The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the picture. Larger and larger diameter mills become common. Lengths tend to shorten. Cement grinding using Grate Discharge principles developed in the ore milling industry applied to the cement industry. This experience plus the years of manufacturing know how unquestionably qualify Grate Discharge grinding for the Cement Industry.

RAW CEMENT GRINDING

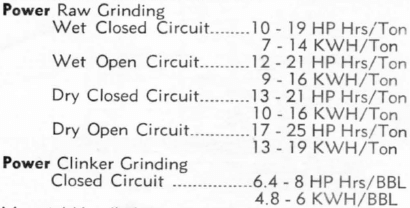

This phase of grinding may be either the wet or dry process, the end product going to a kiln. Material ground consists of limestone, cement rock, marl or marine shells along with secondary materials usually shale or clay. A typical raw mix consists of 75-85% limestone, 12-25% shale, the balance consisting of silica or quartzite and iron oxide. Exact proportioning is dependent upon their chemical properties before and after calcining to cement clinker. For good kiln practice the grind required is 88-92% – 200 mesh for standard cement, 99%-200 mesh for high early. Uniform kiln feed size helps reduce tendency to form kiln rings.

WET VS DRY Grinding of Cement

Wet grinding is generally more efficient and permits a balanced feed direct to the grinding mill since a thorough mixing takes place during comminution. Since dust is not prevalent this hazard is eliminated and a cleaner plant results. More efficient classification is possible although due to high dilutions thickeners are required to provide about 65% solids for kiln feed. Where low cost fuel is available, the extra heat required during calcining, to drive off water, is actually less costly than resorting to less efficient dry grinding.

Improvements in air separators and more efficient dust collecting systems have minimised some of these problems to a point where present day costs become closely parallel. Only close economic study can determine which process should be used.

CLINKER GRINDING

Clinker, the discharge product from the kiln, is partially cooled and broken or crushed to about ¾” – 1″ as feed to finish mills. Fineness of grind is dependent upon the type of cement to be produced. Since fineness of grind falls below standard screen size accuracy, fineness of grind is determined by use of a “Wagner’’ Turbidometer. Desired grind then is expressed for example as 1750 Wagner. Another determination is by air permeability surface area method termed “Blaine”. For close approximation and comparison the two have the following arbitrary relation Wagner = Blaine ÷ 1.75. An indication of Wagner in terms of mesh sizes is provided in the following table:

Cement Grinding Mills

Material Handled 585 – 620# raw material yields 1 BBL cement (376#) or average ratio 1.66 : 1.

Aerial view of typical cement plant. This plant now houses three 9½’ x 25′, an 8½’ x 7′, three 8½’ x 6′ and one 9½’ x 9′ Grate Discharge Ball Mills and one 9½’ x 12′ Open End Cement Rod Mill.

Installation showing one of (3) 9½’ x 25′ Ball Mills at West Coast Cement Plant.

https://www.youtube.com/watch?v=KLErtmt0t4Q