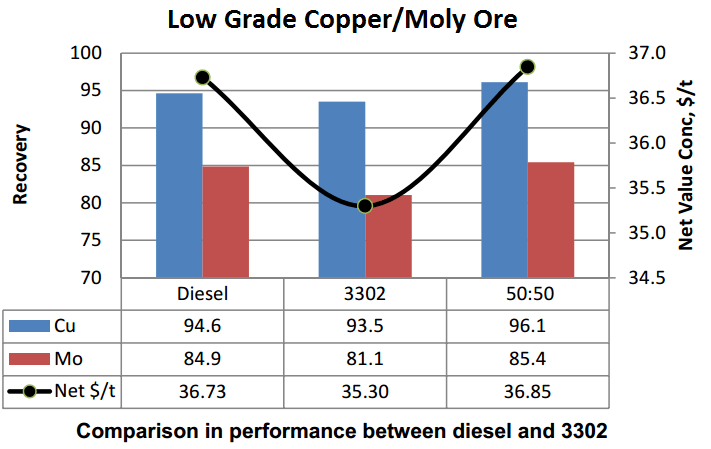

Are design or custom blends better than standard and cheaper fuel oil? Because of the high cost of the ‘designer or custom blend’ reagents, a test was run to determine the economical difference between 3302 and diesel. The evaluation was done with sulfide and transition ores, by treating a freshly prepared sample composite of both ores. The Moly collectors were added to the mill at 100 g/t in all cases, in one test as 100% diesel, in another test as 100% ‘designer or custom blend’ and in a last test as a fifty-fifty (50:50) mixture of diesel and ‘designer or custom blend’.

The “worth” of metals recovered was estimated by assuming the ore had a typical 0.5% copper, 0.02% Mo and with a copper price of US$ 3/Lb, a Moly price of US$ 15/Lb with reagent costs of US$9.9/kg of 3302 and US$ 1.75/kg diesel. In sulfide ore composite, as shown, the best metallurgical performer was the 50:50 mixture, followed by the performance with diesel. The economical comparison indicates that the high cost of ‘designer or custom blend’ makes the 50:50 mixture marginally better at 1.2 cents per ton of feed processed. In consideration with test repeatability, the improvement is marginal.

The marginal economic benefits of using a designer or custom blend (3302 in this case) over diesel seen in both ores prompted the team to select diesel as the collector for Moly in the bulk circuit.