Table of Contents

This report describes work done as part of a Bureau of Mines program to appraise the titanium-mineral resources of Idaho. The work included both field reconnaissance and a spot churn-drilling program. Much general information was available, as a result of earlier work done under the Western Radioactive Minerals Exploration Program conducted between 1950 and 1954 by the Bureau of Mines for the United States Atomic Energy Commission. This particular exploration provided data as to the quantity of ilmenite (TiFeO3) and accessory black-sand mineral concentrates in a number of placer deposits; however, at that time no tests were made to ascertain if the ilmenite was of marketable grade.

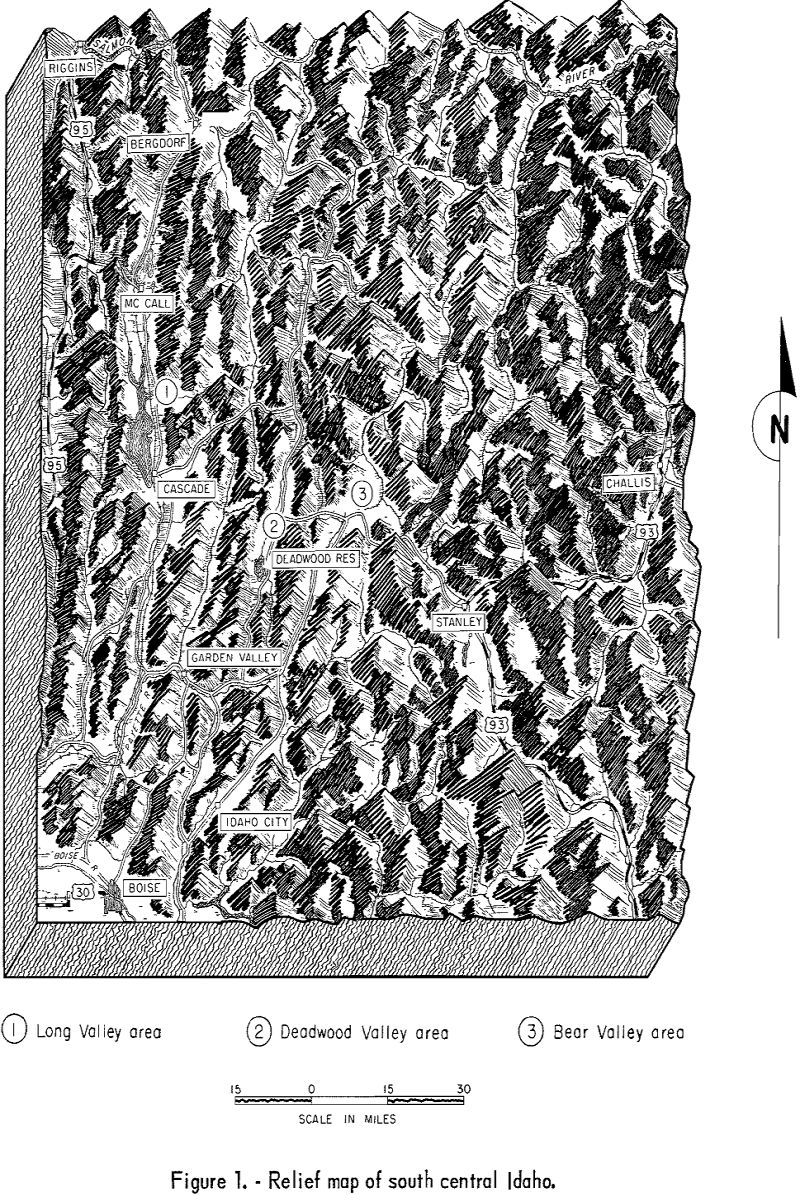

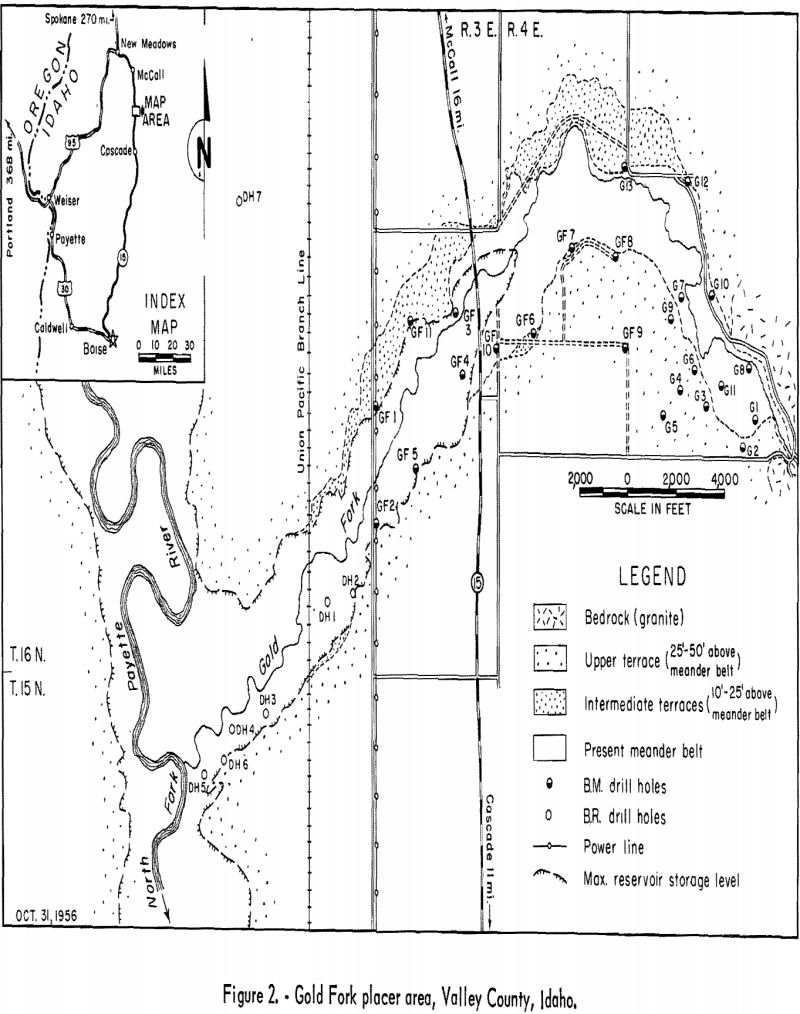

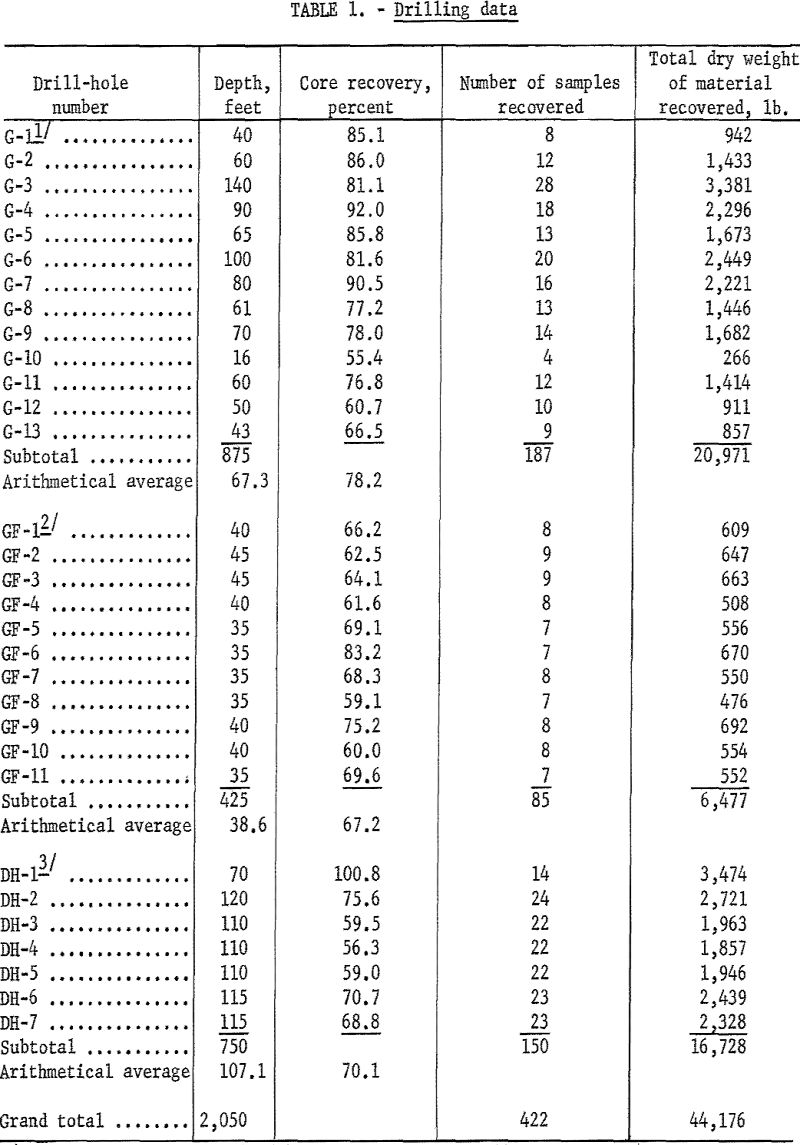

The spot churn drilling was begun in the Gold Fork area of Long Valley, Valley County, Idaho (fig. 1), in August 1956 and was completed during October of the same year. Eleven holes (designated as the GF series on fig. 2) 35 to 45 feet in depth, aggregating 425 feet, were completed during this period. Data from other exploration drilling in 1951 was used in this report. The 13 holes in the G series shown in figure 2 were drilled by the Bureau of Mines for the United States Atomic Energy Commission; the 7 holes of the DH series were drilled by the Bureau of Reclamation. The 20 holes, ranging from 16 to 140 feet in depth, totaled 1,625 feet. The combined number of all samples recovered was 422. Those taken in 1956 were composited for each drill hole and sent to the Bureau of Mines laboratory in Albany, Oreg., for analyses.

