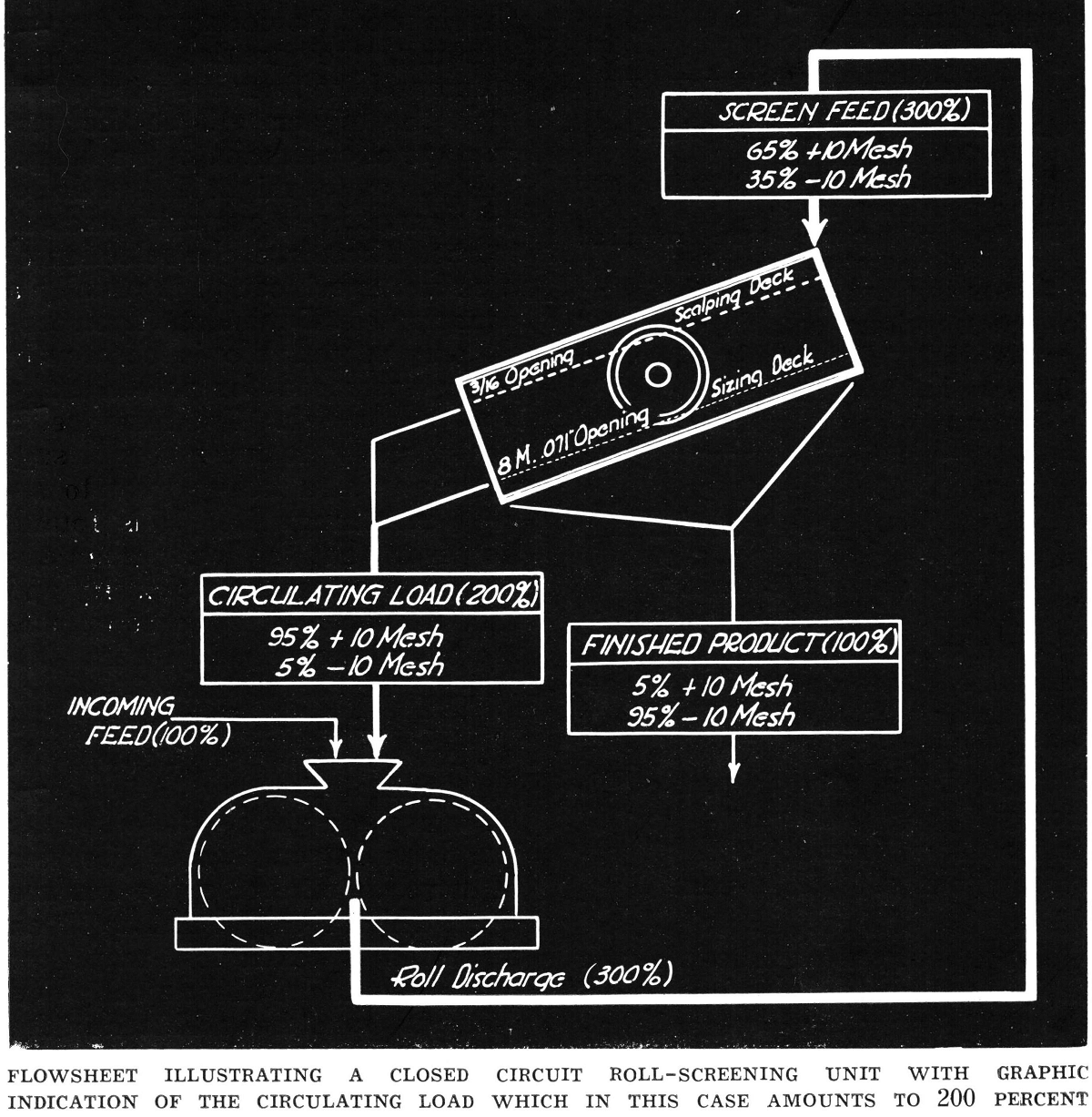

Screening 101

Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of […]

