COARSE FLOTATION OFFERS IMPORTANT SAVINGS THROUGH REDUCED OPERATING COSTS

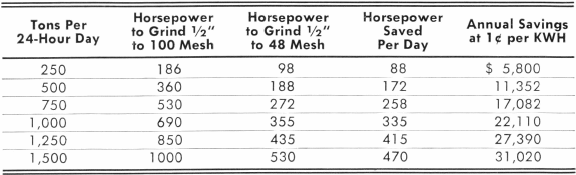

Grinding cost varies greatly depending upon the size reduction required. For example, it takes approximately 50% less horsepower to grind from ½” to 48 mesh than it does to grind the same material from ½” to 100 mesh.

Many minerals are liberated at a coarse mesh and middling particles often can be recovered at a much coarser grind than would be required for total liberation. Flotation of coarse middling particles permits regrind and reflotation involving only a fraction of the original tonnage.

“Sub-A” Flotation has the unique ability to handle coarse particles. This coarse flotation makes possible important savings through reduced operating costs as indicated in the following table of horsepower required for grinding:

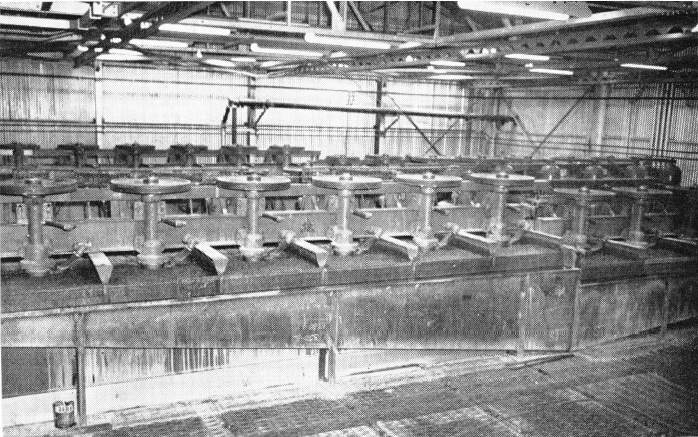

Coarse flotation is practiced at many mills. This 34,000 ton per day mill uses “Sub-A” Free-flow Flotation Machines to float at 20 mesh. Rougher concentrates are then reground and flotation cleaning raises concentrate grade to meet specifications.