The areal extent of the property was not delineated entirely by drilling. Because of the small drilling unit, the GF series of holes in the central portion of the deposit did not test the black-sand values below a maximum depth of 45 feet, although previous drilling in the area indicated mineral values to depths exceeding 100 feet.

Introduction

Ilmenite (FeTiO3) is one of the heavy minerals that occur in the black sands found in varying amounts in most placer deposits.

Ilmenite has become of increasing economic importance as a raw material used in producing titanium pigments and titanium metal. This importance will increase because the less abundant titanium mineral, rutile (TiO2), which is preferred by most titanium-metal producers, may not be available in sufficient quantity to meet future demands.

In July 1956 the Bureau of Mines initiated a program to investigate deposits of titanium minerals in the United States and its possessions in order to provide sources of supply for the titanium industry. Idaho’s titanium resources were studied as part of this program.

Accessory black-sand minerals occurring in the placers that might favorably affect development of the deposits were also included in this study. The more important of these minerals are monazite, thorite, uranothorite, columbite, and columbium-tantalum-bearing uranium minerals.

Work by the Federal Bureau of Mines for the United States Atomic Energy Commission between 1950 and 1954 under the Western Radioactive Minerals Program, provided some information that is included in this report. The Bureau of Reclamation also did some exploration work, which was supervised by the Bureau of Mines, on the downstream portion of the deposit. These sample data were made avail¬able to the Bureau and provided additional information regarding the Gold Fork placer deposit.

History

There is no record of mineral production from the Gold Fork placer deposit in Long Valley. Near the headwaters of the North Fork of the Gold Fork River, hydraulicking and hand mining for placer gold were done before 1900. At the confluence of the North Fork of the Gold Fork and the Gold Fork, about 2 miles east of Long Valley, is Little Valley. J. C. Blood, in a private report dated 1917, wrote that extensive drilling and shaft testing in Little Valley indicated 48,000,000 cubic yards of material averaging 22 cents per cubic yard in gold. A small dredge was later installed, but the mining venture was unsuccessful.

In 1951 the Bureau of Mines did a limited amount of exploration in the Little Valley area, but the results indicated extremely low gold values and virtually no black-sand concentrates except on the rims in ancient stream gravels.

In 1951 the Cosumnes Dredging Co. of California drilled several holes on the north side of the Gold Fork deposit in Long Valley. Apparently the results were not encouraging, as the options to lease were dropped the same year.

Drilling by the Bureau of Mines in the Gold Fork area is discussed under the heading “Work by the Bureau of Mines.”

Location and Accessibility

The portion of the Gold Fork placer area that was investigated is in secs. 24, 25, 26, and 34, T. 16 N. , R. 3 E., B. M., and sec. 30. T. 16 N., R. 4 E., B. M., Valley County, Idaho. The deposit is on the east side of Long Valley, about 11 miles north of Cascade, Idaho, and 100 miles north of Boise, the State capital (fig. 2).

The property is traversed by State Highway 15, a branch line of the Union Pacific Railroad, and a high-voltage transmission line owned by the Idaho Power Co. Secondary county and private roads permit reasonable access to most of the area except below the terraces bordering the present stream channel east of the maximum flowline of the Cascade reservoir. A limited amount of drilling west of the State highway is possible during stages of low water in the reservoir basin.

Physical Features and Climate

The straight-line distance, between a point where the Gold Fork River emerges from a narrow canyon at the extreme eastern limit of the alluvial deposit and its confluence with the North Fork of the Payette River to the west, is about 5 miles (fig. 2). Gold Fork River flows through a trough or channel flanked by gravel terraces or benches ranging from 10 to more than 50 feet in height. The width of the trough is about 1,500 feet at the eastern end and more than 3,000 feet at the western extremity. The basin area that is bounded by gravel terraces forms part of the Cascade Reservoir area for almost 2 miles upstream on Gold Fork from its mouth. As a result, about 50 percent of the total basin area is under water several months each year. Upstream from the reservoir site virtually all the basin floor is swamp area covered with thick brush and a few scattered fir trees on higher mounds. The swamp conditions result from irrigation water that percolates into the areas of lower elevation from cultivated fields on the surrounding terraces. The irrigated benches are used for grazing stock and cultivating grain, seed potatoes, and clover seed.

