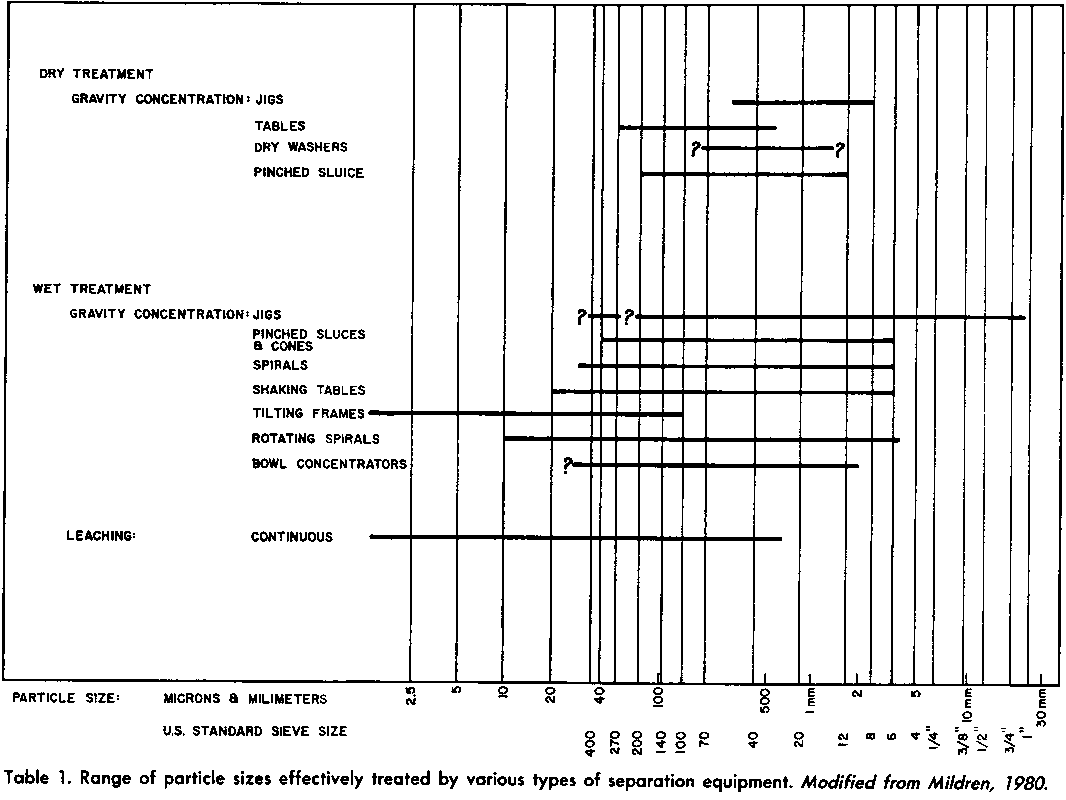

Many types of efficient placer gold recovery equipment are available today. The choices facing those designing a recovery system for a particular site are not easily made. A major consideration, of course, is cost versus recovery, but other factors must also be considered when designing an effective system. The size distribution of the gold is important because it will narrow your selection of equipment that can be used for recovery (Table 1). The size distribution of the raw material will also determine if classification of the ore is necessary for better recovery. The processing capacity of the equipment must conform to the mining plan. Cleaners usually have relatively low capacities and may limit the total amount of ore that can be processed. Finally, as important as the recovery efficiency of the equipment is, in some cases, most notably with high-volume operations, optimum recovery is sometimes sacrificed for increased capacity. Also, efficiency can be affected by factors not controlled by the device, such as feed-flow rates.

The design and implementation of an effective gold recovery system may be simplified in a number of ways. The simplest is to hire a consultant. Many consultants specialize in recovery and have the knowledge and resources to work through whatever problems that may develop. Some equipment companies will process a sample of the ore through their test plants or devices to test the effectiveness of their equipment. If financial limitations preclude the hiring of a consultant, other avenues exist for information. It may be helpful to converse with the operators of successful mines or mills, although they can be less than totally objective. The advice of respected experts can aid in solving problems and making good decisions. Retired miners, libraries, and equipment manufacturers are all good sources of information.

Ideally, most of the research and problem solving should be completed before the equipment is obtained. A systematic approach to gold recovery will reduce the difficulties involved in designing an efficient recovery system. The following section provides information on the equipment and methods used to recover gold in three different types of operation. It is hoped that these examples will be informative and illustrate the effective use of certain types of recovery equipment. A list of vendors and manufacturers is also provided.