The chief ore of lead is galena, a sulphide of lead, common in most mining districts, and frequently associated with blende and copper-pyrites. It always carries more or less silver; so that in the assay of the ore a silver determination is always necessary. Carbonate (cerussite), sulphate (anglesite), and phosphate (pyromorphite) of lead also occur as ores, but in much smaller quantities.

Lead ores are easily concentrated (owing to their high specific gravity, &c.) by mechanical operations, so that the mineral matter Bent to the smelter is comparatively pure.

Lead is readily soluble in dilute nitric acid. The addition of sulphuric acid to this solution throws down heavy, white, and insoluble lead sulphate.

Galena is soluble in hot hydrochloric acid, sulphuretted hydrogen being evolved; but the action is retarded by the separation of the sparingly soluble lead chloride. If a rod of zinc is placed in this solution, metallic lead is precipitated on it as a spongy mass, the lead chloride being decomposed as fast as it is formed. The opening up of the ore is thus easily effected, the sulphur going off as sulphuretted hydrogen, and the lead remaining in a form easily soluble in dilute nitric acid. Galena itself is readily attacked by nitric acid, part of the lead going into solution, and the rest remaining as insoluble lead sulphate. The sulphate is due to the oxidation of the sulphur by nitric acid; its amount will vary with the quantity and concentration of the acid used. Sulphate of lead is soluble in solutions of ammonium or sodium acetate; or it may be converted into carbonate by boiling with carbonate of soda. The carbonate, after washing off the sulphate of soda, dissolves easily in nitric acid. The precipitation of lead from acid solutions with sulphuric acid, and the solubility of the precipitate in ammonium acetate, distinguishes it from all other metals. The addition of potassium chromate to the acetate solution reprecipitates the lead as a yellow chromate.

DRY ASSAY

The dry assay of lead is largely used, but it is only applicable to rich or concentrated ores, and even with these only gives approximate results. Both lead and lead sulphide are sensibly volatile at a moderately-high temperature; hence it is necessary to obtain a slag which is easily fusible. As a reducing agent iron is almost always used, and this is added either in the form of an iron rod, or the crucible itself is made of this metal. The flux used is carbonate of soda.

When a clay crucible is used, the method of working is as follows:—Weigh up 25 grams of the dry and powdered ore, mix with an equal weight of “soda” and 2 grams of tartar; place in a crucible (E. Battersea round), and then insert a piece of iron rod about half an inch in diameter, and of such a length that it will just allow the crucible to be covered. The rod should be pushed down so as to touch the bottom of the crucible, and the mixture should be covered with a sprinkling of borax. Place in a furnace heated to, but not above, redness, and cover the crucible. In about twenty minutes the charge will be fused : the fusion is complete when bubbles of gas are no longer being evolved; and then, but not till then, the iron is withdrawn, any adhering buttons of lead being washed off by dipping the rod a few times in the slag. Cover the crucible, leave it for a minute or two, and then pour. Detach the slag, when cold, by hammering. The weight of the button multiplied by 4 gives the percentage. The commoner errors of students in working the process are too high a temperature and too quick a withdrawal.

A sample of ore treated in this manner gave on duplicate assay 17.5 and 17.6 grams of lead, equalling 70.0 and 70.4 per cent, respectively. By wet assay the sample gave 73.3 per cent. Using an iron crucible, the results will be 1 per cent, or so higher. The crucible must be made of wrought iron; and, if it has been previously used, should be cleaned by heating to dull redness and scraping the scale off with a stirrer. Take 30 grams of the ore, mix with 30 grams of “soda” and 3 grams of tartar; put the mixture in the crucible, and cover with a sprinkling of borax; heat for about twenty minutes at not too high a temperature, and then scrape down the slag adhering to the side with a stirrer. Leave in the furnace till action has ceased. Before pouring, tap the pot gently, and then tilt it so as to make the slag wash over the part of the crucible along which the charge is to be poured. Pour; and, when cold, clean and weigh the button of metal. A crucible may be used from ten to twenty times.

