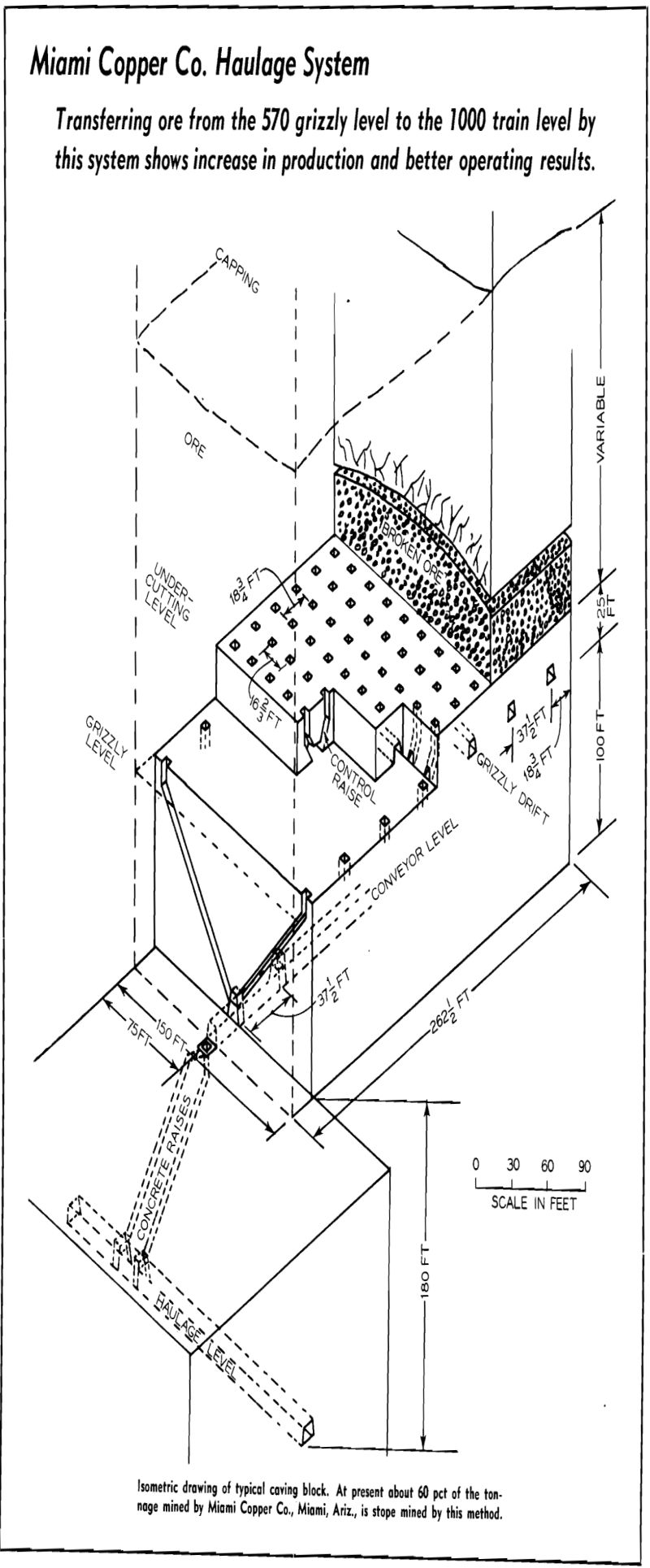

Conveyors were first used underground at Miami Copper Co., in the latter part of 1947. At that time some of the stoping area was too heavy and too close to the haulage level to use conventional haulage. To get the haulage drifts out from under the stoping area belt conveyors were used for the additional lateral transfer. Since 1947 more than 8 million tons have been mined in this manner, with as many as four belt type stopes in production at one time.

When the mining plan for the new low grade was worked out, it was decided to use belts on what otherwise would have been short train haulage transfers to move the ore laterally to centrally located concrete ore passes. One group of these stopes has grizzly levels on the 570, with a belt level on the 670; the other group has grizzly levels on the 720 and belt levels on the 820, with the concrete ore passes bottoming on the 1000, or the existing train haulage level.