The overburden of top soil ranges from less than 1 foot to 4 feet. The depth of the water table was found to be from a few inches to over 30 feet, depending upon whether holes were drilled in the basin area or on the bordering terraces.

The altitude approaches 5,000 feet; as a result, the climate is characterized by comparatively short, mild summers and fairly severe winters. Summer temperatures seldom exceed 90°, whereas winter temperatures may reach minus 30° for short periods. Thunder showers are not uncommon during the summer, and heavy rainstorms can be expected in the early spring and late fall.

Drilling

The Bureau originally began drilling on the Gold Fork deposit June 24, 1951, under the Western Radioactive Minerals Exploration Program. These holes are designated in the tables as the G series. This phase of the drilling was done in the eastern portion of the deposit and was recessed on July 21, 1951, because most of the area was flooded as a result of irrigation. The second drilling phase, designated in the tables as the DH series, was done by the Bureau of Reclamation during November 1951 on the western extension of the deposit. Under a cooperative agreement, the Bureau of Mines supervised this drilling, processed the samples, and furnished the Bureau of Reclamation with analytical results. The purpose of drilling by the Bureau of Reclamation was to determine the amount of black-sand minerals that probably would not be mined as a result of flooding by the backwaters of the Cascade Reservoir. After 1951 the undrilled area, between the extreme eastern and western portions of the deposit, was about 1-½ miles in length (fig. 2); it was in this section that the Bureau of Mines began drilling August 8, 1956. Work was discontinued because of inclement weather on October 25. Holes drilled in this project are designated in the tables as the GF series.

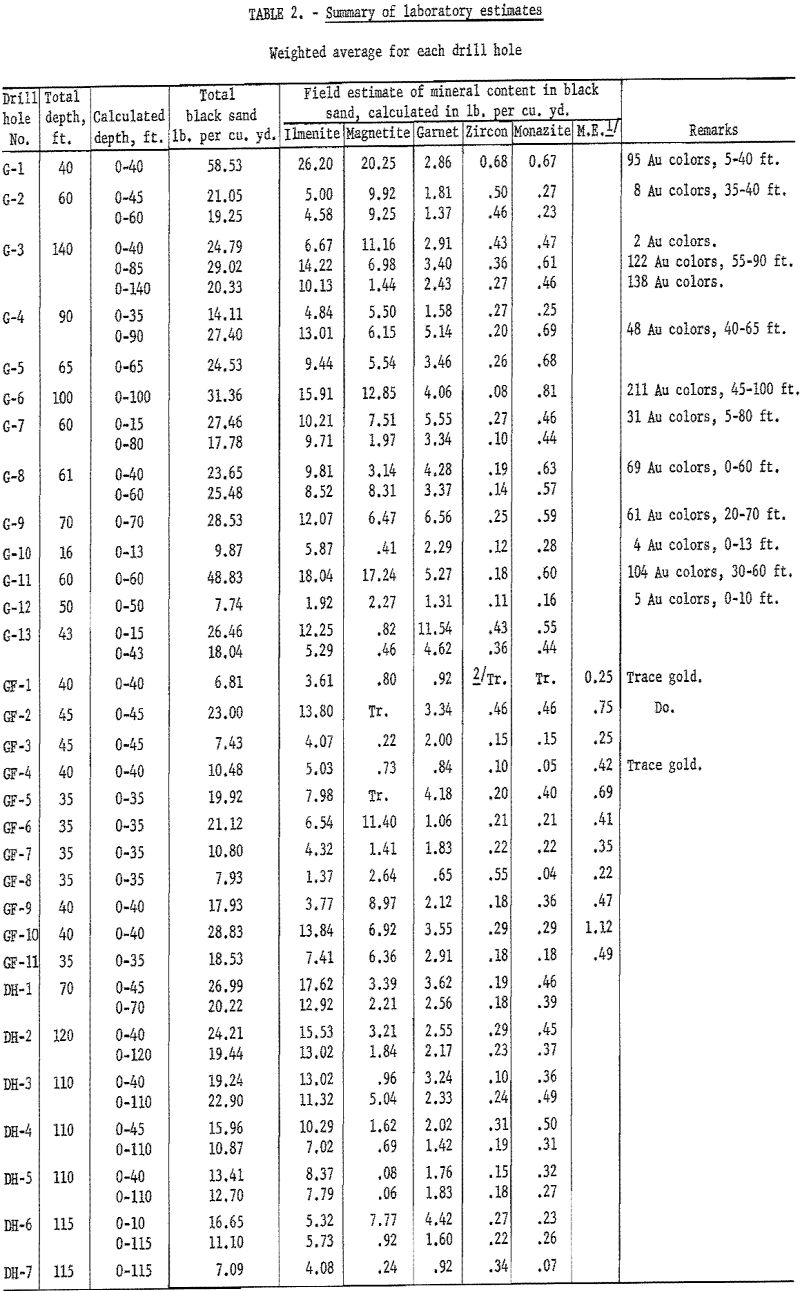

Table 1 lists the holes drilled, depth in feet, percentage of core recovery, and number and weight of samples recovered from each.

