Ff the drill cores indicate that the ore could contain sufficient lumps in the sizes needed for ore media in autogenous and semi-autogenous grinding, then bulk samples (750 kg) of mine run or primary crushed ore, with an even distribution by quantity in the size fractions between 100 mm and 200 mm, should be obtained for media competency tests. The Allis-Chalmers media competency test, which consists of tumbling 50 pieces of ore in a drum 1.8 in diameter and 0.3 m long, has been described previously. Media competency tests should be run on each ore type in the deposit, which the preliminary mining plan shows could, for an extended time period, become a major portion of the mill feed. It is recommended that each type be tested separately. Testing of composites should be reserved for pilot plant testing, if pilot plant tests are to be run.

The basic data that can be obtained from the media competency test is:

- Suitability of the primary media sized ore to be grinding media.

- Bond impact work index.

- Work indices from Bond rod mill grindability test.

- Work indices from Bond ball mill grindability tests.

- Indication of possible hard size fractions or grind limits.

- Possibility for critical size build-up.

- Abrasion index.

The Allis-Chalmers media competency test is used to evaluate the probability of the media sized ore to be good grinding media. It is not an autogenous grinding test, nor an autogenous grindability test. From the media competency test, one of the following recommendations can be made:

- The ore makes good autogenous media and pilot plant testing should be conducted.

- The ore makes questionable media, however, if factors justify further study, pilot plant tests should be run to further explore the possibility of using autogenous or semi-autogenous grinding.

- Media competency is marginal and the possibility for critical size build-up is indicated. However, the overall structure of the ore is such that semi-autogenous grinding appears to be a possible means to grind the ore and pilot plant testing is warranted.

- Further autogenous grinding testwork is not warranted.

- The media size fraction, like the ore itself, breaks readily to a natural grain size. Pilot plant testing is warranted.

It is recommended that before primary autogenous or semi-autogenous grinding is selected as part of, or all of, a grinding circuit, that pilot plant tests be run. This could require from 300 to several thousand tonnes of ore depending upon how extensive the requirements for pilot plant testing. The expense for obtaining the samples, the cost of the testwork, where to perform the pilot plant work, and the length of time required to do the pilot plant work must all be evaluated against the potential advantages of using primary autogenous or semi-autogenous grinding. If semi-autogenous grinding is indicated, the source for, and cost of, obtaining high quality balls in the 100 mm to 125 mm size range should be reviewed. The grinding balls used in semi-autogenous mills must be of top quality so that they will not break from the impact forces encountered in primary semi-autogenous mills.

Pilot plant testing for primary autogenous or semi-autogenous grinding gives the following information needed for selection of mills, circuit design, and mill design. (1), (2) and (3).

- Since the ore determines the nature of the product from an autogenous or semi-autogenous grinding circuit, the first thing to be determined is the suitability of the product for the next processing step.

- Power required for grinding in the autogenous or semi-autogenous mill. The power required for grinding in primary autogenous and semi-autogenous mills, cannot accurately be established using work indices obtained from Bond grindability tests.

- Establish the process control principles to be used.

- Obtain information concerning the ore and the mill discharge, such as material handling, particle shape, classification system to be used, circulating load, ability to produce pebbles, etc., all of which are needed for plant and circuit design.

- Power to be drawn by the plant mills.

- Mill loading; consisting of ore media, steel balls to be used as supplemental grinding media, and slurry, needed to determine stresses to be put on the mill shells, end plates, and heads.

- Load to be carried by the bearings supporting the mill.

- Wear rates.

- Data for designing mill liners.

- For two-stage grinding circuits, obtain samples of primary circuit product to be used for grindability tests to determine the work index of the feed to the secondary mills.

