Slime treatment, as commonly used by metallurgical engineers, includes thickening, agitation, and filtering and as applied, to cyanidation also includes washing by continuous countercurrent decantation (C.C.D.) and/or filters. “Slime” is the general term used to describe the finer portion of pulp in a combination sand and slime-treatment plant and is usually finer than 100 mesh. The so-called “all-slime” type of plant is that in which all of the ore is ground through a relatively fine mesh such as 100 mesh and where no separate treatment of sand and slime is provided.

Equipment used and methods employed are discussed, with examples from practice.

FILTRATION

Filtration may be defined as the separation of liquids from solids by passing the liquid vehicle through a porous medium, which offers free passage to the liquid but refuses passage to the solids suspended therein. Either the solids or the liquid constituent or frequently both may be products of value, and the ratio of liquid to suspended solids in the feed pulp may vary between extremely wide limits. In metallurgical work, however, the filter is usually preceded by a thickener to dewater the pulp as far as possible by gravity, thereby producing a uniform feed and one on which the filter can operate at its greatest capacity and give best washing results.

- It is evident that a differential in pressure must exist on the two sides of the filter medium in order that the liquid will flow through the pores of the filter medium and the retained solids.

- Once this layer of solids has formed, its surface acts as the filter medium, and initially cloudy or dirty filtrates, due to the passage of solids through the relatively large openings of the filter medium, tend to clear up as the solids bridge these openings.

- Since the minute voids between the solid particles in the filter cake resemble capillaries, the flow of liquid may be expressed by a modified form of Poiseuille’s equation. The instantaneous rate of filtration per unit area can be regarded as the ratio of the pressure to the product of viscosity by the sum of cake resistance and filter resistance.

- For incompressible cakes, the rate of flow is directly proportional to the area and inversely to the viscosity and cake thickness. For flocculent or slimy materials, however, the rate may increase but slightly with pressure increase and in some cases actually decrease above a certain critical pressure.

- In general, the thinner the cake the higher the rate of flow, but other considerations, such as washing and drying efficiency and ease of discharge, usually call for a cake of some optimum thickness determined by test.

- The rate of cake formation is also proportional to the ratio of solids to liquid in the feed, but filter capacity in terms of either solids filtered or filtrate clarified is dependent upon completion of the entire cycle, including cake formation, washing, drying, and discharging.

Filtration Media

These may be divided into two main classes—the fabric and the metallic media. Of the former, the most commonly used are of cotton, different weights of duck, twill cloth, and special weaves, sometimes chemically treated for special purposes.

Synthetic-fiber weaves are now widely used. Some, such as vinyon, are resistant to acid attack. Vinyon-N resists considerable heat as well. Rayon, Nylon, and Saran are excellent fibers for certain uses, and all these synthetic materials are available in a wide range of weaves. Although they are more expensive than the natural fibers, increased life often more than compensates for this greater first cost.

Of the metals, there are woven-stainless-steel and monel-metal screens and wire.

The cotton ducks are satisfactory and are used mainly on pressure-type filters. The twill cloths are resistant to abrasion and are widely used on vacuum filters. The special weaves—chain, square, and basket— find their chief application on vacuum filters where high capacities must be obtained with coarse solids and a clear filtrate is not essential. Factors governing the selection of a filtering medium are,

- It must have mechanical strength and resistance to the solution to be filtered and have a satisfactory economic life. This determines the weight and type of the material.

- It must produce a filtrate of desired clarity and retain the smallest particle in the feed. This determines the grade and weave of the cloth.

Filter Cloth

The texture of filter cloth as used in filters in cyanidation for some years has been largely that of so-called twills, and in these cotton fabrics the weight usually runs from 15 to 17½ oz. The texture as such would be difficult to describe except that it produces a diagonal ribbing of characteristic appearance with which all cyanide operators are familiar. This is produced by alternately skipping certain threads in the weaving which on the next threads are not omitted.

At an earlier period the so-called square-weave duck fabrics were used, but they are distinctly unsuited for this work, being better fitted to retain liquids than to permit their passage.

In more recent years there has been a tendency toward lighter material and the synthetics, and with better general understanding of filter fabrics this tendency may proceed still further. Meanwhile, it remains a matter for determination by trial as to the best fabric in a given case.

The price has fluctuated with conditions in the cotton-textile industry. Generally, the material is sold in make-up lengths as well as being stitched for a given width of filter in the case of the Oliver machine. Nowadays, seamless filter cloth up to 14 and 16 ft. in width can be supplied.

