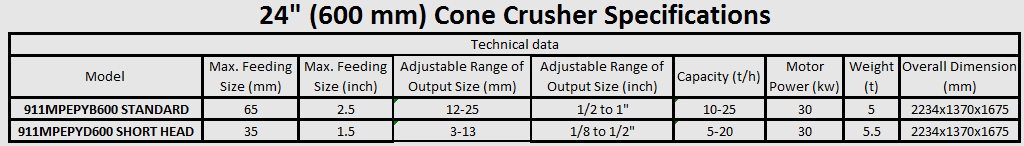

The 911MPEPYB600 is a small (24″) diameter cone crusher is perfect for fine, secondary crushing in small operations. Ideal to re-crush rock discharging from a primary jaw crusher. Feed this short head cone crusher up to 35 mm (1.5″) with a CSS closed side setting 3mm (1/8″) to obtain a P80 crushed product in the 3 to 13mm (1/8″ to 1/2″) range.

When crushing fine, the crusher’s capacity is reduced to 5 to 20 TPH – The finer, the slower.

A manganese-chrome mantle and concave, greased seal, lube system with temperature control.

Chrome-moly main shaft and heavy steel casting main structure.