The pumps in a mineral processing concentrator (plant) can roughly be classified into two groups, PROCESS pumps and SERVICE pumps. A service pump is any pump that provides a service to the process. A Process pump is one whose function is part of the process. The pump doing this type of job will be directly responsible for maintaining the CONTINUOUS OPERATION of the process.

These two different groups will be required to work in a variety of environments and handle various substances. This means their design and construction must change to compensate for adverse operating conditions. This could be anything from pumping Acidic or abrasive material to having to work underwater. Many of the design modifications will be limited to the material that the pump is constructed from. Such is the case in the pumping requirements of acidic chemicals and abrasive ores.

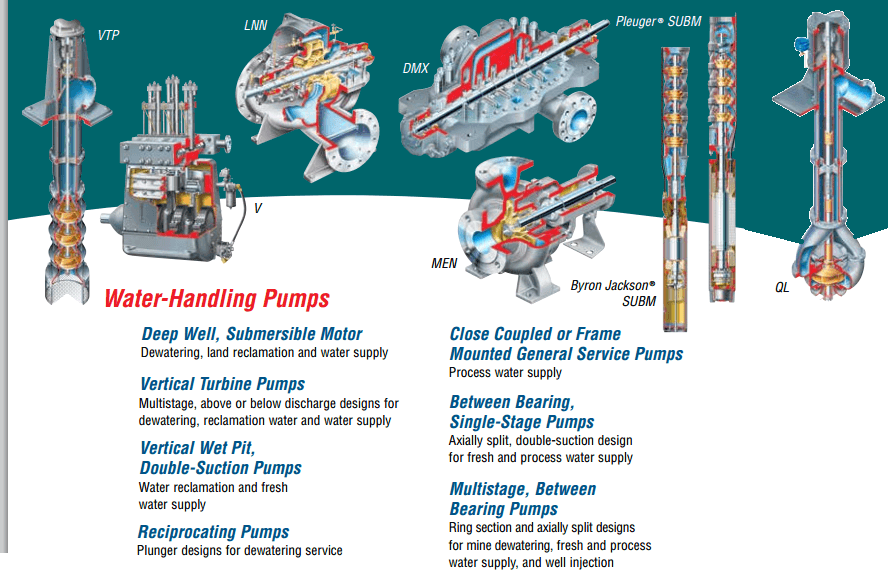

Other design changes may be required due to the pumps working environment. An example of this type of design would be a SUBMERSABLE WELL PUMP or a GREASE PUMP designed to deliver a measured amount of grease. The very number of the different pump designs make it impossible to describe each.

Instead I have picked two pumps that I am going to describe. The SRL TYPE and the DIAPHRAGM TYPE. The reasoning behind using these two as examples is that they exhibit a good range of differences. Both are found in mills, serve in both job categories, and they have the largest impact on an operator’s job performance.

The differences between the two are they pump by using two separate forms of PROPULSION, in some instances have two completely different POWER SOURCES. And finally each has its own UNIQUE pumping characteristics.