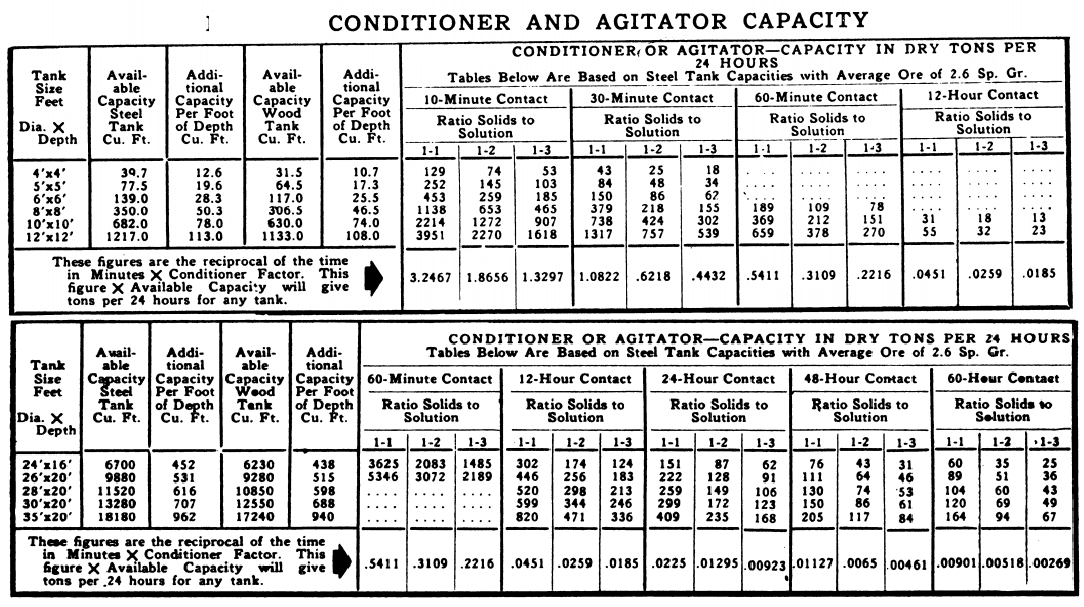

Example 1) It is desired to give 48 hours of contact on 100 tons per 24 hours of 2.7 specific gravity ore in a pulp of 40% solids (1:1.5). What size agitators will be needed?

