China now leads the world in antimony production, having contributed during recent years something over 60 per cent, of the world’s production. The history of the antimony industry of China dates back to 1897 when the Tai Shing Co. was formed, under contract with the Hunan Bureau of Mines, for the smelting of the ore to crude; and in 1908 the Wah Chang Mining & Smelting Co. was formed for the smelting and refining of the ore and crude to regulus. The writer was then asked to take charge of the erection and control of this first plant for regulus production in China and has, since then, been more or less connected with the antimony industry in this country. This paper contains the results of many years’ experience in connection with the Wah Chang Mining & Smelting Co., Changsha; the Pao Tai Mining & Smelting Co., Wuchow; the Loong Kee Smelting Works and the To-Cheng Smelting Works, Hankow; as well as information gathered from various other small smelters, scattered in different parts of the Provinces of Hunan, Hupeh, Kwangsi, and Kwangtung.

An idea of the growing importance of regulus production in this country can be gleaned from the fact that, within a period of about 8 years, the export of regulus from Hunan alone jumped from 3 tons in 1908 to about 6000 tons in 1915; that a production of about 23,000 tons of regulus per year could easily be effected from all the smelters, as tabulated below, most of which were erected a year or two ago under the stimulus of the war booms, if the price at Hankow were to stay somewhere about $900 (Mexican) per ton, half of what it was at its height, thus enabling the utilization of ores from the hinterlands of the provinces; and even under the present ruling of prices and the closing of the less favored smelters, the production of regulus should not be less than 12,000 tons per year.

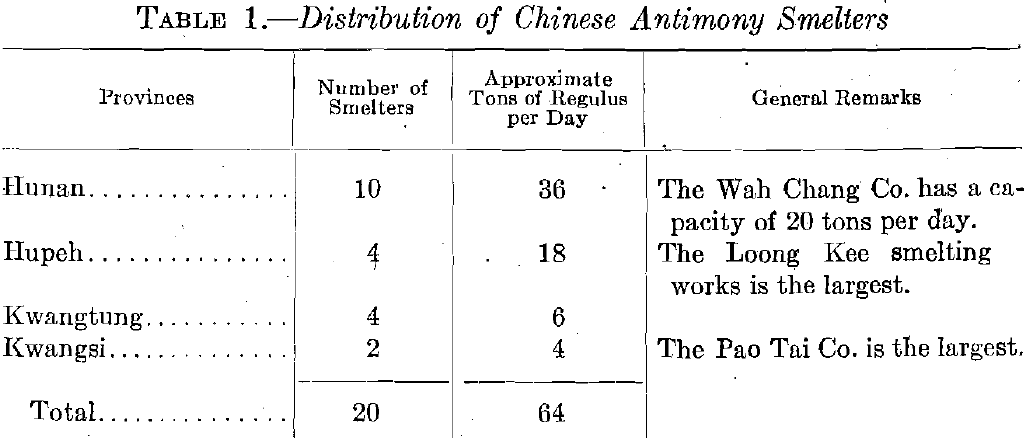

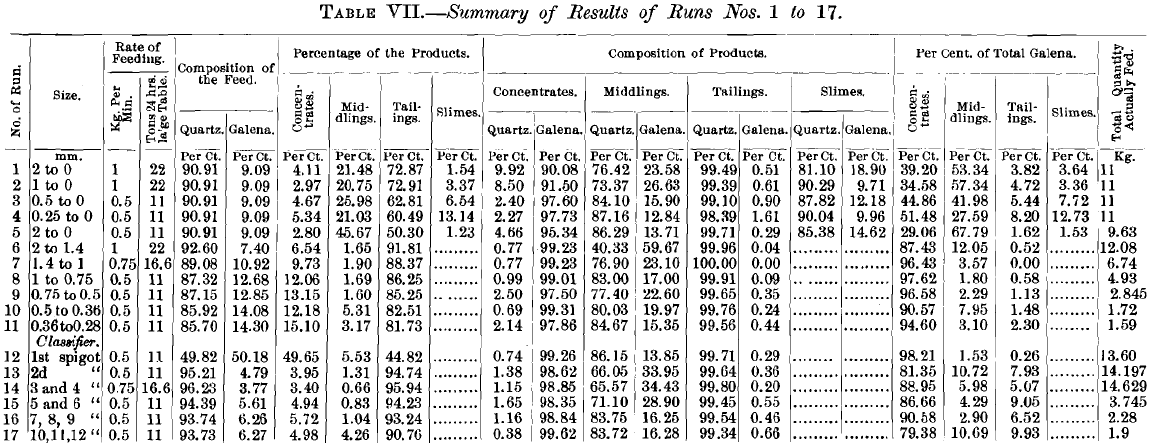

The distribution of the number of smelters according to provinces is shown in Table 1:

II. Furnaces and Smelting Appliances:

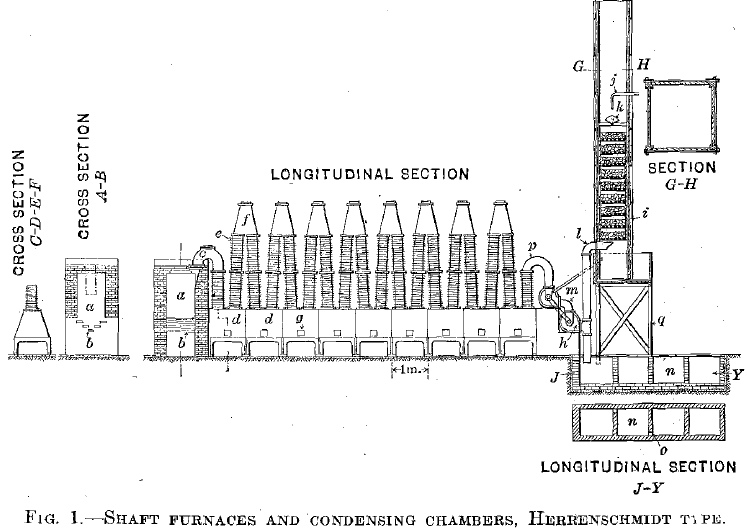

A. Shaft furnaces and condensing chambers for the volatilization process, to roast the low-grade ore or the liquation residue, generally containing 15 to 30 per cent. Sb, and to condense the volatile trioxide.

