Crusher Lubrication System Operation & Maintenance

For easy of Operation & Maintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level, FLOW METERS in the oil lines and/ or VISUAL ACCESS to the discharge point of the oil circuit. This is to allow the operator to gauge the oil […]

Gyratory Crusher Lubrication

The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to. This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore carriers are dumping directly into the crusher. This means that the machinery is […]

Gyratory Crusher Components

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. It is this eccentric bushing and bearing that gives the crusher its crushing action. To understand how it works it might help to learn the dictionary meaning of the word eccentric […]

Compare Gyratory Crusher vs Jaw Crusher

To accomplish this reduction in size takes several steps or stages of crushing and grinding. Primary crushing is the first of these stages. Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER. Although they don’t look anything like they do have similarities that put them into […]

Conveyor Safety Talks

Let us talk about Basic conveyor safety as it is just like being around all moving equipment will be guards of one type or another. It may be to prevent people from falling into the equipment or, in cases where there is a danger of equipment failure, the guards may be designed to contain parts […]

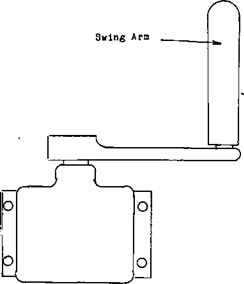

Conveyor Belt Alignment Switch

The other switch I mentioned was a MISALIGNMENT switch. This is a manual swing arm that is placed beside the conveyor belt. If the belt should wander the arm will be struck pushing it out of position and shutting the conveyor down. In most mills the equipment is INTERLOCKED. This means that if one piece of […]

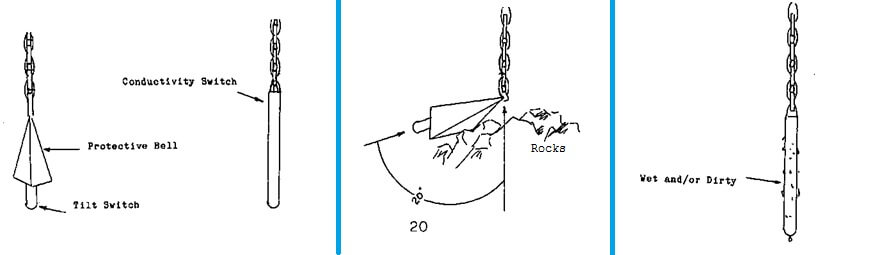

Plugged Chute Detection Probe

A Plugged Chute Detection Probe is an emergency switch that will shut down the equipment should a transfer chute “become plugged. There are two common types of probes, a TILT SWITCH and a CONDUCTIVITY switch. A tilt switch hangs inside the chute. If the chute plugs, the ore will build up to the switch. The […]

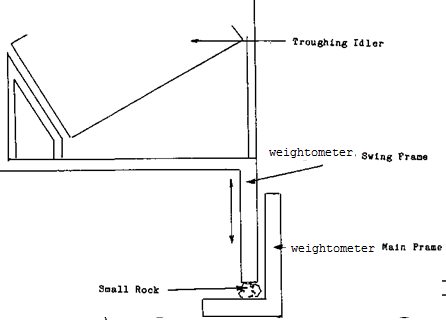

Belt Conveyor Scale – Magnet and Metal Detector

Belt Conveyor weightometers are required to accurately weight and chart the tonnage throughput. An operator is able to catch many problems that are developing simply by watching the tonnage. A drop or increase in tonnage can indicate something going wrong .within the system. MAGNETS, These capture what is known as “TRAMP METAL”. This is metal that […]

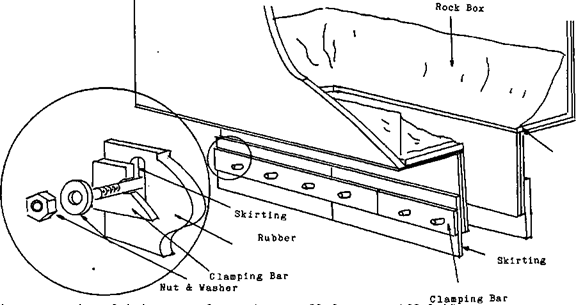

Transfer Chute Skirting

The transfer chute skirting is made from rubber and prevents rock from bouncing and rolling over the edge of the conveyor when it is loaded onto the belt. This skirt runs completely around the chute except for the discharge point at the front. As the skirt and the belt cannot have a lubrication put on […]

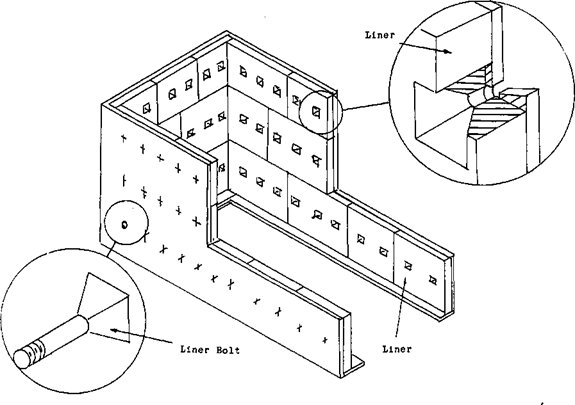

Transfer Chute Liners

These liners have a high carbon content to give them the hardness required. This carbon makes welding these liners very difficult. For this reason the liners are bolted in place. As I mentioned earlier these bolts make excellent early warning indicators for worn-out liners. When the wear on the liner becomes great enough to wear […]