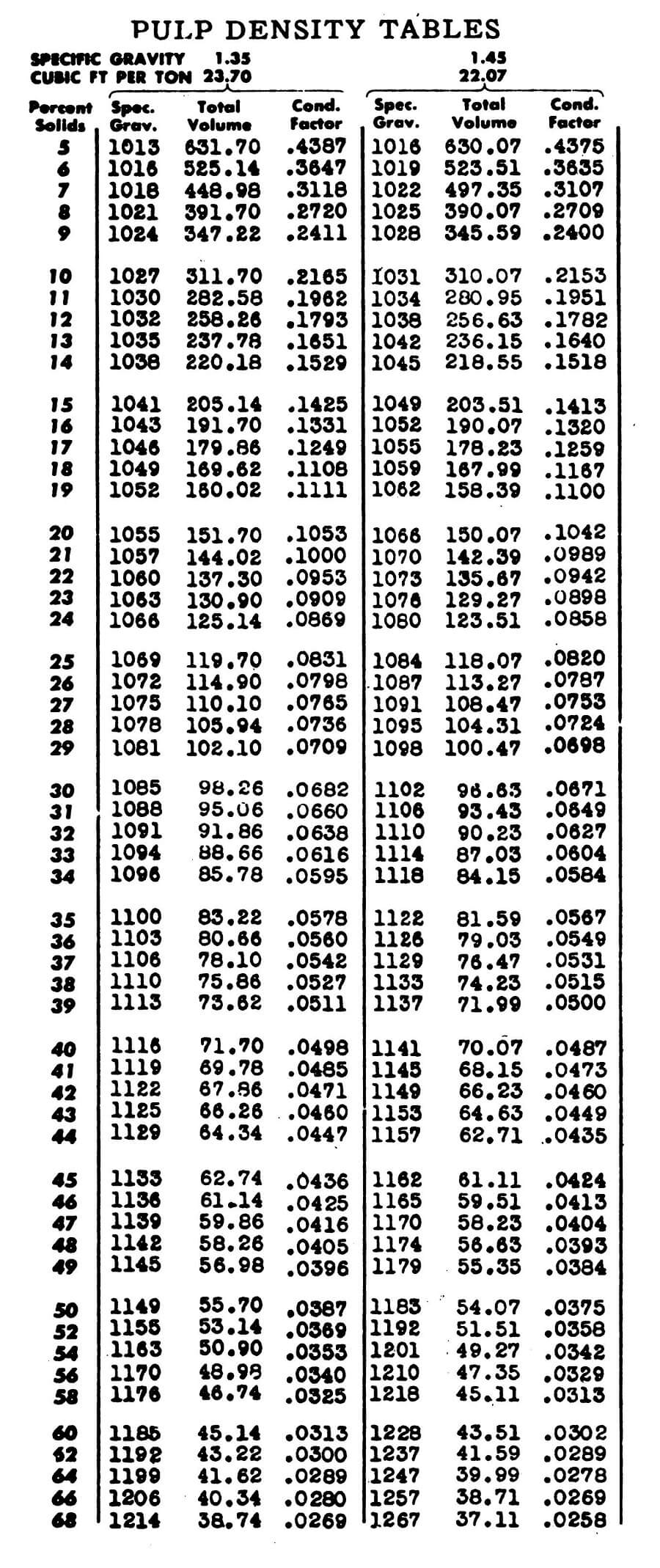

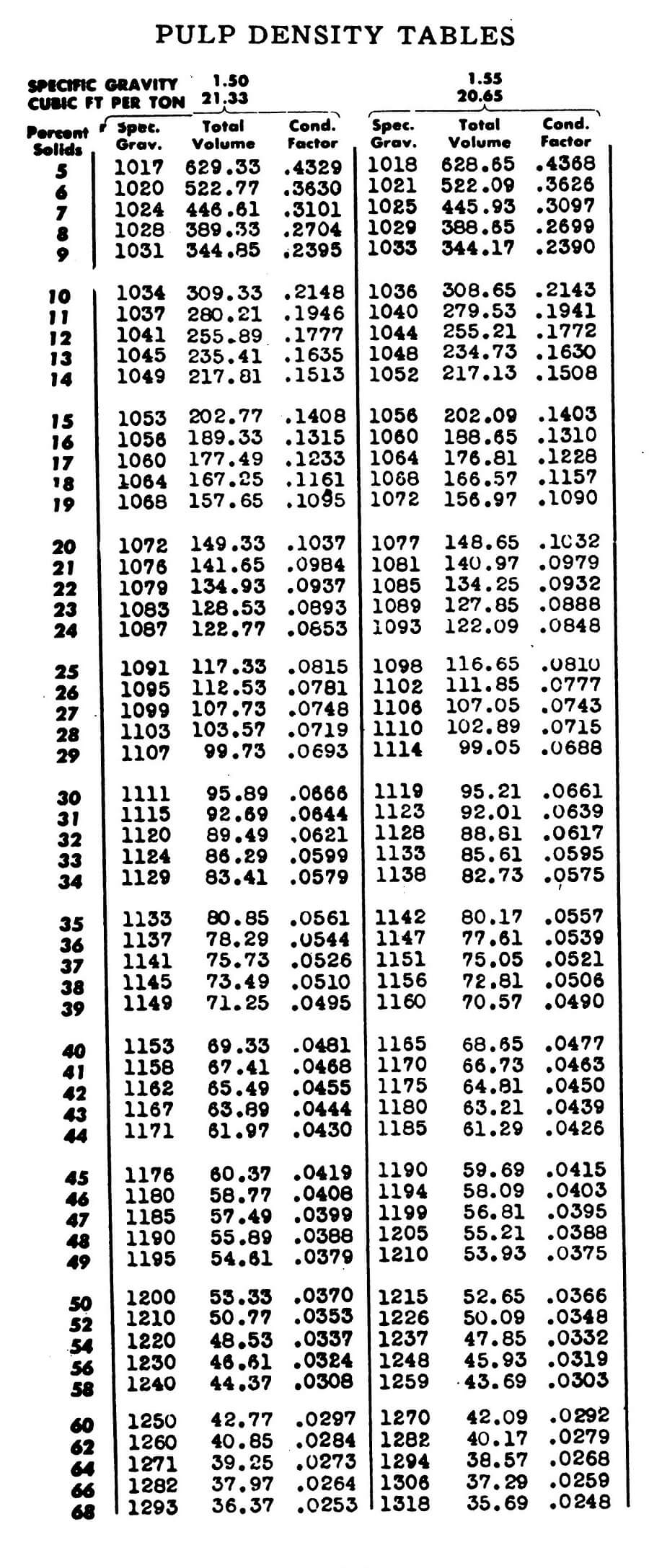

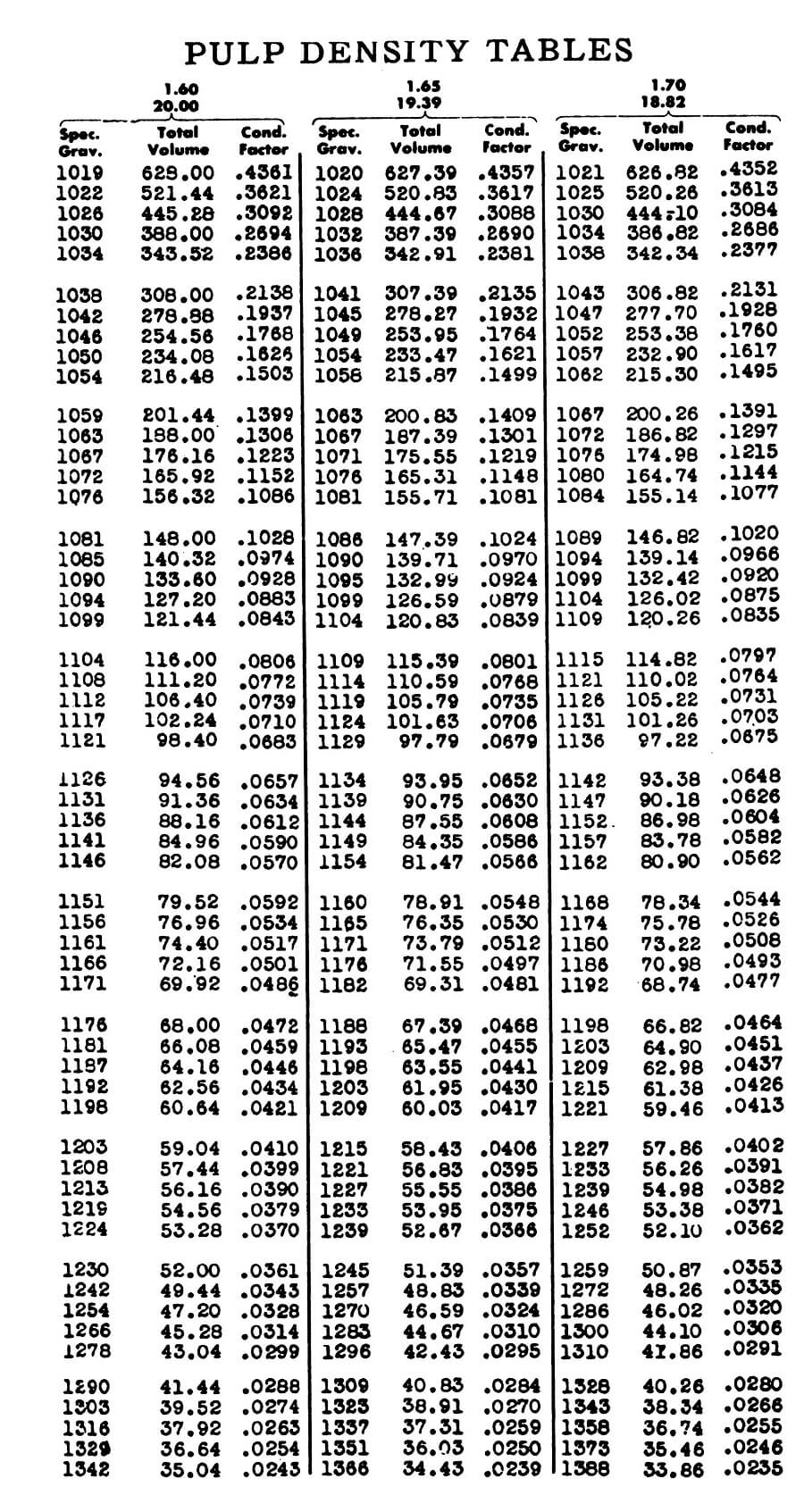

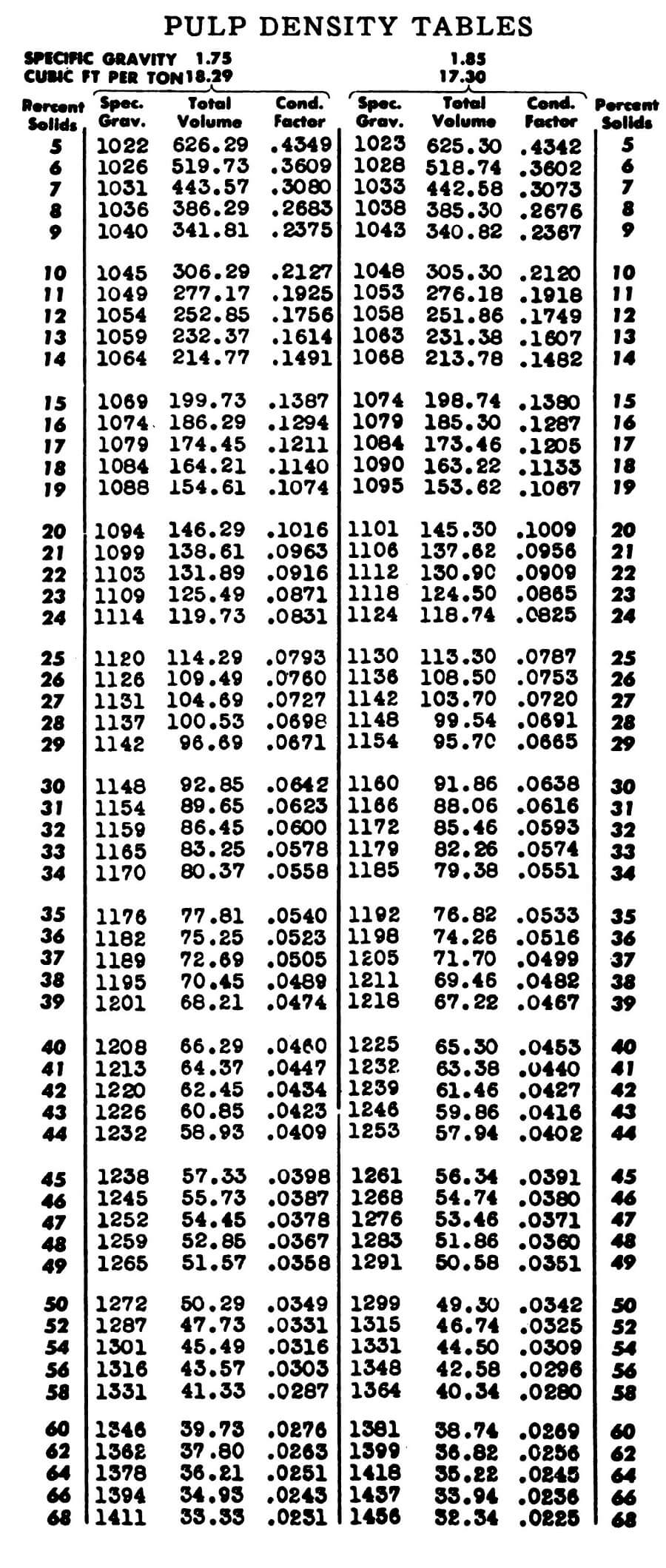

Total volume equals 59.85 –> from our Pulp Density tables.

Tons feed equal 100.

59.85 time 100 equals 5,985 cu. ft. (total volume 24 hour agitation).

Therefore, 5,985 times 2 equals 11,970 cu. ft. (Total volume 48 hours agitation).

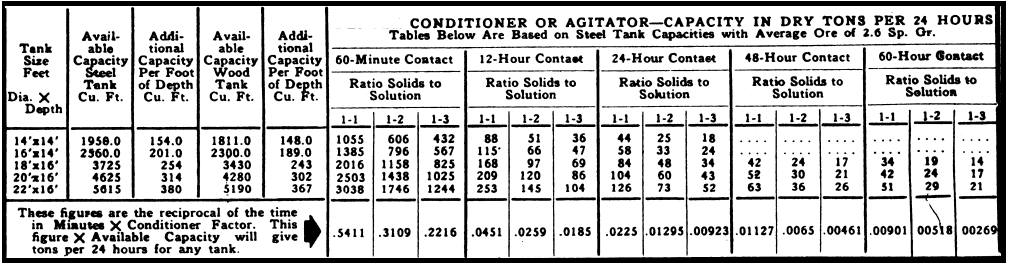

We find that 15′ x 4.5″ x 16′ and 1″ Bolted Steel Tank has an available capacity of 2,860 cu. ft.; therefore, four of these will handle the job.

