Table of Contents

The principle purpose of applying control to any process is to improve its profitability. Even when considering the impact of a plant on its surrounding ecology this is still true, since the sanctions felt most immediately from violations of the regulations are the economic penalties or fines which result. Economic performance can be improved within a plant in several ways.

Control Techniques

The basic control techniques, of which examples from within the minerals processes will be given, may be itemized as follows:

i. Single loop feedback control

ii. Cascade control

iii. Feed forward control usually combined with one of the above

iv. Variable gain control

v. Predictive combined with adaptive control

vi. Optimizing procedures

The two most common difficulties which control loops have to be designed to cope with are process capacitance lags and transport lags. The first are introduced by vessel sizes and the delays in response occasioned by mixing phenomena. The control of density in a sump is subject to this last type of lag. Transport lags are exhibited when material has to travel a certain distance between a disturbance and the point where the response is measured. Both mixing and transport lags occur within the mill in a grinding circuit while a spiral classifier is almost a pure distance velocity lag.

Standard Grinding Circuit with Cyclone Classifiers

In the typical normal grinding circuit the control of the circuit centers on the following loops and parameters:

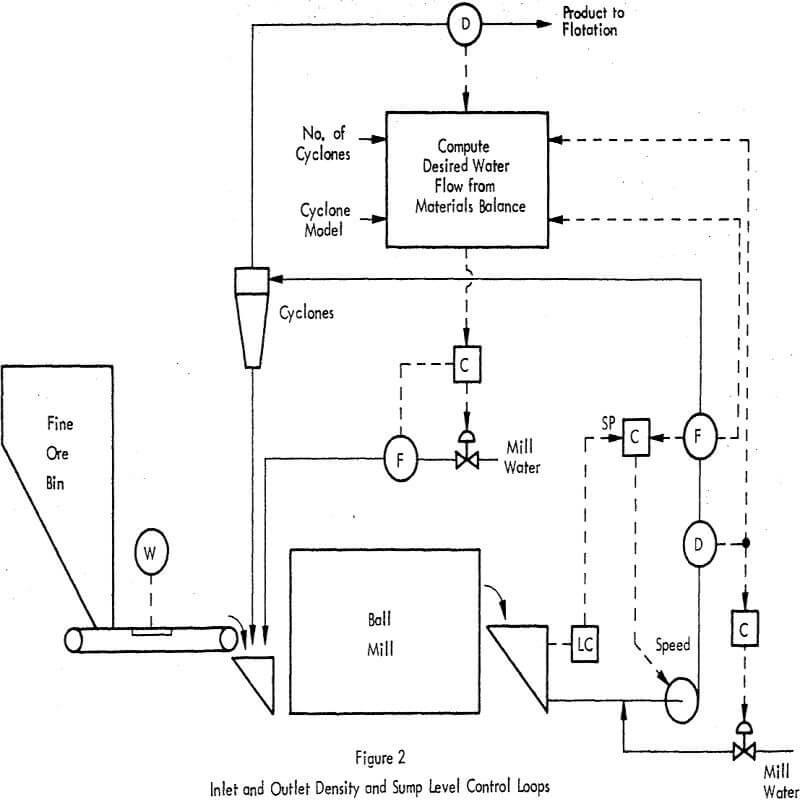

a. Control of pulp density at the mill discharge

This is normally achieved by regulating the flow of water into the mill discharge sump, although improved accuracy and response can be obtained if the point of water injection is just ahead of the suction intake of the slurry pump.

b. Control of slurry level in discharge sump

The control of product size distribution from cyclone classifiers is best achieved by regulating both slurry density and flow at predetermined values. Variable speed pumps are often provided to regulate sump level but a case can be made for furnishing a control loop in which speed is initially controlled to maintain a predetermined slurry flow rate, the level being allowed to fluctuate until an upper or lower limit is encountered in which case the flow set-point is then modified to maintain the level within a safe range.

c. Control of pulp density at the mill inlet

Normally achieved by the addition of water into the inlet sump, the difficulty here is provided by uncertainties as to the recycle flow rate and the consistency of the cyclone underflow. Recycle rate can be obtained by direct measurement of both flow rate and density of the combined cyclone underflow, so long as this is not roping.