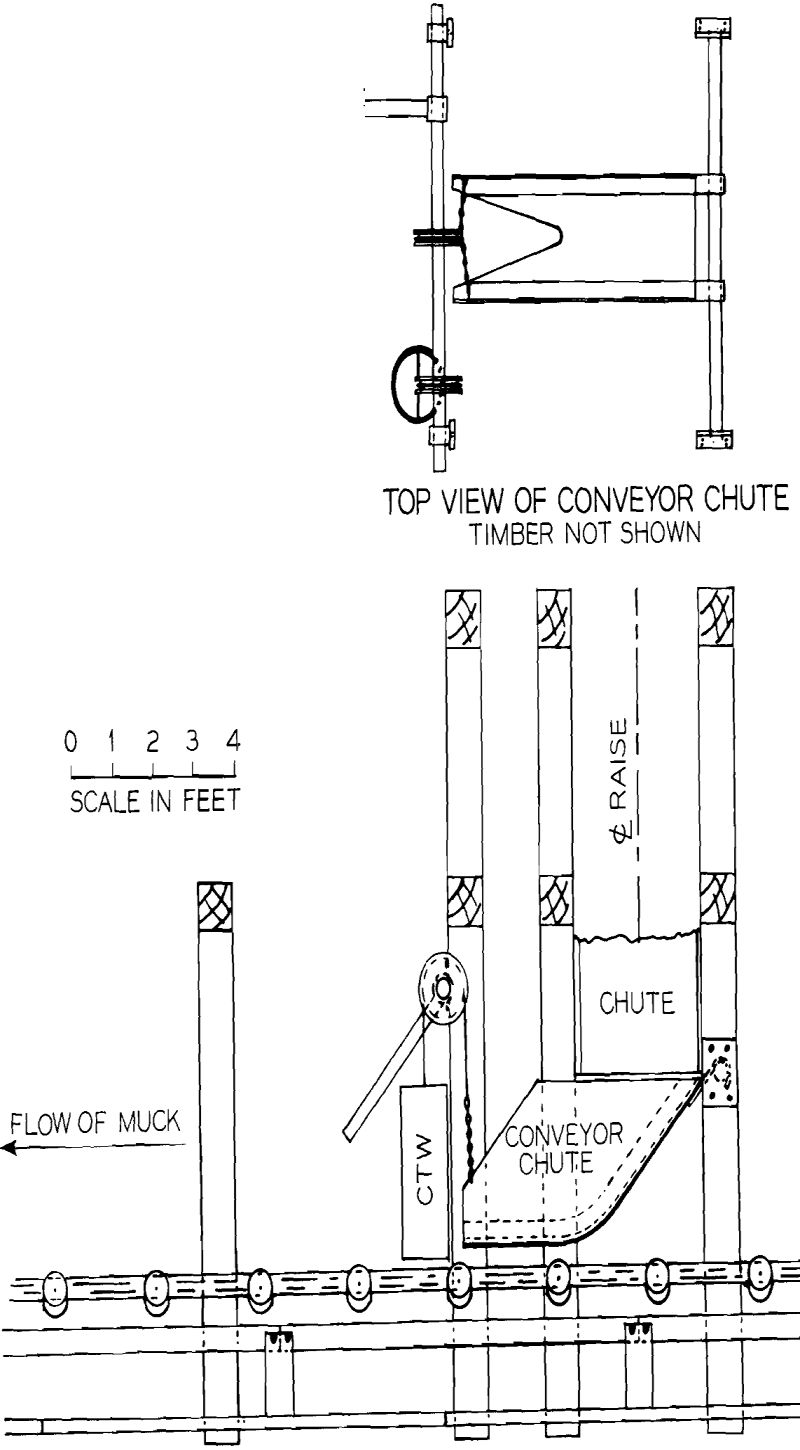

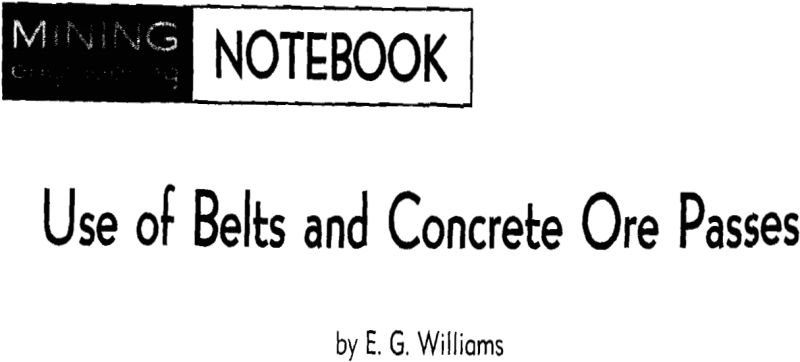

The first belt installed has eleven loading positions controlling twenty-two 100-ft raises fed by slushers. The belt discharges into two 4 ft diam concrete raises. The tops of the raises are designed so that both can be used at the same time or either closed off for repairs.