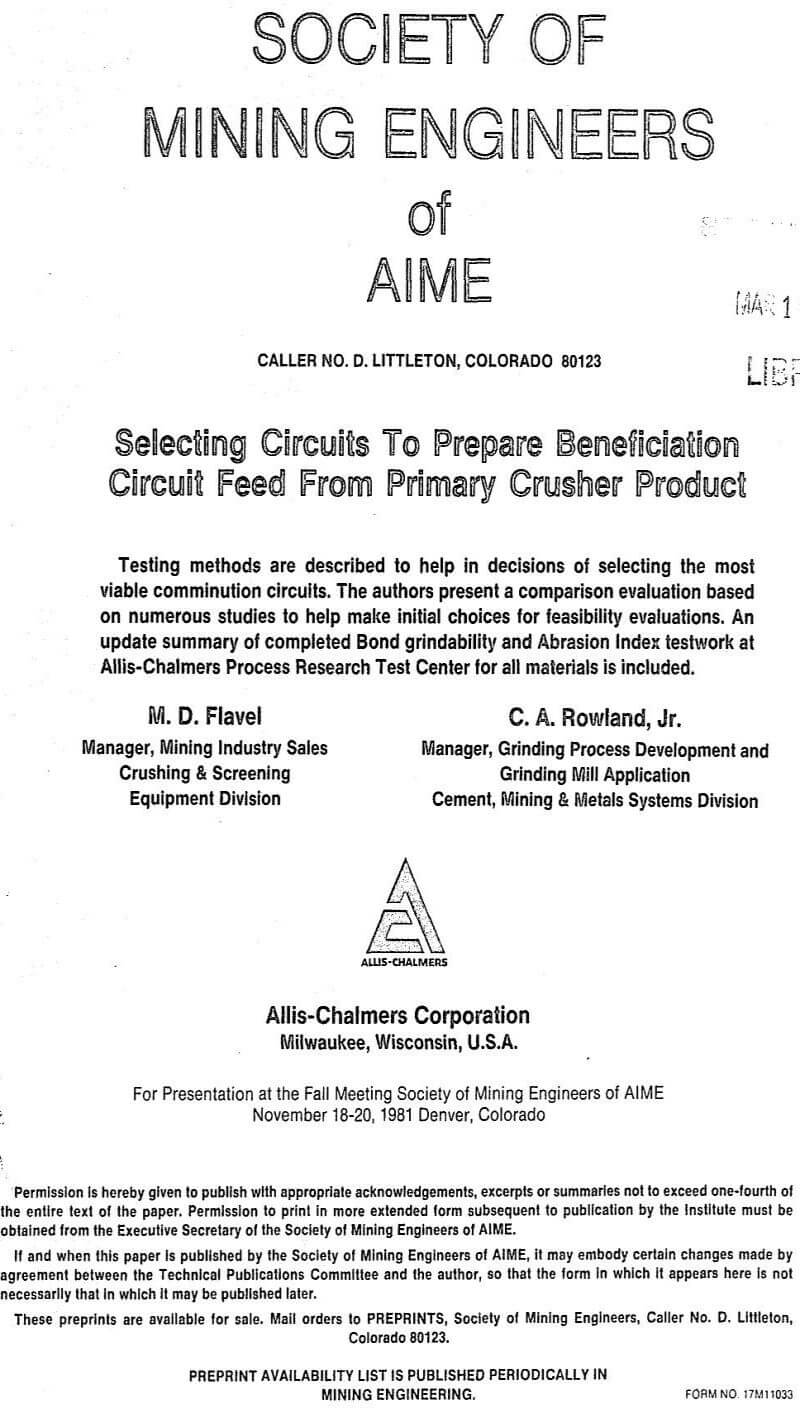

With the completion of the primary autogenous media competency tests and the pilot plant test, three of the four circuits utilizing primary autogenous or semi-autogenous grinding probably can be eliminated and possibly all four, if all the tests results prove unfavorable.

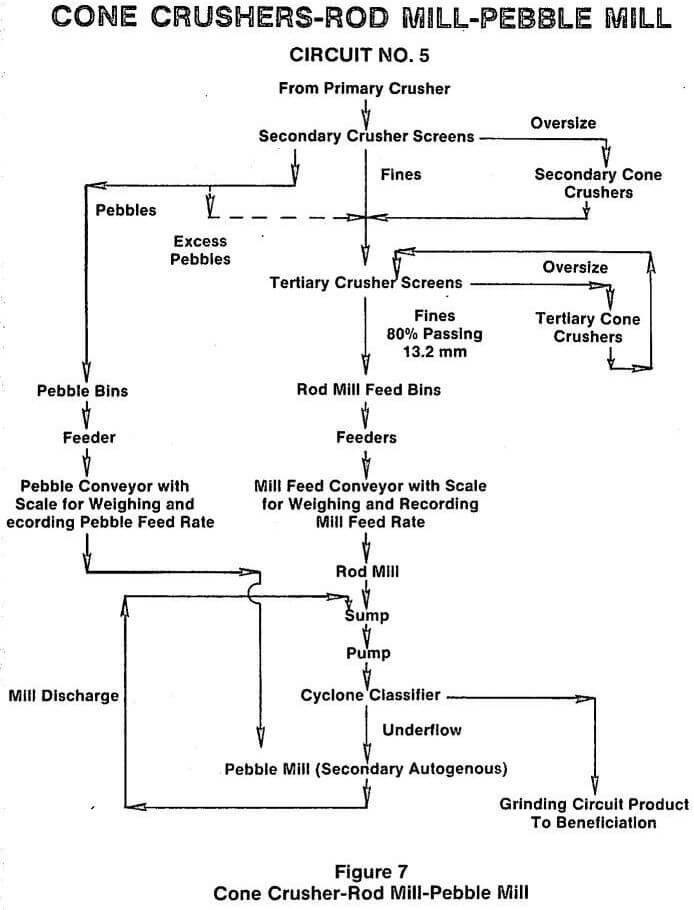

When having the primary and media competency tests run, secondary autogenous media (pebble) competency tests (1) should also be performed if the ore shows any indication that pebble milling could be advantageously used, either in a two autogenous circuit (figure 5a) or in a rod mill pebble mill circuit (figure 7). The sample for this test should consist of one tonne of crushed ore + 75 mm – 150 mm in size. The basic data that can be obtained from the secondary media competency test is:

- Suitability of the secondary media sized ore to be grinding media.

- Bond impact work index.

- Work indices from Bond rod mill grindability test.

- Work indices from Bond ball mill grindability tests.

- Abrasion index of the ore.

- Estimated wear rate as pebbles.

If pilot plant testwork is to be performed and either of the two circuits that can use pebble milling are being tested, it is advisable to include pebble mill testing in the plans. Pebble milling is a substitution of sized ore media for grinding balls in a ball milling circuit receiving feed equivalent in size to a rod mill product. Essentially, it grinds like a ball mill except with more breakage along grain boundaries than transgranular breakage that occurs in ball milling. The method for calculating the power required for grinding in pebble mills is given in Chapter 12, “Minerals Processing Plant Design”. Worn pebbles become part of the mill product.

The pebble media competency test, with or without pilot plant testing, can be used to accept or eliminate pebble milling as a possible grinding circuit. While more expensive to install, the potential savings, by eliminating ball wear, is an attractive advantage that cannot be overlooked.

The primary media and secondary media competency tests will probably give all the work index data from standard Bond grindability tests needed to determine the power required for grinding in rod and ball mills using the procedures described in Chapter 12, “Minerals Processing Plant Design”.