Fig. 1 shows the Herrenschmidt type used by the Wah Chang Co. For a full description, refer to the author’s book on Antimony.

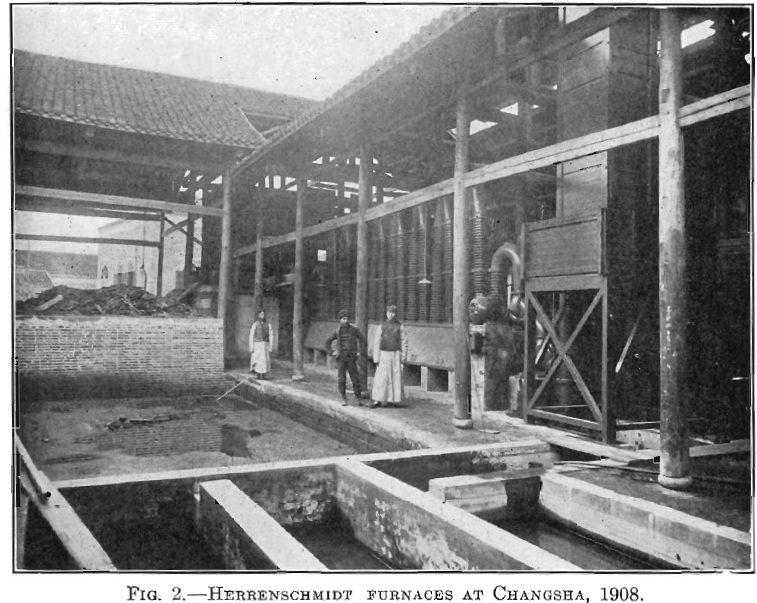

Fig. 2 shows the first Herrenschmidt type put up at Changsha, 1908.

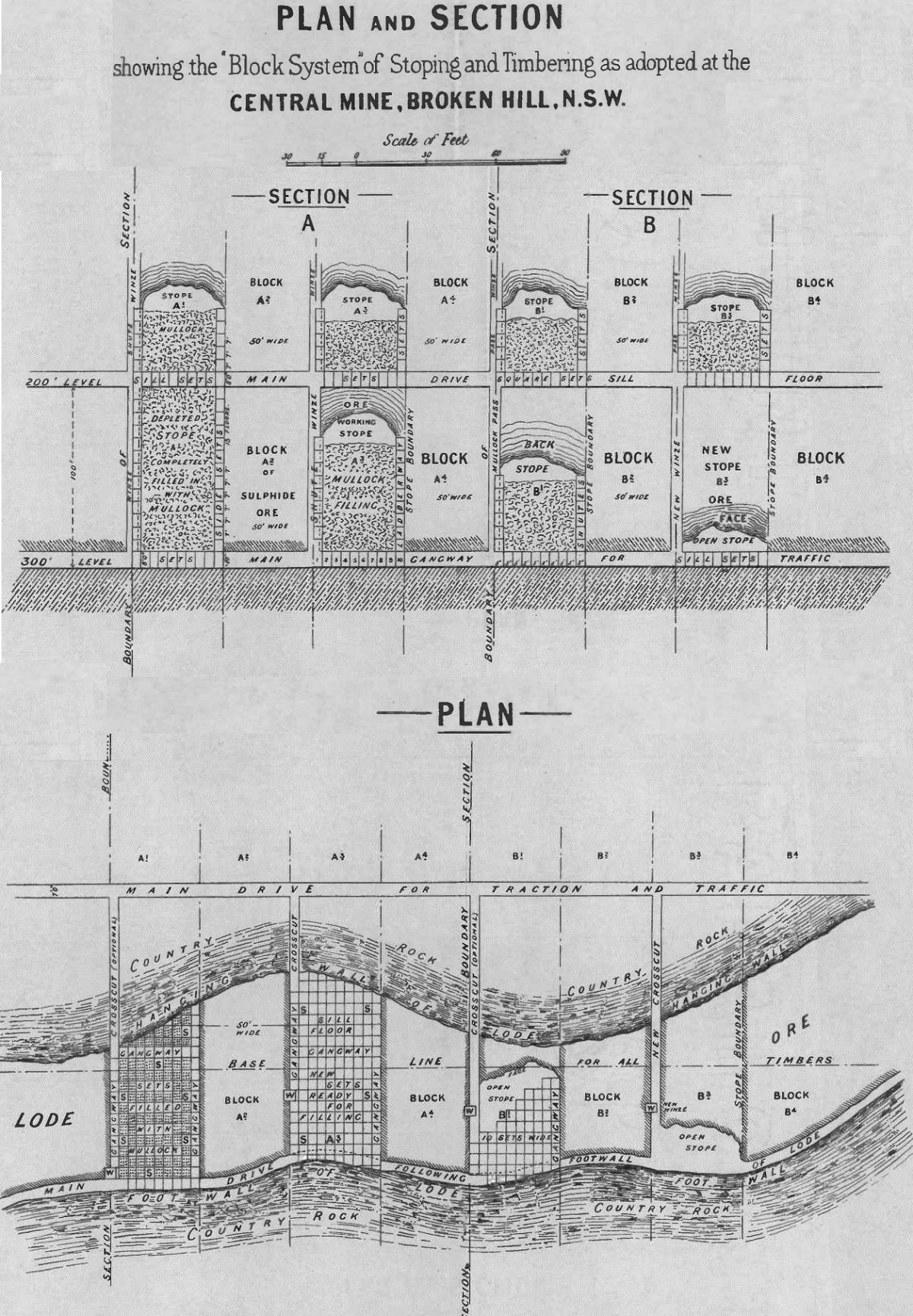

Fig. 3 is a plan and section of the To-Cheng smelter, designed by the writer. A, gas producer. B, C, reduction furnaces, for reducing the trioxide. D, E, shaft furnaces, for roasting the low-grade ore or the liquation residue. F, G, condensing chambers.

