Recommended Rod Mill Bar Length

Ever asked what size/length rods (bars) you need for charging your rod mill? It depends on the rod mill diameter itself. To prevent most conditions leading to rod charge tangling, the generally recommended relationship of rod length to mill diameter Inside liners is 1.4 to 1.6. When this ratio becomes less than 1.25 the risk of […]

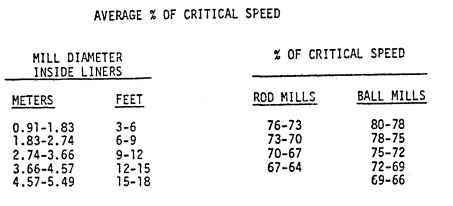

Recommended Mill Operating Speed RPM

Here is a table of typically recommended ball mill speed or rod mill speed as a % of critical will operate at. In summary, the larger the mill, the slower you will want the RPM to be set at and the mill to turn. Ref

Example Locked Cycle Test Results

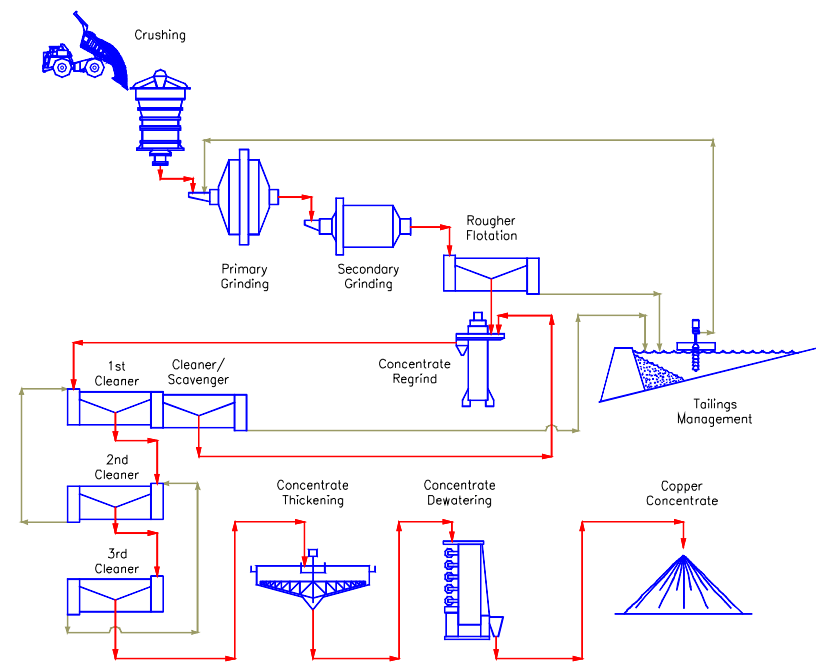

Locked cycle tests were conducted on each of the super composites, using the flowsheet shown below. The flowsheet consisted of a primary grind to a P80 of 150 µm, followed by rougher flotation at pH 9.5 to produce a bulk sulphide concentrate. The rougher concentrate was reground to a P80 of ~30 µm prior to […]

Copper Process Flowsheet Example

A simplified schematic drawing of copper flotation flowsheet. Run-of-mine open pit ore will be crushed in a gyratory crusher. The crushed ore will be processed by means of semi-autogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate. The concentrate will be trucked via the existing road […]

