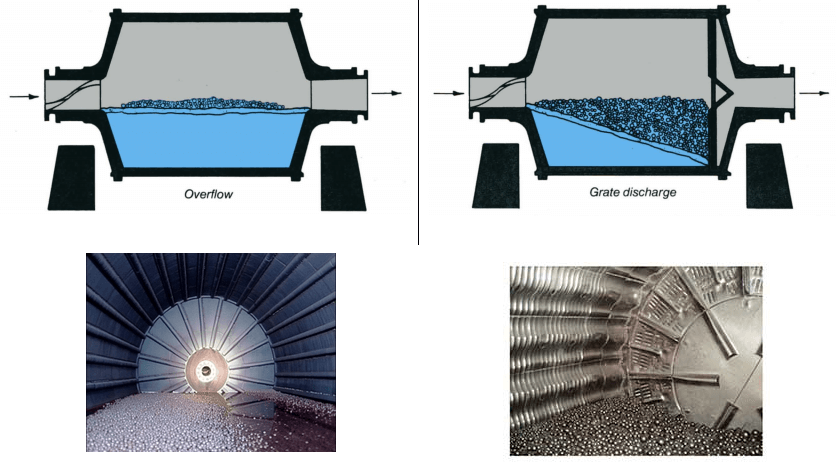

Overflow VS Grate Discharge Ball or Mill – Why Retrofit

Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is wanted, without any respect to the particle size distribution curve. Overflow discharge mills give a final product in an open circuit. Grate discharge mills are used when the […]

KK-8 Kiln Furnace Liner Maintenance

Three products are supplied with the KK-8 for optimizing and extending the life of the kiln liner: Liner Restore, Armor Coat and Spill Stop. All three products must be kept from freezing, or they will become unstable and unusable. Restored Kiln Sections Liner Restore is an alumina silicate based viscous material that is designed for […]

SAG Mill Feed Chute Design| Long Life | Wear Resistant

This design of SAG mill feed chute lasted 9 months seeing 90,000 TPD. It is 600 brinell chrome steel. With the big liners on the bottom of the chute you need to get a Chevron cast into the top to push the feed out to the sides for the first little while and then as […]

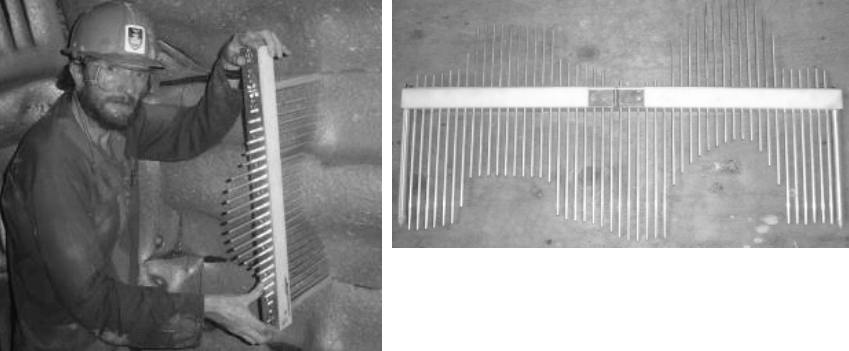

Mill Liner Profiler Tool -Track Liner Wear Pattern

Here is a home-made tool to measure or obtain a fingerprint of your SAG and Ball Mill Liner wear pattern/profile. Each time you shut down, get a profile and build a wear-life over time database to better predict your next reline job or monitor improvements to your liner design. Simple Tool to Track Liner Wear […]

Optimum Mill Liner Spacing | Design Effectiveness SAG

The images (chart) below is industry standard when it comes to the relationship between a mill liner’s lifter bar height and the lifter to lifter spacing. What tonnage do you think this SAG mill liner design gets?

Compare the Benefits of Steel VS Rubber Mill Liners

When are steel liners better than rubber/poly-met liners in a SAG mill or Ball Mill? Let’s compare! Rubber Liners are better for abrasion grinding ie: cascade action but not for cataract mills. The graph below shows the increased operating cost of rubber and steel liners as the grinding ball size increases. Larger mill, larger ball… […]