Occasionally, material is sold in rolls for the mining company to make up its own covers, but the customary practice is to buy the cover readymade. In the case of the American disk filters, which use a specially tailored bag to cover the individual sectors, the covers are made up to fit and are sold by the dozen or other convenient multiple. The bags used on the American filters are occasionally heavier than the covers used on the Oliver filters because at times the wear is greater.

As to the useful period for cloth on cyanide filters, there is a wide variation; a filter life as long as 220 to 230 days has been reported in the case of one large installation—a remarkable performance. From this figure of nearly 8 months we go down through various periods, finding that 150 to 160 days is considered excellent life and that a good many plants are obtaining 100 to 120 days. Where working conditions are severe, the life is less than 100 days, but possibly in all such cases means might be found to increase it.

In removing lime encrustations by hydrochloric acid, 5 per cent is considered too concentrated for safety, and 2 to 2½ per cent is preferable, with reasonably frequent treatments, instead of stronger acids, being used at longer intervals.

The frequency of acid treatment is a factor that varies considerably in different places. In northern Ontario it is used much more often than in other places where lime concentration is less. In this respect it resembles the frequency of acid treatment necessary in the silver cyanide plants in southern Mexico where extremely high lime concentration prevails.

Stage Filtration

Two and sometimes three stages of vacuum filters have been used in series with pulping apparatus between each stage for washing pulp. Diluting liquid is added to each filter cake ahead of each repulper. In some cases partial C.C.D. is employed prior to the filtration stage to reduce the value or grade of liquid going to the filters. Sometimes there are short periods of agitation between the filters.

This method of working has been adopted by several of the Canadian cyanide mills, but its use has not been general elsewhere. Operating costs are relatively high compared with C.C.D. or C.C.D. followed by a single dewatering filter. For examples see descriptions of the Lake Shore, Wright-Hargreaves, and Hollinger cyanide mills in Chap. XV.

Filter Types

Two types of filters are in use—those which employ pressure and operate intermittently, with definite cycles for charging, washing, and discharging; others that employ vacuum and operate continuously or intermittently, with synchronized feeding, cake forming, washing, and discharging. Among the filter presses are the Dehne, Shriver, Merrill, Kelly, Sweetland, and Burt. In the metallurgical field the Dehne found some use in Australia and the Merrill is still in limited use in North America and Central America. Among the vacuum filters in use today are the Moore and Butters leaf filter of the intermittent or cyclic type, the continuous revolving types, including the external drum filters made by Oliver and a number of other manufacturers; the disk type or American filter; the internal drum or Dorrco filter; and finally the more recent horizontal type in which filter pallets revolve around a vertical axis.

Pressure Filters

Dehne Press. The Dehne plate-and-frame filter press has satisfactorily filtered many millions of tons of raw and roasted slime in Australia, particularly in the western states. At Kalgoorlie 100 of them were at one time treating 100,000 tons a month. Their operation was described in detail by M. W. von Bernewitz in 1906 in Proc. Australian I.M.E., now the A.I.M. and M. Most of these presses were of 5-ton capacity per charge. A few were hydraulically closed, but most of them were hand closed. In their discharge much hand labor was used. They can be emptied slowly by reversing the washing valves and opening the filling valve. Pressure filters are expensive in operation, and good results are dependent on careful attention and manipulation on the part of the operator. They have been almost entirely replaced by the continuous vacuum type.

