A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners).

B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to be higher than the Ball Filling Level. Grate Discharge mills will not face this issue.

C) This value represents the Volumetric Fractional Filling of the Voids in between the balls by the retained slurry in the mill charge. As defined, this value should never exceed 100%, but in some cases – particularly in Grate Discharge Mills – it could be lower than 100%. Note that this interstitial slurry does not include the overfilling slurry derived from the difference between the Charge and Ball Filling.

D) Represents the so-called Dynamic Angle of Repose (or Lift Angle) adopted during steady operation by the top surface of the mill charge (“the kidney”) with respect to the horizontal. A reasonable default value for this angle is 32°, but may be easily “tuned” to specific applications against any available actual power data.

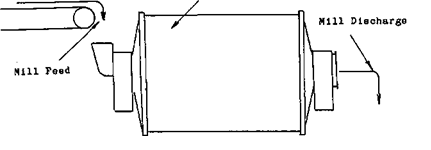

The effect of change of feed size, or of return of a classified fraction, is obtained by direct experiment. This is a more time-consuming method, and its success still depends on the consistency of scale-up factors, but it is inherently a more informative test and will be the method considered here. Such tests usually try to obtain a close duplication of conditions in the test mill to those in the production mill, in everything except mill size. It is advantageous to use as large a mill diameter as feasible considering the expense of the test system and handling the larger quantities of material involved for a larger mill. If the feed under investigation contains large material, a direct duplication test requires a big enough mill diameter to handle the particle and ball sizes involved.