Optimum Mill Liner Spacing | Design Effectiveness SAG

The images (chart) below is industry standard when it comes to the relationship between a mill liner’s lifter bar height and the lifter to lifter spacing. What tonnage do you think this SAG mill liner design gets?

Choke Feed a Cone Crusher | Level Sensor

Here is cone crusher arranged with a Level Sensor interlocked with the feed conveyor. It keeps the crusher feed cavity full for best choke feeding. This is a great way how you can choke feed a cone and crush for a finer product. You do know that choke feeding reduces liner wear? See why in […]

King Gee’s G2 Compression Workwear Ideal for Miners

King Gee, a reputable clothing company, has released the revolutionary new G2 Compression Workwear. Ideal for miners, it “targets key muscles to reduce soreness and improves recovery.” G2 project team leader Nicholas Gronier has spoken with Australian Miner as to how beneficial their new G2 Compression Workwear is. He has explained how the clothing was improved […]

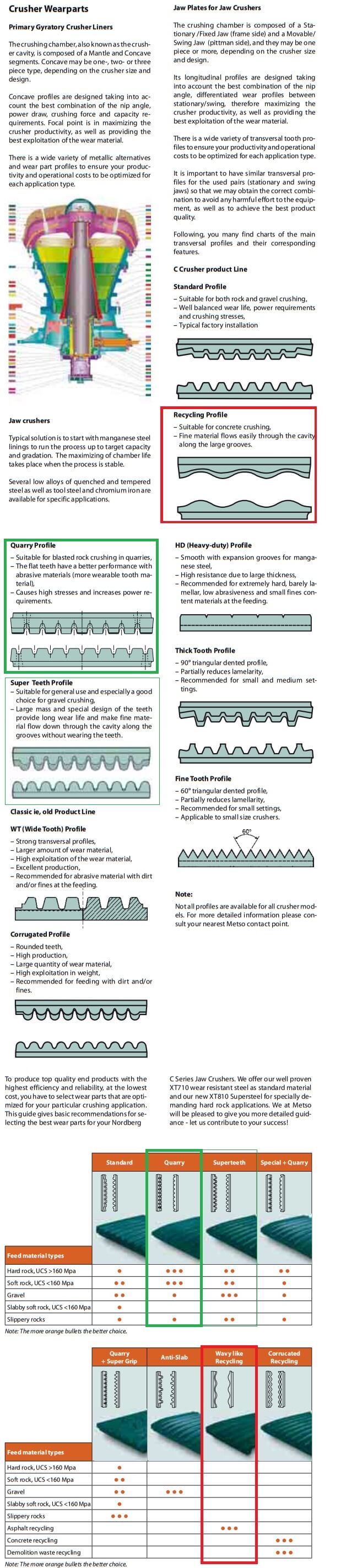

Selecting Jaw Crusher Liners | Shape & Design

A client needed finer crush out of his Jaw Crushers. I proposed this literature from Metso.com to help him select a jaw liner set. Designing your jaw crusher liners for the right function starts with asking ‘what final product crush size distribution do I want’ & ‘what are the physical characteristics of the feed to […]

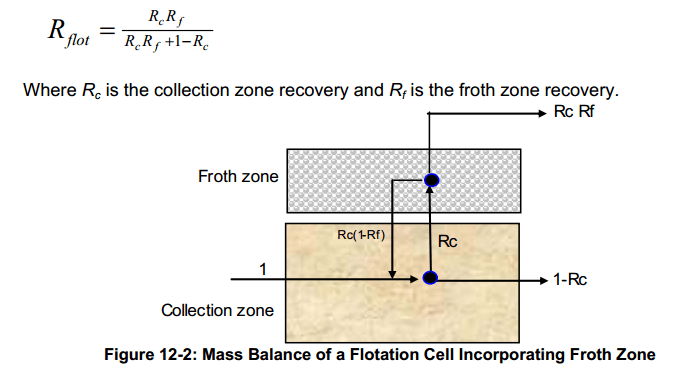

Column Flotation Model Overview

Although the model has been tested against only a limited amount of data the results shown in Figure 6 suggest that the model can be used to predict the flotation of fine particles in a column. The major advantage of the model is its ability to independently examine the influence of operational parameters on the […]