Or we find that four 15′ x 16′ Welded Steel Tanks would give this approximate capacity or four 16′ x 16′ Wood Tanks would be suitable for this application.

Example 2) It is desired to condition 420 tons of 2.9 gravity ore for 25 minutes in a pulp of 30% solids (1:2.33) What size conditioner will be required?

Conditioning factor equals 0.0594.

Number of minutes equals 25.

0.0594 times 25 equals 1.485.

Number of tons equals 420.

1.485 times 420 equals 623.7 (0.0594 times 25 times 420 equals 623.7).

This time we find that 9′ and 2 5/8″ X 10′ Bolted Steel Tank gives an available capacity of 634 cu. ft.—sufficient for the problem.

Or a 9′ x 10′ welded steel tank or a 10′ x 10′ wood tank.

Mathematically inclined users of these tables will undoubtedly be interested in a description of the methods used in calculating them. Although the tables cover a much wider range than is usual, it might be that some special application would call for an extension of the figures in some direction, thus the following information would be helpful.

Total Volume: What is the total volume of a ton of dry solids with a specific gravity of 2.6 in a pulp containing 25% solids?

Solution:

1 ton of solids of 2.6 specific gravity comprises 12.31 cubic feet. 1 ton of water comprises 32.0 cubic feet. With 25 % solids in the pulp there will be one ton of solids plus 3 tons of water. Therefore, the total volume figure will be 12.31 plus 3 times 32 or 108.31 cubic feet.

Conditioning Factor:

The conditioning factor is the total volume divided by 1440, the number of minutes in 24 hours. Thus it gives a figure for use in conditioning problems where contact time is always a matter of minutes instead of hours.

