Centrifugal Sand Pump

The Nor-Sand Centrifugal Sand Pump is an evolution in pump design which overcomes the many difficulties encountered in handling abrasive materials. An unimpeded flow of pulp to the impeller is assured, as provision has been made to prevent coarse material from settling out by providing the pump with a central inlet on the shaft side of the casing. An extension on the gland projects into the zone of centrifuge within the impeller, thus eliminating back pressure on the packing gland. A very small amount of gland water is required to keep the gland free from grit (as low as ½ of 1% of the total volume pumped). As a packing gland is effectively used, the pump develops suction which not only ensures a steady flow of feed but obviates placing the pump at any great depth below its feed sump.

While normally the Nor-Sand Centrifugal Sand Pump will give satisfactory results with an all metal inlet, impeller, and casing; there have been developed a rubber lined inlet and casing which give excellent service under extremely severe conditions. The rubber liner for the casing is so installed that there is no possibility of sand or solution entering between the housing and the liner.

The bearings are protected from liquid or grit by a ‘‘mud slinger” mounted on the rotating shaft, and also by a felt oil seal incorporated in the bearing cap. Hand can be changed in field and horizontal, vertical, or direct-connected motor mountings are available.

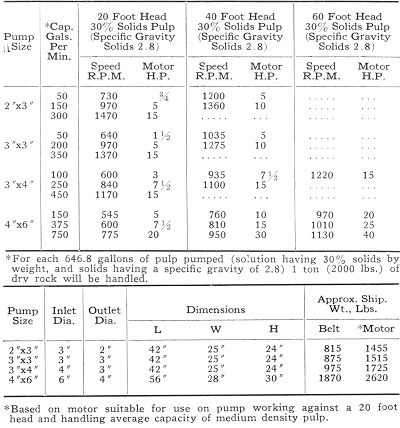

Centrifugal Sand Pump Capacity

Vertical Centrifugal Sand Pump

Vertical Centrifugal Pump is designed to handle frothy concentrates or any material that will flow by gravity into the pump bowl.

The distinctive design feature of this pump is that the feed falls into the large pump bowl. Frothy material is broken down. The pulp or solution then falls by gravity into the horizontally rotating impeller. Fluctuations in feed are taken care of by the pump

bowl. No feed box is required.

A totally enclosed vertical shaft assembly contains the anti-friction bearings that carry the vertical shaft. The impeller is securely fastened by one nut, which facilitates quick replacement when necessary. No stuffing box or packing gland is used. Floor space requirement is low, due to the vertical design, with motor off the floor. Smaller sizes are portable for pilot plant or unit operation. Wearing parts can be easily cleaned when used in processing plants. Alloy parts can be furnished for special conditions. Drive can be by belt or motor and motor drive V-belt or direct connected.

The Vertical Centrifugal Sand Pump is a simple, flexible, pumping unit that has solved many extremely difficult pumping problems. Let us consider your pumping problem and make recommendations for the type, size, and number of pumps to most effectively and economically satisfy your pumping requirements.

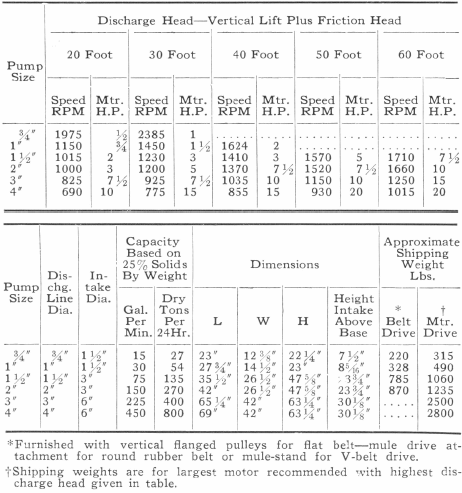

Vertical Centrifugal Sand Pump Capacity

Rubber Lined (Type SRL) Sand Pump

The Rubber Lined (Type SRL) Sand Pump is recognized as standard equipment for handling abrasive pulps in the mining industry. Reports from mill operators emphasize its efficiency, dependability, durability, and economy. Need for standby units has been eliminated. In most cases the power required for the operation of this pump is one-half that required for operation of equivalent all-metal pump and this is an important factor. The saving in power alone pays for the cost of this pump in from four to twelve months. At the same time the efficiency of this pump is 1½ to 3 times that of other types of sand pumps. Rubber parts give a service life of four to ten times that of the best alloy metal parts obtainable. Many Rubber Lined (Type SRL) Sand Pumps handling mill tailings have not replaced wearing parts in three years. An average life of wearing parts of from one to two years is common and instances of extremely long life of wearing parts are not uncommon.