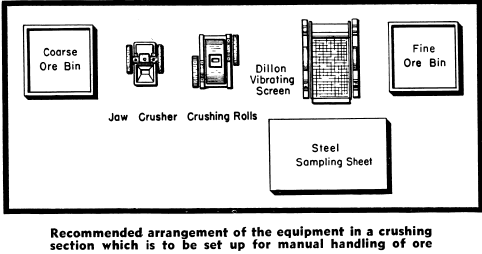

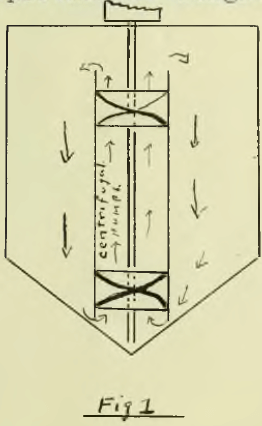

Mineral Processing Pilot Plant Equipment

The testing of tonnage lots of ores and industrial materials by continuous Mineral Processing Pilot Plant operation is in many instances advisable before a full scale milling plant is installed. The treatment of complex ores by new processes or by the use of new or unusual reagents in flotation may involve problems the effect of […]

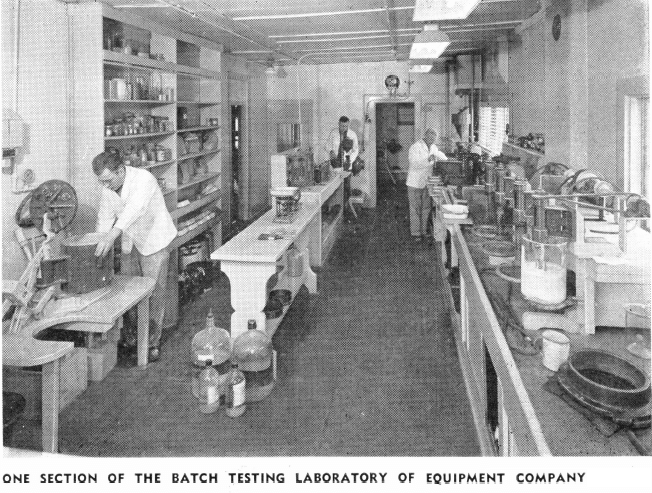

Metallurgical Laboratory Equipment & Test Methods

The Mineral Industries have for many years recognized the importance of small-scale ore dressing tests for determining the amenability of ores to various methods of concentration. The successful development of the flotation process, which was accomplished with the aid of small-scale laboratory machines, gave a decided impetus to the laboratory testing of ores. Today the […]

