Table of Contents

The Stekenjokk plant employs a system with automatic support of the secondary mill with pebbles from the primary autogenous mill. As well as in the Aitik case the Stekenjokk plant has reached its rated capacity and performance after a short running in period.

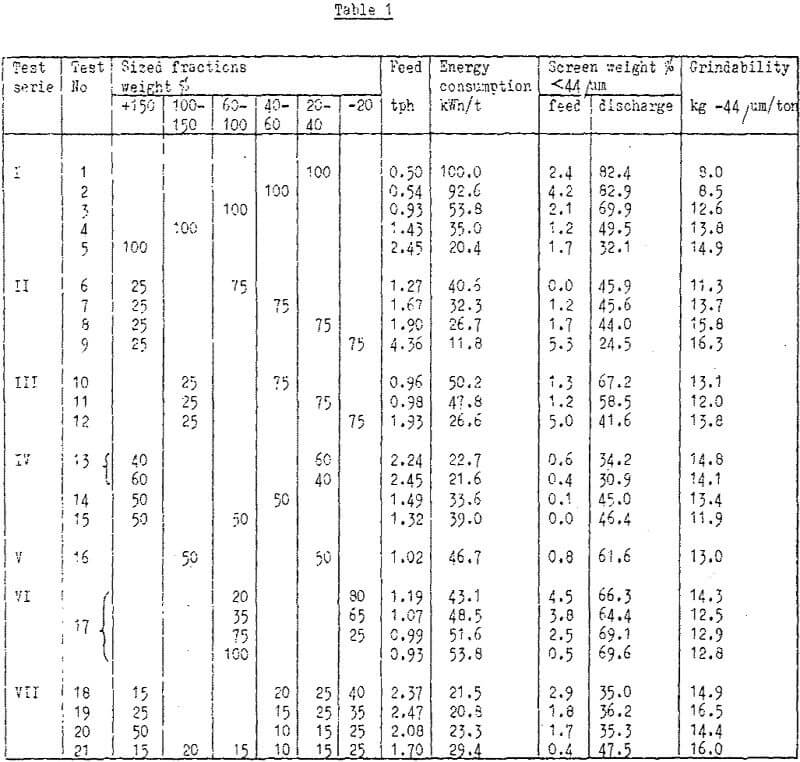

Capacity Variations and Feed Size

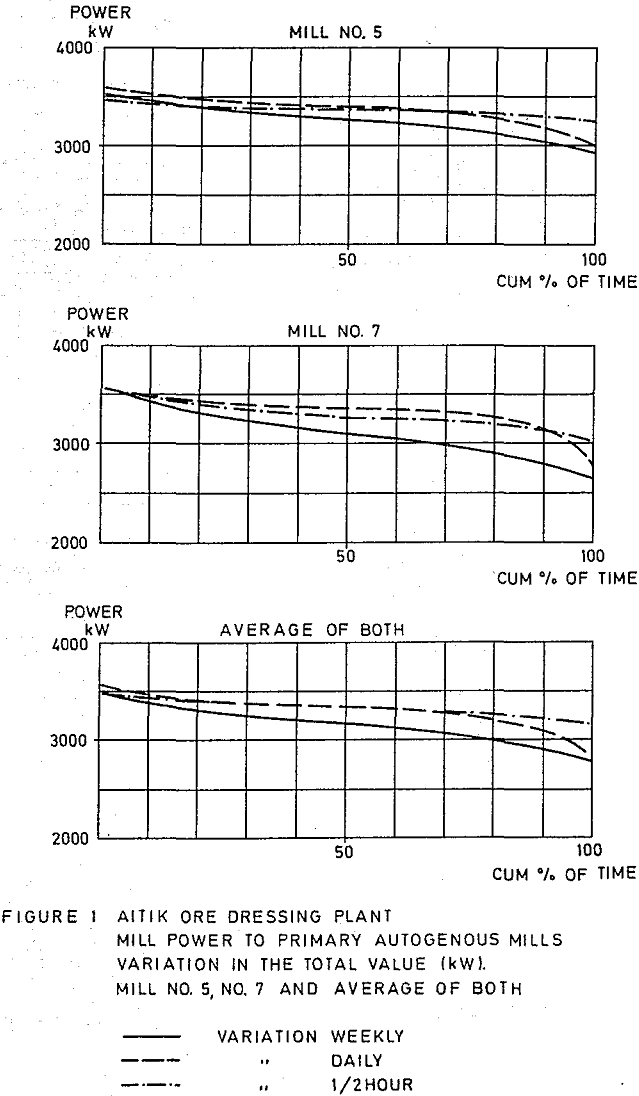

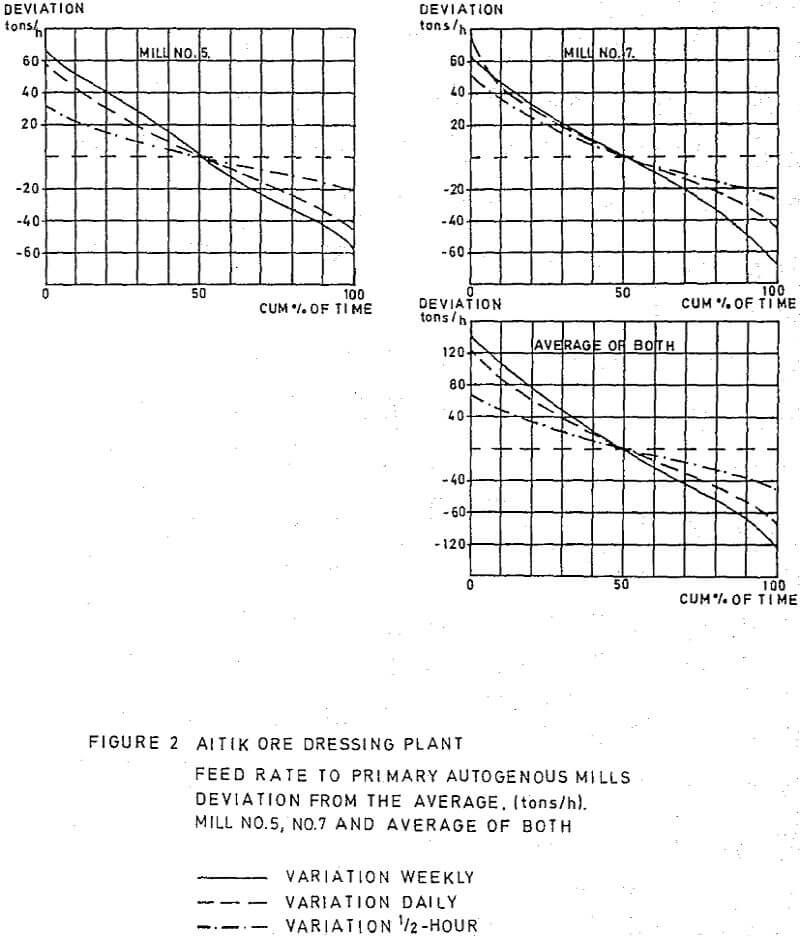

All of these autogenous installations have been performing well beyond specifications. It was studied the frequency of deviation from the average feed rate and power rate from the Aitik plant, where the short time (½ hour) variations are smaller than the long time (daily/weekly) variations.

From the operational point of view the short time variations in feed rate are overcome by the use of a big mill volume and the leveling effect of conditioners ahead of the flotation circuits and also by a well developed process control equipment.

Study of the Capacity/Size Problem

In order to verify these notations a survey was started in the pilot plant in order to study the effect of different particle size distribution of the feed material to the autogenous mill on throughput and grindability. The aim also was to check if the results could lead to criteria by which the applicability of the autogenous grinding for different ore types could be determined.

The pilot plant tests were run with a Canadian copper-nickel ore with pyrrhotite, chalcopyrite and pentlandite as dominating sulphide minerals. The ore is a coarse grained, almost massive olivine gabbro, sometimes partly an anorthosite. The essential minerals are labradorite, pyroxene (augite) and olivine, although the rock to some extend is serpentinized.

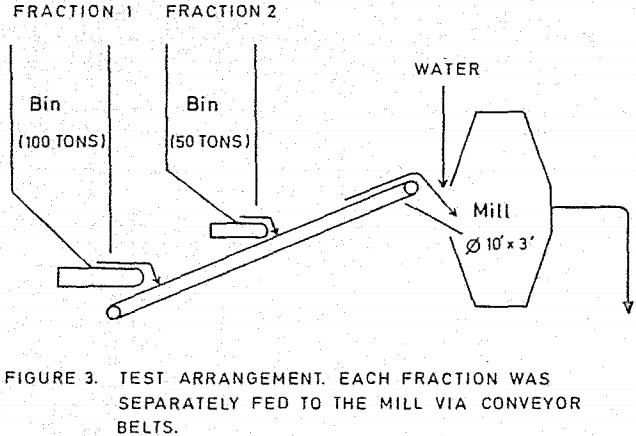