The rubber covered parts consist of a heavy pressure molded rubber covered impeller and a casing liner. The rubber impeller is an open style on all sizes except 8″x 6″ and 10″x 8″, which are closed type. The rubber covered casing liner is in two pieces, the rubber being molded to metal reinforcing plates which bolt to the pump case.

Antifriction ball bearings are used to carry both the radial and thrust load on the impeller. A water seal bushing is between the stuffing box packing and the pump impeller. The amount of sealing water required is usually less than 1% of pump capacity and is only sufficient to keep the pulp from contacting the exposed surface. A shaft sleeve and mud slinger also provide a maximum of protection for the shaft and bearings.

The pump can be arranged for overhead motor drive using a super-imposed motor base on all sizes but the 8″x 6″ and the 10″x 8″, or a horizontal drive where the motor is mounted on a separate base on all sizes.

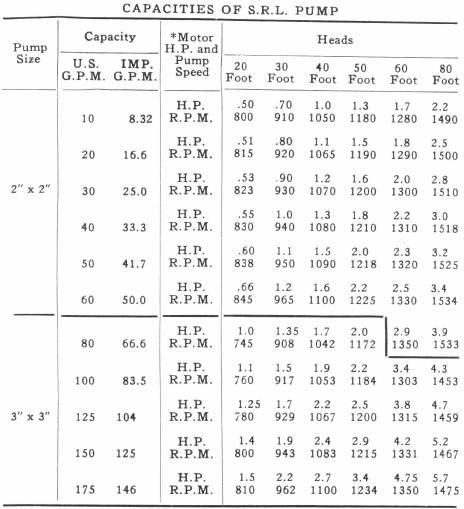

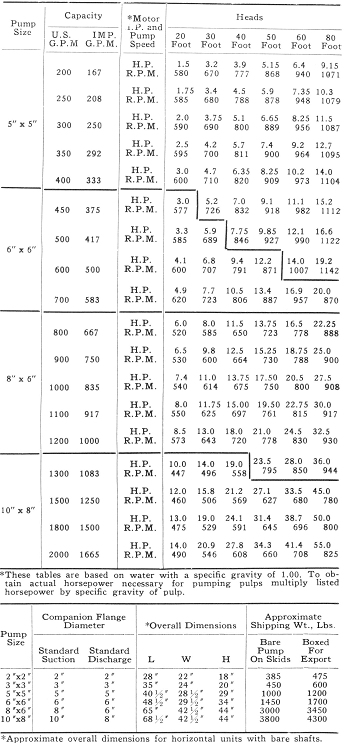

Rubber Lined (Type SRL) Sand Pump Capacity

Wilfley Centrifugal Sand Pump

The Wilfley Centrifugal Sand Pump is used by the mining and other industries throughout the world. Difficult material handling requirements have been satisfactorily met for years by this outstanding centrifugal sand pump.

There are many distinctive features incorporated into this unit such as the well-known centrifugal seal which eliminates the need for the customary stuffing box; slippage seal adjustment; extra heavy wearing parts of rubber or metal, changeable in a few minutes time; and unit construction ball bearing shaft assembly.

Drives can be arranged as either direct-connected, or for flat or V-belt. Motor mountings for V-belt can be made either vertical or horizontal, whichever is most suitable. Overhead motor and V-belt drive is available on all sizes up to and including the 4″ size.

