Table of Contents

The operations of the Electrolytic Zinc Co. of Australasia Ltd. involve the preliminary roasting of zinc concentrate from Broken Hill, New South Wales, at a number of acid-making centers on the Australian mainland. The partially roasted material is shipped to the Tasmanian plant where it was formerly re-roasted prior to leaching, but this practice was gradually abandoned in favor of the flotation of leach residue for the recovery of a concentrate containing about 22 pct sulphide sulphur and known as secondary or Risdon concentrate. This change, together with increased zinc production, called for new furnaces at Risdon for the roasting of 40-50 tons of secondary concentrate and 90 tons of new concentrate per day.

The war situation made it imperative that construction be commenced without delay and to save time it was decided to base the design on that of Skinner type furnaces which had been built in South Australia twenty years earlier.

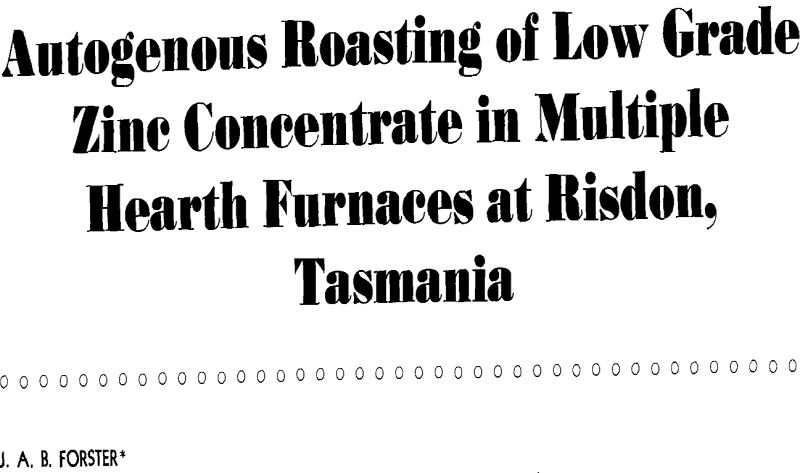

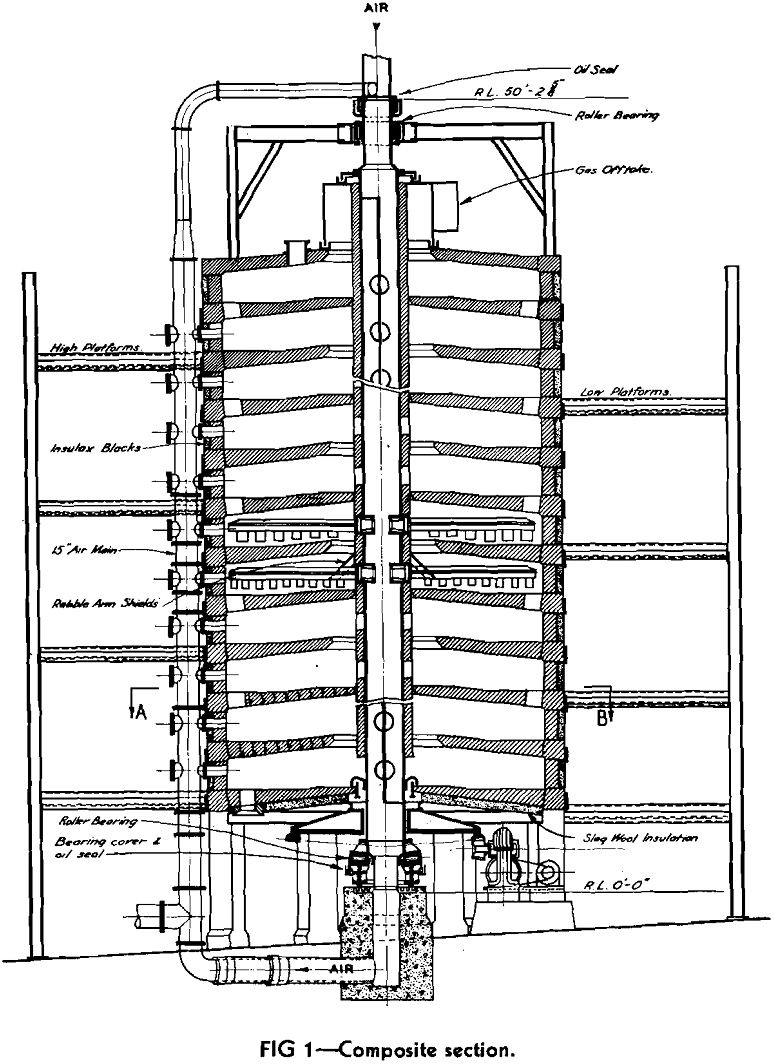

Furnace Design

General specifications for the design were based on the results of experience with several other types of furnace and on the special operating conditions expected.