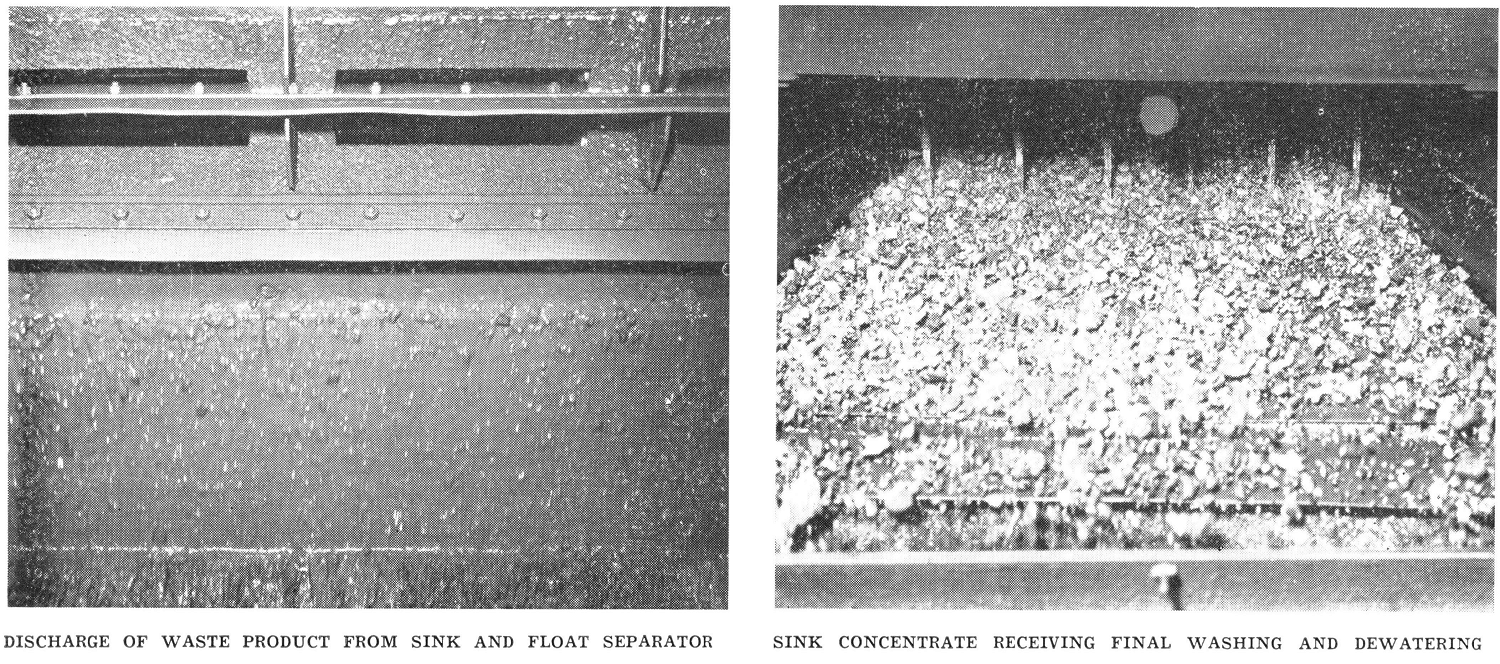

Sink and Float Separation Process

The Sink and Float Separation Process is an alternative to the progressive depletion, during the last quarter century, of ores which could be economically treated by the old methods of gravity concentration necessitated the development of more efficient methods of concentration, the most successful and widely used of these methods being the Flotation Process. But […]

Gold Leaching

Gold Leaching Process Circuit NO. CY-1 This leach plant shows the continuous counter-current decantation system, in which all the ore is first reduced to a very fine state in the grinding mill-classifier circuit, in a Gold Leaching solution. The slime overflow of the classifier, usually 70%—200 mesh, or finer, is sent to the first thickener, known […]

Gold Cyanidation Process

The gold cyanidation process is the most important method ever developed for extracting gold from its ores. The reasons the widespread acceptance of cyanidation are economic as well as metallurgical. It usually obtains a higher recovery of gold than plate amalgamation and is easier to operate than the chlorine or bromine process. It produces the final product in […]

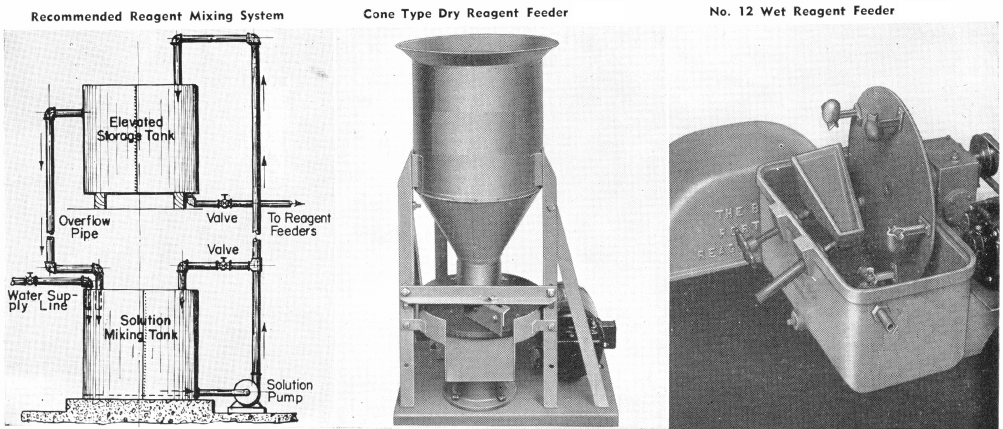

Flotation Reagents: Uses and Advantages in Ore Processing

This data on chemicals, and mixtures of chemicals, commonly known as reagents, is presented for the purpose of acquainting those interested in froth flotation with some of the more common reagents and their various uses. Flotation as a concentration process has been extensively used for a number of years. However, little is known of it as […]