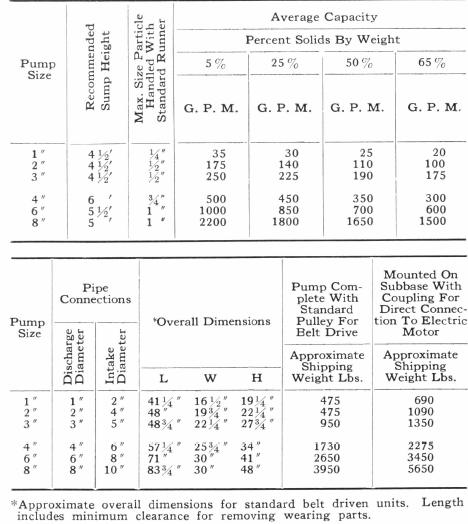

Wilfley Centrifugal Sand Pump Capacity

Wilfley Centrifugal Sand Pump Capacity

Advantages of the Wilfley Centrifugal Sand Pumps

The Wilfley Centrifugal Sand Pump is designed and constructed so as to apply advantageously to almost every condition requiring the handling of gritty pulps, slurries, sludges and hot solutions. Mill pumps, cement slurries, milk of lime, clay slips or any other gritty pulps, slurries or sludges can be handled by this pump.

Special features on the Wilfley Pump have spelt success throughout the years. The Wilfley Seal replaces the customary stuffing box. This centrifugal seal consists of a revolving member called an expeller having wings or paddles radiating from a recess in its centre to its periphery and a stationary member that has a projecting groove. The revolving member is set close to the stationary member which acts as a side wearing plate.