The original hearths had a camber of 8 in. and were very difficult to keep clean. To build flat hearths involved major changes in design, and a compromise was reached by thickening the haunch blocks and five outer rings of hearth blocks as much as minimum door size would allow, but the original camber remains in the central portions of the hearths.

The working doors are covered by outer doors which form chutes right down the face of the furnace to hoppers in the basement where spillage and cake from the hearths are collected. These chutes are ventilated by a fan which exhausts from both top and bottom of each chute so as to be effective when any door is open.

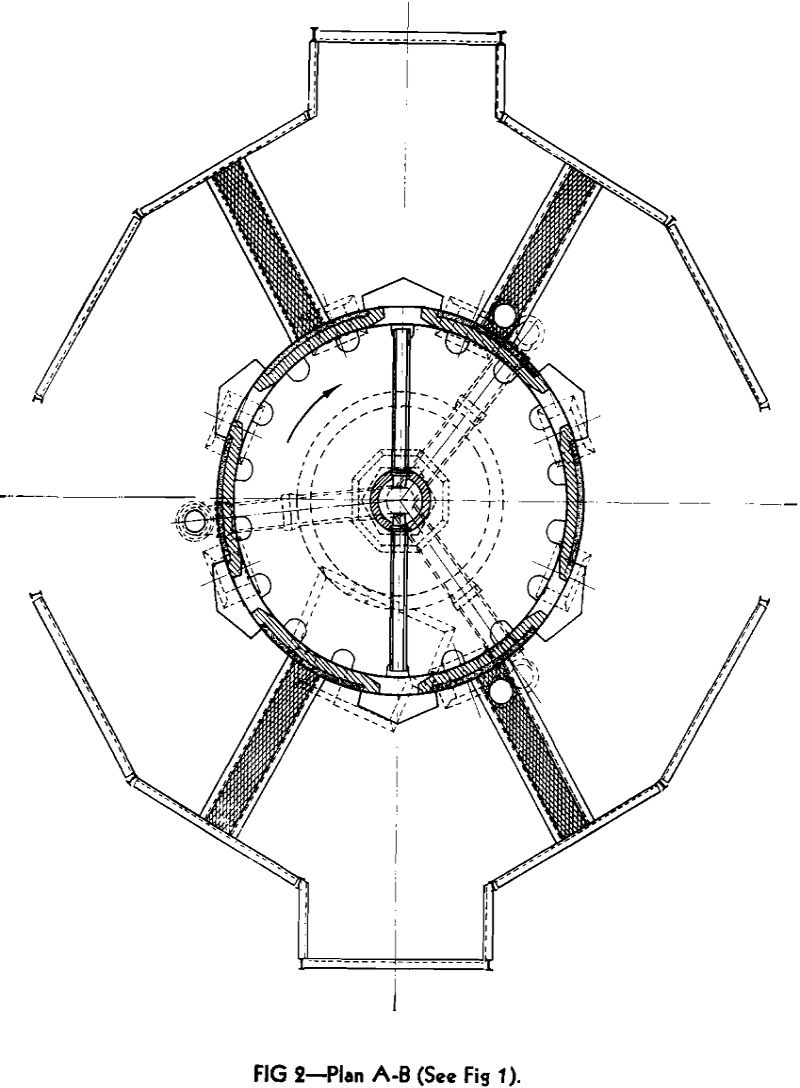

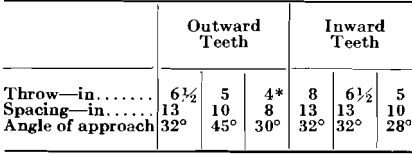

Design and Arrangement of Rabble Teeth

A large contribution to the present performance of these furnaces has been made by improvement in the design and arrangement of rabble teeth. There are five factors of importance in design: angle of approach, throw, spacing, depth and overlap. These have not always had the attention they deserve, though this may mean the difference between failure and success of a furnace.