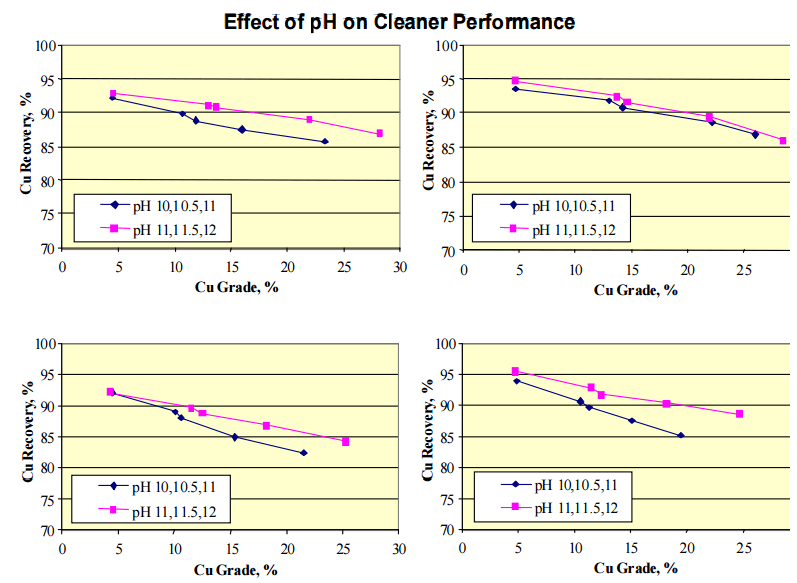

Effect of pH on Copper Cleaner Flotation

In the study, batch cleaner tests were conducted to confirm the target regrind size and select the cleaner pH conditions. The objective of the high pH, collector-starved environment in the cleaners is: To liberate and reject attached silicates, Depress the previously-floated pyrite. If the floatability imparted on the pyrite in rougher flotation is not adequately […]

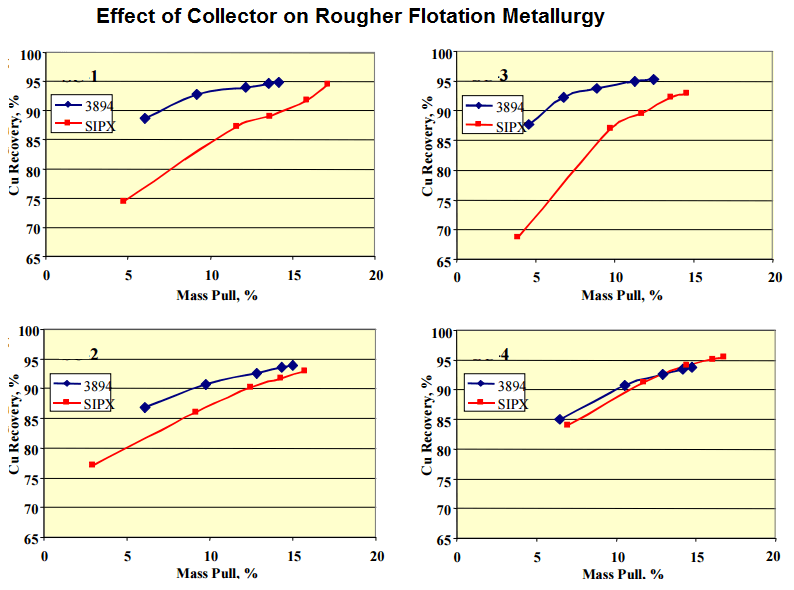

Effect of Collector on Copper Flotation Metallurgy

A pretty clean and relatively easy to treat ore was tested suggesting a collector optimization strategy would probably yield only relatively minor incremental metallurgical improvements. Therefore, collector suite fine-tuning was deemed largely better left for future optimization, possibly when the plant is in operation. In earlier studies Sumitomo had adopted the use of thionocarbamate Cytec […]

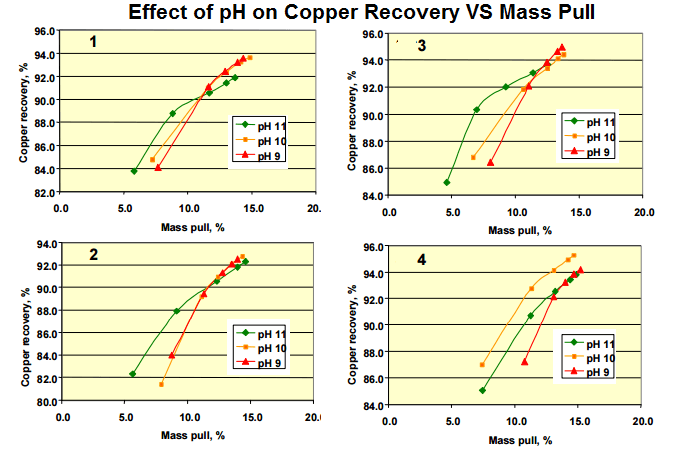

Effect of pH on Copper Flotation Recovery VS Mass Pull

An example of testing the effect of pH on rougher flotation on pit samples and the results are presented. Since this is only an example, it needs reminding that not all ores will respond the same. Here, rougher flotation is most Selective at a pH of 9.5 as pH levels in the 9 to 10 […]