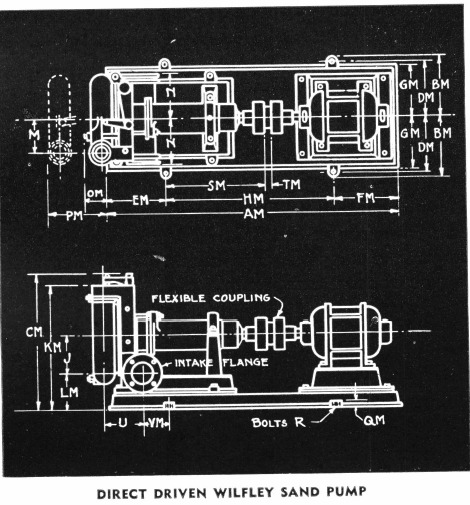

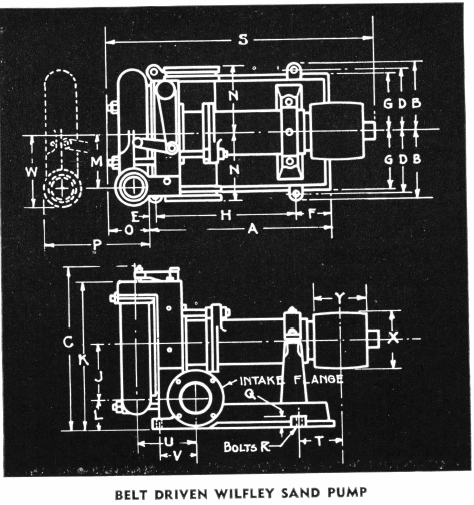

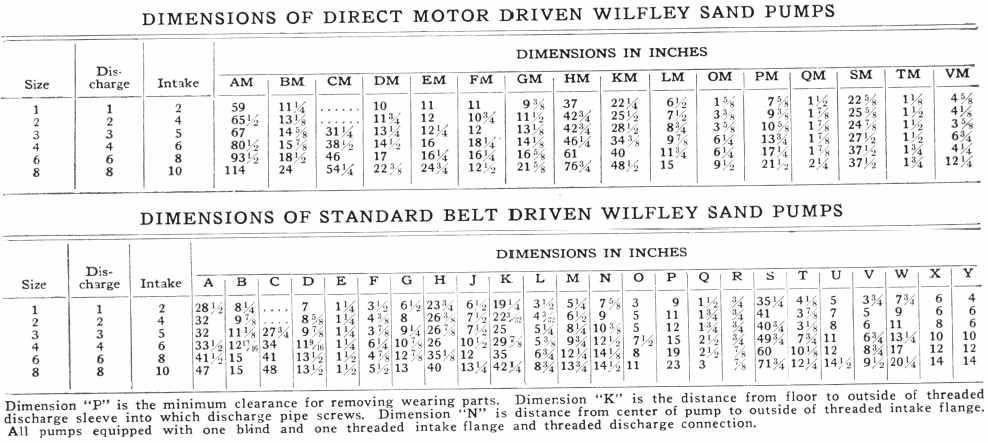

Below are the direct motor and belt driven types of Wilfley Centrifugal Sand Pumps. The belt driven unit is a standard pump, equipped with a flat pulley, while the motor type combines the standard pump with motor on a cast iron bedplate. A special leather link coupling is used between the motor and pump, and allows lateral adjustment of the pump shaft. The compact motor driven unit can be installed in any convenient location.

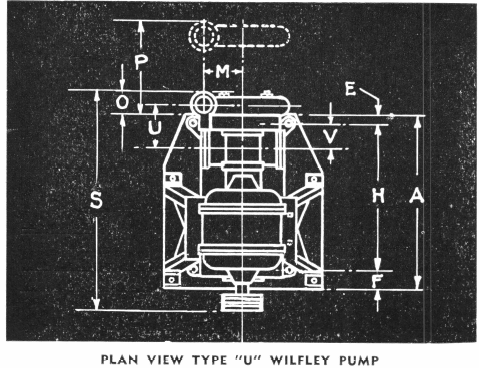

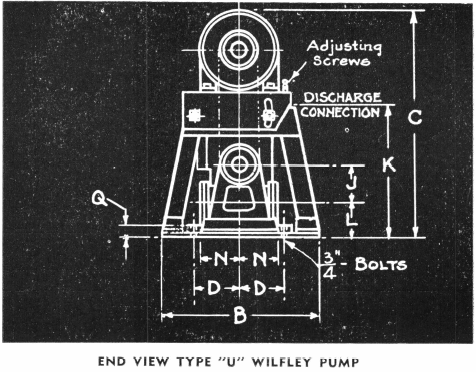

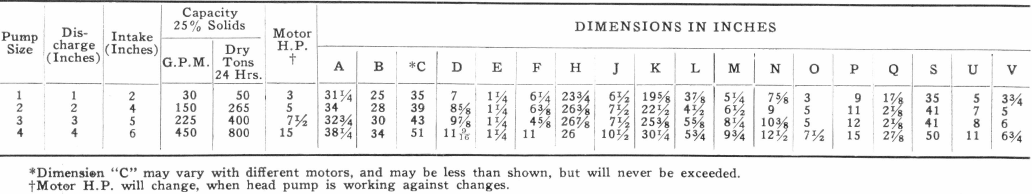

Type “U” Wilfley Centrifugal Sand Pump

Type “U” is recommended:

- Where floor space is limited.

- Where pump is placed in a sump or pit with no drainage.

- Where it is customary to wash floors regularly with a hose.

- Where a belt driven pump is to be converted to a motor drive without additional foundations. (Can be mounted on same foundation bolts as standard belt driven pump.)

V-belt drives have made this unit practical. The Type “U” has the motor mounted directly over the pump on a rugged steel framework. This frame is first riveted and then welded, which results in a rigid, vibrationless support for the motor.

The motor is mounted on a reinforced steel plate, hinged so that the V-belt drive automatically operates at the most efficient tension.

The steel frame and motor are arranged so they do not interfere with intake and discharge connections or the slippage adjustment. Deliveries with this type of drive are prompt.

Prices, deliveries and information on all sizes of Wilfley Pumps including 6″ and 8″ sizes gladly sent on request. Let our engineers help you on any of your pumping problems.