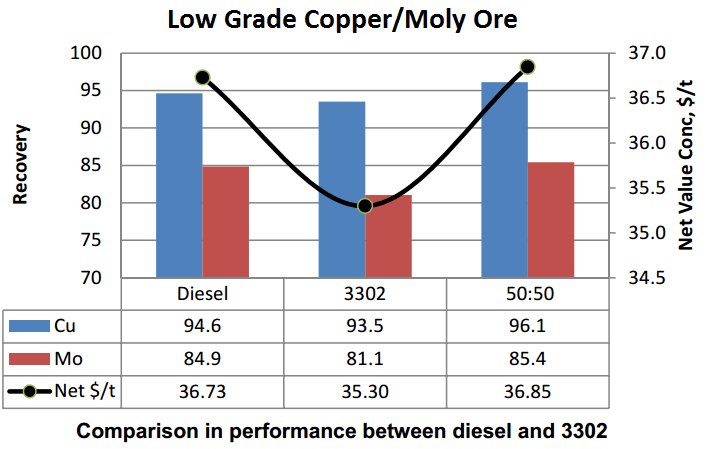

Compare Collectors and Fuel Oil for Moly Flotation

Are design or custom blends better than standard and cheaper fuel oil? Because of the high cost of the ‘designer or custom blend’ reagents, a test was run to determine the economical difference between 3302 and diesel. The evaluation was done with sulfide and transition ores, by treating a freshly prepared sample composite of both […]

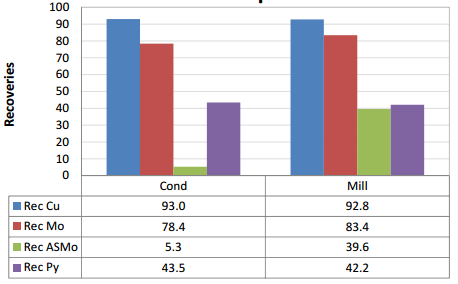

Moly Collector and Addition Point in Flotation

Where is Molybdenum best collected by its collector, Grinding or Conditioning? The protocols of the testwork were done such that a comparison could be made between adding the Moly collector at the milling stage versus the conditioning stage. As shown, the proper addition point for the Moly collector is at the grinding stage. The Moly recovery improvement is […]

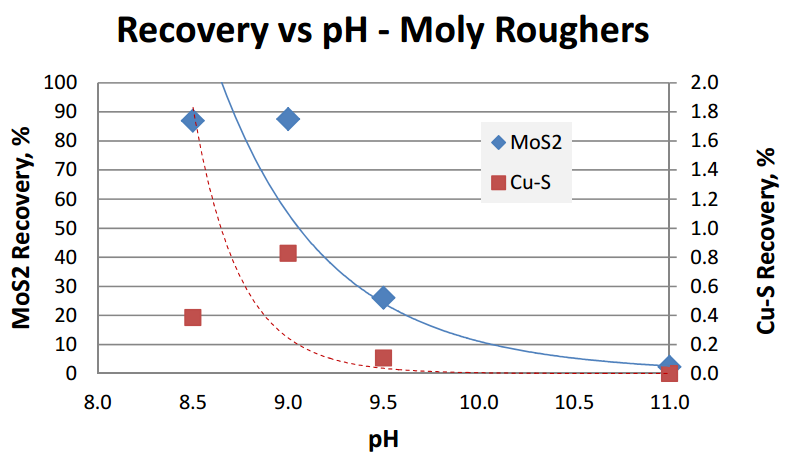

Effect pH on Moly Rougher Recovery by Flotation

pH was varied in the moly flotation in roughers while attempting to maintain a eH in the low -500 mV. The results of the test, shows that the best recoveries of moly are achieved at pH values of 9 and below. The copper recoveries appear to get activated at these low pH values, but the […]