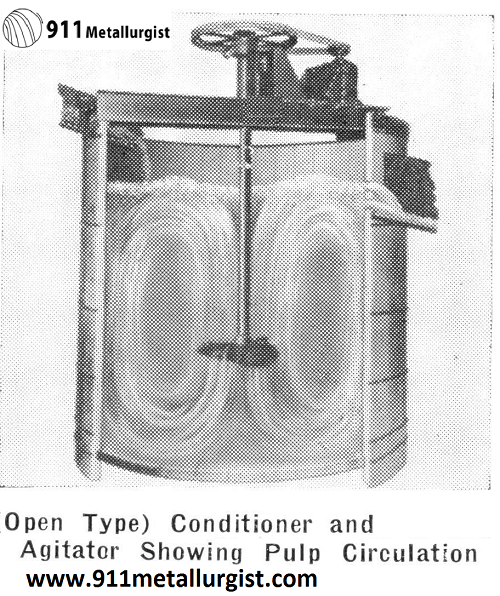

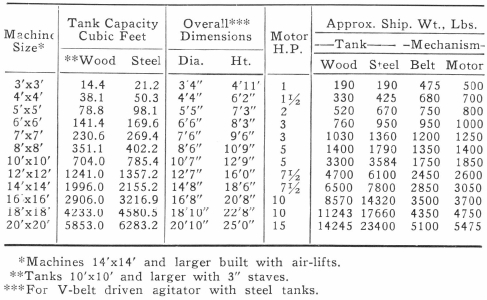

Conditioner and Agitator (Open Type)

(Open Type) Conditioner and Agitator is similar to the Conditioner and Super-Agitator except that the hood and standpipe have been eliminated. This unit can be successfully used where conditions require a moderate agitation or mixing action on light pulps. Many industrial applications where continuous mixing is required utilize this sturdy but economical unit.

Additional data gladly furnished upon request.

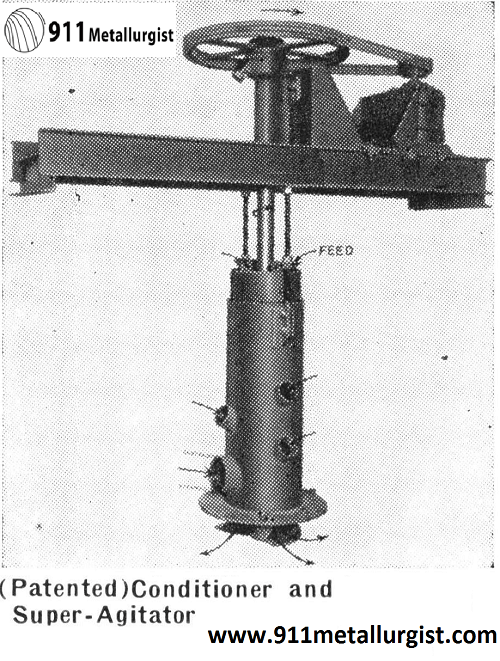

Conditioner and Super-Agitator, (Patented)

(Patented) Conditioner and Super-Agitator is especially designed for intense agitation and aeration. It has a wide application as a conditioner, an agitator, a mixer, or an aerator. It will handle any pulp or slurry, or liquid-solid combination that will flow through a ten mesh screen.

The (Patented) Conditioner and Super-Agitator is a heavy duty machine. The mechanism is supported on a beam type superstructure which may be mounted on an open or closed tank of wood, steel, concrete, or other suitable material. The enclosed antifriction bearing assembly carries the heavy duty shaft and ship type three blade propeller, which may be furnished of cast iron, rubber, or special alloys as required. Recirculation of pulp is controlled by an adjustable collar on the standpipe, and by re¬circulation holes in the standpipe itself. In large tanks auxiliary airlift pipes are supplied to increase circulation and aid aeration.

The (Patented) Conditioner and Super-Agitator can be easily started after a shutdown, and accordingly is valuable for batch work. Short circuiting of pulp when used continuously is prevented by the positive feed to the propeller.

More complete information can be obtained by writing any Equipment Company office.