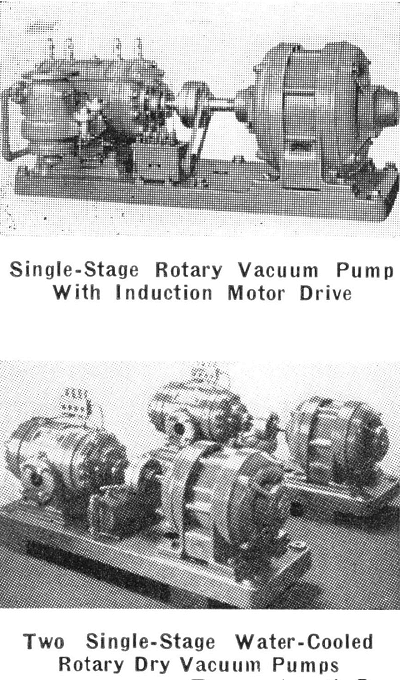

Rotary Vacuum Pump

The Allis-Chalmers Rotary Vacuum Pump is of the highly efficient sliding vane type. It will handle more air or gas at less cost and is simple in construction with few parts to wear or get out of order. This unit consists essentially of a water jacketed casing or cylinder, within which a rotor of smaller diameter is located with its axis eccentric to that of the casing. The rotor is

fitted with blades which are free to move radially in and out of longitudinal slots. This results in the formation of multiple, longitudinal cells in which the air is trapped while being compressed.

When the vacuum pump is in operation, the blades or vanes are forced out by centrifugal action and form a number of cells corresponding to the number of blades or vanes. Each cell goes from a minimum capacity at the bottom of the cylinder, to a maximum at the top, and then back to minimum. This gives the suction and pressure effect with positive displacement characteristics and efficiency for use as either vacuum pump or compressor. Minimum required floor space, light foundations, and ease of installing are some of other advantages. Let us make recommendations.

Rotary Vacuum Pump Capacity

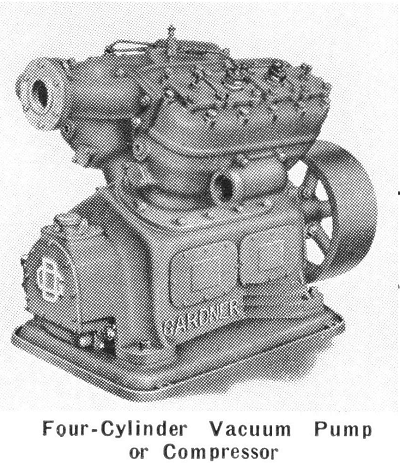

Gardner Vacuum Pump

The Gardner “AA” Vacuum Pump is well known throughout the world as one of the most widely distributed and most completely satisfactory single stage, vertical, vacuum pumps ever built.

The force feed lubrication system, generous bearing areas, simplicity, accessibility, and smooth running qualities, place the Gardner Vacuum Pump far ahead of many similar competitive compressors. These pumps can be used as compressors if desired.

Let us make recommendations for the type and size vacuum pump or compressor best suited to meet your particular requirements.

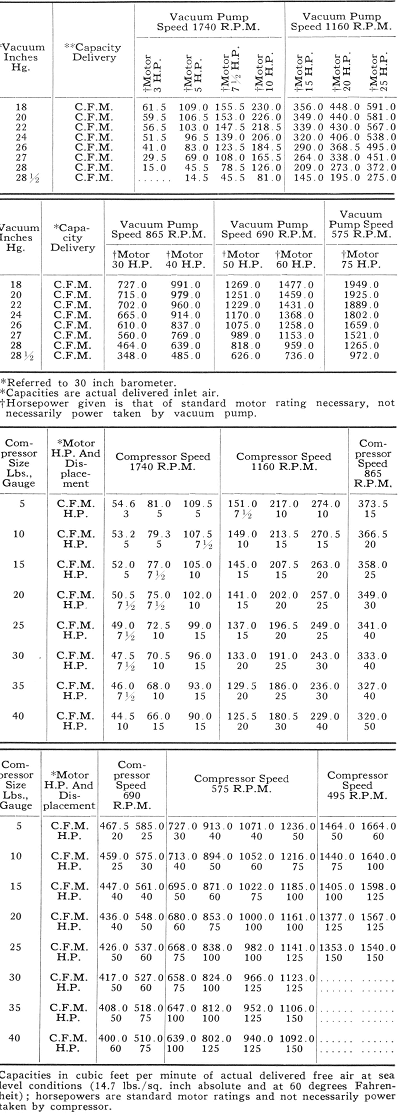

Gardner Vacuum Pump Capacity

Ingersoll-Rand Vacuum Pump

The Ingersoll-Rand Vacuum Pump can be furnished to meet all requirements for Rotary Drum Filters and Disc Filters. Also, other problems requiring a reliable and constant source of vacuum are effectively solved by these pumps.