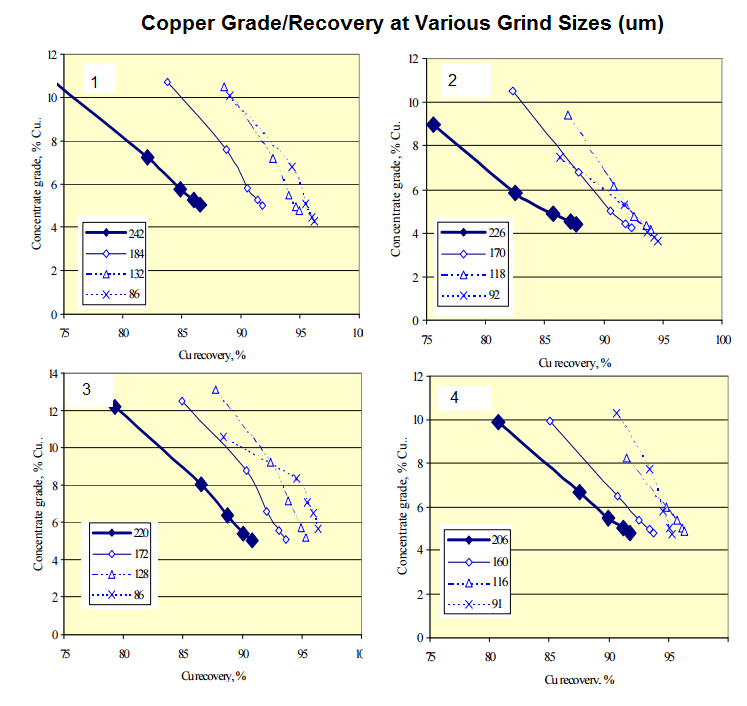

Effect of Primary Grind Size on Copper Flotation

An example of a copper metallurgy study where the effect of primary grind on rougher flotation each of the GeoMetallurgical samples was investigated. A simple economic study was conducted on these copper flotation results, using typical power costs and a net smelter revenue value for copper of 90 cents. This indicated that the optimum grind was […]

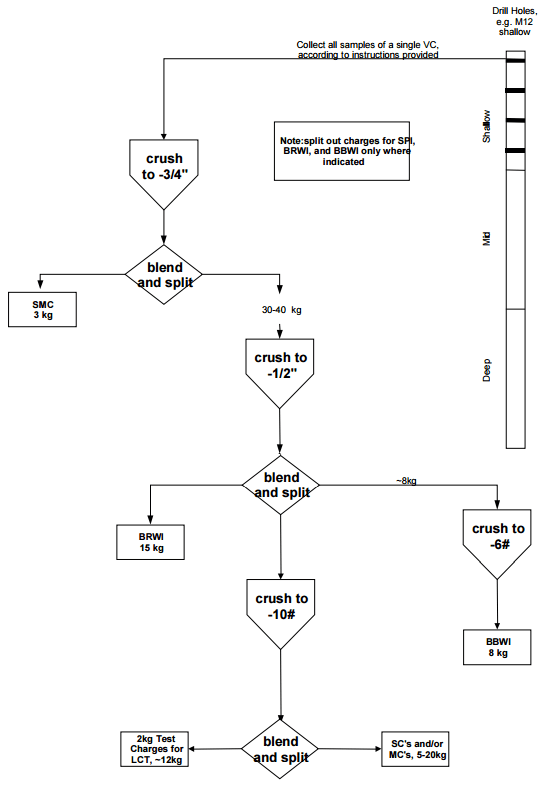

Sample Preparation Flowchart

The samples set aside for the Super Composites (SC) were blended to form the four composites used for the initial flowsheet development program. Each SC was crushed to 100% passing 10 mesh and rotary split into 2 kg charges and a reject fraction. A flowchart summarizing the sample preparation procedure is presented here below. Eighteen […]

666 Gold