These assays are for ores containing the lead chiefly as sulphide. For oxidised ores, charcoal or tartar is employed as the reducing agent. The student may practise on red lead as follows:—Take 30 grams of red lead; mix with 10 grams each of borax and “ soda ” and about 1.5 gram of powdered charcoal; place Sn a small clay crucible with a cover (C. Battersea round), fuse at a gentle heat, and pour when action ceases. This assay will only take a few minutes.

Where lead is present as phosphate (as in the case of pyromorphite), or mixed with phosphates (as sometimes happens), carbonate of soda is a suitable flux; but the phosphate of soda which is formed makes a thick tenacious slag, which is very apt to be carried out of the pot by the escaping gas. A wide-mouth clay pot is taken and a little fluor spar added. For the assay of pyromorphite the following charge may be used:—Ore, 20 grams ; “soda,” 25 grams; tartar, 7 grams; and fluor spar, 5 grams; and 2 grams of borax as a cover. This will melt down in about ten minutes, and should be poured as soon as tranquil.

WET ASSAY

In the case of galena, the best method of getting the lead into solution is to treat with hydrochloric acid and zinc. Put 1 gram of the ore in an evaporating dish 4 inches across, and cover with 10 c.c. of dilute hydrochloric acid. Heat till the evolution of sulphuretted hydrogen becomes sluggish, and then drop in a piece of zinc rod. If the solution effervesces too strongly, dilute it. Continue the heating until the sulphide is seen to be all dissolved; pour off the liquid and wash twice with cold water. Peel off the precipitated lead with the help of a glass rod, and then clean the zinc. Cover the lead with 20 c.c. of water and 5 c.c. of dilute nitric acid, and heat gently till dissolved; all the lead will be in solution, and, when filtered off from the gangue, will be ready for a gravimetric determination. For volumetric work this filtering is unnecessary. Pure zinc should be used for this purpose; the ordinary metal contains lead, and although its amount may be determined and allowed for, the correction required is large.

Galena may be dissolved in hydrochloric acid without difficulty under proper conditions. One gram of the finely powdered mineral treated with 40 c.c. of dilute hydrochloric acid and heated so that the boiling is accomplished very gently will dissolve to a clear solution. With excessive evaporation lead chloride crystallises out and the attack on the galena becomes sluggish.

The ore may be opened up by the following method, which leaves the lead in the form of sulphate. Weigh up 1 gram of the finely powdered ore and place it in an 8oz. flask: add a mixture of 5 c.c. each of sulphuric and nitric acids: boil off the nitric acid. Allow to cool, add 70 c.c. of water, boil, allow to settle and pour off the liquid through a small filter. Wash repeatedly with small quantities of water, keeping the residue in the flask as far as practicable. The residue contains lead sulphate.

Lead sulphate may be dissolved in a solution of sodium hydrate: 5 grams of the soda are sufficient for 1 gram of lead. If the liquor is turbid it is decanted and only the washings passed through a filter. The lead may be recovered from the liquor as sulphide of lead by adding ammonium sulphide, or as metal by precipitating on aluminium.

Lead sulphate may be dissolved by boiling with a solution of sodium acetate : about 40 grams of the salt are needed for 1 gram of lead : in the presence of 5 or 10 c.c. of acetic acid the solution is easier, but solutions with much acid are likely to-cause trouble on boiling by giving up some of their lead sulphate. The lead in sodium acetate solutions may be recovered as chromate or molybdate in the manner described under the heading Volumetric Methods.

GRAVIMETRIC DETERMINATION

Gravimetric Determination,—The lead being in the solution as nitrate or chloride is to be freed from any excess of nitric or hydrochloric acid by evaporation. The residue is to be taken up with water and the resulting solution treated with 5 or 10 c.c. of dilute sulphuric acid. The liquor must be allowed to stand and the clear portion decanted through a filter.

Transfer the precipitate, and wash with very dilute sulphuric acid (1 or 2 c.c. in 100 c.c. of water). The acid must be completely removed with one or two washes with cold water, and then with alcohol. The volume of liquid required for washing is small, as the precipitate is dense and easily cleaned ; but the washing must be carefully done, since if any acid remains it will, on drying, char the paper, and render the subsequent work troublesome. Dry, transfer to a watch-glass, and burn the filter paper, collecting its ash in a weighed porcelain crucible. The filter paper must be freed as much as possible from the lead sulphate before burning, and the ash treated with a drop or two of nitric and sulphuric acids. Transfer the lead sulphate to the crucible ; ignite gently, keeping the temperature below redness; cool, and weigh. The precipitate will contain 73.6 per cent, of lead.