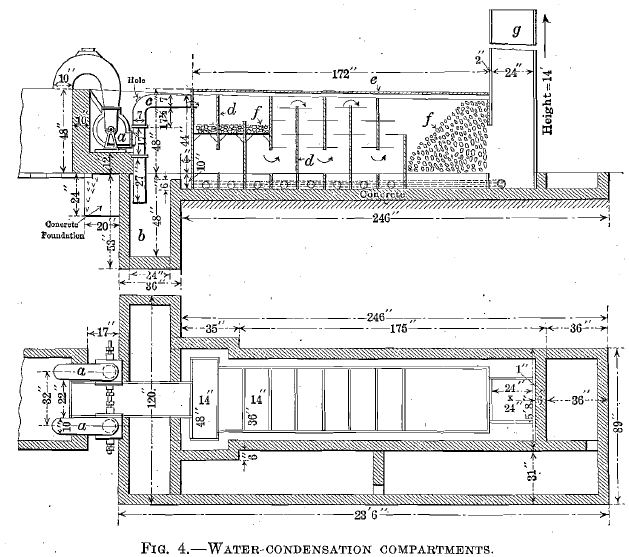

Fig. 4 shows the water condensation compartments at the end of the condensation chambers, F and G, Fig. 3. a, suction fans, b, basin for collecting the wetted trioxide, c, iron pipe for the escape of the sulfurous fume, still holding particles of trioxide, d, wooden compartments, arrow showing the direction of flow of the sulfurous fume, e, wooden top of the chambers, on which is a constant flow of water, trick-

ling down into the chambers below, through a series of holes in the top. f, coke, g, wooden chimney.

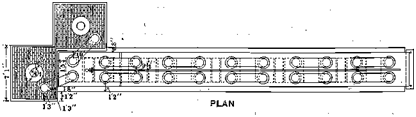

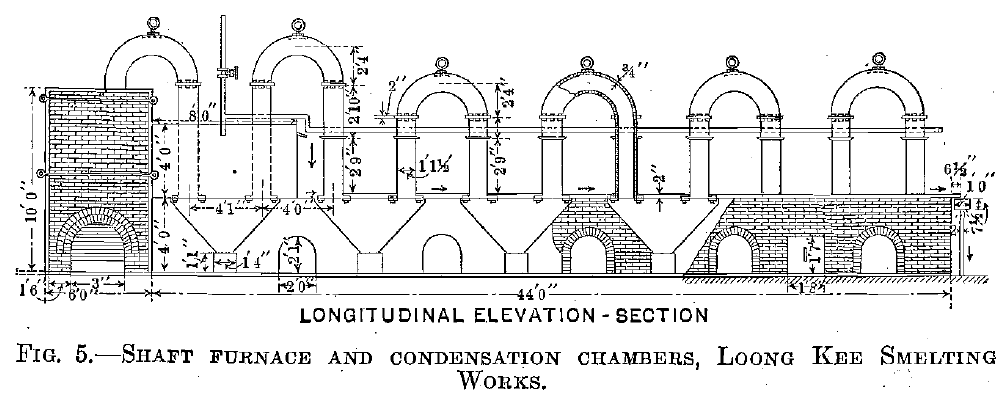

Fig. 5 shows the shaft furnaces and condensation chambers of the Loong Kee Smelting Works.

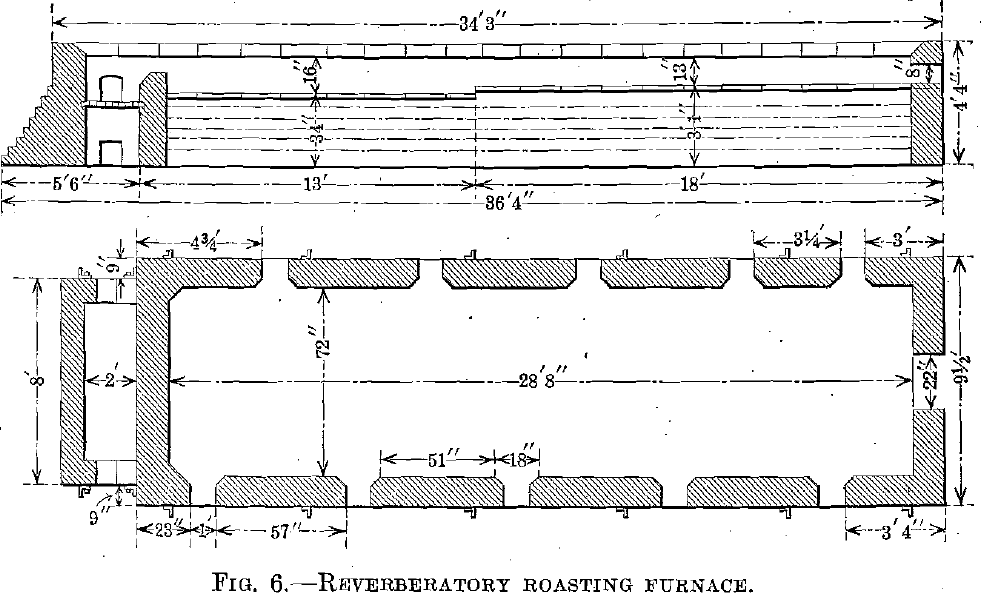

B. Long-bedded reverberatory furnaces for dead-roasting the crude or rich ore to the stable tetroxide.

Fig. 6 shows a general type of furnace adopted by many smelters for this kind of work.