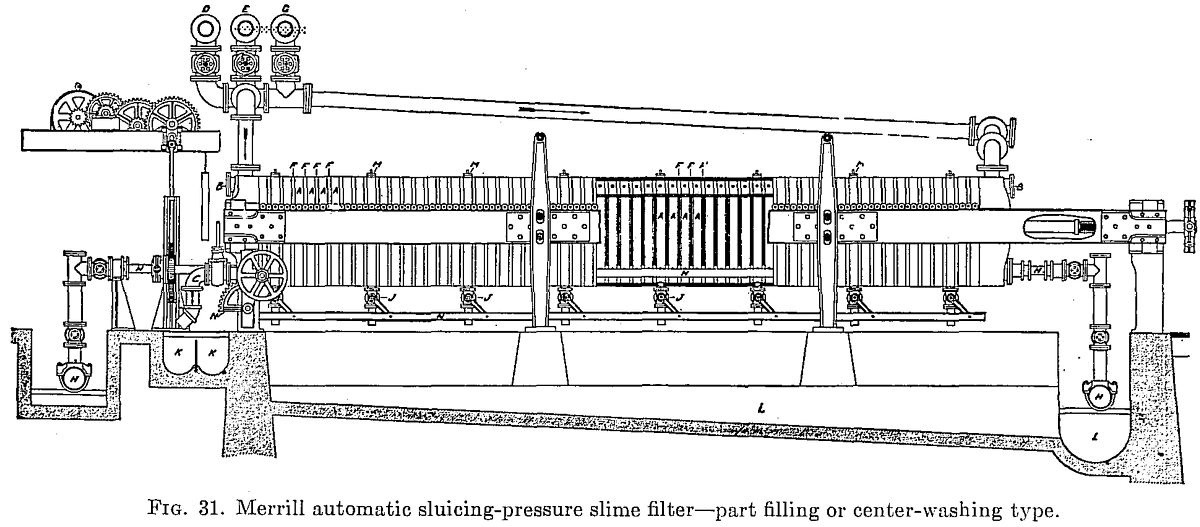

Merrill Press. The Merrill filter press (see Fig. 31) is essentially a plate-and-frame press but is practically automatic in filling and discharge. Unlike the Dehne, the Merrill does not need opening save for renewing cloth or making other minor repairs. Along the median line at the bottom of the press, passing through each plate and frame, is a continuous channel within which is a sluice pipe bearing a series of nozzles, one for each frame. After a cake has been formed and washed, the sluice pipe is oscillated by a small motor through an arc of 180 deg., and water under pressure is discharged from the nozzles. The slime thus washed out of the frame is repulped with the water and discharged from the press through a number of cocks leading from the annular sluicing chamber.