Drilling in 1951 by the Bureau of Mines and Bureau of Reclamation was done with a standard churn drill, using heavy-duty casing with an inside diameter of 6 inches. One 5-foot length of casing was equipped with a drive shoe having an inside beveled cutting edge of 7-½ inches. The depth of 1 hole was 140 feet. Ordinarily, the drilling was discontinued at 115 feet or less, except when bedrock was encountered at a shallower depth.

Drilling in 1956 was done with a smaller unit equipped with 5-inch casing, with 1 section having a 6-inch cutting shoe. Difficulty in pulling casing below a depth of 45 feet made it impracticable to drill deeper, although both upstream and downstream the previous drilling indicated that the black-sand values continued to a much greater depth (table 2).

Casing was driven 2-½ feet, and the resultant core rise was drilled and loosened to permit removal with a standard placer sand pump. Two 2-½-foot sections were combined into one 5-foot sample. Samples were dried in sheet-iron pans over an open fire and screened on a ¼-inch-mesh screen. The oversize was weighed, logged, and discarded. The undersize was weighed, logged, tagged, and transported to the Spokane field laboratory for processing.

No attempt was made to recover the slimes from the drill holes. Previous drilling in other placer deposits indicated that only a trace to 1 percent of extremely fine black sands occurred in the slimes. Subsequent sampling on the dredges also indicated that the larger percentage of black-sand looses was in the smallest mesh sizes. For these reasons, it was not practical to take into account the small black-sand losses in the slimes to evaluate a placer deposit.

Laboratory Procedure at Spokane, Wash.