VOLUMETRIC METHODS

Chromate Method.—This is based upon the re-action between chromate of potash and soluble lead salts in feebly acid solution, whereby an insoluble lead chromate is produced. If the solution is cold the precipitate is very finely divided and difficult to work. On warming, it assumes a darker colour and becomes flocculent; in this condition it settles readily and is easy to filter. The change begins at about 40° or 50° C., and is complete in solutions 10 or 20 degrees hotter. The solubility of lead chromate in faintly acid liquor is perceptible at the temperature of boiling, even if the acid be acetic and only 2 or 3 c.c. are used for each 100 c.c. of the solution. At the ordinary temperature the solubility is not appreciable. Sodium acetate and an excess of potassium chromate reduce the solubility in the hot slightly acid solutions. If during the re-action the lead is in excess, and hot liquors are used, then the precipitate will carry more lead than the formula PbCrO4 warrants, and the excess will vary within rather wide limits according to the manner of working.

A steady worker will obtain fairly concordant results even under these adverse circumstances ; but it is better to keep the potassium chromate in excess, and this is easily done by pouring the hot liquor containing the lead into a solution containing more than enough chromate to precipitate the whole of the lead present. By pouring the lead solution, hot, into a cold chromate solution, one may get a final temperature of about 60 C., and the resulting precipitate will be easy to manipulate ; but if the temperature is not high enough a subsequent warming has no bad result, and brings the lead chromate into the desired condition.

The lead having been converted into lead chromate, its amount may be determined by any method which measures the chromate. A small precipitate may be dissolved in dilute hydrochloric acid and treated with potassium iodide: a titration of the liberated iodine by a standard solution of stannous chloride will measure the lead present. For larger quantities a solution of ferrous chloride will be better : the re-action is that which occurs in the bichromate assay for iron, and the method of working is the same, except that here the iron is in the standard solution and the chromate in the assay liquor; and that the end of the titration is marked by the appearance, instead of the disappearance, of a greenish tint in the test drops on the plate. As the student should learn the iron assay before attempting this, there is no need to repeat the details of the titration here. In dissolving the lead chromate, however, there are some points of importance: the precipitate from one gram of lead may be dissolved in 200 c.c. of water with about 15 c.c. of hydrochloric acid by warming not too quickly and withdrawing the heat as soon as the liquor clears. Overheating decomposes the chromate with liberation, and loss, of chlorine: thus spoiling the assay. With care, quite good results are to be expected, and with small precipitates it is not easy to go wrong. Yet for the assay of an ordinary galena it is safer to avoid the risk and to work an indirect titration.

In the indirect titration a quantity of standard chromate solution for about .1 gram more lead than is expected to be present in the assay liquor is carefully measured from a burette into a 16- ounce flask. The liquor containing the lead is heated to boiling and poured into the cold chromate : its bulk should be such that, after mixing with the chromate, the temperature should be something over 6o° C. The precipitate is then filtered off, and the excess of chromate determined by titrating the filtrate with a standard ferrous solution. By deducting this excess from the quantity originally taken you get the amount used up by the lead.

The Standard Ferrous Solution used for the indirect titration may be made with ferrous sulphate ; but for the direct titration ferrous chloride must be used. This is because of the presence of lead in the assay liquor; the sulphate in the standard solution causes a precipitation of lead sulphate during the titration, and this carries down with it sufficient lead chromate to give it a distinct colour. Lead chloride, even if it separates, causes no such trouble, as it is not liable to the same contamination. In the indirect titration there is no lead in the assay liquor. The standard solution should contain 8.12 grams of iron to the litre in order that 100 c.c. of it shall be equivalent to 1 gram of lead. It is better to make the stock a little stronger than this, and dilute the quantities required from time to time to the exact strength, so that 100 c.c. of it shall require 100 c.c. of the standard chromate for a titration. In making the solution weigh up 8.2 grams of soft iron wire, dissolve it in hydrochloric acid, and dilute to 1 litre. Or take 41 grams of ferrous sulphate crystals, 100 c.c. of dilute sulphuric acid, and, having dissolved the salt with water, dilute up to 1 litre. Measure carefully 80 or 90 c.c. of it, titrate with the standard chromate, and add as much more water as is necessary to equalise the two solutions.

