Grinding and Classification Circuit

Our EXAMPLE Grinding and Classification Circuit is designed to grind 500 tonnes of ore per day, operating 24 hours per day, with an availability of 95%. This circuit will grind -5/8″ material from the Crushing Plant, classify the slurry in one of two cyclones, and pass 70% of the minus 200 mesh material to the […]

How to Improve Cyclone Separation

Good cyclone separation depends upon control of pressure drop, pulp density and apex size. The ‘pressure drop’ may vary but should not change rapidly, and is held at safe levels by keeping an adequate sump level. A falling sump level causes cavitation in the pump and reduction in feed rate; pressure drop in the cyclone […]

Hydrocyclone Rubber Liners

We sell Rubber Liners for Hydrocyclone: You can buy parts like the main body liner, lower cone and Apex or Vortex. Long lasting, good wear and better price VS life relationship than a Linatex types Brand.

Hydrocyclone Wholesale

If you are looking for a affordable quality Hydrocyclone Wholesale, contact us.

Hydrocyclone Feed Pump and Pressure

For a hydrocyclone to work at peak efficiency the volume of slurry and the feed pump delivery pressure must remain constant. If the cyclone feed pump is allowed to SURGE, the up and down pressure will cause poor separation at the point of high and low operating pressure. There is a cycle to a surging pump […]

Hydrocyclones Suppliers

If you are looking for an affordable Hydrocyclones Suppliers, contact us.

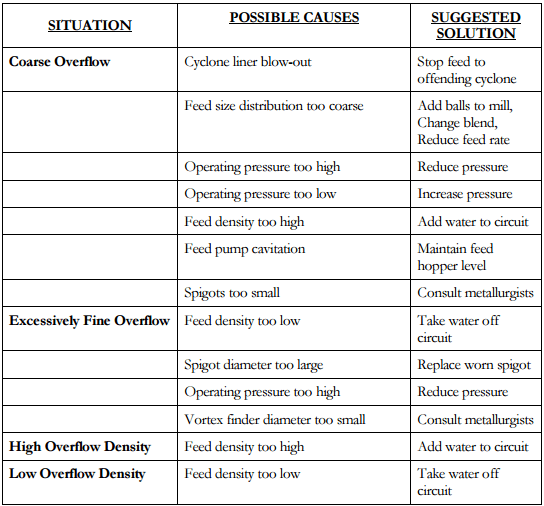

Troubleshooting Hydrocyclones

Here is a simple Table for Troubleshooting Hydrocyclones. Other Hydrocyclone Troubleshooting Tips: Underflow is too wet Apex is too large Vacuum control valve is open too far Inlet pressure is too low Pump is cavitating Underflow is too dry (cone is plugging) Apex is too small. Vacuum control valve is closed too far. Percent solids is too […]

Hydrocyclone Working Principle

The third type of classification used in mining is the Hydrocyclone, commonly called a Cyclone. Unlike the others it has no moving parts and is worked in conjunction of another piece of equipment, a pump. To understand the Hydrocyclone Working Principle we must first know its components. Beginning at the top, there is the OVERFLOW […]

Hydrocyclone Operation

The hydrocyclone operation consist of having the ore slurry pumped into its feed inlet, the ore is then separated by size with the fine material coming out of what is referred to as the “OVERFLOW” via a Vortex Finder. The mineral that still requires grinding is named the “UNDERFLOW” via the Apex Finder. These two […]

Principle of Operation of Hydrocyclone

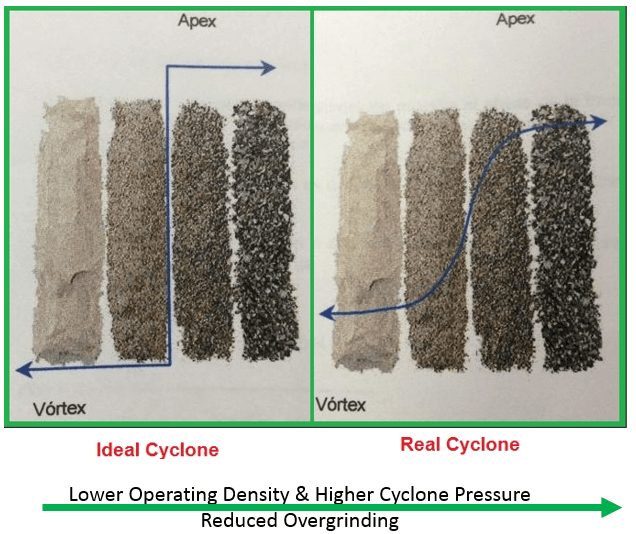

The Principle of Operation of Hydrocyclone is, in simple terms, the forces of gravity and centrifuge to separate large or heavy particles from smaller and lighter one. When sized correctly will “cut” like the ‘real cyclone’ below VS the imaginary ‘ideal’ one on the left. Hydrocyclones are preferred units for sizing or desliming large […]