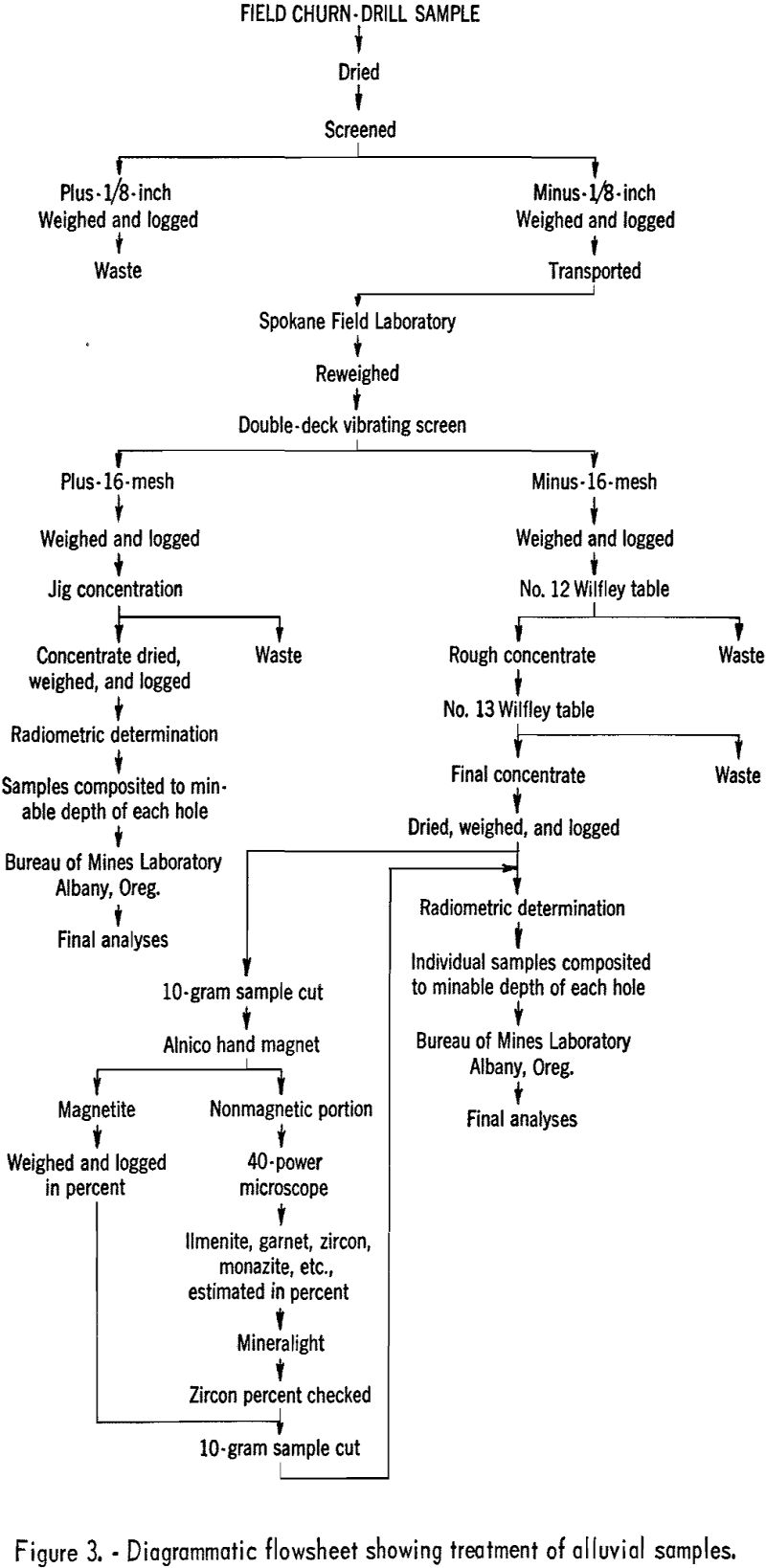

Samples recieved at the Spokane laboratory were reweighed and screened to plus- and minus-16-mesh. All the oversize sample material was combined for each drill hole and jig-concentrated to determine if there were any black sands that exceeded 16-mesh. In the case of the Gold Fork deposit, none were found in sufficient quantities to be of economic importance. Undersized material was rough-concentrated on a No. 12 Wilfley table and reconcentrated on a small No. 13 Wilfley table to recover a clean black-sand concentrate. This material was dried, weighed, and logged. The sample was thoroughly mixed, and a 10-gram cut was taken. Magnetite was removed with an Alnico magnet and the amount weighed and recorded. A small quantity of the remainder was examined under a 40-power binocular microscope, an estimate of the more common black-sand minerals was made, and the amounts of each were recorded. Each sample was checked further with an ultraviolet light for zircon and scheelite, also with a Geiger counter to determine the monazite equivalent in percent as compared with the radioactivity of a standard monazite sample.

The dry weight of the alluvium taken from the drill holes was taken at 2,700 pounds per cubic yard, as indicated by tests made during the drilling program in 1951. Knowing the weight of the original gravel sample and the weight of the black- sand concentrate, the amount of black sand per cubic yard was determined as follows:

Dry wt. of concentrate/Dry wt. of sample x 2,700 = dry wt. of black sand per cu. yd.

(Weight of black sand per cu. yd.) x (estimated percent of any black-sand mineral) = lb. of mineral per cy. yd.

The results of this laboratory examination are shown in table 2.

After the preceding calculations had been made, the concentrates from each drill hole were composited and split on a Jones riffle; a representative sample was sent to the Bureau laboratory at Albany, Oreg. for petrographic, quantitative X-ray spectrographic, radiometric, and chemical analyses.

A diagrammatic flowsheet showing the procedure used for treating the alluvial samples in the Spokane laboratory is shown in figure 3.

Laboratory Procedure at Albany, Oreg.

Black-sand sample concentrates, upon arrival at the Albany laboratory, were split into two portions. One split was sent to the physics laboratory for X-ray spectrographic determination of the Cb2O5 and Ta2O5 content. (The lower limits of analysis by this method are 0.2 percent columbium and < 0.5 percent tantalum.) The second split was sent to the petrographic section for a radiometric analysis to find the uranium equivalent (eU3O8), followed by a petrographic estimation to determine the percentage of the various black-sand minerals present. The sample was then magnetically fractionized, using a Franz Isodynamic Separator, which produced four products: (1) Highly magnetic fraction; (2) titaniferous fraction; (3) ilmenite; and (4) nonmagnetic fraction.

The titaniferous fraction, if any, was ground and chemically analyzed for TiO2. The ilmenite fraction was ground and split into 2 samples: 1 portion was returned to the physics section to be analyzed by the X-ray spectrographic method for percent Cb2O5 and Ta2O5; the remainder was sent to the chemical laboratory for determination of percent TiO2, total Fe (occurring as both FeO and Fe2O3), CaO, MgO, MnO, Al2O3, and SiO2.

Description of Deposit

Size of Deposit

The deposit is exceptionally large, and the total potential mineral-bearing area was not delineated by drilling done by the Bureau of Mines and Bureau of Reclamation. The overall length is about 6 miles, and the width ranges from 1,000 to 4,000 feet where tested. The drill holes ranged from 16 to 140 feet in depth; bed¬rock was encountered in only 3 holes of the 31 drilled – drill holes G-6, G-8, and G-10 (fig. 2).

General Geology

No comprehensive geological report has been published on the placers of the Long Valley area, except for a classified report written in 1952 by Dr. J. Hoover Mackin of the Federal Geological Survey, on behalf of the Raw Materials Division of the United States Atomic Energy Commission.