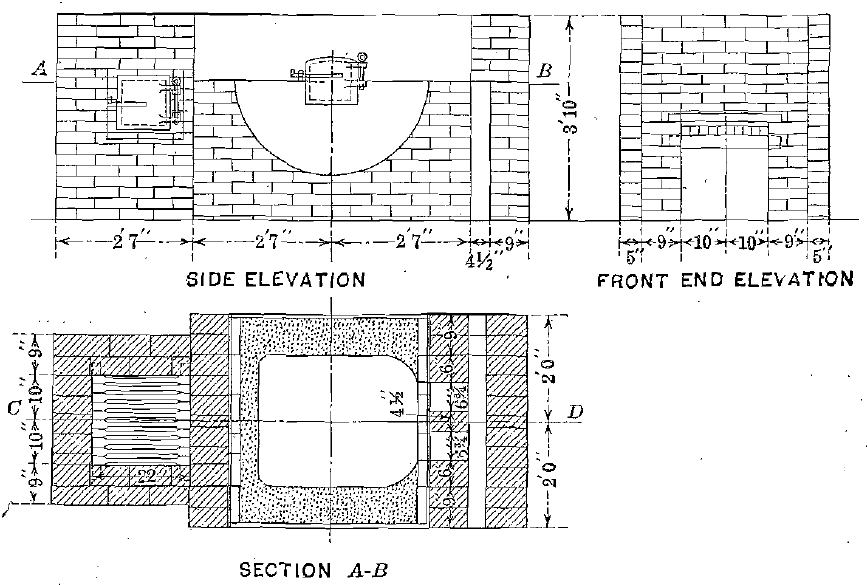

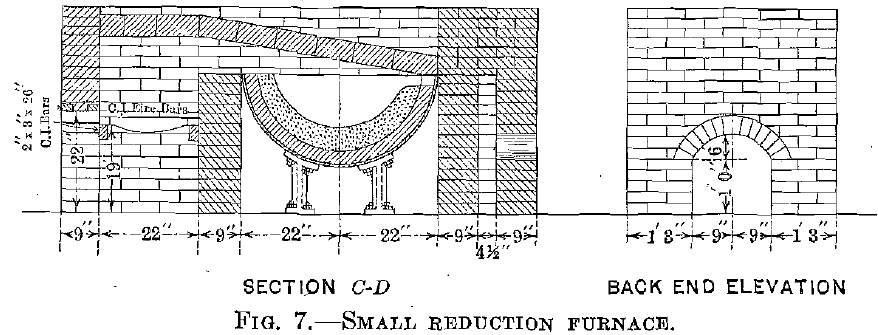

C. Reduction furnaces, for the reducing of the trioxide or tetroxide, or for the direct smelting of crude or rich ore, to regulus.

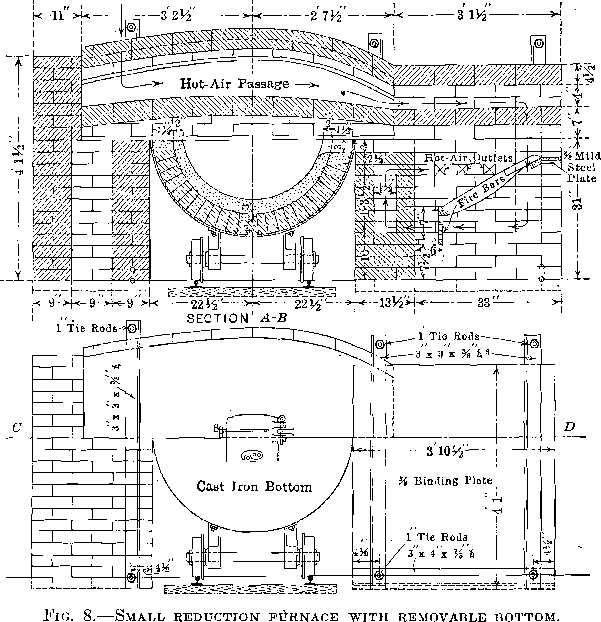

Fig. 7 shows a type of reduction furnace used by most of the small smelters. This furnace has a cast-iron bottom.

Fig. 8 shows a furnace similar to Fig. 7, except that the cast-iron bottom is on wheels, thus facilitating its occasional removal for relining; and that the hot air, from the passage above the roof, can be directed to the inclined grate, producing a partial- gas-firing. This type was put up in the To-Cheng Smelter.

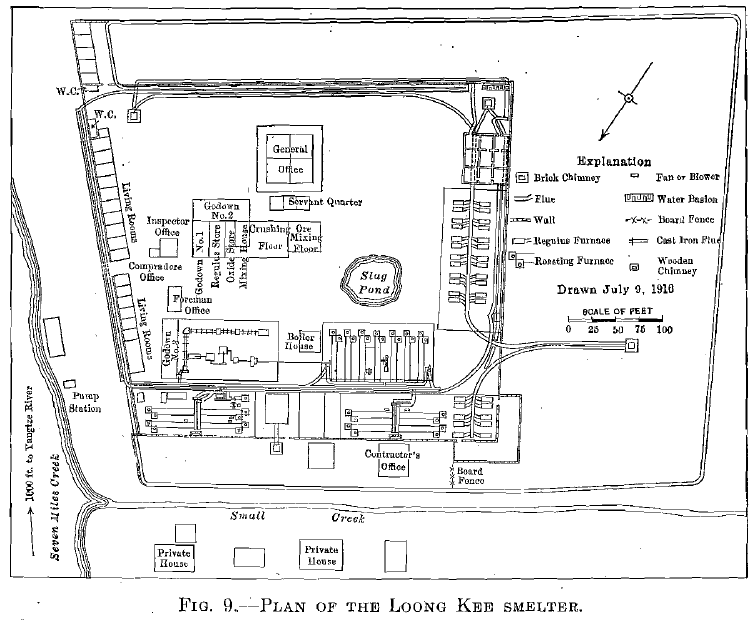

D. Miscellaneous.—Fig. 9 shows the general arrangement in the Loong Kee smelter. Note the elaborate system of flues for condensing.

III. Methods of Smelting:

A. Treatment of Poor Ore, from 20 to 35 Per Cent. Sb.—The process of volatilizing roasting is always adopted to roast these products to the volatile trioxide in shaft furnaces, as shown in Figs. 1, 3, and 5, the trioxide being condensed in different forms of condensation chambers, as already shown.

The Wah Chang Mining & Smelting Co.

(a) Volatilizing Roasting in a Shaft Furnace—The charge consists of a mixture of 100 lb. (45.3 kg.) of ore, ranging from a peanut to a fist in size, and 15 per cent, charcoal. There are approximately two charges per hour

