Pulps of 20% solids is prepared from -200 mesh pyrite concentrate (after froth flotation), and is inoculated with 5% (V/V) of adapted bacterial solution. The bioleaching tests is carried out in 250 ml Erlenmayer flasks, each contained about 220 ml pulp. The pulps is aerated with air bubbling at one liter per minute air flow rate, and is continuously agitated with a magnetic stirrer while the temperature was kept at 30 degrees C.

The bioleaching tests should be started at pH 2.0. The pH left to decrease during the tests, but not less than 1. Partial replacement of the leaching solution with water done by decantation at the rate of 25% by volume per day i.e., about 55 ml/flask/day. Distilled water is added to the leaching solution to compensate for the replaced solution and evaporation. Only partial re-inoculation with 1% (V/V) of adapted bacterial solution every third day is needed to compensate for lost bacteria.

Samples are withdrawn from the replacement leach solutions and analyzed to determine the dissolved metals by a Perkin-Elmer computerized atomic absorption spectrophotometer model 3030. At the end of the bioleaching test, the residues are collected, dried and weighed before use in cyanide leaching.

The residues from the bioleaching tests are treated by standard cyanidation leaching for gold and silver extraction. For cyanidation tests, pulps of 20% solids content are treated for 48 hours at pH 11-11.5 with cyanide leaching solution. The cyanide leaching solution consisted of 18 lb/ton lime and 30 lb/ton sodium cyanide. At the end of test, the pulps are filtered and the filterate was used for determination of gold and silver contents by the atomic absorption spectrophotometer.

Extraction of Gold and Silver from Bioleaching Residues by Cyanidation

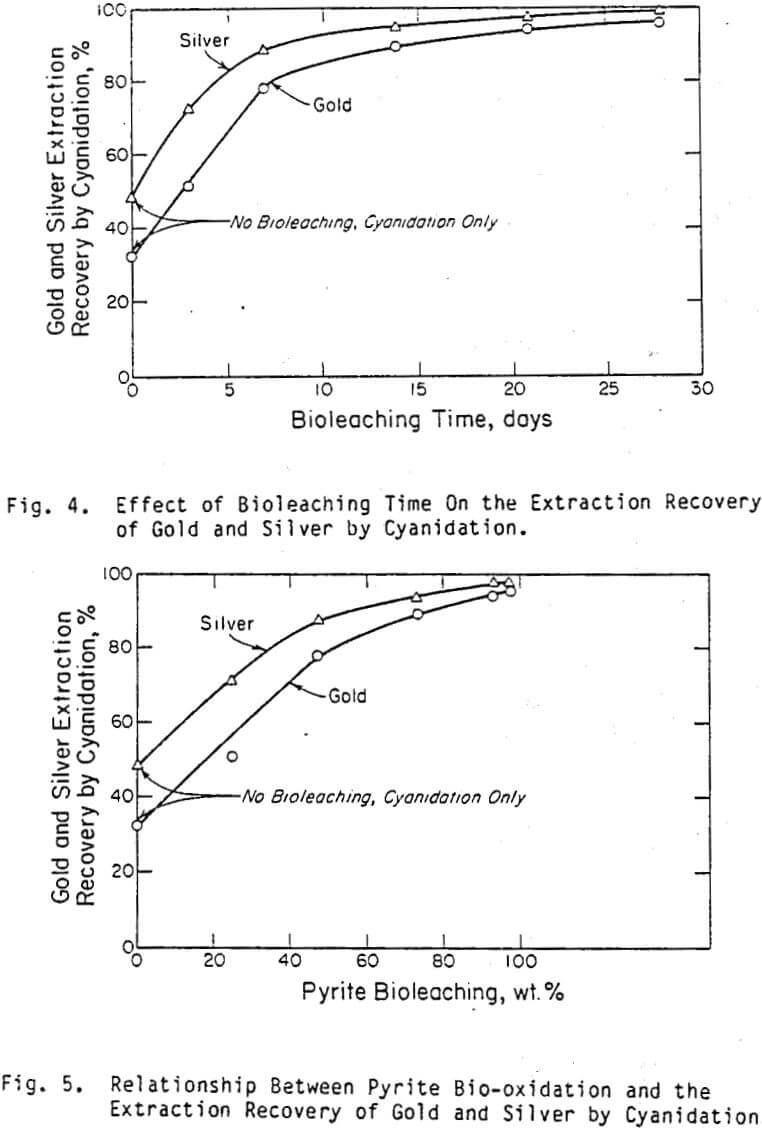

When the bioleaching tests were completed, the leaching solutions were filtered and the residues were washed, dried and weighed. The obtained residues were then treated by cyanide leaching for 48 hours to extract the gold and silver. Figure 4 shows the effect of bioleaching time on the gold and silver extraction by cyanidation. From the figure it is clear that most of the gold and silver (about 89% and 94%, respectively) were extracted after 14 days of bioleaching. While at the end of the test (28 days) the extraction of gold and silver reached to about 95% and 98.6%, respectively. The results showed that bioleaching had markedly increased the extraction recovery of gold and silver compared with direct cyanidation of the pyrite concentrate without bioleaching. The latter approach achieved only 32% and 48% recovery of gold and silver respectively.

The relation between the extent of pyrite bio-oxidation and the extraction of gold and silver by cyanidation. It is clear that at about 70% of pyrite oxidation most of gold and silver (more than 85% gold and more than 90% silver) can be extracted by cyanidation. While at about 98% of pyrite bio-oxidation, 95% of gold and 98.6% of silver can be extracted by cyanide leaching.

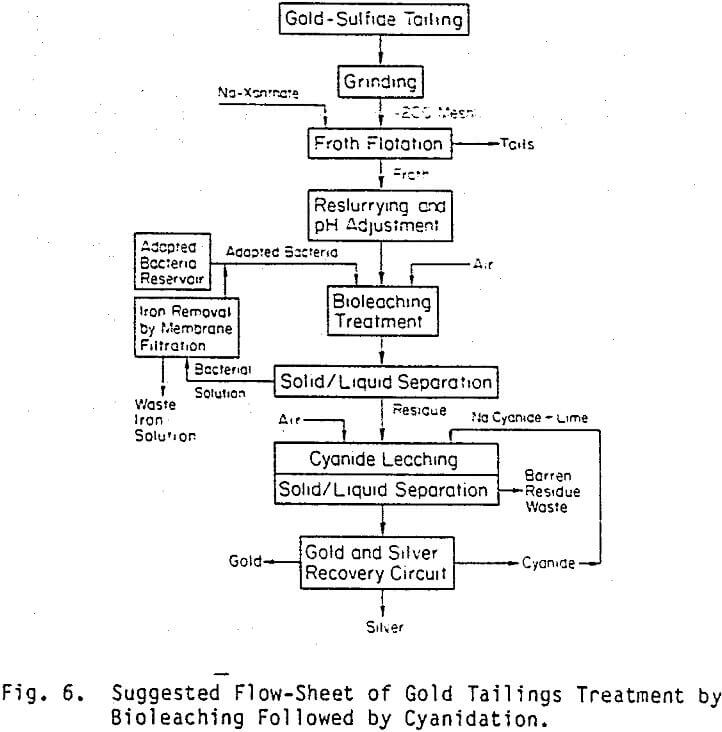

Figure 6 shows the suggested flow sheet of practical application of precious metals extraction from the received tailings. Generally, it can be noticed that the bacterial treatment of this concentrate took relatively long time in spite of the high bacterial activity. This might be due to the high pyrite content of this concentrate (about 82%).