Angle of approach is the angle between the blade of the tooth and the tangent to its circle of movement. If this angle is too large the material being rabbled will not slip across the blade but will tend to build up in front and to be pushed around the furnace; an overloaded condition will quickly develop. If the angle is smaller than need be the blade of the tooth will be too long and heavy in relation to the work required of it. The smaller the angle and the longer the tooth the more difficult it will be to clean the blades when necessary. The angle may be relatively large for material moving down a slope or outward across the hearth, but must be smaller for the same material on upward slopes and for inward rabbling. Free moving material like dry sand can be worked with the most economical angle, 45°, on outward traverses, but angles of less than 30° may be necessary for sluggish or “sticky” material on inward traverses.

The depth of the teeth determines firstly the depth of immobile bed on the hearth, and secondly, in conjunction with spacing, the maximum cross section of material which can be moved effectively at each pass of the arm. Where the material has to traverse a slope it is the depth of tooth nearest the crest which is the determining or effective depth of all teeth on the hearth.

On a flat hearth “slip” is normally a little less than one-eighth of the mobile load gathered by the tooth; on downward slopes and outward traverses it is less, on upward slopes and inward traverses it is more. On cambered inward rabbling hearths, the greater slip tends to increase slip still further, so that there is a distinct tendency for such hearths to become overloaded and, finally, completely choked. It is important in such cases to keep the upward slope to a minimum by having as little immobile bed as possible near the crest. A further and effective remedy is the use of some overlap, that is, having the paths of teeth on one arm overlap the paths of those on the preceding and following arms. It is present when spacing is less than throw multiplied by the number of arms; (by 2 in the special case where four arms operate as two effective pairs). This is, of course, a particular case of the general principle that increased throw tends to thin the mobile bed, for the simplest way of getting overlap is to increase the throw of the teeth without altering the spacing.

Within a few weeks of starting, the first furnace was being operated to the full capacity of its hearth transport system, which proved, under test, to be about 75 tons per day, nonstop. It was obvious that the furnace had by no means attained its full roasting capacity, and if this were to be realized an increase of transport capacity must be obtained. In fact, a very big increase would be necessary for, in any furnace roasting galena bearing concentrate, the transport capacity must considerably exceed roasting capacity if smooth, efficient operation is to be obtained.

At higher loading rates spill from the inside of outward rabbling hearths increased. The teeth nearest the column on these hearths were elongated so that the leading edges of the blades almost touch the column.

The outward teeth most generally used in the Risdon furnaces have the following characteristics:

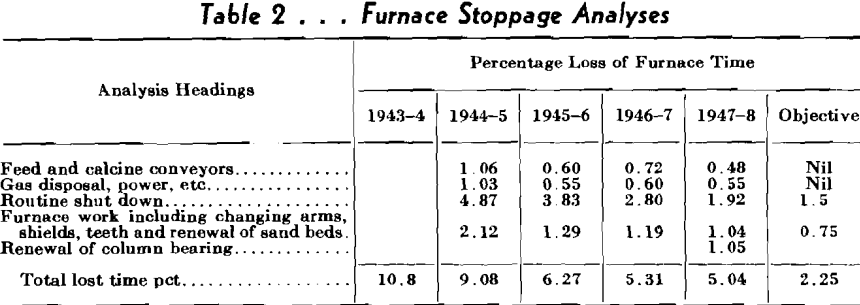

Operation

Consistent roasting performance depends on regular feeding of an evenly graded concentrate, effective temperature control, clean rabbling and a smoothly running furnace.

Because of the characteristics of the feed components and the necessary arrangements for their delivery to the furnaces, the labor needed to obtain satisfactory feed control is much more than the average for other roasting plants. About half the feed consists of secondary concentrate delivered direct from a continuous disc leaf filter liable to vary from hour to hour in amount and from day to day in grade. The remainder, known as the “high grade” feed, is a mixture of screened dross and flue dust from the zinc melting furnaces with high grade zinc concentrate derived from any of four sources and with distinctly differing characteristics; this mixture carries from 26.5 to 28.5 pct sulphide sulphur whereas the secondary concentrate has from 21 to 24 pct. The general effects of this diversity of feed material are described in connection with furnace performance; as far as feed control is concerned it makes feeding at a constant tonnage rate entirely unsuitable. Effort must be directed at keeping the input of sulphide constant.