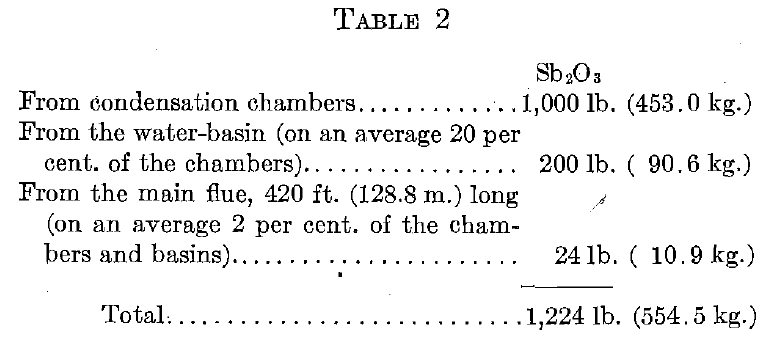

per furnace, depending upon furnace conditions, that is, the interval between charges must be lengthened if it is found that there is fritting of the ores inside the furnace, which must be loosened before another charge is put in. If the charge is composed of liquation residue, the charcoal required for mixing amounts to 20 per cent, for coarse and 24 per cent, for fine. The time interval between charges is about 35 min. for charges of 50 lb. (22.7 kg.) of peanut to fine grain in size; thus the total charge per furnace per 24 hr. amounts to 2240 lb. (1016 kg.). But when the size of the residue ranges from chestnut to fist size., the charges, with the same interval of about 35 min., are then composed of 80 to 90 lb, (36.2 to 40.8 kg.) of residue and 20 to 22 per cent, charcoal, thus making a total charge of about 3600 lb. (1633 kg.) per furnace per 24 hr. The scoria discharged is generally found to contain about 3.5 per cent. Sb for ore and about 4.5 per cent, for residue. The average recovery per shaft furnace per 24 hr. from ore of about 25 per cent. Sb, with a total charge of 4480 lb. (2030 kg.), is shown in Table 2:

Theoretically the trioxide should contain 83.3 per cent. Sb, but as it is always contaminated with sulfur and other impurities, it contains generally 80.5 per cent. Sb.

Hence the percentage loss in antimony is:

100 x (0.25 x 4480) – (1224 x 0.805)/(0.25 x 4480) = about 12 per cent.

Each furnace requires two workmen per shift of 12 hours.

(b) Reduction of the Trioxide to Regulus.—The reduction furnace can smelt two charges per 24 hr. of the following composition:

Sb2O3……………………………………………………………………..3,000 lb, (1,359 kg.)

Charcoal……………………………………………………………………..600 lb, (282 kg.)

Soda……………………………………………………………………………150 lb, (70.5 kg.)

These are thoroughly mixed before being charged into the furnace. The yield of regulus per 24 hr. from 6000 lb. (2718 kg.) of trioxide is from 4100 to 4300 lb. (1858 to 1950 kg.), which is about 70 per cent., exclusive of recoveries from furnace bottoms, flue dust and slag skimming, all of which may amount to at least 5 per cent, of the regulus produced or 3.5 per cent, on the trioxide. Hence the percentage of extraction is 73.5 per cent.; i.e., the loss amounts to 7 per cent., taking the trioxide as containing 80.5 per cent. Sb. Summing up, we have a loss of about 19 per cent, of antimony from ore to regulus. The consumption of coal is 0.55 ton per ton of regulus, and the average life of the hearth bottom is 12 weeks. However, a well constructed bottom may last from 4 to 5 months. Two workmen are required per furnace per shift of 12 hours.

The Loong Kee Smelting Works:

(a) Volatilization Process.—The shaft furnace, as shown in Fig. 5, has a capacity of about 3000 lb. (1360 kg.) of liquation residue per 24 hr. with a consumption of 20 per cent, burnt coal, recovered from the reduction furnace, or 15 per cent. coke. The general practice is to sieve off the fines, to be treated separately from the lumps. Besides the usual condensation chambers at the back of each shaft furnace, there is a main flue of 4517 ft. (1375 m.) in length, to which all the ends of the condensa-

tion chambers are joined, leading finally to a series of gunny bags having a total length of 483.75 ft. (147.3 m.). The total wall area of the main flue, which is built of brick, is 104,395 sq. ft. (9702 sq. m.) and that of the bags is 2012 sq. ft. (188 sq. m.). The relative proportion of the amount of trioxide collected from the different parts of the whole system of condensation is as follows: Condensation chambers : Main flue : Bags = 1.65 : 1:0.09. As the furnaces treat many grades of liquation residue and ore—the scoria of the residue could be profitably re-treated only when regulus was quoted in New York at $0.45 (U. S.) per pound—it is almost impossible to estimate the percentage extraction without having resorted to an elaborate system of sampling and analysis of the charges.

As this has never been done, the following summary of a month’s work is given:

The total regulus amounts to 44,908.4 lb. (20,370.3 kg.). Hence it may be safely assumed that 9 tons of liquation residue are equivalent to 1 ton of regulus. Assuming that the average percentage of antimony in the charges be 17 per cent., the percentage loss from liquation residue to regulus would then be about 30 per cent., which, from my experience, is a close approximation.

Three workmen are required to run two furnaces per 12-hr. shift.

(b) Reduction of the Trioxide.—The reduction furnaces take five charges during 24 hr., each charge having the following composition:

Trioxide……………………………………………………………250.0 lb. (113.3 kg.)

Charcoal……………………………………………………………..37.5 lb. (16.8 kg.)

Soda…………………………………………………………………….5.0 lb. (2.6 kg.)

This mixture is divided into two portions, each being covered with 4 lb. (1.8 kg.) of soda after charging. Hence the total amount of soda required for 250 lb. (113.3 kg.) of trioxide, is 13 lb. (5.9 kg.). Sometimes the charge is not divided up; and, in that case, the charge should contain 13 lb. of soda, instead of 5 lb., and should be covered with 30 lb. (13.6 kg.) of skimmings from the previous charge, which has been mixed with 4 per cent, charcoal and 3 per cent. soda. However, often times the skimmings from the furnaces are smelted separately with the same proportionate amount of soda and charcoal. The amount of coal required to smelt 1 ton of trioxide is about 1 ton. One workman is required per furnace per 12-hr. shift.

B. Treatment of Crude and Rich Ore.—Formerly, that is before the present war, most of the crude was exported, but since then, under the stimulus of war conditions, many small plants have sprung up in Hunan to smelt the crude into regulus.

Wah Chang Mining & Smelting Co.

The crude is first ground into powder in a Chilean mill and is then fed into a double-deck roasting furnace, which can dead-roast 2500 lb. (1133 kg.) of crude to the stable tetroxide in 24 hr. with two workmen. In order to increase the output, a long-bedded reverberatory furnace was installed, which can dead-roast 2000 lb. (906 kg.) of crude per 24 hr. with a consumption of 700 lb. (317 kg.) of coal. Two workmen are required per furnace per shift of 12 hr. The tetroxide resulting there-from is mixed with 6 per cent, soda and 20 per cent, charcoal and is charged into the reduction furnace in the same way as in smelting the trioxide. It is claimed that a recovery of 63 to 65 per cent, is possible.