The Gold Fork placer deposit, in the northern part of Long Valley, is on the western edge of the Idaho batholith that comprises an area of several thousand square miles in central and south central Idaho. Long Valley was formed as a result of a series of block faulting that has a north-south trend. The trough or basin formed has been filled with alluvium deposited by the North Fork of the Payette

River and its tributary streams, including the Gold Fork River, which has cut through the granitic type hills that bound the east side of the valley. West Mountain is a faulted block capped with basalt that rises abruptly several thousand feet above the valley floor on the west side.

On the north side of the deposit a granite ridge extends out into the valley for some distance; it has diverted the stream flow and resultant deposition of the alluvial gravels to the southward. The gravel in the upper horizon of the deposit was usually iron-stained and coarser than that at greater depths. This condition was particularly noticeable for about 1 mile downstream from the mouth of the gorge on the east side of the valley. At varying depths below 30 feet, clay was interbedded with fine sand and gravel. Quicksand and artesian water often were encountered beneath the clay beds.

The ilmenite and accessory black-sand minerals in the deposit were derived from the granitic type rock that was eroded within the Gold Fork drainage system. Gold colors were found in all the G series drill holes except G-13 (fig. 2).

Of the 31 holes drilled in the deposit, only G-1, G-8, and G-10 penetrated bedrock. One hole, G-3, was in gravel to a depth of 140 feet but did not reach bedrock. The amount of black-sand concentrates decreased noticeably below a depth of 105 feet.

The distribution of the black sands was erratic over the areal extent of the deposit and also within the vertical section of the individual drill holes. Drilling indicated that the heaviest black-sand concentration was on the south side of the present channel of the Gold Fork River.

Mineralogy

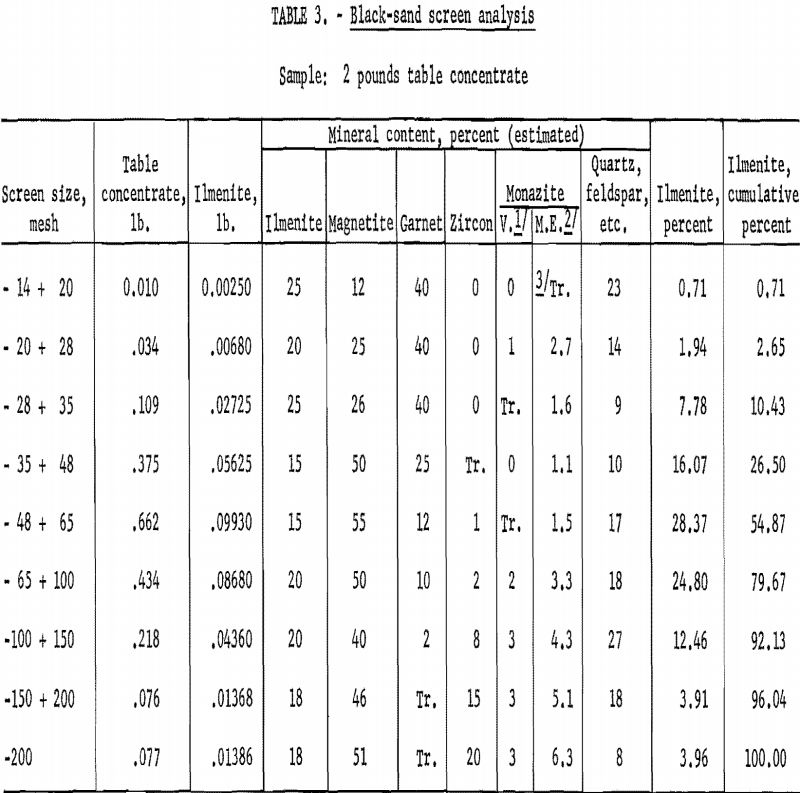

Table 3 shows the results of a screen analysis of composited black-sand concentrates from drill hole GF-9. The quantity of the more common black-sand minerals occurring in the various sizes from minus-14-mesh to minus-200-mesh was estimated in percent and recorded. Only 2.65 percent of the material was plus-28-mesh, and 7.87 was finer than 150-mesh. About 95 percent was in the minus-28-mesh – plus-150-mesh size range.

