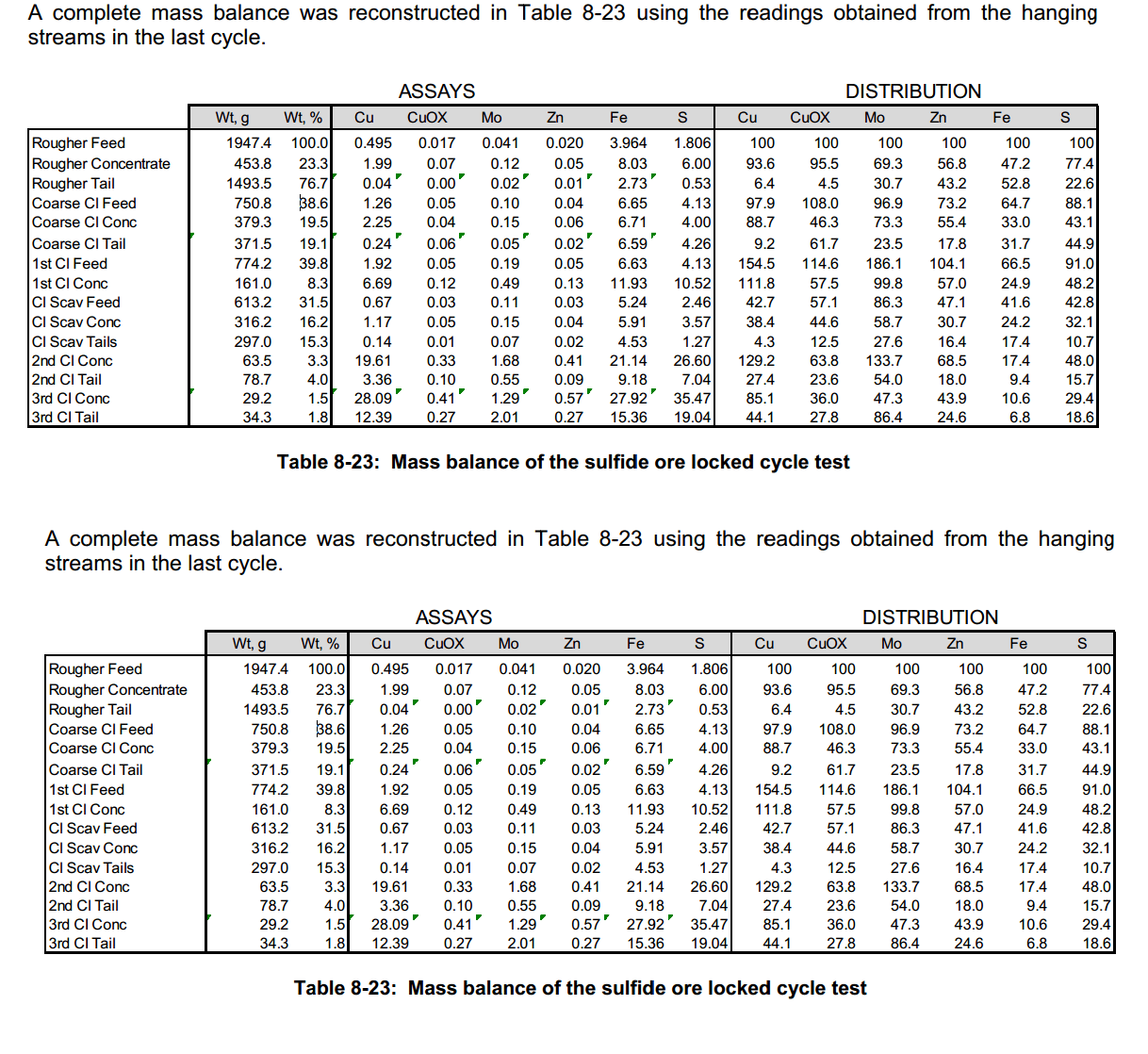

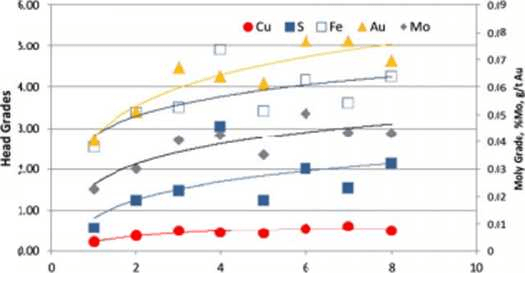

In a flotation locked cycle test, a poor/low moly recovery was obtained at 47.3% as it appeared that molybdenum had not reached equilibrium. The calculated head grade trend, shown in Figure 8-28 indicates that the moly and most of the other elements had not reached convergence when the test was terminated. Figure 8-29 shows the trend in recoveries as the cycles were executed. Moly recoveries appear to be driven into the upper fifties Gold recoveries were trended and as with moly, did not reach equilibrium either. Gold recoveries are expected to reach into the sixties with a concentrate grade of 2.7 g/t.

Convergence was examined by calculating the head grades from the products (see Figure 8-28). Copper minerals achieved convergence from the 6th cycle onwards, whereas gold, moly, sulphur and Iron did not. This is as a result of the slow kinetics of these minerals in the cleaners.

Figure 8-29 shows that a large upset occurred in the test after cycle No 3 and onwards; this is being attributed to the presence of slimes in the regrind feed product. Controlling the regrind performance proved to be difficult in that the recycled streams contained so much fines that the regrind feed screen analysis met the target regrind product starting with the 4th cycle onwards. Figure 8-29 also shows that a large upset in the moly performance occurred during the last 3 cycles, which prevented this mineral reaching the anticipated recovery levels in the low sixties as suggested by the tendency of the first 6 cycles.

911Met Diagnostic:

In this case if they ‘tester’ pulled the crap out of the first cleaner and cherry picked the final cleaner, that would cause the moly never to spit out anywhere (just goes around and around and around – and results in high mass recycles with may be the cause of the problem they mention). Is it sitting in the recycle products at the end of the test? One also need to look into how much went into each cycle compared to how much came out in exit products for each cycle. By the end of the test these should equate. But there’s all kinds of things that could be going on including the wrong conditions for the ore to stabilize. It really depends.

Further troubling, the Laboratory needed 25 minutes for rougher time… they build a plant with 1:1 scale up .. ie: 25 min of real life time.

25 minutes is a very long lab rougher, even for a project with poor kinetics.