The Pao Tai Mining & Smelting Co.

The reverberatory furnace, shown in Fig. 6, can dead-roast 1975 lb. (895 kg.) of crude per 24 hr., with a consumption of 755 lb. (342 kg.) of coal. Two men are required per furnace per shift of 12 hr. The roasted crude, i.e., the tetroxide, after having been mixed with 15 per cent, charcoal and 5 per cent, soda, is then charged into the reduction furnace shown in Fig. 7, which requires about 1300 lb. (589 kg.) of firewood as fuel and two men to work it, per 24 hr. Each charge contains 300 lb. (136 kg.) of tetroxide and requires 6 to 7 hr. for its smelting. On account of the poor quality of crude used, the average yield from crude to regulus is 57.68 per cent., including recovery from flue-dust and skimming. The treatment of rich ore is exactly the same as that of crude, except that proportionately more soda and less charcoal are required for mixing and that the fuel consumed per ton treated is correspondingly higher, as more heat is required for the fluxing of the siliceous, and argillaceous gangue.

The Loong Kee Smelting Works:

This is the only works in China at which crude has been smelted direct to regulus. Each furnace, shown in Fig. 8, can smelt three charges of 200 lb. (90.6 kg.) crude each, per 24 hr. with two workmen. Each charge contains the following ingredients: 200 lb. (90.6 kg.) of crude, mixed with 20 lb. (9.1 kg.) of charcoal, charged first into the furnace, then on top of the charge is spread 100 lb. (45.3 kg.) of soda, and on top of this 88 lb. (39.8 kg.) of iron scrap, preferably sheet scrap, such as waste tinned sheet. The regulus thus obtained has to be re-smelted with a little crude to take up any iron which may be present, sometimes as much as 9 per cent.

Any grade of ore can be smelted directly in this way, but only with proportionate increase of soda and decrease of tin scrap as poorer ores are smelted; but there must come a limit when it is prohibitive to treat any poorer ore this way on account of the amount of soda required and

of the fuel consumed. An exceptional instance was found in this works in the direct smelting of the rich liquation residue, containing at most from 25 to 30 per cent. Sb, when regulus soared up to $0.45 (U. S.) per pound in 1915. In this case the charge was as follows:

Liquation, residue 250 lb…………………………………………………………………………………………….. (113.3 kg.)

Good soft coal. 22 lb…………………………………………………………………………………………………….. (10.0 kg.)

Sheet-iron scrap 20 lb………………………………………………………………………………………………………(9.1kg.)

Iron sulfide (a byproduct from the previous charges)………………………………………………….. 10 lb. (4.5 kg.)

Soda…………………………………………………………………………………………………………………… 60lb. (27.2 kg.)

The time required to smelt this charge is about 9.5 hr., with a production of 46 lb. (20.8 kg.) of regulus.

C. Treatment of Natural Oxide.—The natural oxide of antimony is found mostly at one locality in Sin Hua District, Hunan, but smaller quantities are also found in Kwangsi Province. Its supply has been gradually decreasing so that, as a source of antimony ore, it is losing its importance and only a very limited quantity is now smelted by the small smelters at Changsha. The percentage content of antimony in

the hand-sorted ore, that can be treated with profit, is from 30 to 50 per cent. Its treatment in the Loong Kee Smelting Works is as follows, the charge having the following composition:

Natural oxide…………………………………………………………………………………….100 lb. (45.3 kg.)

Soda…………………………………………………………………………………………………… 10 lb. (4.5 kg.)

Charcoal……………………………………………………………………………………………… 13 lb. (5.9 kg.)

Of course, the amount of soda and charcoal required is increased and decreased respectively in proportion to the decreasing antimony content of the ore treated, and vice versa. The coal consumption is generally high, being approximately 5 tons to 1 ton of regulus produced for the particular grade of ore, with a percentage extraction of 33 per cent.

In some cases when a small amount of the sulfide is so intimately intercalated with the oxide ore as to render their separation by hand impossible, the following proportions for the charge are adopted:

Natural oxide……………………………………………………………………………………………. 100 lb. (45.3 kg.)

Soft coal………………………………………………………………………………………………………. 9 lb. (4.1kg.)

Iron sulfide…………………………………………………………………………………………………… 5lb. (2.3 kg.)

Soda…………………………………………………………………………………………………………. 30 lb. (13.6 kg.)

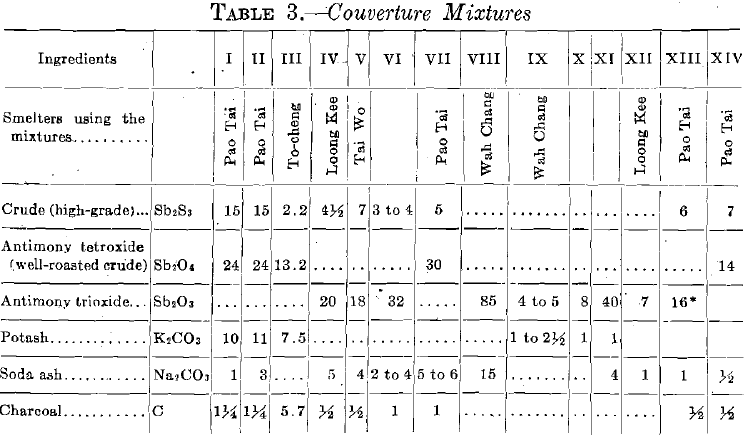

D. Discussion of the Use of Couverture.—As everyone knows, the market always demands good stars with fern-like structure on the slab of regulus before its acceptance. The appearance of such structure does not actually indicate the relative purity of the regulus, but is only the result of cooling it under the cover of a properly prepared starring mixture—in the absence of a proper English term, I shall call it by its French equivalent couverture—whose fusion point is lower than that of antimony, which is 630° C. Of course, when the regulus contains impurities like sulfur, arsenic, lead or iron to any appreciable quantity, its surface shows it by specks, by a leaden appearance or by an ill-defined appearance of the fern-like structure. On the other hand, I have seen many a slab of regulus, with impurities above what are considered to be the limits imposed by buyers, whose stars are still bright and well-defined with all the appearance of well refined regulus. Now since the buyer demands such unnecessary adornment on the regulus, he has to pay for it; for the costs for starring 1 ton of regulus amount to from $10 to $60 (Mexican), according to the market price of the antimony compound used. I have worked and tried out the different mixtures for preparing the couverture shown in Table 3, which have been adopted, the one or the other, according to local conditions, by various antimony smelters in China:

The proper procedure for charging any of the above mixtures is as follows: The compound, after being thoroughly mixed, is immediately charged into the reduction furnace as soon as the skimming is finished. The doors are closed and vigorous firing is maintained; as soon as it is observed that the mixture is completely melted, ladling commences. Each ladle dips into the molten metal and, in coming out, picks up a certain quantity of the molten couverture, which, when poured out together with the metal into a hot mold, completely covers the metal on all sides. Ladling must be done rapidly for each moldful—four or five ladles to one slab of regulus according to the size of the ladle used. The thickness of the solidified couverture varies from 1 to 2 mm. on all sides except the top, which varies from 5 to 7 mm. The amount of couverture required for each charge varies from one-sixth to one-fourth the weight of the regulus produced. It is remarkable that generally the weight of the solidified couverture hammered off from the slab after cooling is less than the original weight of the mixture put in by about one-third, due indubitably in part to volatilization and in part to wall-fluxing during melting. The couverture can be used over again the second or third time, sometimes with an addition of a little soda, until it is so contaminated with impurities that it cannot produce any good stars. Then the wornout couverture is mixed with the ordinary charge of trioxide or tetroxide and is calculated as an equivalent amount of soda required for that charge. In connection with this, the practice at the Loong Kee and the Pao Tai smelters may be mentioned: The Loong Kee smelter uses for every 14 tons of regulus produced 1.14 tons of couverture which, according to No. XII of Table 3, contains 1 ton of trioxide and 0.14 ton of soda. The Pao Tai smelter uses 1 ton of couverture No. XIV for 14.5 tons of regulus.

E. General Discussion on Smelting.—Practically all of the shaft furnaces mentioned for the volatilization process are of the same type, except with minor differences in details as to the form of the grate- bottom and as to size. The ideal ore for treatment in such furnaces is one containing antimony from 15 to 25 per cent.; ore above 40 per cent. Sb would partly volatilize and partly liquate, and part of the liquated product would combine with the volatilized trioxide to form an oxysulfide compound, commonly known as antimony glass, which causes fritting at the lower zone of the furnace. Even with ore from 30 to 35 per cent. Sb, some fritting would occur, necessitating the maintenance of the furnace at a higher temperature than necessary for poorer ores. Hence the paradox: the richer the ore, the higher the percentage of coke required for the charge. It is possible to volatilize an ore of about 20 per cent, with 4 to 6 per cent, charcoal, the temperature being thus kept at low red-heat. On the other hand, with liquation residue, which ranges from 15 to 25 per cent., the problem is different. Here we have a material that loosens up at a very low red-heat, thus partially blocking up the furnace and preventing the free passage of the air upward. To remedy this, some works use a forced draft, while others use an excess of coke, amounting to 30 to 50 per cent, of the charge, thus increasing the porosity of the charge. One can frequently tell when the furnace is blockaded or when the suction fan is choked with the trioxide, especially if water is introduced into it, by observing the appearance of a reddish tint in the issuing trioxide fume, which would be otherwise white with the furnace working under normal conditions. A plausible explanation for the appearance of this reddish tint in the otherwise white trioxide is found in the formation of the compounds Sb2S20, Sb203-2Sb2S3, Sb203-2Sb2S3-4H20 or- Sb2S3-2H20. Some sulfide particles, from want of free oxygen, might be volatilized as such at temperatures above 550° C., and, taking up the moisture still in the ore, would form a hydrated sulfide, which is red in color. Another fact, which seems to substantiate such an explanation, is that whenever a new furnace, or one which has been standing idle for some time, is started, the trioxide fume is frequently colored red at the commencement and continues so until the furnace is well under way. The explanation here is that there must be present a certain amount of moisture in the furnace, and it is this moisture that is taken up by the volatilized sulfide to form the above-mentioned red hydrated sulfide.

As to the different forms of condensation chambers, not enough data are available to enable one to decide definitely which is best. It is obvious that the elaborate flue and bag systems of the Loong Kee Smelting Works should recover more of the volatile trioxide than others without such equipment.

One must have been struck by the comparative smallness of the reverberatory furnaces adopted for the reduction and smelting of the oxide or crude. Some of the reasons that can be enumerated for such practice are:

- Facility in the ladling of the metal together with the couverture.

- Comparatively small output of the smelters.

- Cheapness of installation and of repairing.

- The production of better stars on the slab of regulus.

Undoubtedly for such small types of furnace the fuel consumption is high; but it is still questionable whether, in view of the above reasons, one is justified in installing reduction furnaces larger than those of the Wah Chang Works, already described.

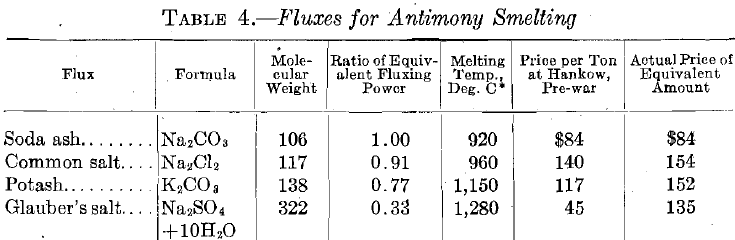

Regarding fluxes for smelting the trioxide, tetroxide, or crude, the best flux from standpoint of higher percentage of extraction, lower consumption of coal and of cheapness, is soda ash. That this is so is indicated in Table 4, and has been borne out in my personal experience:

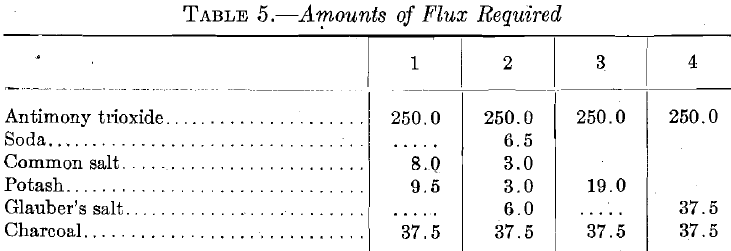

At one time, toward the end of 1915, when soda was so scarce as to command a price of about $450 per ton, several trials were made of some cheaper fluxes, such as common salt, potash, and Glauber’s salt, but invariably the results obtained were unsatisfactory. Among the many experiments tried, Table 5 illustrates the proportionate amount of the different fluxes used to smelt the trioxide:

Using charges made up of the sulfide and the oxide, either trioxide or tetroxide, according to the compositions given by Herrenschmidt, Pelatan or Basse, I have repeatedly obtained very poor results. We should not be surprised that this is so if we remember that chemically the sulfide and the oxide of antimony do not decompose each other, but combine to form what is known as antimony glass, which is irreducible by means of charcoal.