The Standard Chromate Solution is made by dissolving 9.40 grams of potassium chromate in water and diluting to 1 litre : 100 c.c. of it will be equivalent to 1.00 gram of lead. Its strength should be checked by standardising with a known weight of lead, about .7 or .8 of a gram. The standard solution may be made with 7.13 grams of bichromate of potash and 4 grams of bicarbonate of soda instead of the 9.4 grams of potassium chromate.

A Standard Solution of Lead is convenient. It may be made by dissolving 16 grams of nitrate of lead in water and diluting of 1 litre : 100 c.c. will contain 1 gram of lead.

Acetate of Soda Solution.—Weigh up 250 grams of the crystallised salt, dissolve in water, make faintly acid to litmus with acetic acid, and dilute to 1 litre.

Standardising the Chromate Solution.—Weigh accurately a piece of pure lead of about .8 gram. Place in an 8-ounce flask with 10 c.c. of dilute nitric acid, heat to dissolve the metal; and then evaporate nearly to dryness quickly but with care to avoid bumping. Add 20 c.c. or 30 c.c. of water and boil briskly. Cool and add soda cautiously till the precipitate formed becomes permanent. Add a piece of litmus paper; if it is not blue add more soda until this colour is obtained. Add acetic acid until the litmus is reddened and then 2 or 3 c.c. in excess. Add 20 c.c. of sodium acetate solution, and make up with water to 150 c.c. Heat to boiling. Measure into a pint flask from a burette 90 c.c. of the standard chromate solution. Pour the hot lead solution into the chromate; shake well, allow to settle, filter. To the filtrate add 30 c.c. of dilute sulphuric acid, and titrate with standard solution of ferrous sulphate. The assay liquor should be in a basin, as in the bichromate iron assay. The standard iron solution may be run in freely as long as the yellow tint of the chromate remains ; when the assay liquor becomes green test with drops of ferricyanide of potassium solution on a porcelain plate. Continue the titration about 1 c.c. at a time until a bluish tint is obtained. Now bring the burette, with the standard chromate, and run in this solution a drop or two at a time until the bluish tint is no longer obtained, exactly as in the iron assay. The calculation required is best illustrated by an example. Suppose .8105 gram of lead were taken with 90.0 c.c. chromate, then 9 c.c. of the standard ferrous sulphate, and, finally, .3 c.c. of chromate to complete the titration. The total chromate used, that is, the reading of the burette with the chromate solution, would be 90.3 c.c. Of this the 9.0 c c. of ferrous sulphate accounts for, say, 9.1 c.c.: the correction here depends on the relative strengths of the two solutions. Then 90.3-9.1 gives 81.2 c.c. chromate = .8105 gram of lead ; then 100 c.c. = .9982 gram. This is the standard. The chromate solution keeps its strength well. The standard ferrous sulphate weakens on standing.

Determination of Lead in a Rich Galena

Weigh 1 gram of the very finely powdered ore and place in an 8-ounce flask with 40 c.c. of dilute hydrochloric acid. Boil very gently until the attack is complete ; add a few drops of permanganate of potash solution and boil off the excess of acid, briskly at first, then more cautiously, to avoid bumping. Add 20 or 30 c.c. of water, and then soda till the liquor is alkaline. Acidify with acetic, &c., exactly as in the standardising. Having finished the titration, calculate how much of the chromate solution is equivalent to the ferrous sulphate solution you used, and deduct this amount from the total chromate run in: this gives the quantity of chromate solution used up by the lead in 1 gram of the ore. Calculate the percentage in the usual way.