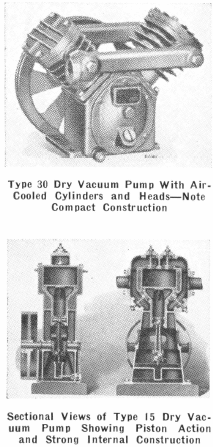

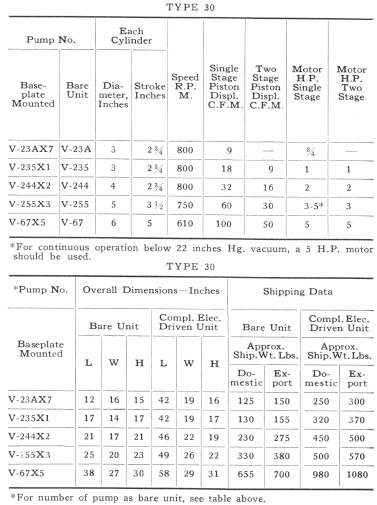

For the smaller installations, the Type 30 dry vacuum pump is recommended. The general data on this vacuum pump is given in tables under pumps for displacements of from 9 to 100 cubic feet per minute.

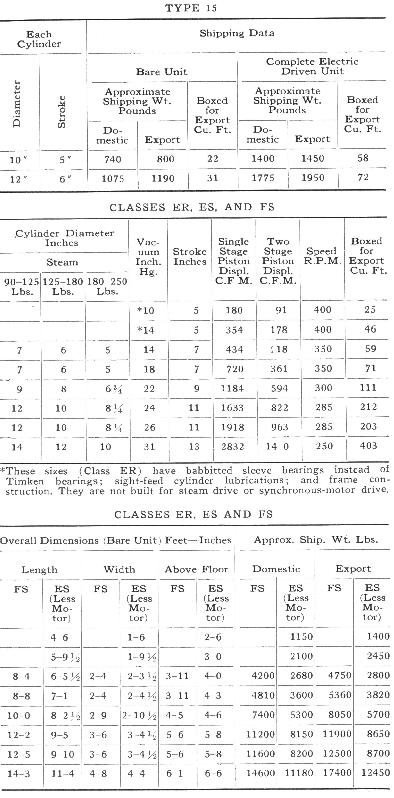

For medium sized installations, the Type 15 vertical, double-acting, dry vacuum pump is preferred. The Type 15 dry vacuum pump is a vertical, water-cooled, double¬acting, single cylinder unit with a trunk-type piston. It can be arranged as a single-stage, double-acting, or a two- stage, single-acting unit. It is available for flat or V-belt drive, with or without a common subbase with the motor. The general data on these vacuum pumps are given in table under pumps for displacements of from 91 to 250 cubic feet per minute.

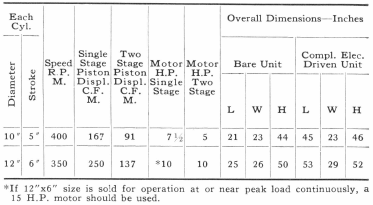

For larger sizes the Class ES vacuum pump is recommended. This is of the straight- line, single cylinder, horizontal cross-head type, designed to operate at moderate speeds and built for heavy, continuous service. Unit is available in single or two-stage construction. Single-stage units are double-acting. Two-stage units are single-acting with opposite ends of the single cylinder arranged in series. The Class ES units are adaptable to any type of drive: V-belt, short belt, long belt, or direct-connected synchronous motor drive on the larger units. The tables following give general data on vacuum pumps for displacements of from 9 to 2,832 cubic feet per minute.