IV. Cost of Smelting:

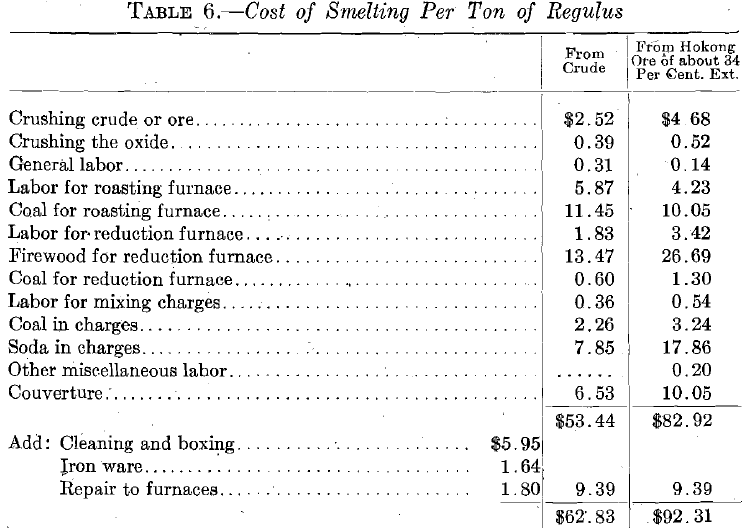

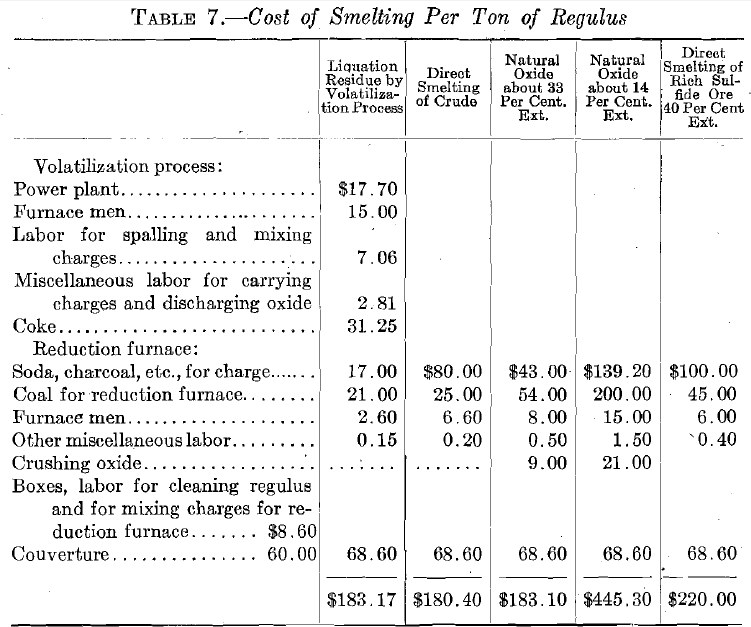

I shall give two detailed cost sheets, one before the war and one during the war, to show the difference in the cost of smelting as affected by the price of materials.

A . The Pao Tai Mining & Smelting Co . (1911).-Cost of materials and labor:

General labor per shift of 12 hr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $0.233

Furnace men per shift of 12 hr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25

Coal per ton . . . . . . . . . . . . . . .-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.20

Firewood per 100 Ib . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30

Charcoal per 100 lb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.00

Soda per 100 lb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.00

B . The Loong Kee Smelting Works (1915).-Cost of materials and labor:

Coal per pound………………………………………………………………….$0.0046

Charcoal per pound………………………………………………………………0.017

Soda per pound…………………………………………………………………….0.03

Coke per pound……………………………………………………………………0.007

Tinned scrap iron per pound………………………………………………….0.013

Antimony trioxide per pound…………………………………………………..0.25

Labor per shift of 12 hr…………………………………………………………….0.40

V. Some Suggestions for Future Improvement:

Due to the lack of capital, and of mutual coordination and cooperation among the smelters and the short-sighted policy of the directors of the different companies, there has not been any marked progress in the metallurgy of antimony in China. Obviously an important line of future progress should be in the direction of eliminating the heavy losses due to volatilization

of the metal during the successive steps of treatment. To be conservative, let us assume the total loss to be 20 per cent. ; then for an annual production of, say, 20,000 tons of regulus, the loss would amount to 4000 tons of regulus, which, at the present market price at Hankow of $300 per ton, would give an appalling dead loss of $1,200,000 to the whole industry. I do not believe that we can totally eliminate this loss, but I do believe that, with the adoption of some such proposals as outlined below, the loss could be kept down to 10 per cent., or possibly less, thus effecting an annual saving of at least $600,000, which would more than pay back the capital outlay for such alterations and additions to the existing plants.

My proposals are :

A. Adoption of a mechanical roaster, such as the Herreshoff or the Wedge type, for roasting the crude or the rich ore.

B. Adoption of a special type of reverberatory furnace for the liquation process.

C. Adoption of gas-firing for the reduction furnace.

D. Adoption of the Cottrell electrical precipitation process.

E. Investigation of the possibilities of electric smelting of the oxide or ore.

F. Investigation of the possibilities of the recovery of the sulfur from the fume by means of the thiogen process, as suggested by Prof. Young.

Practice of Antimony Smelting in China BY CHUNG YU WANG, E. M., A. M., HANKOW, CHINA