Flotation Circuit Process Control

Our subject is “CLASSIC or Not so Advanced but yet Fundamental Flotation Circuit Process Control” Some of you may be familiar with the process; to others it remains a mysterious scheme. To you all I wish to emphasize one point, i. e., flotation is still now more of a science VS art. Our scientific data has […]

Electrolytic Gold Extraction

Gold is so widely distributed in nature and is so much desired on account of its value that the metallurgy of gold is not only one of the most fascinating but also one of the most important industries. Gold occurs in several forms in nature: as free gold; in combination with sulphur, or in the metallic state […]

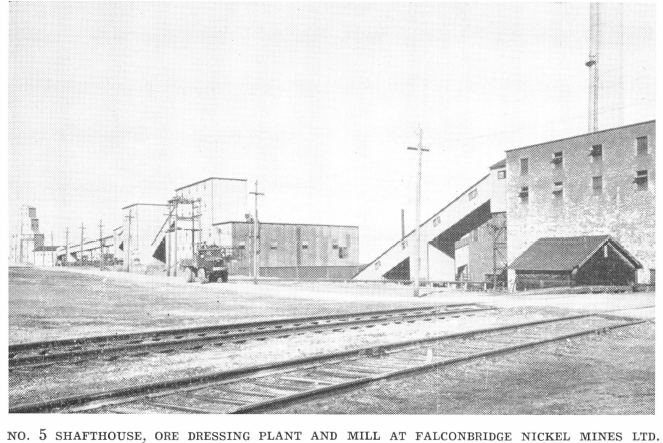

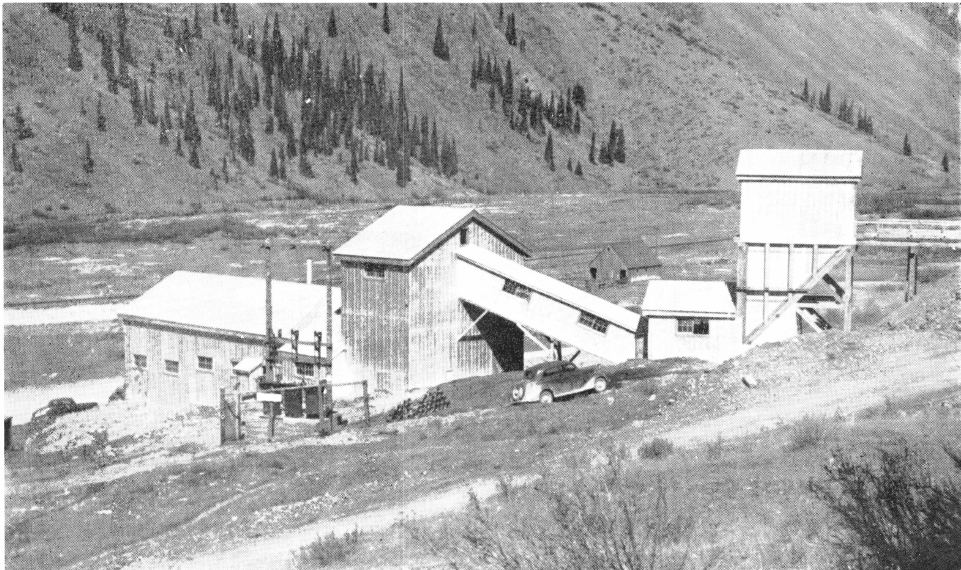

Mineral Processing Plant Design & Construction Example

Metallurgical Recovery, which consists of the percentage of mineral saved, must not be confused with economic recovery which covers the percentage of the gross value of an ore recovered as a net profit. In other words, in commercial practice the prime object is the highest possible net profit over and above all costs. Thus a […]