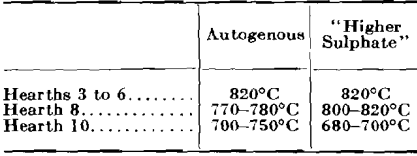

The temperature objectives in autogenous and “higher sulphate”* roasting are:

After allowing for the cost of sand and of putting it in place, the wage saving resulting from the almost complete elimination of chiselling is not very great but the ultimate benefit from the reduction of wear and tear on the hearths and mechanism will be quite considerable.

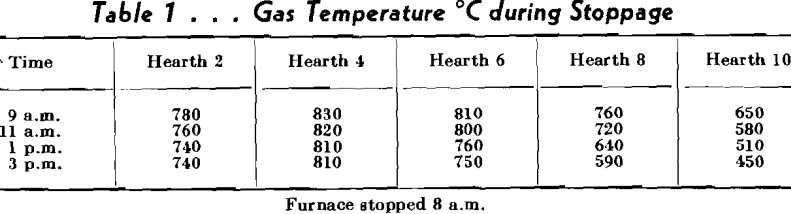

If the roasting is strictly autogenous, the recovery of the lower hearth temperatures is rather slow, taking about four hours for each hour of shut down, unless calcine grade is sacrificed to a serious extent. If an oil burner is used at Hearth 9 to assist recovery, the time is reduced by half at an expenditure of about 6 gal of oil per furnace per hr, and calcine grade does not suffer appreciably.

Roasting Characteristics of Feed Components

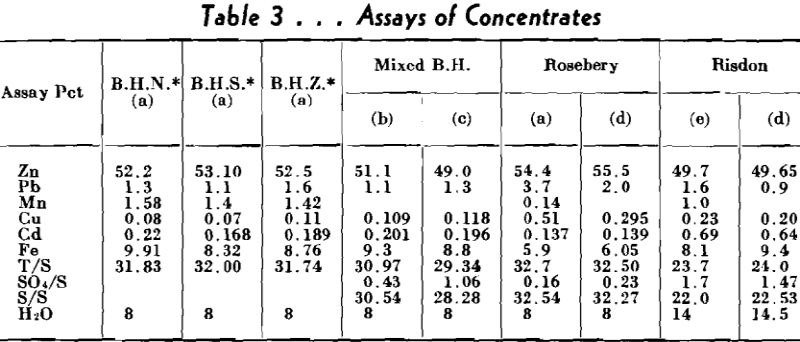

The feed to the furnaces is always a mixture of concentrates from any or all of four sources, three Broken Hill mills and the Company’s own mill at Rosebery, together with secondary concentrate (called Risdon) recovered from leached calcine residues, and latterly about 5 pct of dross and flue dust from zinc melting furnaces. Since feed composition inevitably varies, a knowledge of the roasting characteristics of the different components and mixtures is essential.

The objectives are not constant. The requirements of the zinc plant as a whole, the position in regard to stocks and certain subsidiary operations lead to variations in the stress laid on obtaining maximum oxidation of sulphides which is incompatible with relative completeness of oxidation and production of sulphate.

An iron roasting dish with a false bottom was used in an electrically heated muffle with and without a small exhaust chimney, and temperature was closely controlled throughout. A half inch bed of material was well rabbled every five minutes and the most difficult concentrate was dead-roasted in 2 hr at 800°C under these conditions. In all cases roasting was faster at a bed temperature of 800°C than at 750 or 850°C, and the rates for the various concentrates always fell in the same order. Sulphate is formed to any ex-tent only when sulphide content is relatively low, and under these conditions is more prevalent in the coarse fraction containing aggregates than in — 10 mesh material. Rosebery and Risdon concentrates sulphate much more readily in both coarse and fine fractions than the Broken Hill materials. Table 4 gives assays, sizings, roasting rates and sulphate formation in the tests described and it should be noted that, in general, the progressive or instantaneous isothermal roasting rate for any concentrate is directly proportional to the progressive sulphide concentration and to a proportionality factor which is characteristic of the material and of the conditions of the roast.