Determination of Lead in Poorer Lead Ores

Weigh up 1 gram of the finely powdered ore and heat to about boiling for 10 or 15 minutes. Boil down to a bulk of about 5 c.c., add a small crystal of chlorate of potash towards the end and continue the boiling till the chlorine is driven off. Dilute to 150 c.c. with water : see that the lead chloride is dissolved. Pass SH2, allow to settle, filter. Wash the precipitate back into the flask and complete the cleaning of the filter by pouring over it 20 c.c. of hot dilute hydrochloric acid. Boil down to about 10 c.c. Add a few drops of permanganate solution and boil off the chlorine. Cool: add soda to get a permanent precipitate, acidify with acetic acid, &c., exactly as in the standardising. Use about 10 c.c. of chromate more than you expect the lead to use up. Titrate as before.

MOLYBDATE METHOD

This is based on the reaction between lead salts and ammonium molybdate in solutions made more or less acid with acetic acid. Lead molybdate is formed as a white precipitate which, in the earlier stage of the titration, does not settle readily. When almost all the lead has been thrown down it goes down fairly well, leaving the liquor over it colourless and clear. It is less sensitive to the presence of acetic acid and foreign salts than lead chromate is and its composition does not vary so much with variations in the conditions under which it is precipitated.

The finishing point is got by testing for ammonium molybdate. This is done by bringing a drop of the assay liquor into contact with a drop of a solution of tannin on a porcelain slab; the presence of ammonium molybdate is shown by a brown colour. With such small quantities of molybdate as .1 or .2 c.c. of the standard solution in 200 c.c. or 300 c.c. of water the colour is rather feeble for a sharp determination when tested in this way, especially in the presence of acetic acid. But larger quantities, such as 2 or 3 c.c. of the assay liquor filtered off into test tubes, give much plainer indications. The following plan of working then appears convenient. Let the assay liquor containing the lead and acidified with acetic acid be heated to boiling. Run in the standard solution of ammonium molybdate with occasional reheating until the precipitate begins to settle readily, then proceed more cautiously, adding the molybdate solution 1 c.c. at a time until two drops of the assay liquor give a brown colour when brought into contact with a drop of the tannin solution on the porcelain slab. Filter off 2 or 3 c.c. into a test tube; add three drops of tannin solution : from the depth of colour produced an estimate can be made as to how much the titration is over-done. Run in from a burette a little more of a standard solution of lead than is judged to be necessary to correct for the excess of molybdate used. Suppose 1 c.c. of lead solution added : equivalent to 1 c.c. of the standard molybdate. Filter off into a test tube 2 or 3 c.c. of the assay liquor and again test with three drops of the solution of tannin, which will show no reaction : if it does, add .5 c.c. of lead solution and test again. Then add molybdate solution .1 c.c. at a time, filter off portions into test tubes after each addition. Place the test tubes in a stand in proper sequence, counting from left to right, and note under each tube the corresponding reading of the burette. When a series has been obtained drop into each tube three drops of the tannin solution and shake to complete the mixing. In a few moments the finishing point will be shown with beautiful distinctness ; one of the tubes will show a faint brown tint and those on the right of it a gradually increasing colour : this marks the finish, and the burette reading below this tube is the one required. It will be necessary to deduct from it the equivalent of the lead solution run in.

Worked as just described the portions withdrawn for testing will apparently demand a correction for loss through withdrawal of such considerable quantities of the assay liquor; but if done strictly as described the correction will rarely reach .05 c.c. and need not be made in ordinary cases. The assay may be worked in the ordinary way, finishing off with a drop of the molybdate solution at a time until the test on the porcelain slab shows a faint brownish tint.

The Standard Solution of Ammonium Molybdate is made by dissolving 7 grams of ammonium molybdate in water and diluting to 1 litre. If necessary a few drops of ammonia may be added to clear it. This should be standardised and diluted to the strength 100 c.c. = 1 gram of lead. If the standard as found is 1.04, then 4 c.c. of water should be added to each 100 c.c. of the standard solution.

The Solution of Tannin is made by dissolving 1 gram of tannin in 300 c.c. of water. This solution should be made from time to time as wanted. Solutions of lead and sodium acetate will be required : these should be prepared as described under the Chromate Method.