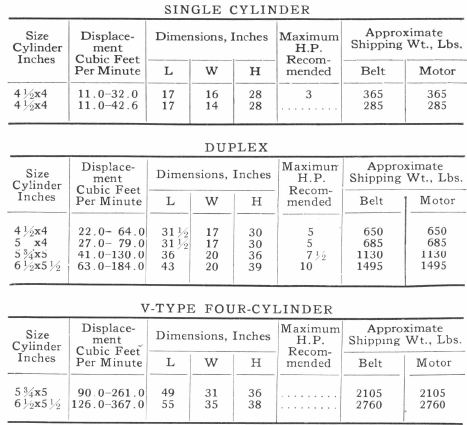

Ingersoll-Rand Vacuum Pump Capacity

Ingersoll-Rand Vacuum Pump Capacity

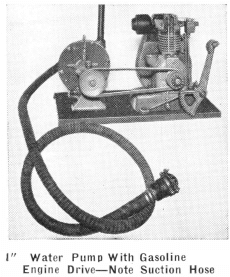

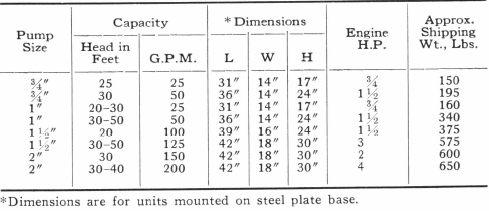

Water Pump

The Water Pump is an adaptable, inexpensive, self-contained unit for lifting or bringing water from available supply or low cost handling of low specific gravity mill solutions. This unit includes a standard gasoline engine, V-belt drive, and pump; all mounted on a steel plate base for portability.

Water Pumps can be furnished without base and engine if desired. Prices of individual pumps and gas engines will be gladly sent upon request.

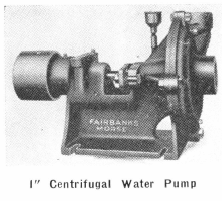

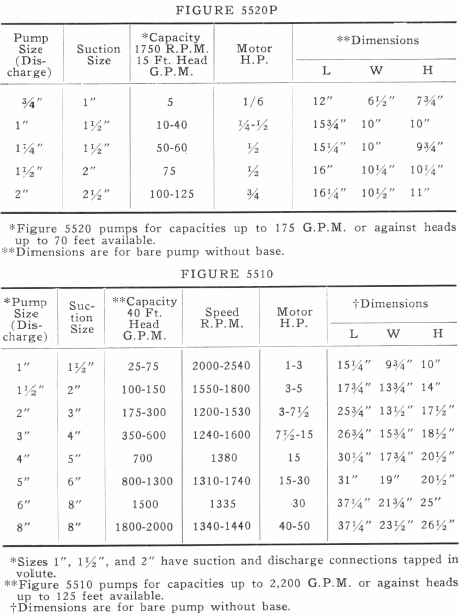

Fairbanks-Morse Centrifugal Water Pump

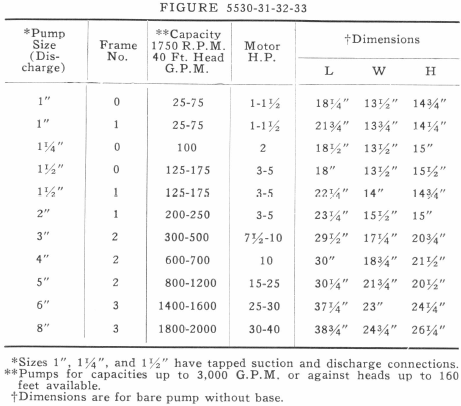

The Fairbanks-Morse Centrifugal Water Pump is a sturdy, inexpensive, side-suction, ball-bearing pump of up-to-date design and construction and is ideal for many applications. It is particularly easy to dismantle as all parts are readily accessible. The pump is built of highest quality materials and is highly efficient due to design resulting from long experience.

Various sizes and models are available to suit most pumping requirements. Units are built in sizes ranging from ¾” to 8″ outlets, for capacities from 5 to 3,000 gallons per minute, and for operating against heads up to 160 feet.

These pumps are designed and built for both general service and heavy duty and may be driven by electric motor, diesel engine, or gasoline engine. Drive may be by flat belt, V-belt, or pump may be direct-connected. Parts are interchangeable and, when necessary due to the nature of the liquid being pumped, may be replaced at moderate cost.

Additional data gladly furnished upon request.

Capacity

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.