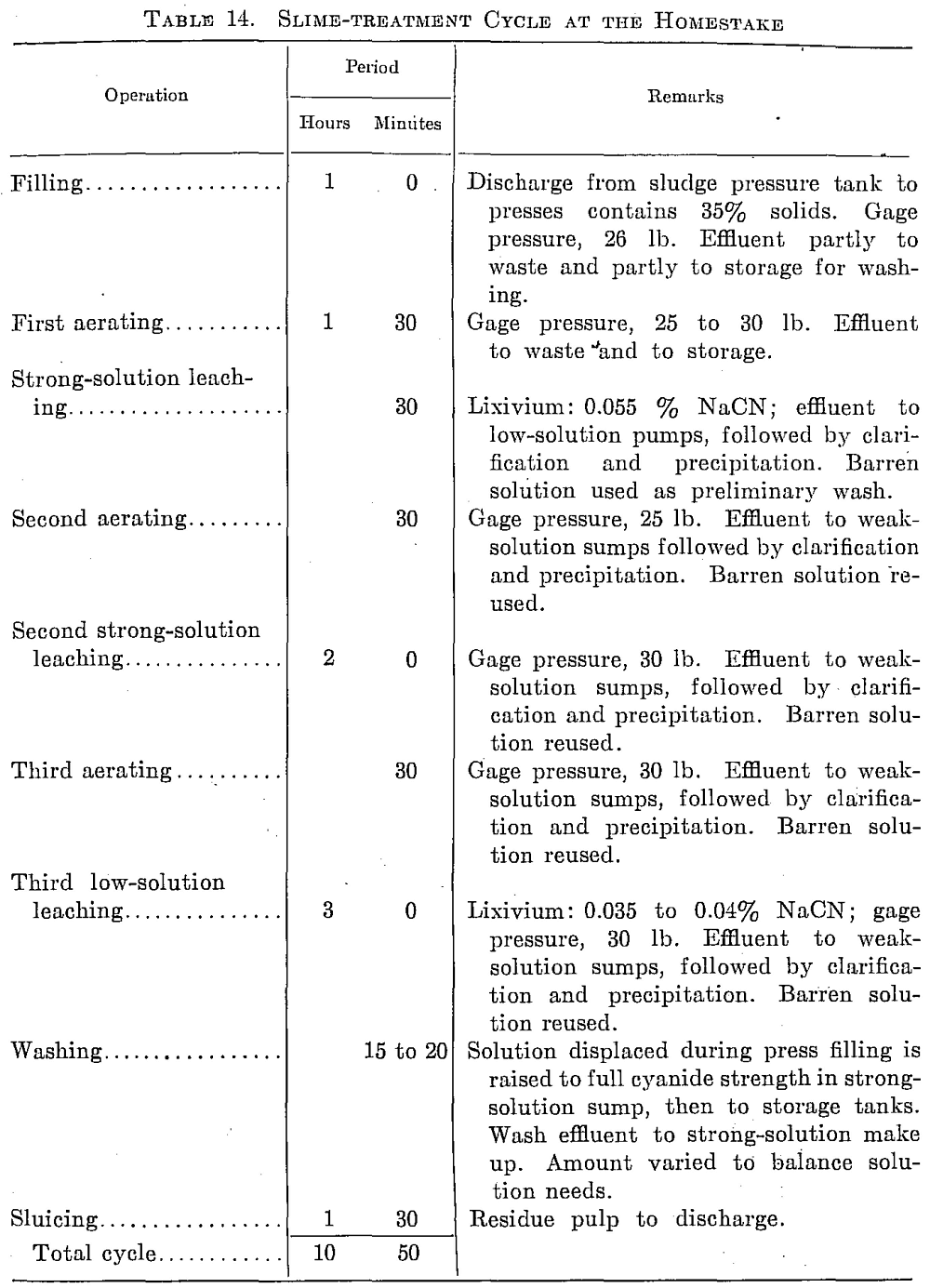

Thirty-one Merrill presses at the Homestake mine, South Dakota, have the capacity to treat—not merely wash and filter—at least 1500 tons a day of slime of which 99 per cent passes 200 mesh. Each of these presses has 90 frames, 6 by 4 ft. by 4 in., the last dimension being the thickness of the slime cake. They hold 26 tons of dry slime. The slime is dewatered at the stamp mills to 35 per cent solids and flows by gravity to the slime- treatment plant three miles distant. The press plates are covered by two cloths—a light muslin twill next to the frame and No. 10 cotton duck which covers the muslin; the muslin prevents the duck from being forced into the plate corrugations. The cotton has a life of 20 months. A typical treatment cycle is shown in Table 14.

While a few other plants use Merrill presses for washing, the Homestake is the only plant practicing direct treatment in Merrill presses.

VACUUM FILTERS

Leaf Filers

Moore and Butters. The Moore was the first of the leaf filters and was developed in 1901. The individual leaf consists of a frame formed of a perforated pipe through which suction and compressed air are applied. The pipe is covered with a filtering medium both sides of which are sewed together in equally spaced vertical seams. Wooden slats are inserted into the pockets between these seams to prevent collapse of the two sides under vacuum and to assist drainage. An assembly of such leaves is known as a “basket.” Four tanks having vertical sides super¬imposed on tapering bottoms are required. The first tank holds the slime to be filtered, the second is filled with barren solution for displacement of the gold-bearing solution in the cake, the third tank is filled with water for displacing the barren solution, and the fourth is used for receiving the washed slime which is loosened from the leaves by compressed air. This residue may be trammed or pumped to the dump. The basket is raised and lowered and moved from tank to tank by means of a chain hoist mounted on an overhead runway extending the full length of the four tanks.

A. Standard container of frame.

B. Feed channel through which the slime pulp enters each frame.

C. Pipe from which water or solution is drawn off during process of filtration.

D. Slime or pulp line.

E. Barren-solution wash line.

F. Filter plate.

G. Water wash line.

H. Sluicing pipe containing water under 60- to 90- lb. pressure admitted at either or both ends.

I. Sluicing motor and gearing.

J. Reside discharge cocks.

K. Effluent solution launders.

L. Discharged residue launder.

M. Peep gate.

N. Lever system for residue discharge cocks.

Butters filter

The Butters filter has been used to a greater extent than the Moore, but both have now been largely replaced by C.C.D. and continuous filters such as the Oliver drum type. The Butters filter is similar in construction to the Moore, but the basket always remains in one tank. Into and from this, according to the cycle, are pumped and discharged slime and washing solutions or water. The treated slime is discharged as in the Moore system.

The Butters filter is still used in the older plants in South Africa. A typical example is found at West Springs mines, where an average of 3685 tons per day is treated, the ore being ground to 66 per cent minus 200 mesh. After thickening and agitation the pulp is filtered on 490 Butters leaves. A total of 4050 tons per day of barren solution is used. The filter discharge contains 30 per cent moisture and assays 0.02 dwt. dissolved gold and 0.17 dwt. undissolved gold per dry ton. Capacity of the filter is about 85 lb. dry solids per day per square foot of canvas.