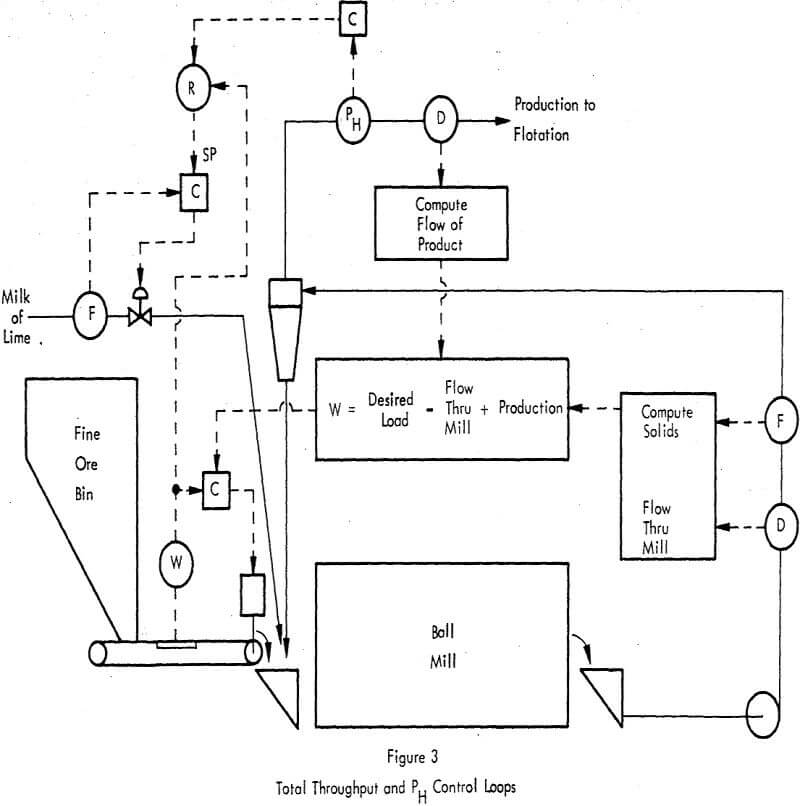

d. Control of mill feed rate from total mill flow

The instrumentation and data used in the above three loops also provides inputs to the loop controlling the total flow through the mill. Since all of the new feed material must report to the mill (i.e., the gain represented by change in new feed divided by the change in total mill flow is unity) there is no basic problem of dynamic control, merely one of measurement of total mill load.

e. Control of Ph by the addition of milk of lime

The control of milk of lime addition rate is best achieved by ratioing this addition rate to the rate of feed of new material, the ratio being modified by a controller or control algorithm responding to changes in the difference between desired and actual values of Ph in the cyclone overflow stream.

Reversed Circuit with Cyclone Classifiers

While the set of control parameters listed for the preceding circuit apply here also, there is a significant difference in the control of total mill throughput which can no longer be performed from simple materials balances. This is because a change in new ore feed rate does not all report to the mill but only that portion of it which reports to the classifier underflow. Since this amount will depend on classifier inlet flow, the number of classifiers in operation and other sensitive and usually unmeasured variables, the problem has become much more complex and simulation studies have shown that the attempt to control mill throughput in this circuit by varying new ore feed rate can introduce instability; although when running with a constant new ore feed rate the circuit of course finds its own equilibrium without oscillations in production rate being exhibited. Once again, the economic gain resulting from the adoption of this system is the ability to raise production by as much as 5% at a given particle size distribution regardless of fluctuations in ore hardness; and without requiring manual interference to avoid plugging of the mill as recycle rate increases with hardness.

Idealized Control System for Flotation Cells

It is very difficult to be able.to blend ores so as to hold the assay constant and variations in recycle rate from cleaners could, even so, frustrate such attempts to smooth out disturbances to the cells. The cost of blending operations is also high, not only in storage and stockpile blending procedures, but also in the close control of the actual working of the ore body which such procedures demand. The design and operation, of a .mine can be much simplified if ores of varying assay and hardness can be handled in a routine way without special steps having to be taken to cope with each new variation as it appears in the mill. One plant has gone a long way towards this objective.

The motivation for applying control techniques to the operations of minerals processes is either directly or indirectly to improve profitability. Improvements in performance begin by removing or reducing the effects of disturbances inherent in processes subject to the unmeasured and random changes in natural raw materials. The earlier in the process we begin this activity the smaller the disturbances at later stages and the easier it becomes to maximize performance.