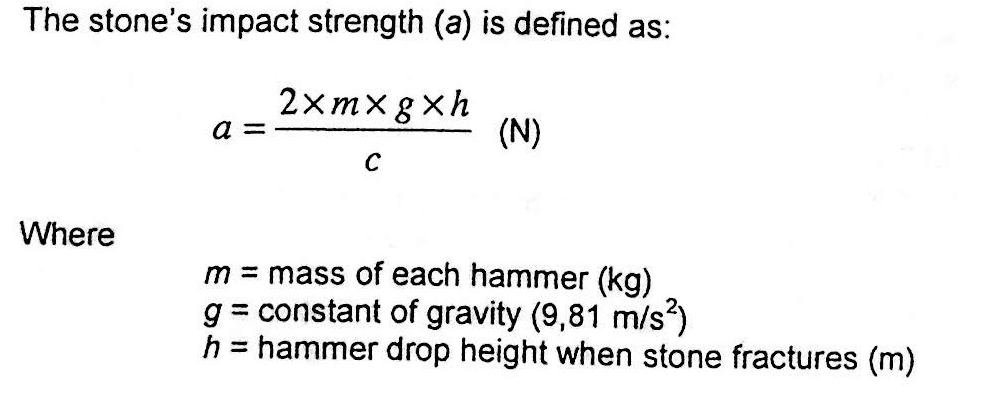

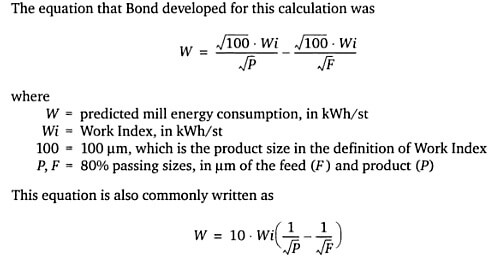

Sizing a crusher can be done reliably calculated thanks to the Impact/Crushing Work Index and the testwork research done by Fred Chester Bond and his 1952 paper. According to Bond’s Third Theory of Comminution, the work/energy input is proportional to the new crack tip length created during particle breakage and equivalent to the work represented by the product – the feed.

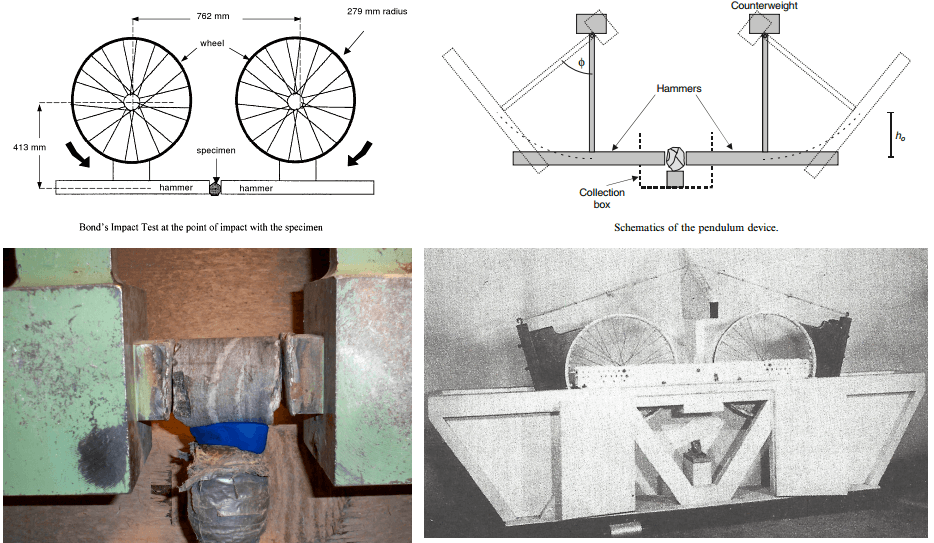

A crude test procedure description of this Crushability test follows in that rock samples smaller than 75 mm but greater than 50 mm are placed 2 “hammers” of 13.6 kg each and mounted to swing on bicycle wheels. Both hammers of the “pendulum” will impact the smallest measured side on the rock. The hammers are set to fall again from a higher drop position to input enough energy to break the rock. This is done 10 times to obtain 10 breaks and the WI (kWh/t) = 53.49 x Impact Crushing Strength / Specific Gravity of the sample. ** jktech.com.au

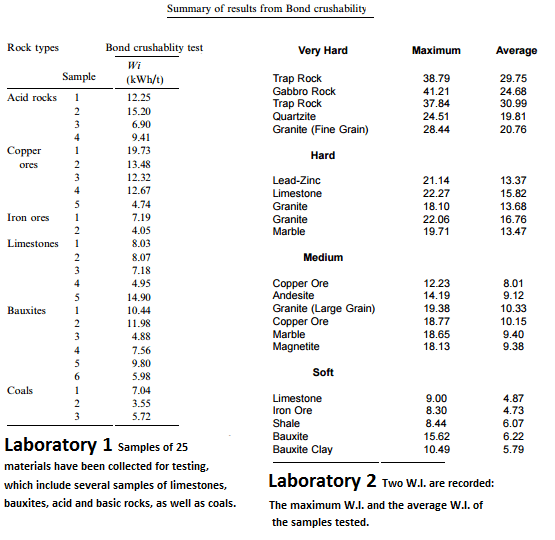

Find a referential Rod Mill Work Index Table here.

https://www.911metallurgist.com/rod-ball-impact-crushing-abrasion-the-bond-work-index-family

The test determines the Bond Impact Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing crushers*. It is also used to determine the required open-side settings (jaw crushers and gyratory crushers) or closed-side settings (cone crushers) for a given product size.

- P80 = 25400 x Oss x (0.04Wi + 0.40)

- P80 = 25400 x Css x 7Ecc x (0.02Wi + 0.70) / (7Ecc – 2Css)

Where Oss = Open-side setting in inches

Css = Closed-side settings in inches

Ecc = Eccentric throw in inches

P80 = Aperture through which 80% of the product will pass.

Wi = Work Index

The impact apparatus consists of two pendulum-mounted hammers, mounted on two bicycle wheels so as to strike equal blows simultaneously on opposite sides of each rock specimen. The height that the pendulum is raised is increased until the energy is sufficient to break the specimen.

Feed Sample Requirements: At least 10 pieces of minus 3” plus 2” ore (20 pieces recommended).

Also see another procedure and Work Index result table.

Here a Summary Table of several crushing work index tests performed by ‘others’ including old Nordberg.

This type of test is Standard, but I consider Sagmilling.com the go-to place for hardness testing management.

EFFECT OF CORE DIAMETER ON THE BOND IMPACT CRUSHING WORK INDEX TEST

*A.G. Doll, R. Phillips and D.J. Barratt https://www.onemine.org/document/document.cfm?docid=214436