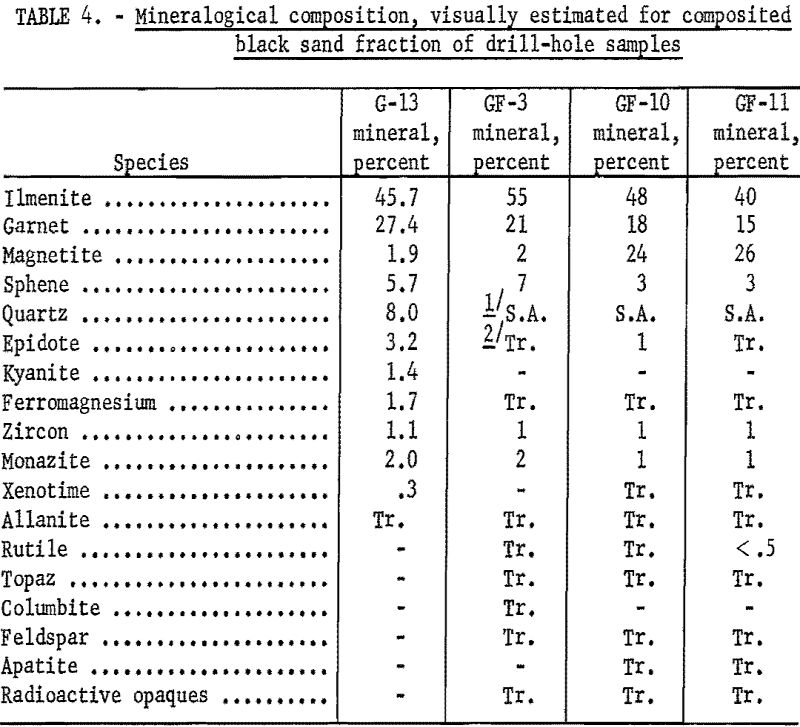

A mineralogical determination, recorded in percent of composited black-sand concentrates from four individual drill holes, is shown in table 4. Ilmenite was the predominant mineral, followed by garnet, magnetite, and sphene. Fine gold was found in the deposit in several upstream drill holes. There did not appear to be any particular relationship between the type and quantity of the minerals present with respect to location of the drill holes in the deposit area. Distribution of the black sands as to quantity or mineral type in the vertical section of the drill holes did not appear to concentrate at any particular horizon.

A few basalt pebbles and cobbles were noted during the course of drilling, but for the most part the gravels included mostly quartz, feldspars, and micas.

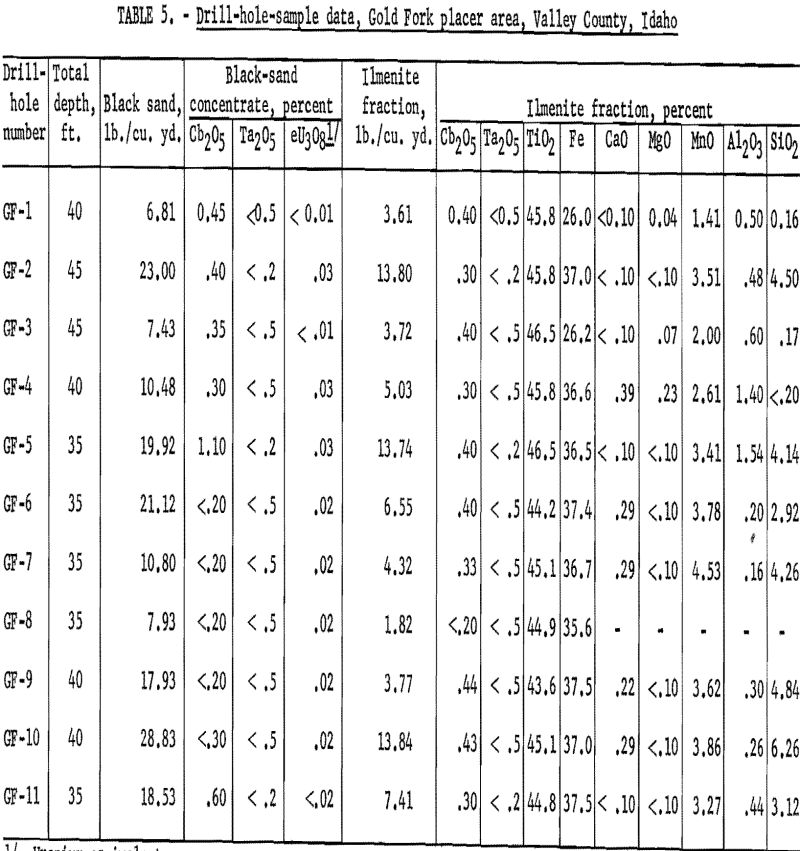

Analytical Results

Results after the black-sand samples were fractioned and the analyses made are listed in table 5. The ilmenite fraction in the black sands ranged from 1.82 to 13.84 pounds per cubic yard. The average titanium dioxide content was 45.3 percent; iron content averaged 34.9 percent. Minor amounts of CaO, MgO, MnO, Al2O3, and SiO2 were present in the ilmenite fraction, which may occur in part either as discrete minerals or as a constituent part of the ilmenite. Columbium and tantalum were found to occur in the ilmenite; but unless a method for recovering it is developed, it has neither economic nor strategic importance.