Standardising the Molybdate Solution.—Weigh accurately a piece of lead foil of about .5 gram. Dissolve in a 4-inch dish with 10 c.c. of dilute nitric acid. Cool: add 5 c.c. sulphuric acid and boil until the sulphuric acid fumes appear. Allow to cool: add 70 c.c. of water : boil and filter. Wash with small quantities of water: keep the lead sulphate in the dish as far as possible. Add 10 c.c. of acetic acid to 80 c.c. of sodium acetate solution ; boil and run through the filter into the dish: boil in the dish until the lead sulphate is dissolved. Transfer to a wide-necked flask and dilute to about 250 c.c. Boil and titrate with standard molybdate solution in the manner described above. Calculate the standard in the usual way.

Assay of a Poorer Lead Ore or Matte.—Weigh up 1 gram of the very finely powdered ore or .5 gram if it is rich in lead. Treat in a 4-inch dish with 5 c.c. sulphuric acid and 5 or 10 c.c. of nitric acid. Boil off the acid till the dense sulphuric acid fumes appear. Allow to cool. Add 70 c.c. of water, boil, filter, &c., exactly as in the standardising.

COLORIMETRIC PROCESS

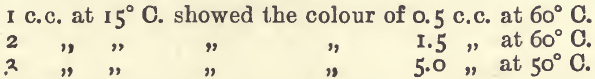

This is based upon the brown coloration produced in very dilute solutions of lead by the action of a solution of sulphuretted hydrogen. The quantity of lead in the 50 c.c. of the assay solution must not much exceed 0.5 milligram, nor be less than 0.01. The sulphuretted hydrogen is used in the form of a solution, and is not bubbled through the assay. The principle of working is the same as previously described.

Standard Lead Solution.—Each c.c. of this should contain 0.1 milligram of lead. It is made by diluting 10 c.c. of the solution of lead nitrate, described under the volumetric process, to 1 litre.

Sulphuretted hydrogen water is made by passing a current of the washed gas into the water till the latter is saturated.

Five c.c. of the sulphuretted hydrogen water are put into a Nessler tube, the measured portion of the assay solution added, and the whole diluted with water to the 50 c.c. mark. Into the standard Nessler tube the same amount of the sulphuretted hydrogen water is put, and diluted to nearly 50 c.c. The standard lead solution is then run in till the tints are equal. The assay solution must not contain much free acid, and if the conditions will allow it, may with advantage be rendered alkaline with ammonia. The chief cause of disturbance is the precipitation of lead sulphide forming a black turbid solution instead of a brown clear one. This may be caused by using hot solutions or an excess of acid. Other metals precipitable by sulphuretted hydrogen must be absent as well as strong oxidising agents.

Effect of Varying Temperature.—The effect of increased temperature is to change the colour from brown to black, and to render the estimation difficult.

Effect of Varying Time.—The colour becomes lighter on standing: 2 c.c. on standing 10, 20, and 40 minutes became equal in colour to 1.7 c.c.

Effect of Acids and Ammonia.—Two c.c. of the solution with 2 c.c. of dilute hydrochloric acid became cloudy and equivalent to about 2.5 c.c.; and a similar result was got with 2 c.c. of dilute sulphuric acid. With 2 c.c. of dilute ammonia the solution became somewhat darker, or equal to 2.3 c.c.; but gave a very clear solution easy to compare.

Determination of Lead in Commercial Zinc

Dissolve 0.1 gram of the metal in 1 c.c. of dilute nitric acid evaporates till a solid separates out, dilute to 100 c.c. with water, and take 20 c.c. for assay. A sample treated in this way required 2.4 c.c.; this multiplied by 5 gives 12.0 c.c., equal to 1.2 milligram of lead, or 1.2 per cent. By gravimetric assay the sample gave 1.10 percent.

PRACTICAL EXERCISES.

1. Thirty grams of galena gave on dry assay 21 grams of lead ; and this, on cupellation, gave 15 milligrams of silver. Calculate the results in per cents, of lead and in ounces of silver to the ton of ore.

2. How many ounces of silver to the ton would be contained in the lead got from this ore if the loss in smelting is equal to that of the assay ?

3. Having given you a sample of white lead freed from oil by washing with ether, how would you proceed to determine the percentage of lead in it?