The tests were performed in a rubber lined 10 ft by 5 ft Hardinge cascade mill. The mill was fed from two different bin systems through balances and conveyor belts.

The feed rate was calculated from flowrate and percent solids of weight.

Energy consumption per ton of feed was calculated from the total energy consumption of each test.

Particle size distribution was determined by conventional screening to -44µm (325 mesh).

Mode of Size Reduction

When a new stone is introduced into the mill charge, comers and sharp edges are quickly thorn away when the fresh stone hits the elder stones already in the charge. Impact towards liners probably also will break the stone to small pieces, whose form and size are determined by weak fissures in the stone. This first stage seems to last up to a couple of minutes. In a second stage the stone and the pieces formed are reduced in size by the attrition in the charge when the stones in the charge are moving and rolling against each other under pressure. In this stage there is also a certain amount of abrasion. This stage lasts until the stone becomes so small that the biggest stones in the charge by impact reduces the stone to pieces.

Further test series were run in order to simulate the normal production mill where the feed normally consists of several different fractions.

A comparison between the individual tests indicates that the throughput increases with the amount of coarse fraction when the size span between the feed fractions is large. However, when the size span gets smaller the proportions between the fractions in the feed seem to loose their influence on the feed rate. This is probably due to the fact that the necessary time of wear gets longer before the stones can be crushed by the feed sized pieces.