During the past 50 years or more there has been a great waste of money, energy, and time in devising, building, and trying many machines to recover gold and platinum, also gemstones, from black sand. Volumes have been written on the subject, and many inquiries have been made by prospectors and others who thought that although they could not save the precious metals, which most likely were never there, some process must be suitable. Near Nome, Alaska, the black sand was rich, and some on the west coast of the South Island of New Zealand is being worked at a profit at the present time. A few spots along the California- Oregon coast were worth handling, as have several along the rivers in the western United States and Canada. The black sands from sluicing and dredging operations are worth careful treatment because they are from the concentration of thousands of yards of gravel daily. By-product black sand from inland placering is often richer than beach sand. But generally, black sand, unless a concentrate, is not worth much effort. In any case, it is worth spending a dollar or two to have an assay made for gold of a carefully taken sample, not selected sand. The mechanical gold pan can be used for sampling test pits of sand.

Most placer gold is associated with black sand, which is composed largely of grains of magnetite (magnetic iron oxide) but may contain varying proportions of hematite (non-magnetic iron oxide, but rendered magnetic by heating), ilmenite (iron-titanium oxide), pyrite and marcasite (iron sulphides), monazite (cerium, lanthanum, thorium phosphate), rutile (titanium oxide), scheelite (calcium tungstate), tourmaline (boron and aluminum silicate), wolframite (iron-manganese tungstate), zircon (zirconium-silicate), chromite (iron oxide and chromium oxide), and other heavy minerals.

A cubic yard of gravel may yield up to 100 pounds of black sand. But more or less of this material does not indicate much or little gold. If too much is present, it is a nuisance in filling the riffles of a sluice-box. The specific gravity of the minerals that compose black sand ranges between 3 and 5. Crude gold’s gravity is 15 to 19, and crude platinum 14 to 19. The gold and platinum particles exist generally as fine, thin scales which are difficult to save. They tend to float and thus be lost; therefore they should be wetted before being panned or washed in any way. The previous metals may be rusty or tarnished, therefore difficult to amalgamate without grinding. If crude platinum metals are present, they probably will not contain more than 65 per cent platinum, and buyers pay for this metal only on the market price for the pure metal. Therefore, transactions will be at several dollars an ounce under the market price.

When a black-sand concentrate has been collected, before it can be treated locally or sold it should be reduced to as small a bulk as possible. By repeated panning, rocking, long-tomming, jigging, tabling, magneting, or passing the sand over cloth of some kind, most of the more or less worthless material may be discarded.

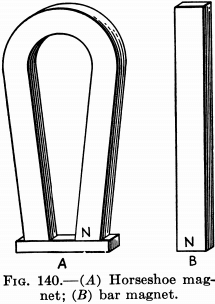

Figure 140 shows a horseshoe magnet and a bar magnet. Care must be taken in using them because the precious metals may be somewhat coated with iron and the magnet might attract some of them with the real iron minerals. By this means some gold may be lost. Therefore the magnetings should be carefully examined before they are discarded. If a piece of cellophane or other material is held over the magnet, only iron minerals will be lifted out.

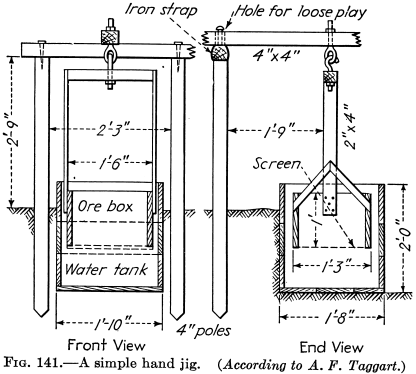

Figure 141 shows a hand-jig which is suitable for treating black sands. The feed may be sized or unsized. The sieve may be movable or fixed. If the former, the sieve constitutes the bottom of a frame or basket which works in a tank of standing water. The simplest jig is a hand-jig whose feed and discharge are intermittent. Jigs with fixed sieves are more common and are generally homemade. The motion of the water is actuated

by a plunger, either at the side of the jig cell or under it. New water must be added to replace what passes over the tailboard and through the hutch.

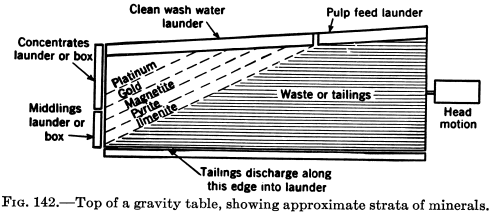

If a placer claim yields much, black sand of value, it might pay to install a small shaking table. These machines are described under Concentration, but Fig. 142 shows the deck of a table while concentrating black sand. The iron minerals are saved as middlings and are returned to the table, while the precious metals are caught in a launder, box, or tub.

When the black sand has been re-concentrated into small bulk, it may be ground and amalgamated at the mine, as described earlier in this section on gold, or sent to a smelter. But first it should be assayed, because its value must be known before smelters will accept it. Some smelters and dealers do not pay for platinum; others make part payment; others make full payment.

In cleaning up at the Rock Creek placer of E. T. Fisher Company, New Atlantic City, Wyoming, amalgam, liquid mercury, and 3 gallons of concentrate are removed from each 12-foot sluice-box which is fitted with riffles. Considerable black sand is washed over during the clean-up, and in the final treatment of the concentrate, when the liquid mercury is washed out and coalesced, most of the sand is wasted. The final riffle material is ground for a half hour in a barrel with mercury and old cast-iron bucket teeth. If grease is present, cyanide or lye is added. The sludge is riffled again, and the black sands discarded. The live mercury is strained; the amalgam is retorted; and the retort gold is shipped to the Mint. The gravel averages 24 cents a cubic yard, according to a report of the Federal Bureau of Mines.