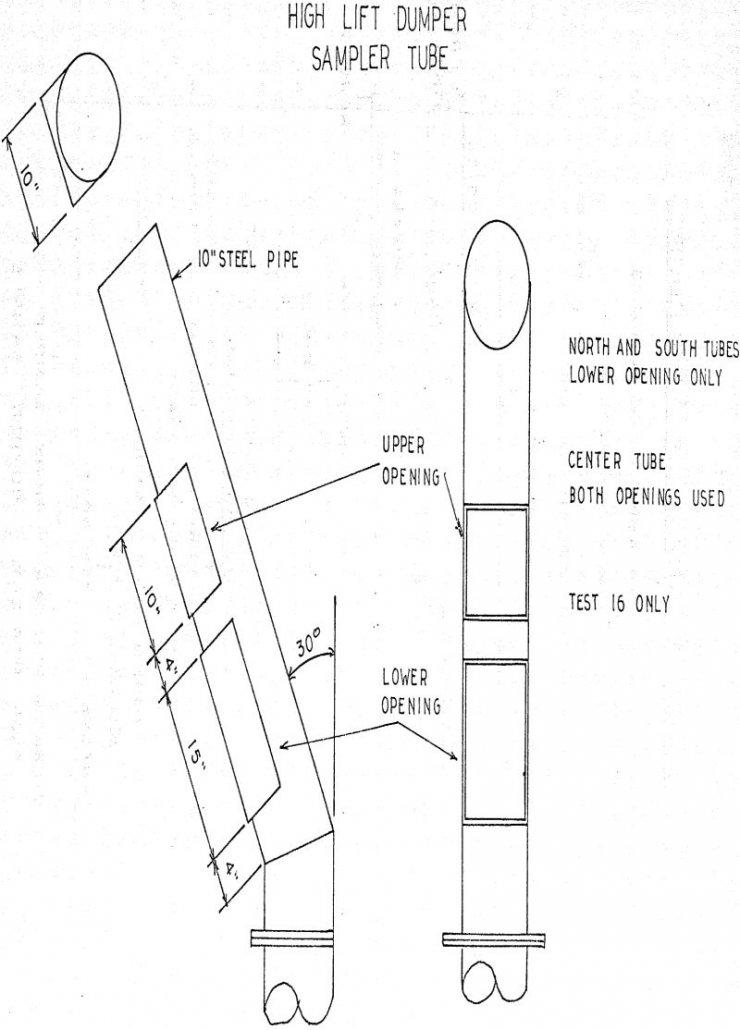

Automatic Sampling at Dumping Points

One of the major problems in the purchase and sale of coal shipped in lake or ocean going vessels has always been, the difficulty in obtaining a true analysis of the shipped coal’s quality because of faulty sampling by manual methods. As long as coal was sampled according to standards set up by ASTM methods […]

Undercut and Fill Mining

Undercut-and-fill- mining is a method developed by the International Nickel Company to deal with abnormal-pillar mining conditions at one of its mines. Results have been such -that its use has been extended to normal pillar recovery operations in other mines of the Company as a replacement for conventional square-set pillar mining. It is anticipated that […]