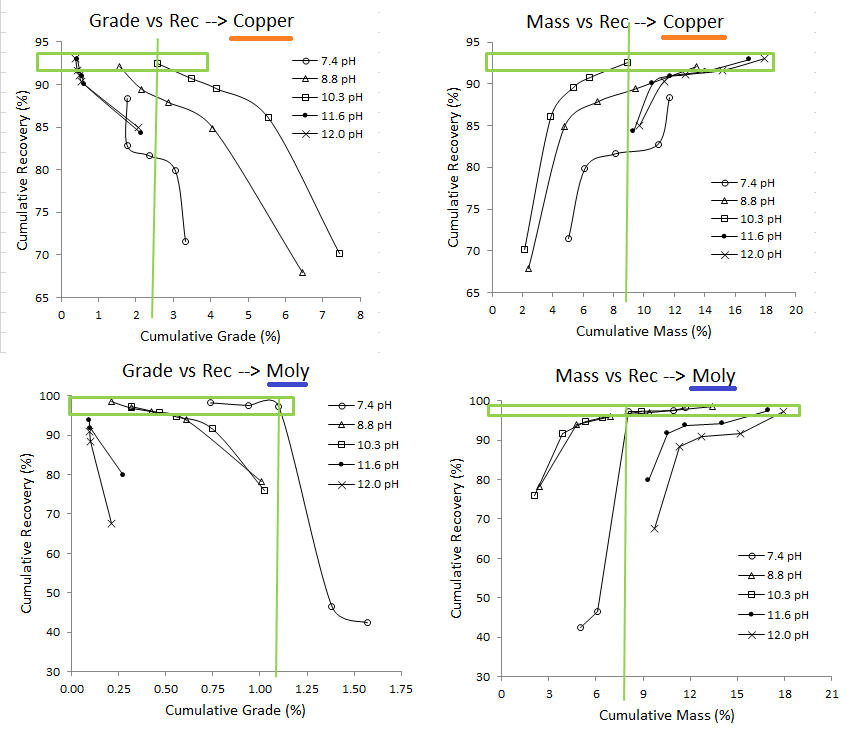

Effect of pH on Bulk Flotation of Copper – Molybdenum

Graphic Conclusions of this particular set of flotation tests: Copper – Irrelevant of pH, with enough float time and reagents, you usually reach a terminal bulk rougher Cu recovery in the low 90s (Green Box) – pH 10.3 gives you that terminal recovery in less mass (9%), more selectively, at a higher Conc grade (2.5%) […]

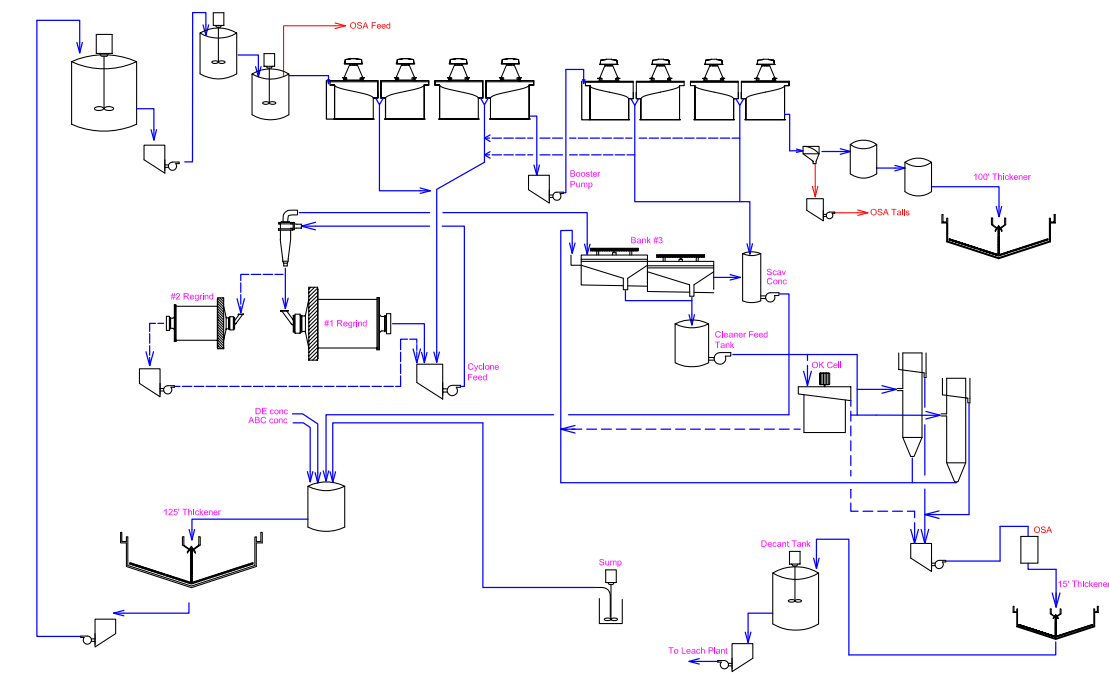

Proven Cu Mo Separation Circuit Flowsheet

Here is a Proven Cu Mo Separation Circuit Flowsheet (by flotation) many will model after. It is used a Canada’s largest copper-molybdenum mine. It uses NaSH and Nitrogen.